Professional Documents

Culture Documents

2 - Inkjet-Printed Flexible Temperature Sensor Silver Nanoparticles Ink

Uploaded by

kamru55l.mzrllalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 - Inkjet-Printed Flexible Temperature Sensor Silver Nanoparticles Ink

Uploaded by

kamru55l.mzrllalCopyright:

Available Formats

Proceedings

Inkjet-Printed Flexible Temperature Sensor Based on

Silver Nanoparticles Ink †

Qiao Jun Liew 1,2,*, Aiman Sajidah Abd Aziz 1, Hing Wah Lee 1,*, Mai Woon Lee 1,

Huzein Fahmi Hawari 2 and Mohd Haris Md Khir 2

1 Flexible Electronics Laboratory, MIMOS Berhad, Kuala Lumpur 57000, Malaysia;

aiman.aziz@mimos.my (A.S.A.A.); mw.lee@mimos.my (M.W.L.)

2 Department of Electrical and Electronic Engineering, Universiti Teknologi PETRONAS,

Seri Iskandar 32610, Perak, Malaysia; huzeinfahmi.hawari@utp.edu.my (H.F.H.);

harisk@utp.edu.my (M.H.M.K.)

* Correspondence: qiao_17004499@utp.edu.my (Q.J.L.); hingwah.lee@mimos.my (H.W.L.)

† Presented at the 7th International Electronic Conference on Sensors and Applications, 15–30 November

2020; Available online: https://ecsa-7.sciforum.net/.

Published: 14 November 2020

Abstract: In this research, a flexible inkjet-printed temperature sensor with in-house silver

nanoparticles ink is presented and compared with the sensor printed with commercial silver

nanoparticles ink. These sensors have an average width of 0.5 ± 0.04 mm in the latter and 0.5 ± 0.03

mm in the former. These serpentine-structure sensors were printed on polyethylene terephthalate

(PET) substrate by using a Fujifilm Dimatix 2850 printer. The corresponding results indicating

resistance have been recorded in the range of 30–100 °C to evaluate the sensor performance. The

result of the studies showed that there was a linear relationship between the resistance and

temperature for both ink types. The printed sensors developed using the in-house ink presented

higher sensitivity, 0.1086 Ω/°C, compared to the commercial ink, which was 0.0543 Ω/°C. Therefore,

the flexible inkjet-printed temperature sensor with the in-house silver nanoparticles ink is

recommended for the large-scale productions and implementations.

Keywords: inkjet-printed; flexible substrate; temperature sensor; silver nanoparticles; printed electronics

1. Introduction

The emerging of IoT has radically impacted the advancement of printed electronics and

fabrication technologies since the printing techniques have been industrialized. Today, paper-based

electronics in the fields of flexible devices and wearables has gained great interest for utilization in a

wide area of electronic systems because of its low costs in setup and methodology, as well as its eco-

friendly fabrication technologies. Therefore, its development has become essential in order to co-exist

with conventional silicon-based manufacturing systems to be deployed in IoT devices.

Among of the IoT technologies, the temperature sensor is one of the most widely employed in

many fields, such as wearable sensors and logistics monitoring systems [1,2]. Most of the publications

reported on temperature sensors as the resistive temperature detectors [3]. In order to fabricate a

high-performance temperature sensor, the type and quality of the ink is one of the challenges of the

printed electronics industry. For instance, the research in [4] and [5] have claimed their devices’

performances are excellent when using gold (Au) and copper (Cu) inks, respectively. However, the

temperature of the paper substrate is not able to withstand both the required curing temperatures of

the Au and Cu inks [6]. Compared to the Au and Cu inks, the silver nanoparticles ink (AgNPs) has

been highly recommended due to the fact that AgNPs has low reactivity to air [7], minimal resistance

Eng. Proc. 2020, 2, 3; doi:10.3390/ecsa-7-08216 www.mdpi.com/journal/engproc

Eng. Proc. 2020, 2, 3 2 of 6

to corrosion [8], a lower melting temperature [9] and lower costs [10]. Because of these, the

commercial silver ink is dominating the market. However, the cost has become one of the greatest

concerns of the industrial interest, as the cost of large-scale productions is high.

