Professional Documents

Culture Documents

List of Documents To Be Reviewed

Uploaded by

DEBASISH RAY CHOUDHURY0 ratings0% found this document useful (0 votes)

4 views2 pagesList of Documents to be reviewed

Original Title

List of Documents to be reviewed

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentList of Documents to be reviewed

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesList of Documents To Be Reviewed

Uploaded by

DEBASISH RAY CHOUDHURYList of Documents to be reviewed

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

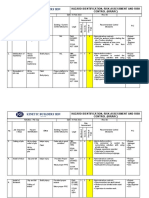

Indian Oil Corporation Limited LPG BP- Rangpo (11-12.09.

2023)

IS0 9001:2015, ISO 14001:2015, ISO 45001:2018, ISO 50001:2018

Scope: Receipt of LPG through bulk Tank Trucks and Storage of the same in above Ground

Bullet Storage Vessel, Bottling of LPG into Cylinders both Domestic and non-Domestic and

despatching through packed Trucks

Scope Rectification: (Two Activities)

Receipt of LPG through bulk Tank Trucks and Storage of the same in above Ground

Bullet Storage Vessel

Bottling of LPG into Cylinders both Domestic and non-Domestic and despatching

through packed Trucks

All the information within tenure of last 11 Months (October, 2022 onwards- Till Date) is

required to be collected.

MANOB AVISHEK AMARNATH DRC & SUDIPTA

List of Documents to be reviewed during Stage II Audit are as follows.

1. Context of the Organization (Needs & Expectation of Interested Parties)

2. IMS Policy

3. IMS Objective & Planning to achieve the Objectives (Target Date with Achievement)

4. Leadership- Roles, Responsibility & Authority

i. Consultation and Participation of Workers

ii. Worker’s agitation related to Health Safety

5. Risk Assessment & Mitigation Planning- QMS

6. Aspect Impact Study- EMS

7. Hazard Identification and Assessment of Risks- OHSMS

8. List of Manpower along with Competency Criteria as per Guideline OISD 154 (Matrix)

9. Training (Imparted and Evaluation Procedure)- including Work at Height Training

10. List of External Service Provider & Along with Periodical Evaluation

11. Procurement- Invoicing and Challan (Samples)

12. Monitoring & Measurement- Calibration (Tank Truck, Pressure Vessel Report, Temperature

Controller, Valve Test Report)

13. Leakage identification of Storage Tanks

14. List of Instruments & Preventive Maintenance Schedule

15. Breakdown Maintenance & Downtime Analysis

16. Preservation of Products

17. Nonconforming Service and its Controlling

18. Order according to

i. Receipt of LPG through bulk Tank Trucks and Storage of the same in above

Ground Bullet Storage Vessel

ii. Bottling of LPG into Cylinders Domestic and despatching through packed

Trucks

iii. Bottling of LPG into Cylinders non-Domestic and despatching through packed

Trucks

19. Safety Committee and deployment of OH&S Lead

20. Safety Committee Meeting

21. Emergency Preparedness, Planning & Response

22. Fire Mock Drill / Mock Drill

23. Evacuation Procedure

24. Identification of Assembly Point (Closed Area (Trapped)/ Open Area) (Site wise)

25. Safety Instruction at Site (English & Local Language)

26. Site-Demarcation & Cordoning Arrangement (Glow Tape)

27. Display of Emergency Contact No. (Police Station, Ambulance, nearby Hospital / Health

Centre, Fire Brigade) at Site along with Blood Group of Worker

28. Health Plan / Medical Health Check-up of Worker & Manager / Physical Fitness for Height

Work / Eye Check-up (Driver of IOCL) (including Registration Number of Doctors)

29. Permit to Work

30. Photo ID Proof of Workers (Blood Group in Photo ID Proof)

31. PPE Issues & Inventory Maintenance

32. Use of Safety Belt, Mask, Hand Gloves, Shoes, Safety Jacket, Helmet, Radiation Proof Jacket

and its Daily Fitness Checking Procedure (Visual Checkup)

