Professional Documents

Culture Documents

Audit Key Points Projects

Uploaded by

THOVITI GANESH0 ratings0% found this document useful (0 votes)

17 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views2 pagesAudit Key Points Projects

Uploaded by

THOVITI GANESHCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

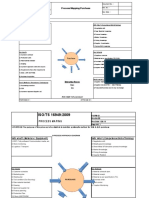

Audit key points:

Project Planning QA & C functions

1) Review of ACE & JCRs 1) Progress on Quality Objectives

2) Overall organization set‐up 2) MRM records

3) MPCS – Latest 3) Context analysis

4) Progress on Milestones 4) Needs and expectations of interested

5) Overall schedule adherence parties.

6) Variance / scope change 5) Customer complaints (Emails / Verbal /

7) Escalations visit observations, Meetings etc.…)

8) Contractual communications & claims 6) Product NCR’s & its closure

9) MPR & customer comments / 7) Internal Audit Calendar & its

resolutions compliance

10) Risks & opportunities 8) Training details

11) EOT and its process (If any) 9) Pending Audit Observations / NCR’s (1st

12) Delays and action plans 2nd & 3rd party audits)

13) Planned Vs Achieved, S Curve 10) Availability of Approved Documents

14) Communication in‐out (Customer, 11) Customer supplied items

vendor & subcontractor) 12) Third party testing records

15) 3 months look ahead plan 13) Samplings – ITP / QAP stages and

16) WBS compliance.

17) Drawings receipt and issue mechanism 14) Sampling ‐ Material traceability

18) Invoices and payments 15) Master Calibration calendar

19) Status of disputes & issues 16) Calibration reports & traceability

20) Customer satisfaction reports 17) Authorizations / Competency

21) Master list of documents and control 18) Laboratory operation & registers

22) Project Deliverables 19) Preservation – Laboratory &

23) Authority matrix equipment’s.

24) Objectives review (Productivity 20) Product Quality Rating (From

parameters) Customer) & MQR’s

25) Bulk Material reconciliation w.r.t ACE 21) Trends of Process & Products

26) Subcontractor evaluation 22) Status of RFI’s

27) Insurance details 23) Batching plant process / Pour cards

28) Quantity paid to S/c Vs customer 24) Raw materials storage & handling

29) Digitalization initiatives 25) Source approvals / Qualifications

30) Cost of rework 26) Best practices / Process improvements

/ innovations

Procurement EHS

1) Master list of vendors 1) EHS KPI’s and progress

2) EMR’s ‐ PO/WO 2) Competence, training & awareness

3) S6 3) Emergency preparedness and control

4) Bulk Materials & Project based supplies 4) EHS inspection & audits

5) CPRS / PHRS 5) Incident investigation and reporting

6) Purchase requirements 6) PPE management

7) RFQ details 7) Lifting tools and tackles certification

8) Comparison statements 8) Safety checklists – Operation and

9) Vendor selection process compliance

10) Vendor assessment records 9) Scaffolding

11) Vendor performance evaluation 10) Material handling

12) Customer satisfaction reports 11) Electrical safety

13) Progress on Objectives 12) Fire protection

14) Specialized agencies 13) Housekeeping, health & hygiene

15) Subcontracting / Hiring 14) Environmental management

16) Department risks & opportunities 15) Certificates

16) Client audit compliances

17) Legal compliances

18) Contractual compliances

19) Medical facilities and first aid facilities

20) Ambulances

P&M Stores

1) P&M Objectives review 1) Organization chart

2) Authorization matrix 2) Master list of records

3) Competency details 3) Stock statement

4) Master list of equipment’s (Asset & 4) Physical verification of stock

Hired) 5) Bulk material details

5) Scheduled Maintenance calendar & 6) Perishable items tracking

checklists 7) Physical storage of paints, diesels &

6) History cards other flammable materials

7) Customer satisfaction records 8) Weigh bridge details & calibration

8) Equipment Fitness reports 9) Preservation of customer items & other

9) Licenses & other statutory details items

10) Legal clearances (E.g.: DG’s, Batching 10) Recommended storage conditions for

plants etc...) special equipment’s / items (if any)

11) Major breakdowns 11) MR to material issue process

12) Idle time analysis 12) Incoming inspection

13) MTTR & MTBF 13) Authorizations

14) Calibration details 14) Status of Fast moving & Nonmoving

15) Productivity data items

16) ATR data 15) First In First Out / Just In Time

17) Department risk reviews 16) MSDS

18) Spare parts reconciliations

19) Equipment utilization

20) SFL Norms

Execution Accounts / Administration / IR

1) Compliance to approved documents 1) Adherence to contractual requirements

(ITP, Procedures & drawings) 2) Cost statement / Revenue register

2) Housekeeping & preservation 3) CSR initiatives

3) Safe workplace (Availability of permits 4) Workmen policy and insurances

& PPE’s) 5) Licenses & approvals (E.g.: ‐ BOCW,

4) Daily / weekly / monthly targets and its EPF, ISMW, ISNW, PCB etc.…)

compliance 6) Biometric attendances

5) Master list of documents and control 7) Labor accommodation

6) Subcontractor management / Job 8) Screening records

allocation 9) Display of labor wages

7) Shift registers 10) Subcontractor payment

8) Site observation register

General Points:

1. Customer meeting

2. Other additional departments / functions – E.g.:‐ Quarry & crushers, Formwork

Departmental Objectives review

Productivity parameters

Compliance to contractual requirements

You might also like

- 21 CFR 820 Audit ChecklistDocument7 pages21 CFR 820 Audit ChecklistFrankMartinez100% (1)

- List of ISO 17025:2017 Documents For Testing LaboratoryDocument4 pagesList of ISO 17025:2017 Documents For Testing LaboratoryGlobal Manager Group93% (56)

- Pharmacovigilance Audit ChecklistDocument2 pagesPharmacovigilance Audit ChecklistJasper Buss Hub80% (5)

- Iqcert International LTD.: Documents Checklist For Grs & RcsDocument3 pagesIqcert International LTD.: Documents Checklist For Grs & RcsMd. Samirul Islam100% (2)

- Strategic Compensation in Canada Canadian 6th Edition Long Test BankDocument25 pagesStrategic Compensation in Canada Canadian 6th Edition Long Test BankJeffreyWalkerfpqrm100% (26)

- IATF 16949 - Internal Audit ChecksheetDocument11 pagesIATF 16949 - Internal Audit ChecksheetHem Upadhyay91% (11)

- VDA6.3 Procss QuestionaireDocument24 pagesVDA6.3 Procss Questionairedesurkarb100% (1)

- Preservation Procedure 1Document18 pagesPreservation Procedure 1Sreni Excel Macros100% (5)

- Audit Agenda and Scope (Draft)Document3 pagesAudit Agenda and Scope (Draft)Niraj PandyaNo ratings yet

- QC SUPERVISOR InterviewDocument7 pagesQC SUPERVISOR InterviewMohamed S. Elrapat100% (5)

- Cost Accounting 2 Fourth Year Second Semester 2020-2021 Chapter (7) Part (Dr. El Ghareeb) (2) Presented By: Dr. Ahmed MokhtarDocument13 pagesCost Accounting 2 Fourth Year Second Semester 2020-2021 Chapter (7) Part (Dr. El Ghareeb) (2) Presented By: Dr. Ahmed Mokhtarمحمود احمدNo ratings yet

- Osg Multinational Services (PVT.) LTD.: Social Audit Document Check ListDocument1 pageOsg Multinational Services (PVT.) LTD.: Social Audit Document Check ListVivo Y12No ratings yet

- Some Common Pints To Check The EvidenceDocument2 pagesSome Common Pints To Check The EvidenceashtaxNo ratings yet

- Process Mapping Purchase: Document No.: - Rev. No: - Rev. Date: - Process Owner: - Purchase InchargeDocument2 pagesProcess Mapping Purchase: Document No.: - Rev. No: - Rev. Date: - Process Owner: - Purchase InchargeVikas MalekarNo ratings yet

- Mandatory Documents and Records (Ref: ISO 9001:2008)Document4 pagesMandatory Documents and Records (Ref: ISO 9001:2008)Shashank ChhajerNo ratings yet

- Social Audit Check ListDocument2 pagesSocial Audit Check ListRifat Ahmed100% (1)

- List of Documents To Be ReviewedDocument2 pagesList of Documents To Be ReviewedDEBASISH RAY CHOUDHURYNo ratings yet

- Application of Management Information System in Production/Manufacturing SectorDocument2 pagesApplication of Management Information System in Production/Manufacturing SectorOmey BadakhNo ratings yet

- Workproducts - Artifacts For ISO9001Document5 pagesWorkproducts - Artifacts For ISO9001selvamuthukumarNo ratings yet

- SUPPLIER - Manual - Rev - H (Commercial String & Tool Company)Document18 pagesSUPPLIER - Manual - Rev - H (Commercial String & Tool Company)Jahmia CoralieNo ratings yet

- Supplier Engagement GuidelinesDocument5 pagesSupplier Engagement GuidelinesffppxxzzNo ratings yet

- PMP Certification - 4daysDocument4 pagesPMP Certification - 4dayssahajNo ratings yet

- Apqp PhasesDocument3 pagesApqp PhasesBharatNo ratings yet

- Sedex Audit Checklist - Uploaded by Compliance Bangladesh - ComDocument1 pageSedex Audit Checklist - Uploaded by Compliance Bangladesh - CommastanNo ratings yet

