Professional Documents

Culture Documents

Hes A3032-99a Specification Standard of Hydrogen Embrittle

Hes A3032-99a Specification Standard of Hydrogen Embrittle

Uploaded by

Preetam KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hes A3032-99a Specification Standard of Hydrogen Embrittle

Hes A3032-99a Specification Standard of Hydrogen Embrittle

Uploaded by

Preetam KumarCopyright:

Available Formats

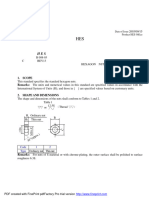

Date of Issue 99/12/24

Product HES Office

HES

HES

A 3032-99A

B REV1

SPECIFICATION STANDARD OF HYDROGEN

EMBRITTLEMENT REMOVAL TREATMENT

1. SCOPE

This standard specifies the removal treatment of hydrogen embrittlement (hereinafter referred to as

baking), resulting from electroplating and acid pickling.

2. APPLICABLE PARTS

The applicable parts for baking shall be as follows:

2.1 Parts which are electroplated after heat treatment (quenching, or quenching and tempering), and

whose true hardness (*1) after the heat treatment exceeds HRC 32 (or equivalent).

2.2 Parts which are electroplated after case hardening (*2) except for nitriding, and whose true hardness

after the heat treatment exceeds HRC 32 (or equivalent).

2.3 Parts which are electroplated after nitriding, and whose nitrided layer has an inside hardness which

exceeds HRC 32 (or equivalent).

2.4 Parts which are electroplated after cold working, and whose true hardness exceeds HRC 32 (or

equivalent).

2.5 Parts which are pickled, and whose true hardness exceeds HRC 40 (or equivalent).

2.6 Other parts which specially require baking.

Note:

(*1) True hardness refers to the hardness of the material below the plated layer. (When performed by

heat treatment in a recarburization atmosphere, some parts, which are specified to be hardened and

tempered in ordinary procedure, may produce a surface hardening phenomena. If 30 for HRC and 340

for HMV obtained as the measured values, they mean HMV 340 ( HRC 34) as the true hardness,

requiring hydrogen embrittlement removal treatment.)

(*2) Refers to carburizing, induction hardening, and flame hardening.

3. BAKING

3.1 The Temperature and Duration of Baking

Temperature: 185 + 10 oC

Duration: 4 hours min.

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

Remarks:

1. Baking conditions other than that given above shall be determined after discussion with the

department responsible.

2. The temperature of baking means the temperature of the baked material.

3.2 Baking procedure

Baking shall be performed immediately after acid pickling and plating. A chemical treatment, such as

zinc chromating, shall be performed after baking.

4. DRAWING INDICATIONS

4.1 Refer to HES A 3010 for the method of indicating baking on the plated parts.

Example: SURFACE TREATMENT: MFZn2-H B

Indication code for baking

4.2 The baking indication for acid pickling shall conform to the processes of each factory, as a rule.

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

Revision Record

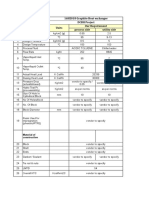

Year Rec Issue NewsNo Prep Conf Appvl Remarks

71 EST 71/09/20 71040 Shimazaki Shimane Sato

74 REV1 74/03/12 74004 Katagiri Shimane Endo

74 Rewrite 87/03/02 ----- Oooka Tomino Katagiri Data transfer to W/P

74 Rewrite 95/02/07 ----- Tanaka Shimada Yamada Data transfer to PC

74 Rewrite 98/06/30 ----- Tashiro Shimada Honda Data transfer to Notes DB

99 Correction 99/08/05 99011 Kobayashi Naya Tomino Correction of errors

99A Correction 99/12/24 99017 Tomonaga Naya Tomino Correction of errors

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

You might also like

- John Deere Standard: JDV 2 Heat Treatment Numbers and DescriptionsDocument13 pagesJohn Deere Standard: JDV 2 Heat Treatment Numbers and DescriptionsFelipe Fernandes100% (1)

- Basic Concepts of Iron and Steel MakingDocument644 pagesBasic Concepts of Iron and Steel Makingclaudia100% (7)

- CNH Spec MAT4030 - Gas CarburizationDocument12 pagesCNH Spec MAT4030 - Gas CarburizationJoe Scopelite100% (1)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- K Refrigeration Oils RenisoDocument2 pagesK Refrigeration Oils Renisobazoka fransiskusNo ratings yet