In this research, the low-cost and flexible in-house inkjet-printed temperature sensor with in-

house silver nanoparticles ink is studied and compared to the sensor printed with commercial silver

nanoparticles ink. The outcome of the research has shown that the performance in temperature

sensing of the in-house sensor is comparable to the commercial sensor.

2. Materials and Methods

2.1. Temperature Sensor Design

In this paper, a meandering shape-type temperature sensor is designed with the dimensions of

6.9 mm × 13.2 mm. The width of the sensor is 0.5 mm and the gap is 0.4 mm. The padding area is 1.5

mm × 1.5 mm. Figure 1 shows the design of a temperature sensor.

Figure 1. Temperature sensor design

2.2. Flexible Substrate and Ink Preparation

The polyethylene terephthalate (PET) substrate used in this study was purchased from

Elephantech Inc. with a thickness of 107 µm ± 32 µm. The PET comes in A4 size and can be cut into

the desired size based on the application. This PET substrate was treated by the manufacturer and

printed with the design directly.

In this study, there were two types of silver nanoparticles ink used to print the temperature

sensor. The first one was the commercial silver nanoparticles ink purchased from Novacentrix (JS-

B25HV). It was designed to print devices/circuits on coated substrates, including PET. Besides that,

this ink was designed for the Dimatix Fujifilm printer and the printing waveform was provided.

Another type of silver nanoparticle ink used in this study was developed by our researcher. The

idea of developing the in-house silver nanoparticles ink (in-house AgNPs) is to produce a low-cost

silver nanoparticles ink and avoid the post-printing process (thermal cure). Table 1 shows the

physical properties of in-house silver nanoparticles ink.

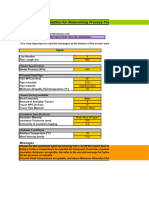

Table 1. Physical properties for JS-B25HV and in-house AgNPs ink.

Properties JS-B25HV In-House AgNPs Ink

Silver content (wt. %) 25 10

Viscosity (cP) 8–10 6.5

Surface tension(dyne/cm) 30–32 57–66

Particle size (nm) 60–80 30–60

2.3. Inkjet Printing

The temperature sensor was fabricated by the inkjet printing technique using a Fujifilm Dimatix

printer-DMP 2850 (Figure 2). The DMP printer offers drop-on-demand (DOD) piezoelectric inkjet

technology, which allows one to deposit fluid materials on a substrate. It allows users to modify the

printer’s parameters in order to obtain the highest printing quality of products based on their

fluids/inks. The silver nanoparticle ink is required to be sonicated around 15 min to avoid

Eng. Proc. 2020, 2, 3 3 of 6

agglomeration between the particles. The fluid (~3 mL) was then put into the cartridge with a syringe,

a needle and a 0.2 um filter. The filter was used to filter out the particles bigger than 0.2 um to prevent

the nozzle head from clogging. It is recommended to keep the cartridge in the idle state for at least

30 min after filling.

Figure 2. DMP-2850 inkjet printer.

The meandering shape-type temperature sensor is designed and saved as the pattern file (.ptn)

using the Pattern Editor (Bitmap images) on the DMP program. The number layers, drop spacing,

image resolution and the leader bar were set properly according to the design specifications. The

leader bar is a vertical line printed to the left of the pattern, for the purpose of pre-jet nozzles and

keep the fluid drop velocity uniform to improve pattern quality.

In order to find the optimum deposition recipe, the printer parameters need to be adjusted based

on the experimental outcome by trial-and-error. The printer parameters that were being investigated

included substrate thickness, tickle control, plate/stage temperature, cartridge temperature, jetting

voltage, meniscus setpoint, number of jets to use, and cartridge print height.

Table 2 shows the optimal printing parameters that were used for commercial ink (JS-B25HV),

while Table 3 shows the optimal printing parameters used for the in-house ink.

Table 2. Printing parameter for JS-B25HV.

Printer Parameter Value

Substrate Thickness (um) 200

Tickle Control (kHz) 5 kHz

Plate Temperature (°C) 40

Cartridge Temperature (°C) 30

Jetting Voltage (v) 22

Meniscus Setpoint (inches H2O) 3.5

Cartridge Print Height (mm) 0.5

Number of jets to use 1

Table 3. Printing parameter for in-house ink.