33. First AID Facility: List of Medicine along with Date of Expiry

34. Tool Box Talk

35. Incident / Near Miss

36. Scaffold Report & Other Engineering Control (Hand Rail)

37. Fire Fighting Equipment (Cylinder / Hose) Periodical Inspection

38. Fire Extinguisher along with Floor Layout Plan and Position of Fire Extinguisher in

Floor Layout Plan

39. Fire Alarm System (Hooter) and Fire Sprinkler inside the Building (Fire Ball)

40. Fitness Certificate of Truck (Contract with Truck Authority)

41. Storage of LPG (Through Chain and vertical alignment)

42. Documentation upon Compliance Obligations

43. DG Emission Checking

44. Ambient Air, Potable Drinking Water, Noise Monitoring Test Report

45. Control upon Changes – Document Control & Document Control Procedure

46. Internal Audit – Date along with List of Nonconformities along with Clause Number and

Date of Closure

47. Management Review Meeting and inclusion of Opportunities for Improvement under

Management Review Meeting

48. Statutory & Regulatory Requirements:

i. PESO

ii. Weights & Measures

iii. PNGRB: Codes of Practices for Emergency Response and Disaster Management

(ERDMP) Regulations, 2010

iv. OISD-169

49. Overall Improvement Planning

You might also like

- Attachment No.1 Subcontractor Evaluation Checklist To Be FilledDocument4 pagesAttachment No.1 Subcontractor Evaluation Checklist To Be FilledpaulNo ratings yet

- Practical Guide to Occupational Health and SafetyFrom EverandPractical Guide to Occupational Health and SafetyRating: 4 out of 5 stars4/5 (13)

- Safety Audit.Document41 pagesSafety Audit.mansoor hussainNo ratings yet

- Excavation and TrenchingDocument12 pagesExcavation and TrenchingWahyu Endra PurwantoNo ratings yet

- Audit Key Points ProjectsDocument2 pagesAudit Key Points ProjectsTHOVITI GANESHNo ratings yet

- Gap Analysis ReportDocument62 pagesGap Analysis ReportSAYED91% (23)

- IADC Bridging Arrangements and IMO UpdateDocument30 pagesIADC Bridging Arrangements and IMO UpdateJuan Pablo CassanelliNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- NEBOSH IOG1 ExaminersFeedback PDFDocument24 pagesNEBOSH IOG1 ExaminersFeedback PDFAyoola Ayodeji100% (7)

- Osha Fatal Accident Assignment For Fall From HeightDocument30 pagesOsha Fatal Accident Assignment For Fall From HeightHadrami HamdanNo ratings yet

- Safety Audit MethodologyDocument5 pagesSafety Audit MethodologyLalit Kumar Das MohapatraNo ratings yet

- Capability Statement RH - Maritime South East Asia Rev 30-11-2011 PDFDocument61 pagesCapability Statement RH - Maritime South East Asia Rev 30-11-2011 PDFMohamad ChandraNo ratings yet

- API 580 TrainingDocument168 pagesAPI 580 Trainingfaheem khan100% (21)

- NEOM OPERATIONS - FM - Hot PTWDocument3 pagesNEOM OPERATIONS - FM - Hot PTWHBHJBMNNo ratings yet

- Unit IA Managing Health and Safety Revision Guide RRCDocument184 pagesUnit IA Managing Health and Safety Revision Guide RRCfrancis100% (6)

- Checklist of Documents Required For WSHMS Audit (Construction)Document1 pageChecklist of Documents Required For WSHMS Audit (Construction)Khuda BukshNo ratings yet

- Asme Awareness Program - 1Document25 pagesAsme Awareness Program - 1Gaurav KhamkarNo ratings yet

- Iso 22000Document11 pagesIso 22000Harits As SiddiqNo ratings yet

- Is Audit Report 14489 (07-03-2018-122522)Document37 pagesIs Audit Report 14489 (07-03-2018-122522)Bhakti Mahbubani100% (4)

- DM-PH&SD-P4-TG02 - (Guidelines For Safety Audit Reports)Document5 pagesDM-PH&SD-P4-TG02 - (Guidelines For Safety Audit Reports)kevinNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- HSE Control of ContractorsDocument12 pagesHSE Control of ContractorsCyril AngkiNo ratings yet

- Assignment - XBLR 3103Document12 pagesAssignment - XBLR 3103Najib Roslan100% (2)

- OHDC Lifting ProcedureDocument12 pagesOHDC Lifting ProcedureHamid Ali100% (1)

- A Guide to Sanitation Safety Planning in the Philippines: Step-By-Step Risk Management for Safe Reuse and Disposal of Wastewater, Greywater, and ExcretaFrom EverandA Guide to Sanitation Safety Planning in the Philippines: Step-By-Step Risk Management for Safe Reuse and Disposal of Wastewater, Greywater, and ExcretaNo ratings yet

