Professional Documents

Culture Documents

IS 15477 2019 Adhesives For Use With Ceramic, Mosaic & Stone Tiles

Uploaded by

lovehackinggalsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IS 15477 2019 Adhesives For Use With Ceramic, Mosaic & Stone Tiles

Uploaded by

lovehackinggalsCopyright:

Available Formats

Hkkjrh; ekud IS 15477 : 2019

Indian Standard

fljsfed] iPphdkjh vkSj iRFkj dh

Vkbyksa esa iz;Dq r vklatd — fof'kf"V

( igyk iqujh{k.k )

Adhesives for Use with Ceramic,

Mosaic and Stone Tiles —

Specification

( First Revision )

lCS 83.180; 91.100.25

© BIS 2019

Hkkjrh; ekud C;wjks

BUREAU OF INDIAN STANDARDS

ekud Hkou] 9 cgknqj'kkg ”kiQj ekxZ] ubZ fnYyh&110002

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI-110002

www.bis.org.in www.standardsbis.in

July 2019 Price Group 8

For BIS use only, New Delhi:2019-08-23 14:24:50

Flooring, Wall Finishing and Roofing Sectional Committee, CED 05

FOREWORD

This Indian Standard (First Revision) was adopted by the Bureau of Indian Standards, after the draft finalized by

the Flooring, Wall Finishing and Roofing Sectional Committee had been approved by the Civil Engineering

Division Council.

This standard was first published in 2004. This revision incorporates the experience gained with the use of this

standard and brings it in line with the latest developments in this field. The following are the significant modifications

incorporated in this revision:

a) Title of the standard has been modified to ‘Adhesives for use with ceramic, mosaic and stone tiles —

Specification’ from ‘Adhesives for use with ceramic tiles and mosaics — Specification’.

b) Adhesives have been classified into five types namely, Type 1, Type 2, Type 3, Type 4 and Type 5.

c) Measurement of adhesion strengths have been modified to load per unit area.

d) Measurement of adhesion strengths are now to be done using UTM.

e) Requirements such as slip and deformation of adhesives have been added.

f) Requirements such as rheology and storage stability have been done away with.

This standard also specifies the procedure for the tests to evaluate the properties of different types of tile adhesives

suitable for fixing tiles of different porosity on various substrates.

The suitability of a tile adhesive largely depends on the following factors of tiles to be fixed: (a) The porosity/

density; (b) Size of tile; (c) The nature, surface and location of the substrate; and (d) The area of application,

interior or exterior submerged conditions or wet areas.

As the tiles installed should establish 100 percent contact with the substrate. However, the following minimum

contact requirements should be used for designing the adhesive: (a) 95 percent contact area for high demanding

conditions; (b) 85 percent minimum contact area for normal conditions; and (c) In case of using spot bonding

technique or blob technique for fixing of tiles for decorative purposes or internal use, where it is sufficient to have

50 percent contact area, the shear bond strength of the proposed adhesive should be at least 10 MPa.

While formulating this standard, considerable assistance has been derived from the following ISO standards:

ISO 13007-1 : 2014 Ceramic tiles — Grouts and adhesives — Part 1 : Terms, definitions and specifications

for adhesives

ISO 13007-2 : 2013 Ceramic tiles — Grouts and adhesives — Part 2 : Test methods for adhesives

The composition of the Committee responsible for formulation of the standard is given in Annex H.

For the purpose of deciding whether a particular requirement of this standard is complied with, the final value

observed or calculated expressing the result of a test or analysis shall be rounded off in accordance with IS 2 : 1960

‘Rules for rounding off numerical values (revised)’. The number of significant places retained in the rounded off

value should be the same as that of the specified value in this standard.

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

Indian Standard

ADHESIVES FOR USE WITH CERAMIC, MOSAIC AND

STONE TILES — SPECIFICATION

( First Revision )

1 SCOPE 3.4 Open Time — Maximum time interval after

application at which tiles can be embedded in the

This standard prescribes the requirements for adhesives

applied adhesive.

used for fixing tiles of different porosity and classifies

the tile adhesive into different types suitable for their 3.5 Adjustment Time — Maximum time interval after

proposed application. which tiles positioned in the adhesive layer can be

This standard covers adhesives for installation of adjusted without significant loss of adhesion.

ceramic (vitrified and non-vitrified), porcelain, clay, 3.6 Shelf Life — Time storage under stated conditions

glass, glass mosaic, metal, natural stone and engineered during which an adhesive is expected to maintain its

stone tiles. working properties.

NOTE — All interior and exterior wall installations of stone

3.7 Slip — Downward movement of a tile embedded

tiles above 3 m height shall be clamped for safety, where the

background is not robust enough to support the load of stone in the combed adhesive layer on vertical surface.

tile installation.

3.8 Deformability — Capacity of hardened adhesive

2 REFERENCE to be deformed by stresses between the tile and the

fixing surface without damage to the installed surface.

The standard listed below contains provisions which

through reference in this text, constitute provisions of 3.9 Transverse Deformation — Deflection recorded

this standard. At the time of publication, the edition at the centre when a beam of hardened adhesive is

indicated was valid. All standards are subject to revision subjected to three-point loading.

and parties to agreements based on this standard are

encouraged to investigate the possibility of applying 4 CLASSIFICATION

the most recent edition of the standard indicated below: The adhesives shall be classified into 5 types. The

IS No. Title recommended application of these types of adhesives

10890 : 1984 Specification for planetary mixer are given in 4.1 to 4.5.

used in tests of cement and

4.1 Type 1 Adhesive

pozzolana

3 DEFINITIONS This adhesive is suitable mainly for tiles with apparent

porosity greater than 3 percent. It is suitable for most

For the purpose of this standard, the following of the clay and ceramic (non-vitrified) tiles of small

definitions shall apply. dimension (size not more than 300 mm x 300 mm) and

3.1 Fine Thin Bed Fixing — A process of tile fixing the majority of cement based backgrounds (substrates)

into a bed of an adhesive average of 2 mm in final bed like cement plaster, cement concrete, cement screed,

thickness. etc, and for interior dry area applications only.

3.2 Thin Bed Fixing — A process of tile fixing into a NOTE — Type 1 adhesive generally contains varying small

amounts of chemical polymers, hence the name general purpose

bed of an adhesive average of 6 mm in final bed

adhesive is suitable for general, internal, clay or ceramic floor

thickness. and wall tiling. The vital minor amounts of chemical polymers

enable powder adhesives, which are based on bulk cement and

3.3 Medium Thick Bed Fixing — A process of tile

filler, to be modified to have appropriate properties.

fixing into a bed of an adhesive not less than average

6 mm and not exceeding average 12 mm in final bed 4.2 Type 2 Adhesive

thickness.

This adhesive is suitable mainly for tiles with an

NOTE — If level variation on floor or wall is more than an

apparent porosity less than or equal to 3 percent. It is

average 12 mm in 3 m length (excluding intentional slope for

floors, provided for flow of liquids to drain points), surface suitable for vitrified/fully vitrified tiles, glass mosaic

preparation as required to bring the surface true to plumb level tiles, all stones, dense and large dimension (More than

shall be taken up with appropriate materials. 300 mm × 300 mm size) tiles and stones (slabs), and

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

where background and location is more demanding like technical products, generally referred as polymer modified

wet areas, submerged areas, etc. This type of adhesive adhesives, and are required in situations where the background

(substrate) or the tile or the surface is particularly challenging.

is recommended for both interior floor and wall

applications, and for exterior floor applications. 4.5 Type 5 Adhesive

4.3 Type 3 Adhesive This adhesive is suitable for all types of tiles including

engineered stones (manufactured stones) which are

This adhesive is suitable mainly for tiles and stone tiles

intended for installation on glass or metallic substrates

on exterior wall substrates like plaster or concrete. It is

suitable for tiles like ceramic, clay tiles, basalt tiles, like, grid iron, mild steel, stainless steel, aluminum or

vitrified, glass mosaic tiles and porcelain tiles and all copper, etc. It is suitable for metal tiles, glass tiles,

natural stone tiles. engineered stones or for all types of tiles and stones to

be installed on different cement based substrates like

4.4 Type 4 Adhesive cement screeds, plaster, concrete, drywall boards like

gypsum boards, plywood, wood, metals composite

This adhesive is suitable mainly for tiles and stone tiles

boards, modified backer boards and the metallic

which are included in Type 1, Type 2 and Type 3 but

substrates.

intended for installation on dry wall board substrates.

