Professional Documents

Culture Documents

Apqp Phases

Uploaded by

Bharat0 ratings0% found this document useful (0 votes)

61 views3 pagesOriginal Title

APQP PHASES

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

61 views3 pagesApqp Phases

Uploaded by

BharatCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

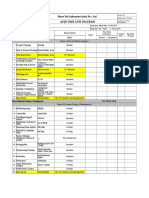

APQP PHASES

Phase - 1st Status

1 Receipt of Enquiry along with specification / Drawing/ Reference sample etc.

2 Pre Feasibility Study

3 Clarification from customer for incomplete information

4 Technical Feasibility

5 Cost Estimation (Quotation submission to customer).

6 Receipt of LOI from Customer

7 Preparation of CFT

8 Preparation of Timing Chart & APQP Responsibilty

9 Traninig Of APQP / FMEA / MSA / SPC & Spl Measuring Tools

Phase - 2nd

9 Process Flow Chart (Prototype)

10 Bill of Material (BOM if any)

11 Past Problem History Study

12 Component Drawing (if reqd)

13 Component Drawing Review

14 Review of process Flow chart

15 Identification of Special Characteristics

16 Evaluation of Regulatory/ Statutory requirement, Enviroment, Health & Safety.

Phase - 3rd

1 Process FMEA

2 Development Targets

3 Controlplan ( Prototype )

4 Tool Manufacturing

5 Identification of New Resources Requirement (Man, Mtl., Machine, Measuring eq etc)

6 Sourcing of Raw Material/BOPs (Identification & Approval of Suppliers)

7 Sample Trial Run & Submission of OK Samples

8 Follow-up results from customer during product development

9 Review with customer & Update Past Defect History & Control Plan etc.

10 Layout plan

Phase - 4th

1 Component procurement (RM & BOP)

2 SPC Plan

3 Operator Process Instruction / SOP / Process Sheets & Trainings

3 Operator Process Instruction / SOP / Process Sheets & Trainings

4 Logistic Study & Packaging finallization.

5 Pre Launch Control Plan

6 MSA / Gauge R&R Plan

7 Process audit

8 Production Trial Run (Pilot Lot)

9 Process / Product validation

10 Process Capability Evaluation (Cp Cpk Study)

11 MSA / Gauge R&R Study

12 Defect summary of T0, T1 & T2 trials

13 PPAP Submission

14 Customer Approval

Phase - 5th

Feedback Analysis & Corrective Action

TGR & TGW Summarization

Production Control Plan

Sign off PSW

Start OF Initial Production Control

You might also like

- Exedy India Ltd. APQP Process DocumentsDocument3 pagesExedy India Ltd. APQP Process Documentssam1hi5No ratings yet

- 390018-Lito Garcia Junio-Production Team LeaderDocument3 pages390018-Lito Garcia Junio-Production Team LeaderATKNo ratings yet

- APQP Time Plan for 150 X 75 Steel Hollow SectionDocument4 pagesAPQP Time Plan for 150 X 75 Steel Hollow SectionRakesh PandeyNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- Shree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramDocument2 pagesShree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramS. R. OvhalNo ratings yet

- F.disp.01 Schedule V-S Dispatch PlanDocument6 pagesF.disp.01 Schedule V-S Dispatch PlanSaurabhNo ratings yet

- TVS MOTOR COMPANY Audit Date Check Sheet for Significant Production Trial Run (SPTRDocument5 pagesTVS MOTOR COMPANY Audit Date Check Sheet for Significant Production Trial Run (SPTRSAKTHIVEL ANo ratings yet

- Sidhi Alcast: Machine Maintenance RecordDocument1 pageSidhi Alcast: Machine Maintenance Recordpulkit gargNo ratings yet

- Quality Planning AgreementDocument13 pagesQuality Planning AgreementShanmugam BalasubramaniamNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument36 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Procedure For New DevelopmentsDocument2 pagesProcedure For New DevelopmentsspdhimanNo ratings yet

- 03 Knowledge Sharing 7 QC ToolsDocument107 pages03 Knowledge Sharing 7 QC Toolsravi javaliNo ratings yet