- Subcontractor Hse Mobilization Checklist PDFDocument2 pagesSubcontractor Hse Mobilization Checklist PDFshareyhouNo ratings yet

- Food Safety AuditsDocument207 pagesFood Safety Auditssabir21100% (1)

- Simultaneous Operation (SIMOPS) : Term of Referance (Tor)Document25 pagesSimultaneous Operation (SIMOPS) : Term of Referance (Tor)kokykarkar80% (5)

- API RP 578 Pmi Don MearsDocument29 pagesAPI RP 578 Pmi Don Mears16740386100% (1)

- Incinerator SOP-TemplateDocument5 pagesIncinerator SOP-TemplateIr Complicated100% (1)

- Adopting ISO 14064Document39 pagesAdopting ISO 14064Tan Hong Tat100% (3)

- Instruction Manual GLB3026!2!2426gr Crane1-4Document293 pagesInstruction Manual GLB3026!2!2426gr Crane1-4Jan Ernst Depacto83% (6)

- 1815 Audit ReportDocument4 pages1815 Audit ReportNIMISHNo ratings yet

- Custody Transfer John SweeneyDocument22 pagesCustody Transfer John Sweeneymetasla100% (1)

- Audit Report: Standard - Food Safety Management SystemDocument6 pagesAudit Report: Standard - Food Safety Management Systemawadesh3100% (1)

- Guide to Food Safety and Quality during Transportation: Controls, Standards and PracticesFrom EverandGuide to Food Safety and Quality during Transportation: Controls, Standards and PracticesNo ratings yet

- OISD Standard 244 DraftDocument94 pagesOISD Standard 244 DraftSuresh GanesanNo ratings yet

- Turnaround Management for the Oil, Gas, and Process Industries: A Project Management ApproachFrom EverandTurnaround Management for the Oil, Gas, and Process Industries: A Project Management ApproachRating: 2 out of 5 stars2/5 (1)

- OGP Documnet 476Document36 pagesOGP Documnet 476mechafuadNo ratings yet

- Traffic Direction and ControlDocument25 pagesTraffic Direction and ControlRhyner Gelilang100% (2)

- Housekeeping NC II CG-2Document19 pagesHousekeeping NC II CG-2Lerwin Garinga100% (2)

- IBP1698 - 12 Regulations For Drilling Units: Brazilian Petroleum, Gas and Biofuels InstituteDocument9 pagesIBP1698 - 12 Regulations For Drilling Units: Brazilian Petroleum, Gas and Biofuels InstituteMarcelo Varejão CasarinNo ratings yet

- LCS English SAMDocument9 pagesLCS English SAMJavier RestrepoNo ratings yet

- Pse - 2015 Hipo and FatalitiesDocument34 pagesPse - 2015 Hipo and FatalitiesDeepak RajoriaNo ratings yet

- Sedex-Dec. Requirements - Part 2Document3 pagesSedex-Dec. Requirements - Part 2Hanan ZayedNo ratings yet

- Circular 09/2014 (ISM) : SubjectDocument7 pagesCircular 09/2014 (ISM) : SubjectDenise AhrendNo ratings yet

- Industry & Govt Changes Post MacondoDocument27 pagesIndustry & Govt Changes Post Macondonam172No ratings yet

- CoP - 11.0 - Safety in Heat (V2.1) 2013Document12 pagesCoP - 11.0 - Safety in Heat (V2.1) 2013Anonymous y1pIqcNo ratings yet

- Site Inspection of Ship Recycling Facilities in IndiaDocument47 pagesSite Inspection of Ship Recycling Facilities in IndiaAnjaana PrashantNo ratings yet

- LOBP ISO 14001 Report - Shell Pakistan...Document3 pagesLOBP ISO 14001 Report - Shell Pakistan...IHSAN YAQOOBNo ratings yet

- S.No Description of Work Action PlanDocument3 pagesS.No Description of Work Action PlanRohit SinghNo ratings yet

- Fera Full Topic Assessment TemplateDocument13 pagesFera Full Topic Assessment TemplateAnonymous uLAATWpfNo ratings yet

- Refrigerated Transportation Best Practices Guide WEBDocument41 pagesRefrigerated Transportation Best Practices Guide WEBznim04No ratings yet

- Post School AssignmentDocument24 pagesPost School AssignmentAjith PandithasekaraNo ratings yet