It is suitable for all types of tiles and stones except NOTE — Type 5 adhesive is generally a mixture of synthetic

metal tiles or engineered stones to be installed on dry resin, mineral fillers and organic additives in which hardening

occurs by chemical reaction. They are available in one or more

wall board substrates like gypsum boards, plywood, component forms and in essence, these cover polyurethanes,

wood, calcium silicate boards, medium density fibre epoxy adhesives and the like.

boards, fiber cement boards, cement boards, bison

panel, etc. 5 REQUIREMENTS

For all tiles/stones of size more than 600 mm × 600 mm, 5.1 Tensile Adhesion Strength

the adhesive shall also comply with ‘S1’ category of

transverse deformation. For all tiles/stones of size more When tested in accordance with the method given in

than 1 200 mm × 1 200 mm, the adhesive shall also Annex A, the mean tensile adhesion strength of adhesive

comply with ‘S2’ category of transverse deformation. shall comply with the requirements given in Table 1.

Similar results to polymer modified adhesive can be 5.2 Shear Adhesion Strength

achieved by the addition of a liquid admixture to the

standard general purpose adhesive which is called as When tested in accordance with the method given in

polymer fortified adhesive. This is a more of specialist Annex B, the mean shear adhesion strength of adhesive

and technical solution that provides enhanced adhesion shall comply with the requirements given in Table 1.

and increased flexibility. Thus, by addition of liquid 5.3 Open Time

admixture to Type 1 adhesive, its properties can be

enhanced to meet the performance criteria of Type 2 or When tested in accordance with the method given in

Type 3 or Type 4 adhesive. Annex C, the open time shall not be less than that stated

NOTE — Type 2, Type 3 and Type 4 adhesives are more

by the manufacturer.

Table 1 Minimum Tensile and Shear Adhesion Strength of Adhesive

(Clauses 5.1 and 5.2)

Sl Characteristic Requirement

No. N/mm2

Type 1 Type 2 Type 3 Type 4 Type 5

(1) (2) (3) (4) (5) (6) (7)

i) Tensile adhesion strength, Min:

a) Dry condition 0.5 1.0 1.5 1.5 2.0

b) Wet condition — 1.0 1.0 1.0 —

ii) Shear adhesion strength, Min:

a) Dry condition 1.0 1.25 1.5 1.5 6.0

b) Heat aging condition — 1.0 1.0 1.0 3.0

c) Wet condition — 1.0 1.0 1.0 —

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

5.4 Adjustment Time 8 PACKING AND MARKING

When tested in accordance with the method given in 8.1 Packing

Annex D, the adjustment time shall not be less than The packing of the adhesive shall comply with the

that stated by the manufacturer. following:

5.5 Slip (Required for Vertical Application Only) a) Adhesive shall be suitably packed in leak proof

and moisture proof bags or containers, and

When tested in accordance with the method given in b) Liquid admixture/liquid components of

Annex E, the slip shall not be more than 0.5 mm. Slip adhesive shall be bottled in suitable leak proof

resistant adhesives shall be designated as ‘T’. and moisture proof containers.

5.6 Deformability (Required for Vertical 8.2 Marking

Application Only) 8.2.1 Each bag or liquid container of adhesive shall be

legibly and indelibly marked with the following:

When tested in accordance with the method given in

Annex F, the deformability shall be within the range a) Name of the manufacturer and the trade-mark,

mentioned below for a particular class as stated by the if any;

manufacturer: b) Batch or lot number;

c) Month and year of manufacturing;

Sl Classification Transverse d) Type of adhesive that is Type 1 or Type 2 or

No. Deformation Type 3 or Type 4 or Type 5;

i) Deformable adhesive, S1 > 2.5 mm, < 5.0 mm e) Special characteristics:

ii) Highly deformable > 5.0 mm 1) Deformability — To be marked with ‘S1’

adhesive, S2 or ‘S2’, if and as applicable.

2) Slip resistance — To be marked with ‘T’,

6 CONDITIONING if applicable.

f) Open time and adjustment time of the

Unless otherwise stated, all the tests shall be carried

adhesive;

out at standard atmospheric conditions of 27 ± 2 °C

g) Storage life and storage condition for the

temperature and 65 ± 5 percent humidity.

adhesive; and

7 INSTRUCTIONS h) Appropriate mixing instructions.

Adhesive supplied in accordance with this standard, 8.2.2 BIS Certification Marking

when mixed and spread in accordance with the The product(s) conforming to the requirement of this

manufacturer’s instructions, shall be suitable for tile/ standard may be certified as per the conformity

stone fixing on those types of background for which assessment schemes under the provisions of the Bureau

they are recommended by the manufacturer. The of Indian Standards Act, 2016 and the Rules and

manufacturer’s instruction shall be carefully Regulations framed thereunder, and the products may

followed when any pre-mixing of the adhesive is be marked with the standard mark.

required.

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

ANNEX A

(Clause 5.1)

DETERMINATION OF TENSILE ADHESION STRENGTH

A-1 APPARATUS and adhesive (AF-T) (see Fig. 1B). The test

value equals the adhesive strength. In some

A-1.1 Square Notched Trowel — Trowel used shall

cases the failure may occur in the adhesive

be with 6 mm × 6 mm square notch trowel with a clear

layer between the tile and the pull head plate

internal gap of 6 mm between adjacent notches.

(BF) (see Fig. 1C). In this case, the adhesive

A-1.2 Weight — Weight shall be of mass 2 kg strength is greater than the test value and the

occupying less than 50 mm × 50 mm cross-sectional test shall be repeated.

area. b) Cohesive failure within the adhesive

A-1.3 Pull Head Plates — These shall be square or (CF-A) — Failure occurs within the adhesive

circular metallic plates, with dimensions of 50 ± 1 mm layer (see Fig. 1D).

edge or diameter and a minimum thickness of 8 mm c) Cohesive failure in the substrate or in the tile

with a suitable fitting for connection to the test (CF-S or CF-T) — The failure occurs within

machine. the substrate (CF-S) (see Fig. 1E) or within

the body of the tile (CF-T) (see Fig. 1F). In

A-1.4 Universal Testing Machine (UTM) — UTM this case, the strength of the adhesive is greater

shall be capable of applying the load to the pull head than the test value.

plate at the rate of 250 ± 50 N/s through a suitable

fitting that does not exert any bending force. A-3 TEST SPECIMENS

A-1.5 Laboratory Oven, controlled at 70 ± 3 °C. A-3.1 For tensile adhesion strength test, tile or stone

shall be cut to sizes of 50 ± 1 mm × 50 ± 1 mm, with a

A-1.6 Concrete Test Substrate — Concrete test nominal minimum thickness of 6 mm or more. The tile

substrate shall be 40 ± 5 mm thick, having a moisture pieces required for the testing shall be five for each

content of less than 3 percent by mass, and water test condition. Hence, a total of ten tile pieces shall be

absorption at the surface after four hours of testing in prepared for tensile testing of an adhesive.

range of 0.5 cm3-1.5 cm3. The cohesive strength shall

be at least 1.5 N/mm2. A-3.2 For Type 1 adhesive, ceramic tiles with porosity

more than 3 percent shall be used for testing. For Type 2,

NOTES

Type 3, Type 4 and Type 5 adhesives, vitrified or porcelain

1 A method for manufacturing a suitable concrete test slab

and the procedures for measuring the cohesive strength and tiles with porosity less than 3 percent shall be used.

surface water absorption is given in Annex G for information

only. A-4 MIXING OF THE ADHESIVE

2 Other test substrates — Other substrates may be used upon

agreement, if the substrate is recommended for tile

The amount of water and/or liquid admixture,

application by the adhesive manufacturer. To demonstrate required for preparing the adhesive, shall be as stated

compatibility with other optional substrates, the adhesive by the manufacturer in proportion by mass (for

shall be applied to the selected substrate with cohesive example, the amount of liquid, in litres and the

strength of greater than 1.0 N/mm2 or if cohesive failure

occurs in the substrate, the requirement is considered

amount of powder, in kg to be mixed shall be

satisfied. declared). If a range of values are given, the average

shall be used.