- Criteria for Evaluating Supplier Audit FrequencyDocument1 pageCriteria for Evaluating Supplier Audit FrequencyRakesh ChauhanNo ratings yet

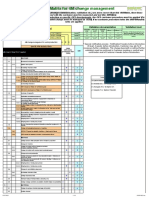

- Change Management C Pillar Stacking Reduced From 1+4 To 1+2Document18 pagesChange Management C Pillar Stacking Reduced From 1+4 To 1+2shobha shelarNo ratings yet

- Turner End Yoke Development Plan IssuesDocument85 pagesTurner End Yoke Development Plan IssuesrohitbaggaNo ratings yet

- Customer Satisfaction Survey ProcedureDocument1 pageCustomer Satisfaction Survey ProcedureAnkur GuptaNo ratings yet

- Appendix - 9 - APQP - Timing - PlanDocument1 pageAppendix - 9 - APQP - Timing - PlanChandru JattiNo ratings yet

- APQP Timeline PlanDocument1 pageAPQP Timeline PlanPradeep Kumar KelembathNo ratings yet

- OBS - 510 - Rev 01 - Eng MilliporeDocument4 pagesOBS - 510 - Rev 01 - Eng MilliporeSakthy ArunaNo ratings yet

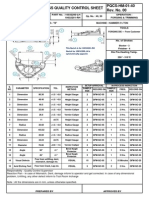

- VCIPL PQCS-HM-01-40 Process Quality Control Sheet for Forging & TrimmingDocument1 pageVCIPL PQCS-HM-01-40 Process Quality Control Sheet for Forging & TrimmingBalram JiNo ratings yet

- Mohindra Fasteners CQI 9 Audit ObservationsDocument2 pagesMohindra Fasteners CQI 9 Audit ObservationsAsif AliNo ratings yet

- Tool Development PlanDocument3 pagesTool Development PlanTrivesh SharmaNo ratings yet

- PPAP Check ListDocument4 pagesPPAP Check ListSameer SaxenaNo ratings yet

- PFMEA - 4th Edition PFMEA RankingDocument2 pagesPFMEA - 4th Edition PFMEA RankingDjurdjina PetkovicNo ratings yet

- MTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Document9 pagesMTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Sahil WadhwaNo ratings yet

- pure cotton pvt ltd final inspection reportDocument4 pagespure cotton pvt ltd final inspection reportTarun PariharNo ratings yet

- Production Validation TemplateDocument1 pageProduction Validation Templatesathyabalaraman100% (1)

- Part Approval File Checklist Mandatory Documents For All PartsDocument2 pagesPart Approval File Checklist Mandatory Documents For All Partssumit_saraf_5No ratings yet

- Trouble HistoryDocument7 pagesTrouble HistoryShahzaibUsmanNo ratings yet

- PDF Process Audit Vda 63Document9 pagesPDF Process Audit Vda 63Shahrazed ZineNo ratings yet

- Calibration ProcedureDocument5 pagesCalibration ProcedureManu SharmaNo ratings yet

- LSAI SQA Manual FileDocument39 pagesLSAI SQA Manual FileSivakumar LNo ratings yet

- Apqp Advanced Product Quality PlanningDocument27 pagesApqp Advanced Product Quality PlanningRajesh KumarNo ratings yet

- PPAP Package for Inner Pipe PartDocument31 pagesPPAP Package for Inner Pipe PartPk NimiwalNo ratings yet

- PFD and Pqcs of Can Rear BreakDocument16 pagesPFD and Pqcs of Can Rear BreakVikas KashyapNo ratings yet

- 02 Manufacturing Process Design InputsDocument3 pages02 Manufacturing Process Design InputsRaja DuraiNo ratings yet

- APQP Responsibility MatrixDocument3 pagesAPQP Responsibility MatrixSuraj RawatNo ratings yet

- Defect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byDocument6 pagesDefect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byParthiban DNo ratings yet

- MOM - Control PlanDocument17 pagesMOM - Control PlanraghulramasamyNo ratings yet

- Control Plan: Pre-Launch Production PrototypeDocument1 pageControl Plan: Pre-Launch Production PrototypeAnkur DhirNo ratings yet