- Part 6 Performance MonitoringDocument24 pagesPart 6 Performance Monitoringalex.kollosovNo ratings yet

- CSMS Safety StarDocument22 pagesCSMS Safety StarAjudya Prida PratamaNo ratings yet

- Safety Audit: Scope of WorkDocument3 pagesSafety Audit: Scope of WorkRohit ShuklaNo ratings yet

- British Compressed Gases Association: REVISION 2: 2015Document5 pagesBritish Compressed Gases Association: REVISION 2: 2015rieza_fNo ratings yet

- Petroleum HSEC ControlsDocument90 pagesPetroleum HSEC ControlshazopmanNo ratings yet

- Scope of WorkDocument3 pagesScope of Work64104641100% (1)

- Nabl 126Document31 pagesNabl 126Gazal GuptaNo ratings yet

- Insert Facility/Institute Logo Here: TemplateDocument5 pagesInsert Facility/Institute Logo Here: TemplateIr ComplicatedNo ratings yet

- 668 1190794978046-4. Buncefield SafetystandardDocument118 pages668 1190794978046-4. Buncefield SafetystandardAdelChNo ratings yet

- Oh&s Manual For Is 18001-2007Document33 pagesOh&s Manual For Is 18001-2007subhankNo ratings yet

- C9 - HSE SpecificationsDocument7 pagesC9 - HSE SpecificationsDheeraj MenonNo ratings yet

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- Industrial Hygiene Plan: in Compliance With ISO 9001:2015, 14001:2015, & 45001:2018Document8 pagesIndustrial Hygiene Plan: in Compliance With ISO 9001:2015, 14001:2015, & 45001:2018Mohammed AffrozeNo ratings yet

- HIRADC - Pile CapDocument4 pagesHIRADC - Pile CapKalai ArasanNo ratings yet

- Is111 Unit 4Document16 pagesIs111 Unit 4ReyMartNo ratings yet

- Remington ChainsawDocument88 pagesRemington Chainsawahmed_patel_12No ratings yet

- Guidelines For Restarting Industrial Units After Lockdown PDFDocument4 pagesGuidelines For Restarting Industrial Units After Lockdown PDFNDTVNo ratings yet

- TENACITODocument8 pagesTENACITOGeancarloNo ratings yet

- Miscellaneous Functions PDFDocument332 pagesMiscellaneous Functions PDFOom HasanudinNo ratings yet

- NEBOSH IGC2 Past Exam Paper April 2005Document2 pagesNEBOSH IGC2 Past Exam Paper April 2005SOHAIB AWANNo ratings yet

- IOGP 432-02 Risk Management in Geophysical OperationsDocument38 pagesIOGP 432-02 Risk Management in Geophysical OperationsMuhammad MuhammadNo ratings yet

- Mark Romano ResumeDocument3 pagesMark Romano ResumeMark RomanoNo ratings yet

- Dimethylformamide - Nugentec Ghs MsdsDocument8 pagesDimethylformamide - Nugentec Ghs MsdsstabinmathewNo ratings yet

- MSDS Burnshield Dressings 1BDocument5 pagesMSDS Burnshield Dressings 1BJarrod CurrinNo ratings yet

- MSDS Bimoli Botol & Pouch PDFDocument3 pagesMSDS Bimoli Botol & Pouch PDFDwi Puji RahayuNo ratings yet

- Schedule of Activities: The Pinnacle Hotel and Suites, Davao CityDocument2 pagesSchedule of Activities: The Pinnacle Hotel and Suites, Davao CitySarangani Davao del SurNo ratings yet

- Indradrive MPX - 1xDocument90 pagesIndradrive MPX - 1xJonathan JonesNo ratings yet

- Hot Work Permit FormDocument3 pagesHot Work Permit FormKarthik KarunanithiNo ratings yet

- Library GODocument17 pagesLibrary GOtaraNo ratings yet

- EC Safety Data Sheet: Cellpack DFLDocument8 pagesEC Safety Data Sheet: Cellpack DFLtorqueuNo ratings yet

- Krohne Optimass1000 Manual PDFDocument52 pagesKrohne Optimass1000 Manual PDFDonni AzharNo ratings yet

- Cold WP PWIE 27 - 10 - 20 Access ControlDocument2 pagesCold WP PWIE 27 - 10 - 20 Access ControlHBHJBMNNo ratings yet

- Rizwan - 3 Phase SeparatorDocument10 pagesRizwan - 3 Phase SeparatorJoyal PaulNo ratings yet