Printer Parameter Value

Substrate Thickness (um) 200

Tickle Control (kHz) 5 kHz

Plate Temperature (°C) 40

Cartridge Temperature (°C) 30

Jetting Voltage (v) 15

Meniscus Setpoint (inches H2O) 4

Cartridge Print Height(mm) 0.5

Number of jets to use 1

Eng. Proc. 2020, 2, 3 4 of 6

2.4. Sensor Characterization

The geometrical characterization was performed using an optical microscope. The microscope

was used to make sure the printed sensors matched the design and to monitor printed quality

visually.

The temperature sensor was characterized by measuring the resistance between 30 °C and 100

°C with increments of 10 °C. The resistance values were measured using the FLUKE digital multi-

meter.

3. Results and Discussion

3.1. Geometrical Characterization

Before the electrical characterization, the printed sensors were observed using an Olympus

microscope to investigate the surface morphology and uniformity. Figures 3 and 4 show the

microscope images for both ink types. Besides that, the dimension of the printed sensors is measured

and compared to the design layout. Table 4 show the comparison between the design layout and the

actual print. The inkjet printing methods present several adverse effects that cause inaccuracy in the

printed structures. Based on the microscope results, the percentage errors for all the printed sensors

are less than 10%, which is considered an acceptable result.

Figure 3. Microscope image for JS-B25HV.

Figure 4. Microscope image for in-house ink.

Table 4. Comparison of the sensor dimension between design layout and actual printed sensor.

Parameter Design JS-B25HV In-house Ink

Finger width (mm) 0.5 0.5 ± 0.04 0.5 ± 0.03

Gap between fingers (mm) 0.4 0.4 ± 0.04 0.4 ± 0.03

3.2. Electrical Characterazation

The performances of the temperature sensors were evaluated in the temperature range of 30 °C

to 100 °C, with increments of 10 °C each time step. Figure 5 shows the relationship between resistance

and temperature for both ink types. A total of six experiments were carried out. All of these showed

a linear relationship between resistance and temperature.

Eng. Proc. 2020, 2, 3 5 of 6

Figure 5. Relationship between resistance and temperature for JS-B25HV (Experiement 1–3) and for

In-house ink (Experiment 4–6).

The temperature coefficient of resistance (TCR) can be calculated by

𝑅 −𝑅

𝑇𝐶𝑅 = (1)

𝑅 (Δ𝑇)

where R100 and R30 denote the resistance value obtained at temperatures 100 °C and 30 °C,

respectively, and ΔT is the change in temperature. The definition of TCR is the resistance change

factor per degree Celsius of temperature change.

Besides that, the sensitivity (S) of the temperature sensors can be calculated by

𝑅 −𝑅

𝑆= (2)

Δ𝑇

where R100 and R30 denote the resistance values obtained at temperatures 100 °C and 30 °C,

respectively, and ΔT is the change in temperature. The result in Table 5 show that the printed

temperature sensor fabricated using the in-house ink obtained a higher-sensitivity performance

compared to the commercial ink.

Table 5. Sensitivity and TCR of printed temperature sensor.

Experiment Temperature Coefficient of Resistance(c−1) Sensitivity (Ω/°C)

1 12.3626 × 10−4 0.0514

2 11.6026 × 10−4 0.0457

3 13.4704 × 10−4 0.0543

4 9.9668 × 10−4 0.1071

5 10.0343 × 10−4 0.1086

6 7.3363 × 10−4 0.0786

Eng. Proc. 2020, 2, 3 6 of 6

4. Conclusions

The flexible temperature sensors were developed with an inkjet printer (DMP2850) using two

types of ink: JS-B25HV and in-house silver nanoparticles ink. The performances of the printed sensors

were evaluated by varying the temperature from 30 °C to 100 °C. The result show that the printed

sensors have a linear relationship between resistance and temperature for both inks. The printed

sensors developed using the in-house ink gave the higher sensitivity, which was 0.1086 Ω/°C,

compared to the commercial ink. Therefore, the in-house ink is comparable to the commercial ink

and has great potential industrial applicability.