- 0IATFACTIVITYDEPT23Document1 page0IATFACTIVITYDEPT23Dilshad AliNo ratings yet

- 4.4.1 Turtle Diagram ADocument3 pages4.4.1 Turtle Diagram ArohitNo ratings yet

- Departmental Wise Measurable Master - 2Document13 pagesDepartmental Wise Measurable Master - 2VenkatesanNo ratings yet

- 1.1 Signing Off The ProductDocument3 pages1.1 Signing Off The ProductJSG GroupNo ratings yet

- Audit-Checklist (Grain Commission)Document10 pagesAudit-Checklist (Grain Commission)KatelynNo ratings yet

- CON-EPM-APD-01-2008-v1 Appendix A - Owners RequirementsDocument9 pagesCON-EPM-APD-01-2008-v1 Appendix A - Owners RequirementsTariq JamalNo ratings yet

- 100 - QC Inspection & Test Plans (Construction Phase)Document4 pages100 - QC Inspection & Test Plans (Construction Phase)MohamedNo ratings yet

- Crai CMC Ia CPP 005Document2 pagesCrai CMC Ia CPP 005Ravi ShankarNo ratings yet

- PQ Visit Agenda For EPC ContractorDocument2 pagesPQ Visit Agenda For EPC ContractorUbaid ur-RehmanNo ratings yet

- Asme Awareness Program - 1Document25 pagesAsme Awareness Program - 1Gaurav KhamkarNo ratings yet

- Unit 10 Purchasing and Contracting For ProjectsDocument21 pagesUnit 10 Purchasing and Contracting For ProjectsŠhivãm PřăJąpãtiNo ratings yet

- Saep 380 PDFDocument10 pagesSaep 380 PDFbassamNo ratings yet

- CMR and SMRDocument19 pagesCMR and SMRBalot EspinaNo ratings yet

- JQA Experiences As A DOE and Current Status of CDMDocument23 pagesJQA Experiences As A DOE and Current Status of CDMconnlingNo ratings yet

- Riad M Mahfouz, CIPM, HEM, CHCQMDocument33 pagesRiad M Mahfouz, CIPM, HEM, CHCQMShorbanNo ratings yet

- Pharmainform Pharmainform: RF Environment SurveyDocument7 pagesPharmainform Pharmainform: RF Environment SurveymasiNo ratings yet

- Pipeline Integrity Management Systems ": LEVEL FoundationDocument3 pagesPipeline Integrity Management Systems ": LEVEL FoundationSalah JallaliNo ratings yet

- Unit 3-QMS DevelopementDocument12 pagesUnit 3-QMS DevelopementMorc LenoirNo ratings yet

- Saep 397Document9 pagesSaep 397munnaNo ratings yet

- GMP ChecklistDocument11 pagesGMP ChecklistWerner Schrammel100% (1)

- 9001 2015 All in One ContentsDocument2 pages9001 2015 All in One ContentsAdmin dahsNo ratings yet

- UKCA ChecklistDocument3 pagesUKCA ChecklistMohammed AbdullahNo ratings yet

- Skoda Specific Quality Requirement v3Document24 pagesSkoda Specific Quality Requirement v3Yo GoldNo ratings yet

- Nabl 126Document31 pagesNabl 126Gazal GuptaNo ratings yet

- Mfjo694 MRB 0001 IndexDocument2 pagesMfjo694 MRB 0001 IndexAkhtar Ansari100% (1)

- Inst. Insp. and Qua. Con.Document5 pagesInst. Insp. and Qua. Con.engrrahman3135100% (3)

- CMRP Practice QuestionsDocument4 pagesCMRP Practice Questionslinbaba123No ratings yet

- Checklist of Documents Required For WSHMS Audit (Construction)Document1 pageChecklist of Documents Required For WSHMS Audit (Construction)Khuda BukshNo ratings yet

- QM 01 ANNEX II Key Busines ProcessDocument4 pagesQM 01 ANNEX II Key Busines ProcessVinod SaleNo ratings yet

- PARAS 0029.CHRCsVettingAviationWorkers .FinalReportDocument68 pagesPARAS 0029.CHRCsVettingAviationWorkers .FinalReportRey Eduard Q. UmelNo ratings yet

- CEAT Requirement For Raw Material DevelopmentDocument1 pageCEAT Requirement For Raw Material DevelopmentvishnuNo ratings yet

- Vendor Audit ChecksheetDocument5 pagesVendor Audit ChecksheetSanjay KumarNo ratings yet

- Compression of Schedule M To Proposed Schedule M: Part I-ADocument2 pagesCompression of Schedule M To Proposed Schedule M: Part I-ASangram Kendre100% (1)