- Sr. No. Metric Goal Data Source Base Line: TallbrosDocument3 pagesSr. No. Metric Goal Data Source Base Line: TallbrosVikas KashyapNo ratings yet

- Automotive customer requirement checklistDocument2 pagesAutomotive customer requirement checklistmahesk_dmNo ratings yet

- 4M Change ManagementDocument2 pages4M Change ManagementDamodaran RajanayagamNo ratings yet

- Form30TM Advanced Product Quality Planning-APQPDocument1 pageForm30TM Advanced Product Quality Planning-APQPShinichi SuzukiNo ratings yet

- WI-R&D-33 - Field Validation of ClutchDocument3 pagesWI-R&D-33 - Field Validation of ClutchDisha ShahNo ratings yet

- Development Procedure 16-08-2021Document6 pagesDevelopment Procedure 16-08-2021CompdevpNo ratings yet

- COQ Elements Data Source Value Percentage Contribution Per AH Percentage SalesDocument10 pagesCOQ Elements Data Source Value Percentage Contribution Per AH Percentage SalesmuthuselvanNo ratings yet

- Grafica XRDocument1 pageGrafica XRAlfonso CruzNo ratings yet

- 18 Point Ppap Plan Approval-WaiverDocument4 pages18 Point Ppap Plan Approval-WaiverBrenda GillNo ratings yet

- 4 M Change LatestDocument8 pages4 M Change LatestVikas KashyapNo ratings yet

- Nyloc Nut Is 7002 PDFDocument11 pagesNyloc Nut Is 7002 PDFsanjibkrjana0% (1)

- Tool Life Monitoring RecordDocument4 pagesTool Life Monitoring RecordMani ManishNo ratings yet

- QMS Cross Audit 18Document4 pagesQMS Cross Audit 18rajesh sharmaNo ratings yet

- Nikhil Quality 6YOEDocument3 pagesNikhil Quality 6YOENikhil DhimanNo ratings yet

- R&R Study: 1 2 3 4 5 6 7 8 9 10 Average Op / Trial SampleDocument3 pagesR&R Study: 1 2 3 4 5 6 7 8 9 10 Average Op / Trial SampleluminyNo ratings yet

- Metal Forms IMaRQ Audit ReportDocument17 pagesMetal Forms IMaRQ Audit ReportVijay OfficialNo ratings yet

- C8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnDocument1 pageC8 TurtleDiagramCustomerFeedbackProcess顾客反馈过程乌龟图 EnBAlaNo ratings yet

- Advanced Quality Planning Status ReportDocument2 pagesAdvanced Quality Planning Status ReportrajivggocNo ratings yet

- APQPDocument2 pagesAPQPSachin Kumbhar67% (3)

- Layout Plan 2021Document3 pagesLayout Plan 2021BharatNo ratings yet

- Layout Inspection Report for Connector PipeDocument13 pagesLayout Inspection Report for Connector PipeBharatNo ratings yet

- PL2303CheckChipVersion ReadMeDocument3 pagesPL2303CheckChipVersion ReadMeLaci PopNo ratings yet

- Format Issue RecordDocument4 pagesFormat Issue RecordBharatNo ratings yet

- Aditya Kumar SinghDocument2 pagesAditya Kumar SinghBharatNo ratings yet

- Curriculam Vitae: Alok KumarDocument2 pagesCurriculam Vitae: Alok KumarBharatNo ratings yet

- Phone Pe Contact DetailsDocument4 pagesPhone Pe Contact DetailsBharatNo ratings yet

- 0 - Resume DhtanwarDocument3 pages0 - Resume DhtanwarBharatNo ratings yet

- Ashok SrivastavaDocument2 pagesAshok SrivastavaBharatNo ratings yet

- Resume: Saurav Rohilla: Sauravrohilla126Document3 pagesResume: Saurav Rohilla: Sauravrohilla126BharatNo ratings yet

- R K PathakDocument5 pagesR K PathakBharatNo ratings yet

- Profile Summary: Mobile: +91-8470014679Document2 pagesProfile Summary: Mobile: +91-8470014679BharatNo ratings yet

- Dhan Singh's CV for Inventory Management RolesDocument3 pagesDhan Singh's CV for Inventory Management RolesBharatNo ratings yet