2010 2nd International Conference on Industrial Mechatronics and Automation

Adaptive neural network tracking control of robot manipulators including motor

dynamics: Dynamic surface backstepping methodology

XiwenGuo Qunjing Wang Cungang Hu Zhe Qian

Department of Electrical Engineering Department of Electronic Science and Department of Electrical Engineering

& Automation Technology & Automation

Hefei University of Technology Anhui University Hefei University of Technology

Hefei, China Hefei, China Hefei, China

xwgu02008@163.com wqunjing@sina.com hfliuchun@126.com

Abstract-To solve the trajectory tracking control problem for centralized control may not be economical feasible in some

rigid-link robot manipulators including actuator dynamics, a specific situations, Kim [10] combined the concepts of

novel neural network (NN)-based adaptive algorithm is decentralized scheme, fuzzy logic backstepping and adaptive

discussed. In the proposed control algorithm, radial basis scheme for the motion control of RLED robots.

function neural network (RBFNN) is adopted to approximate However, there is a substantial drawback of "explosion

the nonlinear dynamics of the robot manipulators'

of complexity" within the conventional backstepping

electromechanical system. Moreover, the key features are that,

technique in all aforementioned works, which is caused by

firstly, the unmatched & uncertainties of the system are

the repeated differentiations of certain nonlinear functions as

the order of the system increases. Swaroop et al. [11] firstly

overcame, secondly, the problem of "explosion of complexity"

derived dynamic surface control (DSC) technique to solve

inherent in the conventional backstepping method is avoided

due to combing with "dynamic surface control" (DSC)

approach. Finally, simulation results are included to

the problem by introducing a first order low-pass filter at

demonstrate the tracking performance and the effectiveness of

each step of the conventional backstepping procedure.

proposed algorithm. Recently, the DSC idea was extended to uncertain single

input single-output (SISO) [12] and multi-input multi-output

Index Terms-rigid-Iink robot manipulators, adaptive (MIMO) systems [13].

neural network control, dynamic surface backstepping, Accordingly, motivated by aforementioned works in

trajectory tracking, motor dynamics literature, a novel adaptive neural network control algorithm

using DSC technique is proposed. First, we present the robot

I. INTRODUCTION

manipulators model with unknown uncertainties in both

nominal model and external disturbances. The radial basis

In the past decades, there has been a rapid growth of function neural network (RBFNN) is adopted to approximate

research efforts aimed at the development of systematic the nonlinear dynamics of the robot manipulators'

design methods for the trajectory tracking control of rigid electromechanical system. Then, we design the virtual

link robot manipulators including motor dynamics. This is control items with the methods of three steps by using DSC

especially true in both the case of high-velocity movement technique. The adaptation laws for all weights of RBFNN

and highly varying loads [1]. The inclusion of the actuators are induced in Lyapunov sense. Finally, we simulate the two

into the dynamic equations complicates the controller design links rigid-link robot manipulators to show the tracking

and its stability analysis since the systems are described by performance and the effectiveness of proposed algorithm.

higher order differential equations [2]. Many remarkable This paper is organized as follows: In section II, we

results have been obtained owing to the advances in introduce the model and basis properties of rigid-link robot

nonlinear and intelligent control techniques such as sliding manipulators incorporating motor dynamics, while the

mode control [3], fuzzy control [4], and neural network (NN)

RBFNN structure is presented. In section III, a simple

control [5] et al.

adaptive control algorithm for rigid-link robot manipulators

As one of the most important approaches, the

backstepping technique has received considerable attention. is proposed. Simulation results are discussed in section IV.

Chun and Yury [6] proposed a backstepping based hybrid Section V contains the conclusions.

adaptive controller for robot motion control. This approach

II.

didn't require derivative computation of the regression

MODEL DESCRIPTIONS

matrix. Lotfazar [7] developed the problem of nonlinear

Model of electromechanical system

position control of a 5 DOF robot manipulator by using the

A.