A-1.7 Mixer for Mixing the Adhesive — See IS 10890

for specification of mixer. A minimum quantity of 2 kg of the adhesive shall be

prepared in a mixing bowl using mixer as per IS 10890

NOTE — Use of mixer is recommended for mixing the

adhesive. with mixing instructions as given in the technical data

sheet provided by the manufacturer.

A-2 FAILURE PATTERNS

Let the adhesive mature in accordance with the adhesive

The modes of failure may be a combination of any of manufacturer’s instructions followed by further mixing

that given below, which shall be recorded for each for 15 s.

specimen:

A-5 PREPARATION OF SPECIMENS

a) Adhesion failure (AF-S or AF-T) — Failure

occurs at the interface between adhesive and A-5.1 Take five test piece tiles of size 50 ± 1 mm ×

substrate (AF-S) (see Fig. 1A) or between tile 50 ± 1 mm × 6 mm or higher thickness.

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

A-5.2 Apply a thin layer of the adhesive, mixed as given adhesion strength of the adhesive as per the

above, to the concrete slab with a straight edge trowel. procedure given in A-7.

Then apply a thicker layer and comb with a square

A-7 PROCEDURE

notched trowel. The trowel shall be held at an angle of

approximately 45° to the substrate at a right angle to A-7.1 After pull head plates are strong enough,

one edge of the slab and drawn across the slab parallel determine the tensile adhesion strength of adhesive

to that edge (in a straight line). Place at least five test by placing the tile on concrete slab to be tested exactly

tiles 50 mm apart on the adhesive. Load each tile with in axial line of pull head, and subject the unit to tensile

2 kg for 30 s. loading at a rate of 250 ± 50 N/s to the specimen.

Note the tensile adhesion strength of the specimen. A

A-6 CONDITIONING suitable arrangement shall be made for clamping the

Condition one set of five specimens for each of the substrate to hold in position while the test is in

regimes as appropriate: progress.

a) Dry condition — After storing for 27 days A-7.2 Failure of the unit shall be deemed to have

under standard conditions, bond the pull occurred when the applied force reaches a maximum

head plates to the tiles with a suitable high value. Then test each of the other specimens similarly.

strength adhesive (Example, Epoxy). After If one or both of the test tiles are broken in the test,

further 24 h storage under standard record the value at which the breakage occurs, and

conditions, determine the tensile adhesion include it in the mean tensile adhesion strength

strength of the adhesive as per the procedure calculation if, the value is within 15 percent of the

given in A-7. mean value. Discard any individual result in which

the breaking force differs by more than 15 percent

b) Wet condition — Condition the specimens

from the mean value. If 3 or more out of the 5 units

under standard conditions for 7 days and

fail at forces outside these limits, repeat the whole

thereafter immerse in water at standard

test.

temperature. After a total of 20 days, remove

the specimens from water, wipe with a cloth, A-8 EXPRESSION OF RESULTS

and bond the pull head plates to the tile or

stone. After a further 7 h under standard Calculate for each conditioning sequence the tensile

conditions, immerse the specimen in water at adhesion strength (N/mm²) as the mean tensile adhesion

standard temperature. breakage of at least three specimens. The bond area

On the following day (that is after a total of for calculating the adhesive tensile strength may be

21 days), remove the specimens from water taken as 85 percent for normal conditions and

and immediately determine the tensile 95 percent for high demanding conditions.

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

FIG.1 FAILURE PATTERNS

ANNEX B

(Clause 5.2)

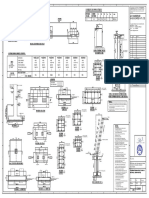

DETERMINATION OF SHEAR ADHESION STRENGTH

B-1 APPARATUS shall be capable of applying the compression load with

B-1.1 Square Notched Trowel — See A-1.1. displacement at the rate of 5 ± 0.5 mm/min.

B-1.2 Support for Shear Specimen — Test Unit B-1.5 Laboratory Oven, controlled at 70 ± 3 °C.

Holder — Support for shear bond specimens shall be B-2 TEST SPECIMENS

as given in the shear bond test jig (see Fig. 2) to place

the tile such that edges are loaded against the non- B-2.1 For Type 1 adhesive, ceramic tiles with porosity

movable support. more than 3 percent shall be cut to size of 100 ± 1 mm ×

100 ± 1 mm, with a nominal minimum thickness of

B-1.3 T- Spacer Bar, made of brass or steel and shall 6 mm or more. Two test pieces are required for each

be as given in Fig. 3. specimen (test unit). Five such cut tiles are required

B-1.4 Universal Testing Machine (UTM) — UTM for Type 1 adhesive for each condition.

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

B-2.2 For Type 2 to Type 5 adhesives, vitrified or regimes as appropriate:

porcelain tiles with porosity less than 3 percent shall a) Dry condition — 28 days under normal

be cut to size of 100 ± 1 mm × 100 ± 1 mm, with a laboratory conditions.

nominal minimum thickness of 6 mm or more. Two

b) Heat ageing condition — 14 days under

test pieces are required for each specimen (test unit).

normal laboratory conditions followed by

Five such cut tiles are required for each of the Type 2

14 days at 70 ± 3 °C.

to Type 5 adhesive for each condition.

c) Wet condition — 7 days under normal

B-3 PREPARATION OF SPECIMENS laboratory conditions followed by 21 days in

Prepare mortar as specified in A-4. Assemble 5 shear water at laboratory temperature.

specimens of 100 ± 1 mm × 100 ± 1 mm tile for each B-5 PROCEDURE

condition, with a minimum of 3 mm mortar layer by

bonding the two pieces of tile together for each specimen. B-5.1 On completion of conditioning, remove the

The 3 mm mortar bonding layer shall be established by specimen from the conditioning environment. Remove

placing 3.2 mm thick T- spacer bar on the smallest tile five specimens assembled as directed above. Insert it

edge; be sure to rub all of the mortar off the underside of into the test unit holder mounted in the UTM machine

the spacers by sliding them back and forth along the edge. and individually test with compression loading with

The top tile shall be placed with the cut edge opposite to displacement at a rate of 5 ± 0.5 mm/min, so that the

that of the bottom tile’s cut edge and squeezed until a mortar is stressed to failure. Record these values.

3 mm thickness of mortar is obtained. The specimen shall B-5.2 Each specimen shall be tested and the failure

be constructed so that the cut edge will be loaded. The load shall be recorded. If one or both of the test tiles

tile shall then be slid back and forth along the stainless are broken in the test, record the value at which the

steel spacers to ensure proper thickness of the mortar. breakage occurs, and include it in the mean shear

The tile shall then be slid to ensure a 6-8 mm offset. adhesion strength calculation if, the value is within

Care shall be taken in removing the stainless steel spacer 15 percent of the mean value. Discard any individual

so as not to cant or slide the tiles in relation to each other result in which the breaking force differs by more than

or to alter the offset distance. Specimens shall not be 15 percent from the mean value. If more than three out

individually handled for 24 h and shall be treated with of the five units fail at forces outside these limits, repeat

care until broken. the whole test.