- Fire Heat PDFDocument231 pagesFire Heat PDFasif rahimNo ratings yet

- Economics and Benefits of High Temperature Sintering of High Performance Alloys PDFDocument12 pagesEconomics and Benefits of High Temperature Sintering of High Performance Alloys PDFSAMIT JAINNo ratings yet

- Berutox FB 22: Technical Product InformationDocument1 pageBerutox FB 22: Technical Product InformationMauricio SánchezNo ratings yet

- Product Information: Multi-Silicone GreaseDocument3 pagesProduct Information: Multi-Silicone Greasekamalkraj4002No ratings yet

- Rubric HM 32 en FR MotulDocument2 pagesRubric HM 32 en FR MotulQuy NguyenNo ratings yet

- Shell Heat Transfer Oil S4 X: Performance, Features & BenefitsDocument2 pagesShell Heat Transfer Oil S4 X: Performance, Features & Benefitsrodrigonicolasdiaz1No ratings yet

- 3M™ Scotch-Weld™ 3524 B A FSTDocument3 pages3M™ Scotch-Weld™ 3524 B A FSTАндрей МошкинNo ratings yet

- Hydraulic Oil HM 46: Product Data SheetDocument1 pageHydraulic Oil HM 46: Product Data SheetDavidNo ratings yet

- She Tds TherbDocument2 pagesShe Tds TherbNhu Kien PhamNo ratings yet

- PDS - Addinol Gear Oil CLP 10, 68, 100, 150, 220, 320, 460, 680Document2 pagesPDS - Addinol Gear Oil CLP 10, 68, 100, 150, 220, 320, 460, 680LeoNo ratings yet

- Shell Thermia B PDFDocument2 pagesShell Thermia B PDFEduardo Dreifus100% (1)

- Study and Analysis of Cryogenic Machining of Hard Components and Investigation of Tool WearDocument7 pagesStudy and Analysis of Cryogenic Machining of Hard Components and Investigation of Tool WearPrashant JondhaleNo ratings yet

- Sikaflex Tank N PDS PDFDocument5 pagesSikaflex Tank N PDS PDFnajmuddinNo ratings yet

- CAF 1, CAF 1 Extra Fluid: Industrial and Professional RangeDocument4 pagesCAF 1, CAF 1 Extra Fluid: Industrial and Professional Rangemuhammad_andinovaNo ratings yet

- TDS Loctite Nordbak Wearing - CompoundDocument3 pagesTDS Loctite Nordbak Wearing - CompoundSadamNo ratings yet

- Castrol Hyspin AWS HX RangeDocument2 pagesCastrol Hyspin AWS HX RangeGunco TirNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument11 pagesNational Oil Corporation: Rev Date Description Checked Approvedrty2No ratings yet

- Berutox FE 18 EP: Technical Product InformationDocument1 pageBerutox FE 18 EP: Technical Product InformationMauricio SánchezNo ratings yet

- Technical Data Sheet For Bechem GreaseDocument1 pageTechnical Data Sheet For Bechem GreaseSandeepNo ratings yet

- Ficha Oleo Termico - UnlockedDocument2 pagesFicha Oleo Termico - UnlockedWisard MagalhãesNo ratings yet

- Shell Heat Transfer Oil S2Document2 pagesShell Heat Transfer Oil S2Mudabbir Shan Ahmed100% (2)

- Reniso SP Series - Ficha TecnicaDocument5 pagesReniso SP Series - Ficha TecnicaJavier ChangNo ratings yet

- Cuttinf FluidsDocument29 pagesCuttinf Fluidsshrikanth100% (1)

- Pi Oks 476 113678 enDocument2 pagesPi Oks 476 113678 enSophia RoseNo ratings yet

- Fire HeatDocument231 pagesFire HeatprabhuarunkumarNo ratings yet

- LSR LC-50-2004Document3 pagesLSR LC-50-2004tarot.insights4uNo ratings yet

- Merkel - Guides-Guide Strip FBDocument3 pagesMerkel - Guides-Guide Strip FBÖzgür GürkanNo ratings yet

- Shell Heat Transfer Oil S2 TDSDocument2 pagesShell Heat Transfer Oil S2 TDSHemanthNo ratings yet

- FAG Rolling Bearing Grease Arcanol LOAD400: Characteristics Unit Test Method ValueDocument3 pagesFAG Rolling Bearing Grease Arcanol LOAD400: Characteristics Unit Test Method ValueUdit JainNo ratings yet

- Northcutt, Inc HC Refrigerant Products Training ManualDocument50 pagesNorthcutt, Inc HC Refrigerant Products Training ManualLv RamanNo ratings yet