Author Contributions: conceptualization, Q.J.L., H.F.H. and H.W.L.; methodology, Q.J.L. and A.S.A.A.;

validation, Q.J.L., A.S.A.A. and M.W.L.; writing—original draft preparation, Q.J.L.; writing—review and

editing, H.W.L.; visualization, Q.J.L.; supervision, H.W.L., H.F.H. and M.H.M.K.; funding acquisition, H.W.L.

All authors have read and agreed to the published version of the manuscript.

Funding: This research was funded by ministry of Science, Technology and Innovation (MOSTI), grant number

P0110020110122.

Acknowledgments: We would like to acknowledge the financial support provided by ministry of Science,

Technology and Innovation (MOSTI) through the 11th Malaysia Plan development expenditure (DE) funding.

Conflicts of Interest: The authors declare no conflict of interest.

References

1. Barmpakos, D.; Segkos, A.; Tsamis, C.; Kaltsas, G. A Disposable Inkjet-Printed Humidity and Temperature

Sensor Fabricated on Paper. Proceedings 2018, 2, 977.

2. Ali, S.; Khan, S.; Bermak, A. Inkjet-Printed Human Body Temperature Sensor for Wearable Electronics.

IEEE Access 2019, 7, 163981–163987, doi:10.1109/access.2019.2949335.

3. Dankoco, M.D.; Tesfay, G.Y.; Benevent, E.; Bendahan, M. Temperature sensor realized by inkjet printing

process on flexible substrate. Mater. Sci. Eng. B 2016, 205, 1–5, doi:10.1016/j.mseb.2015.11.003.

4. Cui, W.; Lu, W.; Zhang, Y.; Lin, G.; Wei, T.; Jiang, L. Gold nanoparticle ink suitable for electric-conductive

pattern fabrication using in ink-jet printing technology. Colloids Surf. A Physicochem. Eng. Asp. 2010, 358,

35–41, doi:10.1016/j.colsurfa.2010.01.023.

5. Lim, S.; Joyce, M.; Fleming, P.D.; Aijazi, A.T.; Atashbar, M. Inkjet Printing and Sintering of Nano-Copper

Ink. J. Imaging Sci. Technol. 2013, 57, 1–7, doi:10.2352/j.imagingsci.technol.2013.57.5.050506.

6. Saha, T.K.; Knaus, T.N.; Khosla, A. Investigation of Printing Properties on Paper Substrate. J. Electrochem.

Soc. 2018, 165, B3163.

7. Öhlund, T.; Schuppert, A.; Andres, B.; Forsberg, S.; Andersson, H.; Schmidt, W.; Nilsson, H.-E.; Zhang, R.;

Olin, H. Assisted sintering of silver nanoparticle inkjet ink on paper with active coatings. RSC Adv. 2015, 5,

64841–64849, doi:10.1039/C5RA06626C.

8. Wignes, F.L.; Glascoe, C.; Makar, G.; Karacolak, T.; Sekhar, P. A paper based 2-element antenna for WLAN

MIMO applications fabricated using inkjet technology. Microw. Opt. Technol. Lett. 2017, 59, 2785–2790,

doi:10.1002/mop.30822.

9. Hassan, A.; Ali, S.; Hassan, G.; Bae, J.; Lee, C.H. Inkjet-printed antenna on thin PET substrate for dual band

Wi-Fi communications. Microsyst. Technol. 2016, 23, 3701–3709, doi:10.1007/s00542-016-3113-y.

10. Huang, Q.; Shen, W.; Fang, X.; Chen, G.; Guo, J.; Xu, W.; Tan, R.; Song, W. Highly flexible and transparent

film heaters based on polyimide films embedded with silver nanowires. RSC Adv. 2015, 5, 45836–45842,

doi:10.1039/c5ra06529a.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional

affiliations.

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access

article distributed under the terms and conditions of the Creative Commons Attribution

(CC BY) license (http://creativecommons.org/licenses/by/4.0/).