B-4 CONDITIONING B-6 EXPRESSION OF RESULTS

Condition one set of five specimens for each-of the Calculate for each conditioning sequence, the shear

adhesion strength (N/mm²) as the mean shear adhesion

breakage of at least three specimens.

All dimensions in millimetres.

FIG. 2 SHEAR BOND TEST JIG

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

FIG. 3 SPACER BAR

ANNEX C

(Clause 5.3)

DETERMINATION OF OPEN TIME

C-1 APPARATUS C-3 PROCEDURE

C-1.1 Square Notched Trowel — Trowel used shall C-3.1 The adhesive shall be applied onto a gypsum

be with 6 mm x 6 mm square notch trowel with a clear board using trowel. Tile pieces of size 50 ± 1 mm ×

internal gap of 6 mm between adjacent notches. 50 ± 1 mm shall be fixed to the adhesive with a 2 kg

of mass placed on the tiles for 30 s to improve the

C-2 TEST SPECIMENS

contact.

C-2.1 For open time test, tile shall be cut to size of

50 ± 1 mm x 50 ± 1 mm, with a nominal minimum C-3.2 At definite intervals of time, say 5 min, 10 min,

thickness of 6 mm or more. Ten such tiles have to be 15 min, etc, each designated tile, each time be flipped

prepared for the test. to see the area of contact of adhesive behind the tile.

C-2.2 Ceramic tiles with absorption more than 3 percent C-4 RESULT

shall be used for Type 1 adhesive and vitrified or

porcelain tiles with less than 3 percent absorption shall The open time is defined as the last measurement of

be used for Type 2 or Type 3 or Type 4 or Type 5 time in minutes before the adhesive fails to wet

adhesives. minimum of 50 percent of tile area.

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

ANNEX D

(Clause 5.4)

DETERMINATION OF ADJUSTMENT TIME

D-1 APPARATUS D-3 PROCEDURE

D-1.1 Square Notched Trowel — Trowel used shall D-3.1 The adhesive shall be applied onto a gypsum

be with 6 mm × 6 mm square notch trowel with a clear board using trowel. Tile pieces of size 50 ± 1 mm ×

internal gap of 6 mm between adjacent notches. 50 ± 1 mm shall be fixed to the adhesive keeping a

minimum gap of 35 mm between adjacent tiles, with a

D-2 TEST SPECIMENS 2 kg of mass placed on the tiles for 30 s to improve the

D-2.1 For adjustment time test, tile shall be cut to size contact.

of 50 ± 1 mm × 50 ± 1 mm, with a nominal minimum D-3.2 At definite intervals of time, say 5 min, 10 min,

thickness of 6 mm or more. Ten such tiles have to be 15 min, etc, each designated tile, each time be rotated

prepared for the test. through 90° and then turned back to its original position.

D-2.2 Ceramic tiles with absorption more than 3 percent

D-4 RESULT

shall be used for Type 1 adhesive and vitrified or

porcelain tiles with less than 3 percent absorption shall The adjustment time is defined as the last measurement

be used for Type 2 or Type 3 or Type 4 or Type 5 (time in minutes) before the tile fails to rotate.

adhesives.

ANNEX E

(Clause 5.5)

DETERMINATION OF SLIP

E-1 APPARATUS (see Fig. 4) E-2 TEST SPECIMENS

E-1.1 Steel straight edge. E-2.1 For slip test, tile shall be cut to sizes of 100 ±

1 mm × 100 ± 1 mm, with a nominal minimum thickness

E-1.2 Clamps, to hold the straight edge in place.

of 6 mm or more. Three such tiles have to be prepared

E-1.3 Masking Tape, approximately 25 mm wide shall for the test.

be used.

E-2.2 For Type 1 adhesive, ceramic tiles with porosity

E-1.4 Two pieces of 25 ± 0.5 mm × 25 ± 0.5 mm × more than 3 percent must be used for testing. For

10 ± 0.5 mm spacers made from stainless steel shall be Type 2, Type 3, Type 4 and Type 5 adhesives, vitrified

used. or porcelain tiles with porosity less than 3 percent

should be used.

E-1.5 A weight of mass 5 kg with a cross-sectional area

less than 100 mm × 100 mm shall be used. E-3 PROCEDURE

E-1.6 Vernier Caliper, accurate to 0.01 mm shall be Prepare mortar as specified in A-4. Secure the steel

used. straight edge at the top of the concrete substrate so that

E-1.7 Concrete test substrate as specified in A-1.6 shall its bottom edge is horizontal when the slab is raised to

be used. its vertical position. Position 25 mm wide masking tape

immediately below the steel straight edge, and apply a

E-1.8 Square Notched Trowel — Trowel used shall thin layer of the adhesive to the concrete slab with the

be with 6 mm × 6 mm square notch trowel with a clear straight edge of trowel.

internal gap of 6 mm between adjacent notches.

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

Then apply a thicker layer of adhesive to the surface of within 0.1 mm accuracy. Then lift the concrete substrate

the concrete substrate so that it just overlaps the bottom slab carefully into a vertical position. After 20 ± 2 min,

edge of the masking tape. Comb the adhesive at right re-measure the gap, as before, at its maximum point.

angles to the straight edge with trowel, holding at 45° The maximum slip of the tile under its own weight is

to the base of concrete substrate. the difference between the two readings.

Immediately remove the masking tape, position 25 mm Carry out the test for three tile specimens and report

spacers as shown against the straight edge; and after each individual result and the mean value in mm.

2 min, place the 100 ± 1 mm × 100 ± 1 mm cut tile

specimen against the spacers as shown in Fig. 4 and E-4 TEST RESULTS

load it with a weight of mass 5 kg for 30 ± 5 s. Slip in millimetres shall be reported for individual and

Remove the spacers, and measure the gap between the average value. Tile must not sag more than 0.5 mm

straight edge and the tile with the vernier caliper to from its original position.

FIG. 4 SLIP APPARATUS

10

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

ANNEX F

(Clause 5.6)

DETERMINATION OF DEFORMABILITY

F-1 APPARATUS mould gently from the flow table and carefully remove

the template vertically. Apply a layer of release agent

F-1.1 Substrate — Polyethylene film with minimum

to the Template B and position it centrally over the

thickness of 0.15 mm.

specimen. Load the template with a weight capable of

F-1.2 Plastic Container — A plastic container that is exerting a force of 100 ± 0.1 N and an approximate

capable of being sealed to make it air tight, with an cross-sectional area of 290 × 45 mm. The applied

internal volume of 26 ± 5 litre (say, a container with pressure ensures that the material fully fills the recess

dimensions 600 ± 20 mm × 400 ± 10 mm × 110 ± of the template to the required thickness. Remove any

10 mm). excess material from the sides of the template and 1h

later, remove the weight. After 48 h, remove the

F-1.3 Support — Rigid, smooth and flat support for

template. Prepare five samples for each test

the polyethylene film.

F-1.4 Anvil — A metallic construction with dimensions F-3 PROCEDURE

as shown in Fig. 5.

F-3.1 Conditioning

F-1.5 Test Jig — Two metallic cylindrical supports of

Immediately after the removal of Template B place five

diameter 10 ± 0.1 mm, spaced 200 ± 1 mm centre to

specimens, on the support, horizontally into the plastic

centre, of length 60 mm minimum (see Fig. 6).

container and seal it to make it air tight. Condition the

F-1.6 Template A — A smooth, rigid, non-absorbent test units at 27 ± 2 °C. After 12 days remove them from

rectangular frame of internal dimensions 280 ± 1 mm × the plastic container and condition them for 14 days in

45 ± 1 mm × 5 ± 0.1 mm [For example, made from air in standard conditions.

polytetrafluoroethylene (PTFE) or metal] (see Fig. 7).