- Gpcdoc Sa Tds ThermiaDocument2 pagesGpcdoc Sa Tds ThermiaAbdelrahman MagdyNo ratings yet

- NOR 1453363 000 00 W-HTX EnglischDocument46 pagesNOR 1453363 000 00 W-HTX Englischgültekin gökNo ratings yet

- Airtop HTDocument1 pageAirtop HTtribolasNo ratings yet

- Aircol HC 7, HC 10Document2 pagesAircol HC 7, HC 10Vladislav TrempoletsNo ratings yet

- MOLYKOTE 165 LT Gearwheel Grease 71-0179D-01Document2 pagesMOLYKOTE 165 LT Gearwheel Grease 71-0179D-01bravindranath5768No ratings yet

- Aceite MR520Document4 pagesAceite MR520capc.asesoriasNo ratings yet

- Eni OSO 32: Eni OSO 32 Is A High Performance Antiwear Hydraulic Oil, Specifically Designed To Meet The MostDocument2 pagesEni OSO 32: Eni OSO 32 Is A High Performance Antiwear Hydraulic Oil, Specifically Designed To Meet The MostCelineKevinNo ratings yet

- Flexible Adhesive For Performance Assembly: 1.1. ProcessingDocument4 pagesFlexible Adhesive For Performance Assembly: 1.1. ProcessingjpolancosNo ratings yet

- en9.docx-F2-R Lubricats For Refrigerant Circuit PartsDocument3 pagesen9.docx-F2-R Lubricats For Refrigerant Circuit PartsRafa Lopez PuigdollersNo ratings yet

- Procedimiento de Reparación TurbinaDocument4 pagesProcedimiento de Reparación Turbinajaime huertasNo ratings yet

- 16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideDocument2 pages16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideBhaumik BhuvaNo ratings yet

- Globaltherm M Product Information SheetDocument4 pagesGlobaltherm M Product Information SheetMalek MahmoudNo ratings yet

- Fkm80 Karta Materiałowa Cog Vi500Document2 pagesFkm80 Karta Materiałowa Cog Vi500DacetIronForceNo ratings yet

- Project Presentation - NITIN - AKASH - UEMSHDocument24 pagesProject Presentation - NITIN - AKASH - UEMSHUmesh MouryaNo ratings yet

- Foodmax Grease CAS S 2 LS - TDS - 263701301 - ENDocument2 pagesFoodmax Grease CAS S 2 LS - TDS - 263701301 - ENDeath Heart100% (1)

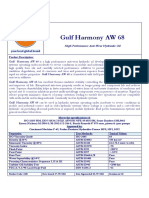

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 DataHitesh MahajanNo ratings yet

- 3508 Gulf Harmony AW 68 DataDocument1 page3508 Gulf Harmony AW 68 Datakatty_89No ratings yet

- FAG Rolling Bearing Grease Arcanol MULTITOP: Characteristics Unit Test Method ValueDocument3 pagesFAG Rolling Bearing Grease Arcanol MULTITOP: Characteristics Unit Test Method ValuemmrNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- DO200026Document19 pagesDO200026utkuNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Reactive Distillation: Status and Future DirectionsFrom EverandReactive Distillation: Status and Future DirectionsKai SundmacherRating: 1 out of 5 stars1/5 (1)

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingFrom EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingNo ratings yet

- Hes D6501-03 General Test Methods For CoatingDocument28 pagesHes D6501-03 General Test Methods For CoatingPreetam KumarNo ratings yet

- Hes B008-03 Hexagon NutsDocument5 pagesHes B008-03 Hexagon NutsPreetam KumarNo ratings yet

- Hes D6001-99 General Test Methods For PlatingDocument39 pagesHes D6001-99 General Test Methods For PlatingPreetam KumarNo ratings yet

- Hes D2008-03 Zink-Alminium Composite CoatingDocument8 pagesHes D2008-03 Zink-Alminium Composite CoatingPreetam KumarNo ratings yet

- Collar Pivot 38 MMDocument1 pageCollar Pivot 38 MMPreetam KumarNo ratings yet

- Axle Push Lever - 21CDocument1 pageAxle Push Lever - 21CPreetam KumarNo ratings yet

- Hes A3003-03 Chamfer of Thread EndDocument5 pagesHes A3003-03 Chamfer of Thread EndPreetam Kumar100% (1)

- Collar Muffler MountDocument1 pageCollar Muffler MountPreetam KumarNo ratings yet

- Axle Push Lever - B - 97Document1 pageAxle Push Lever - B - 97Preetam KumarNo ratings yet