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Report On Sheet Metal FabricationDocument30 pagesReport On Sheet Metal FabricationM.A.K. S. Pathan97% (34)

- William Ury Power of A Positive No Bantam - 2007Document227 pagesWilliam Ury Power of A Positive No Bantam - 2007Tam Jeopardy100% (1)

- Powerplant QuestionsDocument19 pagesPowerplant QuestionsAshok KumarNo ratings yet

- Printed Electronics TechnologiesDocument73 pagesPrinted Electronics TechnologiesDivyang Patel100% (1)

- ResumeDocument3 pagesResumeAstig Kuging63% (8)

- Finding Targets PDFDocument9 pagesFinding Targets PDFSteve TangNo ratings yet

- Mba633 Road To Hell Case AnalysisDocument3 pagesMba633 Road To Hell Case AnalysisAditi VarshneyNo ratings yet

- Kunst 1600 Case AnalysisDocument3 pagesKunst 1600 Case AnalysisrakeshNo ratings yet

- Conceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. RamegoudaDocument4 pagesConceptual Design of Blanking Tool For Washer Special: Nandish Harti DR D. Ramegoudaaravindan476No ratings yet

- ManuscriptDocument7 pagesManuscriptkamrul.malsxxc44No ratings yet

- 1 - Inkjet Printing On PET Substrate ReportDocument5 pages1 - Inkjet Printing On PET Substrate Reportmasum.sNo ratings yet

- 2 - Printed Electronics On Flexible Substrates Using Inkjet TechnologyDocument4 pages2 - Printed Electronics On Flexible Substrates Using Inkjet Technologymasum.sNo ratings yet

- Computer Program For Automatic Calculation of Tube Sheet Details in A Heat ExchangerDocument7 pagesComputer Program For Automatic Calculation of Tube Sheet Details in A Heat ExchangerLakshmi KanthNo ratings yet

- A) Process Description and Potential MaterialsDocument10 pagesA) Process Description and Potential MaterialsSaddy DipoNo ratings yet

- Experimental Investigation of Mustard Oil Based Nano Cutting Fluid On CNC Turning OperationDocument13 pagesExperimental Investigation of Mustard Oil Based Nano Cutting Fluid On CNC Turning OperationIJRASETPublicationsNo ratings yet

- Bizhub 43 - Service Manual - Ver.253363295-B PDFDocument232 pagesBizhub 43 - Service Manual - Ver.253363295-B PDFKonstantin PohocinskyNo ratings yet

- LIS 2022 New 1-49-55Document7 pagesLIS 2022 New 1-49-55Lppm Politeknik JambiNo ratings yet

- Buckling Analysis of 3D Printed ABS ThinDocument10 pagesBuckling Analysis of 3D Printed ABS Thinvignesh alagarsamyNo ratings yet

- 4 - Materials and Process Parameters For Ink-Jet Printing and CuringDocument18 pages4 - Materials and Process Parameters For Ink-Jet Printing and Curingmasum.sNo ratings yet

- 3 - Inkjet Printing of Ag Nanoparticles Using Dimatix Inkjet PrinterDocument12 pages3 - Inkjet Printing of Ag Nanoparticles Using Dimatix Inkjet Printerkjjgeya.ehtuNo ratings yet

- International Journal of Chemtech Research: Pravin Pawar, Raj Ballav, Amaresh KumarDocument6 pagesInternational Journal of Chemtech Research: Pravin Pawar, Raj Ballav, Amaresh KumarMuhamad BaharudiantoNo ratings yet

- Ijme - Optimization of Process Parameters by Warm Deep Drawing of Cylindrical Cup of Nickel 201Document10 pagesIjme - Optimization of Process Parameters by Warm Deep Drawing of Cylindrical Cup of Nickel 201Impact JournalsNo ratings yet

- 27-04-2021-1619516012-6-Ijme-1. Ijme - Optimization of Process Parameters by Warm Deep Drawing of Cylindrical Cup of Nickel 201Document10 pages27-04-2021-1619516012-6-Ijme-1. Ijme - Optimization of Process Parameters by Warm Deep Drawing of Cylindrical Cup of Nickel 201iaset123No ratings yet