F-3.2 Transverse Deformation

NOTE — A round hole of 2 mm diameter drilled at each internal

corner is recommended to ease production of the test piece. After conditioning has been completed, remove the

F-1.7 Template B — A smooth, rigid, non-absorbent specimens from the polyethylene film and measure their

mould or similar device capable of producing a test thickness, using a caliper with 0.01 mm precision, at

specimen of dimensions 300 ± 1 mm × 45 ± 1 mm × three positions, that is, in the middle and 50 ± 1 mm

3 ± 0.05 mm (see Fig. 8). from each end. If the three values fall within the required

tolerance of 3.0 ± 0.1 mm, calculate the average value;

F-1.8 Test Machine — The test machine shall be a discard any specimen which falls outside the required

press, capable of applying the anvil to the test piece at permissible thickness. Place the test sample on the test

a rate of 2 mm/min. jig. The starting point is defined when the anvil touches

F-1.9 Flow Table — The flow table used for the the sample. Deform the sample, from the starting point,

compaction of the 280 mm × 45 mm × 5 mm specimen with a transverse load applied by the anvil at a rate of

(see Fig. 9). 2 mm/min until failure. Record the deformation from

the starting point, in mm. Repeat the test on the other

F-2 TEST SPECIMENS test pieces. Discard any individual result in which the

deformation differs by more than 15 percent from the

F-2.1 Preparation of Substrate mean value. If more than three out of the five units

Fix the polyethylene film firmly to the rigid support, result deformation values outside these limits, repeat

ensuring the surface to which the adhesive is to be the whole test.

applied is not distorted (that is, without pleats or F-4 TEST RESULTS

wrinkles).

The transverse deformation is determined to 0.1 mm,

F-2.2 Preparation of Test Units by calculating the average value of the deformations

Hold the Template A firmly onto the polyethylene film. obtained in the test. Deformation value in millimetre

Trowel sufficient adhesive across the template and then shall be reported for individual and mean values for

screed clean so as to neatly and completely fill the hole deformability of adhesive (mm). The adhesive

in the template. Clamp the mould firmly to the flow deformability is classified as ‘S1’ or ‘S2’ Class based

table and compact the sample using 70 jolts. Lift the on the result obtained from this test.

11

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

All dimensions in millimetres.

FIG. 5 ANVIL

1. Cylinderical support diameter (10 ± 0.1 mm). Length 60 mm minimum

2. ADHESIVe (3 ± 0.1 mm) THICK

FIG. 6 T EST JIG

All dimensions in millimetres.

FIG. 7 T EMPLATE A

12

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

All dimensions in millimetres.

F IG. 8 T EMPLATE B

All dimensions in millimetres.

FIG. 9 FLOW T ABLE

13

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

ANNEX G

(Clause A-1.6)

CONCRETE TEST SLAB

G-1 GENERAL INFORMATION h) Conditioning : The slabs shall be

A concrete test slab suitable for the adhesive tests stored for 24 h under

described in this standard may be manufactured and standard conditions

followed by 6 days

tested using these described procedures.

water immersion at 20 ±

G-2 TEST CONDITIONS 2°C.

Before use or before

Test conditions given in 5 shall apply. being tested for water

G-3 APPARATUS absorption and surface

cohesive strength, the

G-3.1 Pull Head Plates — As given in A-1.3. concrete slabs shall be

stored separately, in

G-3.2 Universal Testing Machine (UTM) — As given

vertical position, in a

in A-1.4.

dry and ventilated

G-3.3 Carsten-Rohrchen Flask, or other suitable environment, for at least

apparatus for measuring the water absorption at the 3 months and

surface of the concrete slab (see Fig. 10). conditioned for at least

24 h under standard test

G-4 CONCRETE TEST SLAB conditions.

The test surface shall have a finish similar to that

G-4.1 Manufacture of the Concrete Slab obtained by using a wooden float and shall be clean

The specification (listed in A-1.6) may be achieved by and dust-free at the time of the test.

using the following procedure to manufacture the G-4.2 Measurement of Surface Water Absorption

concrete slab:

Water absorption at the surface of the concrete slab

a) Binder : Portland cement. shall be determined by the following method:

b) Aggregate : Gravel sand, of up to 8 a) Bond a measuring tube graduated in ml

mm particle size, (Carsten Rohrchen flask) to the concrete slab

continuous grading by means of a suitable sealant.

curve between A and B b) After the sealant has cured, fill the measuring

(see Fig. 11). tube with water, to the upper level.

c) Mix ratio of binder : 1:5 in proportion by c) Record the drop in water level during the 4 h

and aggregate mass. duration of the test. The total drop in water

level at the end of 4 h gives the surface water

d) Ultrafines content : 500 kg/m³ prepared

absorption.

per m³ of concrete concrete shall contain

concrete ultrafines in d) Perform at least three tests on a reference

order to be properly concrete slab from each batch and calculate

workable and have a the average surface absorption.

closed structure: the G-4.3 Measurement of Surface Cohesive Strength

ultrafines content

consists of cement and The tensile strength between the pull head plate and

aggregate particle size concrete surface shall be at least 1.5 N/mm2. The

up to 0.125 mm. strength shall be determined by bonding at least five

pull-head plates directly to the slab, for example, with

e) Water-cement ratio : 0.5 an epoxide resin, and determining the tensile adhesion

f) Manufacture : Vertically or strength by applying a force which increases at a

horizontally in moulds, constant rate of 250 ± 50 N/s.

avoid the use of any

mould release agent. G-4.4 Measurement of Moisture Content

g) Compaction : 90 s on a vibrating table The specimen of size 100 mm × 100 mm shall be

at 50 Hz. weighed, W1 shall be weighed to nearest 1 g. The

specimen, then, shall be dried out at 105 ± 5°C in a

14

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

thermostatically controlled oven until constant mass is to the batch;

obtained within a duration of 4 h. Immediately after b) Handling and storage of concrete slabs before

remvoing from the drying oven, the specimen shall be testing;

weighed (if necessary by cooling to room temperature

c) Water absorption of concrete slab,

in a suitable desiccator), and weighed, W obtained. The

representative of the batch;

moisture content, in percent of the dry block, shall be

determined as follows, correct to one decimal place: d) Moisture content of the concrete slabs,

representative of the batch;

= (W1/W – 1) × 100 e) Tensile adhesion strength of concrete slab,

G-4.5 Data Recorded representative of the batch;

f) Any other factor that might have influenced

The following items shall be recorded:

the result; and

a) Description of the concrete slab and reference g) Date of test.

All dimensions in millimetres.

FIG. 10 APPARATUS FOR EVALUATING WATER ABSORPTION (CARSTEN — ROHRCHEN FLASK)

15

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

FIG. 11 GRADING CURVES FOR 8 mm M AXIMUM P ARTICLE SIZE

16

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

ANNEX H

(Foreword)

COMMITTEE COMPOSITION

Flooring, Wall Finishing and Roofing Sectional Committee, CED 05

Organization Representative(s)

In Personal Capacity (L/109, Sarita Vihar, New Delhi) SHRI ASHOK K HURANA (Chairman)

Ardex Endura India Pvt Ltd, Bengaluru SHRI K. P. PAULSON

SHRI GOPINATH KRISHNAN (Alternate)

Building Materials & Technology Promotion Council, New Delhi SHRI S. K. G UPTA

SHRI PANKAJ GUPTA (Alternate)

Carborundum Universal Limited, Chennai SHRI R. RAJAGOPALAN

DR N. R AMASUBRAMANIAN (Alternate)

Central Public Works Department, New Delhi SHRI RAJESH KUMAR K AUSHAL

SHRI ARUN KUMAR TYAGI (Alternate)