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- A Blueprint for Implementing Best Practice Procedures in a Digital Forensic Laboratory: Meeting the Requirements of ISO Standards and Other Best PracticesFrom EverandA Blueprint for Implementing Best Practice Procedures in a Digital Forensic Laboratory: Meeting the Requirements of ISO Standards and Other Best PracticesRating: 3 out of 5 stars3/5 (1)

- Mission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsFrom EverandMission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsRating: 5 out of 5 stars5/5 (1)

- Slips, Trips and Falls: Safety Checks Please Tick (3) Yes No NA If No, Action Required byDocument2 pagesSlips, Trips and Falls: Safety Checks Please Tick (3) Yes No NA If No, Action Required byThupten Gedun Kelvin OngNo ratings yet

- Operations Management Mms 1Document355 pagesOperations Management Mms 1amithariaNo ratings yet

- Akademi Laut Malaysia ALAM Course Calendar 2015Document6 pagesAkademi Laut Malaysia ALAM Course Calendar 2015Abraham Immanuel AdamNo ratings yet

- Test Certificate NDT / Inspection: - YOKRIDocument9 pagesTest Certificate NDT / Inspection: - YOKRIikponmwonsaNo ratings yet

- Mukiwa Change Management Model AnswersDocument6 pagesMukiwa Change Management Model AnswersMadalitso MukiwaNo ratings yet

- Component Seals: and Machine Specific Plug in SealsDocument72 pagesComponent Seals: and Machine Specific Plug in SealsDamonNo ratings yet

- Equalisation On Investment FundsDocument10 pagesEqualisation On Investment FundsWilling ZvirevoNo ratings yet

- Project Plan Elements: Overview: This Is A Short Summary of The Objectives and Scope ofDocument6 pagesProject Plan Elements: Overview: This Is A Short Summary of The Objectives and Scope ofĐông ĐôngNo ratings yet

- Assignment 9 - Arundel PartnersDocument2 pagesAssignment 9 - Arundel PartnersRon KurtzbardNo ratings yet

- 1st Quarterly Exam Org and ManDocument2 pages1st Quarterly Exam Org and Mankatherine corveraNo ratings yet

- Loctite Case SolutionDocument10 pagesLoctite Case SolutionLavina DNo ratings yet

- COBIT 5 - Performance-Measurement-Metrics-for-IT-Governance - Joa - Eng - 1116Document7 pagesCOBIT 5 - Performance-Measurement-Metrics-for-IT-Governance - Joa - Eng - 1116yi wangNo ratings yet

- Tanda Terima ApdDocument3 pagesTanda Terima ApdBahar Agus KurniawanNo ratings yet

- Penggunaan Sistem Pembayaran E-Money Berbasis Server Untuk Mendukung Gerakan Cashless Society Pada Generasi MilenialDocument8 pagesPenggunaan Sistem Pembayaran E-Money Berbasis Server Untuk Mendukung Gerakan Cashless Society Pada Generasi MilenialSyahrakansa PutraNo ratings yet

- Blueprint Training Presentation:: Maintenance Work OrdersDocument24 pagesBlueprint Training Presentation:: Maintenance Work OrdersUrea3 MaintenanceNo ratings yet

- FMEA BlankDocument4 pagesFMEA BlankJonjon SarmientoNo ratings yet

- FSA QuestionsDocument1 pageFSA QuestionsNadeemNo ratings yet

- 13 Long Term Construction ContractsDocument2 pages13 Long Term Construction ContractsJem ValmonteNo ratings yet

- JSA 03 To Do Work On Concrete Mixer, Concrete Pump, Vibrator, De-Watering Pump.Document3 pagesJSA 03 To Do Work On Concrete Mixer, Concrete Pump, Vibrator, De-Watering Pump.mehtab uddinNo ratings yet

- Accurate Industrial Controls PVT LTD: Job DescriptionDocument2 pagesAccurate Industrial Controls PVT LTD: Job DescriptionANIRBAN BISWASNo ratings yet

- Q CH 5 PART ONEDocument3 pagesQ CH 5 PART ONEJoud ZaneedNo ratings yet

- Supply Chain Management SCM: Course: Management Information System MIS 201Document10 pagesSupply Chain Management SCM: Course: Management Information System MIS 201Abdelrahman MohamedNo ratings yet

- Assignment Brief - POM A1Document4 pagesAssignment Brief - POM A1ye yeNo ratings yet

- Raftar Express India PVT LTD Profile.Document8 pagesRaftar Express India PVT LTD Profile.mohdmashaallah5No ratings yet

- Business StrategyDocument18 pagesBusiness StrategyValeria CostoNo ratings yet

- Software Project Management: Activity PlanningDocument56 pagesSoftware Project Management: Activity PlanningAhmed Nasir Haji HassanNo ratings yet

- Lecture Slides - Chapter 5 & 6Document102 pagesLecture Slides - Chapter 5 & 6Phan Đỗ QuỳnhNo ratings yet