- Co2 Sensor EMCDocument4 pagesCo2 Sensor EMCsnfulNo ratings yet

- LK4 ProDocument46 pagesLK4 ProРуслан БагаутдиновNo ratings yet

- ESMDocument10 pagesESM47 Bhushan BariNo ratings yet

- Mark Scored:: M M M M MDocument5 pagesMark Scored:: M M M M MRamesh ShresthaNo ratings yet

- Optimization of Minimum Quantity Lubricant (MQL) Conditions in Milling of Mild SteelDocument6 pagesOptimization of Minimum Quantity Lubricant (MQL) Conditions in Milling of Mild SteelputtaNo ratings yet

- Inkjet Printing of Perovskites For Breaking Performance - Temperature Tradeoffs in Fabric-Based ThermistorsDocument9 pagesInkjet Printing of Perovskites For Breaking Performance - Temperature Tradeoffs in Fabric-Based Thermistorszune153No ratings yet

- Study On Optimization of 3D Printing Parameters: IOP Conference Series: Materials Science and EngineeringDocument6 pagesStudy On Optimization of 3D Printing Parameters: IOP Conference Series: Materials Science and EngineeringGaby ZeledónNo ratings yet

- Monolayer Die For Tubes 1 MM To 6 MMDocument19 pagesMonolayer Die For Tubes 1 MM To 6 MMvenkithankamNo ratings yet

- Design and Finite Element Analysis of Micro Punch CNC Machine Modeling For Medical DevicesDocument8 pagesDesign and Finite Element Analysis of Micro Punch CNC Machine Modeling For Medical DevicesniteshNo ratings yet

- CSN-A2 User ManualDocument70 pagesCSN-A2 User ManualTeo SanabreNo ratings yet

- Machinability and Chip Morphology Study of Inconel 740H and Haynes 282 For Advanced-Ultra Supercritical ApplicationsDocument18 pagesMachinability and Chip Morphology Study of Inconel 740H and Haynes 282 For Advanced-Ultra Supercritical ApplicationsIJRASETPublicationsNo ratings yet

- Series: CE5000-60 CE5000-120Document2 pagesSeries: CE5000-60 CE5000-120esojhmeNo ratings yet

- Study Regarding The Optimal Milling Parameters For Finishing 3D Printed Parts From Abs and Pla MaterialsDocument7 pagesStudy Regarding The Optimal Milling Parameters For Finishing 3D Printed Parts From Abs and Pla MaterialsDaniel BarakNo ratings yet

- Thermal Receipt PrinterDocument10 pagesThermal Receipt PrinterMayra PeñaNo ratings yet

- Ijet18 10 03 096Document5 pagesIjet18 10 03 096miltoncobaNo ratings yet

- Service Information: Location SubjectDocument16 pagesService Information: Location SubjectNebi aktaşNo ratings yet

- Effect of Work Material Hardness and Machining Parameters On Burr-Formation and Surface Finish in Micro-Milling of AISI D2 SteelDocument6 pagesEffect of Work Material Hardness and Machining Parameters On Burr-Formation and Surface Finish in Micro-Milling of AISI D2 SteelVinay PaulNo ratings yet

- 4592-Article Text-8789-1-10-20201230Document13 pages4592-Article Text-8789-1-10-20201230Ayman EttahallouNo ratings yet

- An Experimental Investigation On Surface Quality and Dimensional Accuracy of FDM Components PDFDocument7 pagesAn Experimental Investigation On Surface Quality and Dimensional Accuracy of FDM Components PDFnewkid2202No ratings yet

- Ftp-628 Mcl101/103, Easy Loading Method: Battery Drive, Ftp-608 Series 2" HDocument6 pagesFtp-628 Mcl101/103, Easy Loading Method: Battery Drive, Ftp-608 Series 2" HinfoNo ratings yet

- 27-04-2021-1619516100-6-Ijme-2. Ijme - Optimization of Process Parameters in Deep Drawing of Monel-400 Conical CupDocument10 pages27-04-2021-1619516100-6-Ijme-2. Ijme - Optimization of Process Parameters in Deep Drawing of Monel-400 Conical Cupiaset123No ratings yet