CSIR-Central Building Research Institute, Roorkee SHRI S. K. S INGH

SHRI ACHAL KUMAR MITTAL (Alternate)

CSIR-Central Glass & Ceramic Research Institute, Naroda DR S ATYENDRA N ATH MISRA

CSIR-Central Road Research Institute, New Delhi DR RAKESH K UMAR

Choksi Laboratories Limited, Indore SHRI R. D. MATHUR

SHRI RAMESH BASAPPA (Alternate)

Construction Chemicals Manufacturers Association, Navi Mumbai SHRI UPEN PATEL

SHRI SAMIR SURLAKER (Alternate)

Construction Industry Development Council, New Delhi SHRI P. R. S WARUP

SHRI RAVI JAIN (Alternate)

Delhi Development Authority, New Delhi CHIEF ENGINEER (DWK )

SUPERINTENDING ENGINEER (P) (Alternate)

Directorate General of Border Roads, New Delhi COL INDRA KUMAR JAGGI

Engineers India Limited, New Delhi SHRI J. K. B HAGCHANDANI

SHRI AKHILESH MAURYA (Alternate)

Ultratech Cement Limited, Mumbai SHRI B. KUMAR

Gyan Construction Company, Mumbai REPRESENTATIVE

H. R. Johnson (India) Limited, Dewas SHRI G. S. PATNAIK

SHRI ARUN RAO (Alternate)

Indian Council of Ceramic Tiles & Sanitaryware, New Delhi SHRI ARUN RAO

SHRI P. K. SHARMA (Alternate)

Institution of Engineers (India), New Delhi SHRI K. K. K APILA

Lloyd Insulation (India) Pvt Limited, New Delhi SHRI MOHIT KHANNA

SHRI K. K. MITRA (Alternate)

Mapie Construction Products India Pvt Ltd, Bengaluru DR G. S. R AVI SHANKAR

SHRI ABHIJIT DUTTA (Alternate)

Military Engineer Services, Engineer-in-Chief’s Branch, New Delhi SHRIMATI MALA MOHAN

SHRIMATI NAMRATA KOHLI (Alternate)

Modern Tiles & Marble, New Delhi SHRI SUBHASH KAPOOR

SHRI KAMESWAR RAU (Alternate)

Morbi Dhuva Glaze Tiles Association, Morbi SHRI N ILESH JETPARIA

SHRI JERAM MADHAV KAVAR (Alternate)

Municipal Corporation of Greater Mumbai, Mumbai REPRESENTATIVE

MYK Laticrete India, Hyderabad DR P. ARJUNAN

SHRI N. RADHAKANTH (Alternate)

National Council for Cement and Building Materials, Ballabgarh DR S. K. BREJA

National Highways Authority of India, New Delhi SHRI S. C. J INDAL

SHRI R. P. K HANDELWAL (Alternate)

17

For BIS use only, New Delhi:2019-08-23 14:24:50

IS 15477 : 2019

Organization Representative(s)

National Test House, Kolkata SHRI D. V. S. PRASAD

SHRI ALOKE DEV (Alternate)

National Tiles Corporation, Panchkula SHRI PREM CHAND GUPTA

SHRI S. R. GARG (Alternate)

New Delhi Municipal Corporation, New Delhi REPRESENTATIVE

Premier Polyfilm Limited, Ghaziabad DR SANJEEV K. VERMA

SHRI R. K. NARAD (Alternate)

Research, Designs and Standards Organization, Ministry of EXECUTIVE DIRECTOR (WORKS )

Railways, Lucknow SHRI ASHUTOSH KUMAR (Alternate)

Responsive Industries Limited, Mumbai SHRI RISHABH AGARWAL

SHRI ABHISHEK AGARWAL (Alternate)

Shriram Institute of Industrial Research, New Delhi DR P. K. KAICHER

DR LAXMI RAWAT (Alternate)

Somany Ceramic Ltd, Bahadurgarh SHRI G. G. TRIVEDI

DR ASHUTOSH GOEL (Alternate)

Super Tiles and Marble Private Limited, Mumbai SHRI ASHOK RAJPUROHIT

SHRI SUDHAKAR MODI (Alternate)

Xebec Design and Facilities Private Limited, New Delhi SHRI D EEPAK GAHLOWT

SHRI SAMIR BANERJI (Alternate)

BIS Directorate General SHRI S ANJAY PANT , SCIENTIST ‘F’ and Head (Civil Engg)

[REPRESENTING DIRECTOR G ENERAL (Ex-officio)]

Member Secretaries

SHRI SRIKANTH YAJALA

Scientist ‘C’ (Civil Engg), BIS

AND

SHRI MILIND GUPTA

Scientist ‘C’ (Civil Engg), BIS

18

For BIS use only, New Delhi:2019-08-23 14:24:50

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 2016 to promote

harmonious development of the activities of standardization, marking and quality certification of goods

and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission in writing of BIS. This does not preclude the free use, in the course of

implementing the standard, of necessary details, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of

‘BIS Catalogue’ and ‘Standards : Monthly Additions’.

This Indian Standard has been developed from Doc No.: CED 05 (10108).

Amendments Issued Since Publication

Amend No. Date of Issue Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones : 2323 0131, 2323 3375, 2323 9402 Website: www.bis.org.in

Regional Offices: Telephones

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002 { 2323 7617

2323 3841

Eastern : 1/14 C.I.T. Scheme VII M, V. I. P. Road, Kankurgachi

KOLKATA 700054 { 2337 8499, 2337 8561

2337 8626, 2337 9120

Northern : Plot No. 4-A, Sector 27-B, Madhya Marg, CHANDIGARH 160019

{ 26 50206

265 0290

Southern : C.I.T. Campus, IV Cross Road, CHENNAI 600113

{ 2254 1216, 2254 1442

2254 2519, 2254 2315

Western : Manakalaya, E9 MIDC, Marol, Andheri (East)

MUMBAI 400093 { 2832 9295, 2832 7858

2832 7891, 2832 7892

Branches: A H M E D A B A D . B E N G A L U R U . B H O PA L . B H U B A N E S H WA R . C O I M B ATO R E .

D E H R A D U N . D U R G A P U R . FA R I D A B A D . G H A Z I A B A D . G U WA H AT I .

HYDERABAD. JAIPUR. JAMMU. JAMSHEDPUR. KOCHI. LUCKNOW. NAGPUR.

PA RWA N O O . PAT N A . P U N E . R A I P U R . R A J K O T. V I S A K H A PAT N A M .

Published by BIS, New Delhi

For BIS use only, New Delhi:2019-08-23 14:24:50

You might also like

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Fljsfed) Ipphdkjh VKSJ Irfkj DH Vkbyksa Esa Iz QDR Vklatd Fof'Kf"VDocument21 pagesFljsfed) Ipphdkjh VKSJ Irfkj DH Vkbyksa Esa Iz QDR Vklatd Fof'Kf"VPramukh Test houseNo ratings yet

- Hollow Clay Tiles For Floors and Roofs - Specification: Indian StandardDocument12 pagesHollow Clay Tiles For Floors and Roofs - Specification: Indian StandardDevesh Kumar PandeyNo ratings yet

- D 1779 - 98 R04 Rde3nzk - PDFDocument3 pagesD 1779 - 98 R04 Rde3nzk - PDFMarceloNo ratings yet

- The Manuf. of Paver BlockDocument4 pagesThe Manuf. of Paver BlockMirtunjay KumarNo ratings yet

- Is 4990-1993Document15 pagesIs 4990-1993PRASANT KUMAR BIPRANo ratings yet

- Material Selection: 3.1. Concrete ConstituentsDocument4 pagesMaterial Selection: 3.1. Concrete ConstituentsZXCvincentNo ratings yet

- The Manufacture of Concrete Paving Blocks 2021Document5 pagesThe Manufacture of Concrete Paving Blocks 2021refiloemkn1No ratings yet