- Axle 4LSDocument1 pageAxle 4LSPreetam KumarNo ratings yet

- Axle Push Lever - BK - 44Document1 pageAxle Push Lever - BK - 44Preetam KumarNo ratings yet

- Axle Push Lever - BK-7Document1 pageAxle Push Lever - BK-7Preetam KumarNo ratings yet

- Heat Treatment For Knife SteelsDocument3 pagesHeat Treatment For Knife SteelsvagelisNo ratings yet

- Chapter 4 Heat Treatment of SteelDocument29 pagesChapter 4 Heat Treatment of SteelDa Champ Cena100% (2)

- KTMDocument2 pagesKTMKevin TarlaNo ratings yet

- Summary of Changes (Section II-d-met.)Document16 pagesSummary of Changes (Section II-d-met.)Wagner Renato AraújoNo ratings yet

- HT Index PDFDocument7 pagesHT Index PDFxuangNo ratings yet

- Vale International Pellet Plant PDFDocument2 pagesVale International Pellet Plant PDFSrinivasanNo ratings yet

- Bhushan Steel - Plant and FacilityDocument6 pagesBhushan Steel - Plant and Facilityanurag3069No ratings yet

- S.Pathak & N.K Gupta: Heat TreatmentDocument2 pagesS.Pathak & N.K Gupta: Heat TreatmentdgpkidNo ratings yet

- 1.2714 enDocument2 pages1.2714 enreza razaviNo ratings yet

- 2811 Additional Parts 2Document2 pages2811 Additional Parts 2Danı PrasNo ratings yet

- Pig Iron and Its ManufacturingDocument1 pagePig Iron and Its ManufacturingAli AimranNo ratings yet

- Af15 2Document18 pagesAf15 2Agniva DuttaNo ratings yet

- Nptel: Steel Making - Web CourseDocument2 pagesNptel: Steel Making - Web CourseSahil JhambNo ratings yet

- Heat Treat Definitions PDFDocument3 pagesHeat Treat Definitions PDFmastorfaizalNo ratings yet

- TSH5200G 6 P 1Document11 pagesTSH5200G 6 P 1Reginaldo Santos100% (1)

- MMS Unit IVDocument4 pagesMMS Unit IVAdula RajasekharNo ratings yet

- Agglomeration of Iron OreDocument13 pagesAgglomeration of Iron OreDevansh MankarNo ratings yet

- Traksi: Pengaruh Post Weld Heat Treatment (PWHT) Terhadap Struktur Mikro Dan Kekerasan Sambungan Las Stainless SteelDocument9 pagesTraksi: Pengaruh Post Weld Heat Treatment (PWHT) Terhadap Struktur Mikro Dan Kekerasan Sambungan Las Stainless SteelHendra AwanNo ratings yet

- Tabel Aisi Astm SelectedDocument5 pagesTabel Aisi Astm SelectedJuan CogolludoNo ratings yet

- Blast FurnaceDocument3 pagesBlast FurnaceNarendra Singh ShekhawatNo ratings yet

- Ferrous Metal - Iron and SteelDocument56 pagesFerrous Metal - Iron and Steelsubhash sureshNo ratings yet

- KMPD Process ChartDocument4 pagesKMPD Process Chartfiki_pramudyaNo ratings yet

- Print Key Characteristics Project 3235Document49 pagesPrint Key Characteristics Project 3235Gokul Prasad ChettiNo ratings yet

- SC37 SC42 SC46 SC49 Scc3 Cast Steel Gear: G G G G GDocument3 pagesSC37 SC42 SC46 SC49 Scc3 Cast Steel Gear: G G G G GJayce GreenfelderNo ratings yet

- MSS SP 75 2019 High Strength, Wrought, Butt Welding FittingsDocument42 pagesMSS SP 75 2019 High Strength, Wrought, Butt Welding FittingsJed Kevin MendozaNo ratings yet

- CQI-9 Special Process: Heat Treat System AssessmentDocument1 pageCQI-9 Special Process: Heat Treat System AssessmentalbertNo ratings yet

- Case Hardening Heat TreatmentDocument15 pagesCase Hardening Heat TreatmentHazrat BelalNo ratings yet

- High Manganese Carbon Steels (1500 Series) / 231Document4 pagesHigh Manganese Carbon Steels (1500 Series) / 231Gil CabreraNo ratings yet

- Flowchart Inco ProcessingDocument3 pagesFlowchart Inco ProcessingWilly ApryantoNo ratings yet