- Experimental Investigation of Key Parameters On The Effects of Cavity Surface Roughness in Microinjection MoldingDocument6 pagesExperimental Investigation of Key Parameters On The Effects of Cavity Surface Roughness in Microinjection Moldingregil01No ratings yet

- Design and Analysis of Gating and Risering System For Casting of Ball ValvesDocument5 pagesDesign and Analysis of Gating and Risering System For Casting of Ball ValvesRemi Joel Boris EssecofyNo ratings yet

- Optimization of Gating System For Sand Casting Using Sequential Quadratic ProgrammingDocument6 pagesOptimization of Gating System For Sand Casting Using Sequential Quadratic ProgrammingIJRASETPublicationsNo ratings yet

- Nano Dimension: Lab-On-ChipDocument4 pagesNano Dimension: Lab-On-Chipyufencha1548No ratings yet

- YT YS3000A Crush TesterDocument3 pagesYT YS3000A Crush TesterEng.Abdalla QassemNo ratings yet

- Thermal Line Printer: For Kiosk ApplicationsDocument2 pagesThermal Line Printer: For Kiosk ApplicationsivaldeztNo ratings yet

- Process Capability Improvement of HSS Drill Bit Manufacturing ProcessDocument16 pagesProcess Capability Improvement of HSS Drill Bit Manufacturing ProcessIJRASETPublicationsNo ratings yet

- Die Casting Mold Design of The Thin-Walled Aluminum Case by Computational Solidification SimulationDocument6 pagesDie Casting Mold Design of The Thin-Walled Aluminum Case by Computational Solidification SimulationmetmlzmuhNo ratings yet

- Kuo2021 Article CharacterizationsOfPolymerInjeDocument18 pagesKuo2021 Article CharacterizationsOfPolymerInjeAsad UllahNo ratings yet

- Parametric Investigation of FDM Process Parameter On Impact Strength of 3D-Printed PartDocument8 pagesParametric Investigation of FDM Process Parameter On Impact Strength of 3D-Printed PartIJRASETPublicationsNo ratings yet

- Steam TracingDocument47 pagesSteam TracingPascal CustonNo ratings yet

- CoroPlusToolGuide Report 2023-01-12Document5 pagesCoroPlusToolGuide Report 2023-01-12FEL EmpiresNo ratings yet

- CDocument15 pagesCBiswanath PatroNo ratings yet

- Quality of Your Lab Quality of Your LabDocument4 pagesQuality of Your Lab Quality of Your LabJagdish RajanNo ratings yet

- Data Sheet For Basic Design Based On Mutag Biochip 30™ High-Performance Carrier MediaDocument2 pagesData Sheet For Basic Design Based On Mutag Biochip 30™ High-Performance Carrier MediaSAGAR APTENo ratings yet

- 1 Computer Aided Flank Wear Measurement in End Milling Cutting PDFDocument14 pages1 Computer Aided Flank Wear Measurement in End Milling Cutting PDFTbk TongbankhamNo ratings yet

- CTC 3D Printer Manual PDFDocument38 pagesCTC 3D Printer Manual PDFEdinIbrahimovicNo ratings yet

- Service Bulletin: Comp. SystemsDocument8 pagesService Bulletin: Comp. SystemsNebi aktaşNo ratings yet

- Project Timeline: Phase 1: Preparation Phase 2: StudyingDocument2 pagesProject Timeline: Phase 1: Preparation Phase 2: StudyingGazzara WorldNo ratings yet

- Development of Low Cost Recycled HDPE Filament Extruder For 3D Printing FilamentDocument7 pagesDevelopment of Low Cost Recycled HDPE Filament Extruder For 3D Printing FilamentLIEU TAINo ratings yet

- 13 - Invisible and Flexible Printed Sensors Based On ITO Nanoparticle Ink For Security ApplicationsDocument7 pages13 - Invisible and Flexible Printed Sensors Based On ITO Nanoparticle Ink For Security Applicationskamru55l.mzrllalNo ratings yet

- 4 - Review of Materials and Fabrication Methods For Flexible Nano and Micro-Scale Physical SensorsDocument55 pages4 - Review of Materials and Fabrication Methods For Flexible Nano and Micro-Scale Physical Sensorskamru55l.mzrllalNo ratings yet