- 809 PDFDocument11 pages809 PDFDEE RBNo ratings yet

- Mortar: Section 2.3.1Document3 pagesMortar: Section 2.3.1Zul HakimNo ratings yet

- Grout For Concrete MasonryDocument9 pagesGrout For Concrete MasonrySana UllahNo ratings yet

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To Informationsudhir5441No ratings yet

- Dm-dsi-SPEC09 - Corrosion PR & Odor CNTRLDocument13 pagesDm-dsi-SPEC09 - Corrosion PR & Odor CNTRLhardikNo ratings yet

- 1.4 Mortar and Mortar Joints: Summary of RequirementsDocument4 pages1.4 Mortar and Mortar Joints: Summary of RequirementsmarianaNo ratings yet

- Construction of Walls Using Precast Concrete Stone Masonry Blocks - Code of PracticeDocument10 pagesConstruction of Walls Using Precast Concrete Stone Masonry Blocks - Code of PracticeovprabhakaraNo ratings yet

- Successful PlasteringDocument13 pagesSuccessful PlasteringCoulis UtaumireNo ratings yet

- Asphalt Glass Felt Used in Roofing and Waterproofing: Standard Specification ForDocument3 pagesAsphalt Glass Felt Used in Roofing and Waterproofing: Standard Specification ForMohammad YaseenNo ratings yet

- INPRO Perlite Concrete Brochure 2014Document6 pagesINPRO Perlite Concrete Brochure 2014shabnam58No ratings yet

- Attachment #03Document1 pageAttachment #03Mohab AzizNo ratings yet

- 99999-9-3SS-AFTC-00002 Mosaic TilesDocument14 pages99999-9-3SS-AFTC-00002 Mosaic Tilesmido medoNo ratings yet

- Chippings For Surface Dressings Note03Document2 pagesChippings For Surface Dressings Note03CarolNo ratings yet

- C34 PDFDocument3 pagesC34 PDFJayakumar AnanthaNo ratings yet

- 134 - As Struck Finishes PDFDocument2 pages134 - As Struck Finishes PDFJonathan KeoughNo ratings yet

- TTA Presentation On Recent Changes To BS 5385 Part 1 2018 Reduced File SizeDocument26 pagesTTA Presentation On Recent Changes To BS 5385 Part 1 2018 Reduced File SizeMohab AzizNo ratings yet

- GroutingDocument11 pagesGroutingirshad khanNo ratings yet

- SAK19-274 Surface Bonding Cement TDSDocument2 pagesSAK19-274 Surface Bonding Cement TDSKeeth DilendyNo ratings yet

- Sop FDRDocument17 pagesSop FDRashutoshpathakcivilNo ratings yet

- Sand Cement Floor Screeds 18092009Document12 pagesSand Cement Floor Screeds 18092009David PuenNo ratings yet

- is.809.1992-RUBBER FLOORING MATERIALSDocument14 pagesis.809.1992-RUBBER FLOORING MATERIALSArun CherianNo ratings yet

- Ramos, Jessabelle A. Bsce 3D: Section 09 30 33 - Stone TilingDocument4 pagesRamos, Jessabelle A. Bsce 3D: Section 09 30 33 - Stone TilingJessabelle RamosNo ratings yet

- TilingDocument33 pagesTilingAnonymous PkvM83sNo ratings yet

- IS 14458 - 4 Banded Dry Stone WallsDocument9 pagesIS 14458 - 4 Banded Dry Stone WallsAnju KarkiNo ratings yet

- Is 14458Document9 pagesIs 14458thirumalaichettiar0% (1)

- IS 14458 - 5 Cement Stone WallDocument9 pagesIS 14458 - 5 Cement Stone WallAnju Karki100% (2)

- Decoding Multi-Purpose Waterproofing, Crack Isolation, Sound Reduction and Uncoupling MembranesDocument6 pagesDecoding Multi-Purpose Waterproofing, Crack Isolation, Sound Reduction and Uncoupling MembranesibrahimNo ratings yet

- Resurfacing of ConcreteDocument8 pagesResurfacing of ConcreteMuhammad Shakil JanNo ratings yet

- Tek 09-04aDocument9 pagesTek 09-04aRaquelNo ratings yet

- Base Concrete Placement: 1. SubgradeDocument1 pageBase Concrete Placement: 1. Subgradeapuhapuh_153349No ratings yet

- Aac Block Adhesive: Product DescriptionDocument2 pagesAac Block Adhesive: Product DescriptionmaznahNo ratings yet

- Technical Note TN 01 Cementitious Mortars and Grouts PDFDocument4 pagesTechnical Note TN 01 Cementitious Mortars and Grouts PDFebetaniaNo ratings yet

- Laying-Floor-Screeds 111Document40 pagesLaying-Floor-Screeds 111LjubenNo ratings yet

- Adhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method ForDocument4 pagesAdhesion-in-Peel of Elastomeric Joint Sealants: Standard Test Method Forמשה אביסדריסNo ratings yet

- Is 4990Document17 pagesIs 4990AnuradhaPatraNo ratings yet

- Mortar Props of Render MortarDocument18 pagesMortar Props of Render MortarRachel IngramNo ratings yet

- 2690 1 2023 PDFDocument12 pages2690 1 2023 PDFDevesh Kumar PandeyNo ratings yet

- Installation of Heated Screeds and Substrates For Laying Floors - Technical NotebookDocument44 pagesInstallation of Heated Screeds and Substrates For Laying Floors - Technical NotebookMajd M. KhalilNo ratings yet

- Is 12727 PDFDocument14 pagesIs 12727 PDFJanardhana ReddiNo ratings yet

- Astm C383 971Document1 pageAstm C383 971jamshid khanNo ratings yet

- MASTERFLEX 700i v4Document2 pagesMASTERFLEX 700i v4RUDRA KARMAKARNo ratings yet

- Coreflor: (Non-Metallic Monolithic Surface Hardening Compound)Document2 pagesCoreflor: (Non-Metallic Monolithic Surface Hardening Compound)Ye YintNo ratings yet

- Bond Strength of Ceramic Tile To Portland Cement Paste: Standard Test Method ForDocument5 pagesBond Strength of Ceramic Tile To Portland Cement Paste: Standard Test Method Forjun floresNo ratings yet

- Astm C 34Document3 pagesAstm C 34Professor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- 7113 PDFDocument9 pages7113 PDFgopeeNo ratings yet

- Successful Plastering PDFDocument8 pagesSuccessful Plastering PDFDean KoortzenNo ratings yet

- Prefabricated Asphalt Reservoir, Pond, Canal, and Ditch Liner (Exposed Type)Document3 pagesPrefabricated Asphalt Reservoir, Pond, Canal, and Ditch Liner (Exposed Type)Mohammad YaseenNo ratings yet

- Colgrout PDFDocument14 pagesColgrout PDFadhirajn4073No ratings yet

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- SP 46 EngineeringDrawing Practice For Schools and Colleges PDFDocument213 pagesSP 46 EngineeringDrawing Practice For Schools and Colleges PDFlovehackinggalsNo ratings yet

- IS 1200 Part 9Document11 pagesIS 1200 Part 9lovehackinggalsNo ratings yet

- Duties Responsibilities of Various Officers andDocument18 pagesDuties Responsibilities of Various Officers andSita RamNo ratings yet

- Negotations Post TenderDocument3 pagesNegotations Post TenderlovehackinggalsNo ratings yet

- Is 17372 2020Document12 pagesIs 17372 2020lovehackinggals100% (1)

- Is 12778Document17 pagesIs 12778lovehackinggalsNo ratings yet

- 1823-From PortalDocument4 pages1823-From PortallovehackinggalsNo ratings yet

- Is 808Document60 pagesIs 808lovehackinggalsNo ratings yet

- Grant of Completion Certificate Under The Lease & Execution of Perpetual LeaseDocument1 pageGrant of Completion Certificate Under The Lease & Execution of Perpetual LeaselovehackinggalsNo ratings yet