- 4 - Printing Functional Electronic Circuits and ComponentsDocument131 pages4 - Printing Functional Electronic Circuits and Componentskamru55l.mzrllalNo ratings yet

- Digital Power and Performance Analysis of Inkjet Printed Ring OscillatorsDocument6 pagesDigital Power and Performance Analysis of Inkjet Printed Ring Oscillatorskamru55l.mzrllalNo ratings yet

- Practicewith Argument Athletesas ActivistsDocument30 pagesPracticewith Argument Athletesas ActivistsRob BrantNo ratings yet

- READMEDocument2 pagesREADMEtushar patelNo ratings yet

- Reviewer in PE&H 1st Quarter 18-19Document7 pagesReviewer in PE&H 1st Quarter 18-19rhex minasNo ratings yet

- Er6f Abs 2013Document134 pagesEr6f Abs 2013Calibmatic JobNo ratings yet

- 8051 Programs Using Kit: Exp No: Date: Arithmetic Operations Using 8051Document16 pages8051 Programs Using Kit: Exp No: Date: Arithmetic Operations Using 8051Gajalakshmi AshokNo ratings yet

- HP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningDocument2 pagesHP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningParesh BabariaNo ratings yet

- QSMT Chapter 1Document5 pagesQSMT Chapter 1Rachelle Mae SalvadorNo ratings yet

- I. Objectives Ii. Content Iii. Learning ResourcesDocument13 pagesI. Objectives Ii. Content Iii. Learning ResourcesZenia CapalacNo ratings yet

- Brp-Rotax Chassis Approval FormDocument3 pagesBrp-Rotax Chassis Approval Formdelta compNo ratings yet

- Toftejorg TZ-75 Rotary Jet Head - Portable: Fast, Effective Impact CleaningDocument3 pagesToftejorg TZ-75 Rotary Jet Head - Portable: Fast, Effective Impact CleaningSamo SpontanostNo ratings yet

- Gates Crimp Data and Dies Manual BandasDocument138 pagesGates Crimp Data and Dies Manual BandasTOQUES00No ratings yet

- (Word 365-2019) Mos Word MocktestDocument4 pages(Word 365-2019) Mos Word MocktestQuỳnh Anh Nguyễn TháiNo ratings yet

- GATE Chemical Engineering 2015Document18 pagesGATE Chemical Engineering 2015Sabareesh Chandra ShekarNo ratings yet

- Tecsun Pl310et PDFDocument30 pagesTecsun Pl310et PDFAxel BodemannNo ratings yet

- 2018-2019 Annual Algebra Course 1 Contest: InstructionsDocument2 pages2018-2019 Annual Algebra Course 1 Contest: InstructionsNaresh100% (1)

- TinkerPlots Help PDFDocument104 pagesTinkerPlots Help PDFJames 23fNo ratings yet

- Flow Through A Converging-Diverging Tube and Its Implications in Occlusive Vascular Disease-IDocument9 pagesFlow Through A Converging-Diverging Tube and Its Implications in Occlusive Vascular Disease-IRukhsarAhmedNo ratings yet

- Measures of Indicator 1Document2 pagesMeasures of Indicator 1ROMMEL BALAN CELSONo ratings yet

- Filling The Propylene Gap On Purpose TechnologiesDocument12 pagesFilling The Propylene Gap On Purpose Technologiesvajidqc100% (1)

- Code of Federal RegulationsDocument14 pagesCode of Federal RegulationsdiwolfieNo ratings yet

- INJkon 01 4.0 ManualDocument93 pagesINJkon 01 4.0 ManualJansirani SelvamNo ratings yet

- Aristotle Metaphysics Lambda Accessed 201111 Classicalk LibraryDocument19 pagesAristotle Metaphysics Lambda Accessed 201111 Classicalk Librarygijsbo2000No ratings yet

- 3DD5036 Horizontal.2Document6 pages3DD5036 Horizontal.2routerya50% (2)

- KSP Solutibilty Practice ProblemsDocument22 pagesKSP Solutibilty Practice ProblemsRohan BhatiaNo ratings yet