- Chapter-18 Breaches (Change of Purpose or Unauthorised Construction)Document3 pagesChapter-18 Breaches (Change of Purpose or Unauthorised Construction)lovehackinggalsNo ratings yet

- Inspection of PropertiesDocument2 pagesInspection of PropertieslovehackinggalsNo ratings yet

- Scrutinisation of Building PlanDocument1 pageScrutinisation of Building PlanlovehackinggalsNo ratings yet

- Cost of Preparation of Various DocumentsDocument3 pagesCost of Preparation of Various DocumentslovehackinggalsNo ratings yet

- Additional Construction in Open Areas in Connaught PlaceDocument1 pageAdditional Construction in Open Areas in Connaught PlacelovehackinggalsNo ratings yet

- Additional ConstructionDocument3 pagesAdditional ConstructionlovehackinggalsNo ratings yet

- Allotment of LandDocument7 pagesAllotment of LandlovehackinggalsNo ratings yet

- Sanction of Plans Under The LeaseDocument2 pagesSanction of Plans Under The LeaselovehackinggalsNo ratings yet

- Demarcation & Handing Over Possession of LandDocument1 pageDemarcation & Handing Over Possession of LandlovehackinggalsNo ratings yet

- S - 3001 Foundatiom and Details (Main Gate) - ModelDocument1 pageS - 3001 Foundatiom and Details (Main Gate) - ModellovehackinggalsNo ratings yet

- Sub-Division of PlotsDocument4 pagesSub-Division of PlotslovehackinggalsNo ratings yet

- Permanent Chnage of PurposeDocument1 pagePermanent Chnage of PurposelovehackinggalsNo ratings yet

- Delegation of PowersDocument4 pagesDelegation of PowerslovehackinggalsNo ratings yet

- Acquisition of LandDocument1 pageAcquisition of LandlovehackinggalsNo ratings yet

- Digitally Signed: RAKESH KUMAR RAI Sun Mar 01 10:55:07 IST 2020 Secretary, BEE New DelhiDocument1 pageDigitally Signed: RAKESH KUMAR RAI Sun Mar 01 10:55:07 IST 2020 Secretary, BEE New DelhilovehackinggalsNo ratings yet

- Statistics Without Tears by Stan BrownDocument294 pagesStatistics Without Tears by Stan BrownlovehackinggalsNo ratings yet

- The Energy Conservation Act, 2001 No 52 2001: Ministry of Law, Justice and Company AffairsDocument22 pagesThe Energy Conservation Act, 2001 No 52 2001: Ministry of Law, Justice and Company Affairssumitsonu4uNo ratings yet

- CEHv10 Module 01 Introduction To Ethical HackingDocument157 pagesCEHv10 Module 01 Introduction To Ethical Hackinglovehackinggals100% (1)

- Types of LeasesDocument2 pagesTypes of LeaseslovehackinggalsNo ratings yet

- Printed The Strange Case of DR Jekyll & MR HydeDocument96 pagesPrinted The Strange Case of DR Jekyll & MR HydelovehackinggalsNo ratings yet

- Prospectus: (A Statutory Body Under Ministry of Power, Government of India)Document22 pagesProspectus: (A Statutory Body Under Ministry of Power, Government of India)skredhu56789No ratings yet

- Welding of Inconel 718: Byj. GordineDocument7 pagesWelding of Inconel 718: Byj. GordineVigneswaranNo ratings yet

- Energy BalanceDocument29 pagesEnergy BalanceAlinta AyuningtyasNo ratings yet

- Data Bank Reid SherwoodDocument88 pagesData Bank Reid SherwoodAlejandro Sandoval GuillénNo ratings yet

- Cre 1 Solution PDFDocument21 pagesCre 1 Solution PDFSaints Burner Christopher100% (1)

- HLB Calculator FacebookDocument5 pagesHLB Calculator FacebookcatalinNo ratings yet

- Seppic Hand HygieneDocument37 pagesSeppic Hand HygieneVinay Bahadur KulshreshthaNo ratings yet

- DisulfiramDocument1 pageDisulfiramIvanne Hisoler100% (1)

- Sop Subarashi - Us-1 (MSDS)Document5 pagesSop Subarashi - Us-1 (MSDS)Daniel ChristianNo ratings yet

- 303 - Gastrointestinal Physiology) Gastric Secretion - The Cephalic - Gastric PhaseDocument5 pages303 - Gastrointestinal Physiology) Gastric Secretion - The Cephalic - Gastric Phasekedas70No ratings yet

- Asme Sec Viii D2 Ma App 5 PDFDocument15 pagesAsme Sec Viii D2 Ma App 5 PDFMarín HernándezNo ratings yet

- Shpa Standards of Practice For The Safe Handling of Cytotoxic DR 2005Document9 pagesShpa Standards of Practice For The Safe Handling of Cytotoxic DR 2005Lan FdzNo ratings yet

- Walter B. Cannon and " Voodoo' Death": A Perspective From 60 Years OnDocument3 pagesWalter B. Cannon and " Voodoo' Death": A Perspective From 60 Years OnPatricksia Utopian STsetia Ciel'erNo ratings yet

- Sumitomo Chemical Alumina (ENG)Document16 pagesSumitomo Chemical Alumina (ENG)Lawrence LauNo ratings yet

- Individual Paper Proposal For Biochar Literature ReviewDocument2 pagesIndividual Paper Proposal For Biochar Literature ReviewraiiinydaysNo ratings yet

- Protease ELU Activity AssayDocument2 pagesProtease ELU Activity AssayYunita KurniatiNo ratings yet

- 2 Presentation India Base-Seal Final For 11-04-2016 KLDocument56 pages2 Presentation India Base-Seal Final For 11-04-2016 KLSivaneswaran SabaratnamNo ratings yet

- Experiment No 1 (Tray Dryer)Document8 pagesExperiment No 1 (Tray Dryer)mjunaidNo ratings yet

- Lecithins, Acetylated Product Safety SummaryDocument3 pagesLecithins, Acetylated Product Safety SummaryHabtamu Asmare100% (1)

- BS 5896 2010Document33 pagesBS 5896 2010shashiresh50% (2)

- Visual Inspection and Other NDE Methods and SymbolsDocument92 pagesVisual Inspection and Other NDE Methods and Symbolstuvu100% (2)

- Environmental Pollution and Need To Preserve EnvironmentDocument3 pagesEnvironmental Pollution and Need To Preserve EnvironmentLakshmi Devar100% (1)

- Air Striping & AerationDocument31 pagesAir Striping & Aerationnasir mehranbod100% (1)

- Symphony Soil: of TheDocument32 pagesSymphony Soil: of Theramoo.csaNo ratings yet

- Introduction To Cotton FibreDocument8 pagesIntroduction To Cotton FibreDebasish GhoshNo ratings yet

- Industrial Seals CatalogDocument40 pagesIndustrial Seals CatalogAnonymous C05BLcNo ratings yet

- 1046a User's Guide 01046-90004Document180 pages1046a User's Guide 01046-90004omarou18No ratings yet

- Catalog FittingsDocument18 pagesCatalog FittingsBe-ToolNo ratings yet

- DETAILED LESSON PLAN Earth and Life Sciences Grade 11 Week 13Document9 pagesDETAILED LESSON PLAN Earth and Life Sciences Grade 11 Week 13Austin Capal Dela Cruz100% (4)

- Characterization of Indigenous Steel Bars For Use in Hydroelectric Projects in BhutanDocument10 pagesCharacterization of Indigenous Steel Bars For Use in Hydroelectric Projects in BhutanInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Crystals 10 00909 PDFDocument12 pagesCrystals 10 00909 PDFDimas Agung SetiajiNo ratings yet