integrator backstepping method. On the other hand, Kwan et The mechanical subsystem dynamics for robot

al. [8] concerned with the application of a robust neural manipulators actuated by DC motors can be written as [6-7]:

network (NN) controller for the motion control of rigid-link M(q)ij+C(qii>4+G(q)+F@+I;. =T

electrically driven (RLED) robots. By using the concept of (1)

incorporating fuzzy logic into a neural network, Rong [9] (2)

presented fuzzy neural network (FNN) controller. Due to the

52

978-1-4244-7656-5/10/$26.00 ©2010 IEEE ICIMA2010

� 0)

where q, q, q denote the n x 1 vectors of joint angular

110..1-;

position, angular velocity, and angular acceleration, �

respectively, M( q) is the n x n symmetric positive-defmite

inertia matrix, C( q, q) denotes the n x 1 coriolis and

Ap,I-;

centrifugal force vector, G( q) is the n x 1 gravity force �

vector, F ( q) denotes the n x 1 frictional force vector, 7;. is

the external bounded joint torque disturbance, and 't denotes

the n x 1 joint torque vector. The constant positive defmite

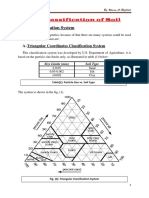

diagonal matrices L , R , K e' 7;; represent the Figure I. RBFNN model structure

n x n electrical inductance, the n x 1 electrical resistance,

where i is the number of robot manipulator's freedoms. I

the n x n back-emf coefficients, and the n x 1 external

and j are the numbers of hidden nodes and output nodes

bounded voltage disturbance. U denote the n x 1 input

respectively. The choice of the Gaussian network parameters

armature voltage vector. And KT is n x n positive definite

constant diagonal matrix of motor current-torque coefficients. [Js cJ] used in our control algorithm is

-

�a/�" exp

2b/

. =

Assumption 1: Suppose that, the rigid-link robot

manipulators can divided into two subsystems: nominal motivated by the discussion in [12]. The output of the

values and external disturbance terms, where the nominal RBFNN is calculated by the weighted sum method:

2

values M.g� qq,(j)- G{cj}. Ftq� Kr L, R, K. are known and lis - c�11

- - - - - - - -

l

bounded [12]. 1; = ;=1 I e* __exp[

.[2; 2b;

] (9)

Assumption 2: For given desired trajectory, the system

states q,q ,q are all uniformly bounded available for Note that the optimal weight vector e· defmed above is a

feedback. quantity required only for analytical purposes. e and e

, �

Follows the assumption 1-2, the dynamics for robot denote estimated weight vector and estimated error vector.

manipulators actuated by DC motors can be rewritten: Accordingly, in this paper, the output of the RBFNN can be

M(qjj + C(qiJ)q + G(q) + F@ + �.(q,q,I) = KT! (4) rewritten:

(5)

Let us put the system's dynamic (4-5) in a state space (lO)

form. With the state vectors chosen asxj =q, x2 =q, x3 =I , (11)

then the form Eq. (4-5), we have:

where 0a p,; =diag[ e a p,;] denote estimated weight

, ,

� =�

I I

00

matrices, iio/ ,; =diag[8a/ P,;] denote estimated error

-'i =Ml(Xj)lKM -C(Xj,-'2P2 - G(\) F(-'2)]+L\(Xj -'2 Xj)

- , ,

(7) p

X3 =r [U-RX3-KeX2]+.:1p(X2,X3'U) matrices. denote reconstruction errors.

- -

(8) ea/i3,i

-1

where: Assumption 3: Suppose that, the optimal weight matrices

.:1u(q,qJ) =_M-l(q)""'i..u(q,qJ) O*";p,; and reconstruction errors ea/i3,i are all bounded as

.:1p(q ,LU) =-L-l""'i..p(q J,U) follows:

B. Model ofRBFNN system 1 0' o/pllF �oo/PM' IleU/PllF �eU/PH

The RBFNN is known in the field of an approximation of where Oo/PM' eu/PH are all positive constants.

non-linear function and pattern recognition. Especially it has The update law for the weight vector is derived in the

a faster convergence property due to its simple structure [12]. next section.

Fig.1 shows the schematic diagram of a RBFNN.

III. ADAPTIVE RBFNN CONTROL FOR ROBOT SYSTEM

Here, we incorporated the DSC technique into an

adaptive neural network tracking design algorithm for robot

manipulators including motor dynamics. Similar to the

traditional backstepping method, we designed the control

law step by step as follows.

Step 1: Defmed 1st error surface S 1 =X - qd , then

l

differentiated:

53

� (12) IV. SIMULATION

Chose virtual control variable x2 = diag[x2,] ...x2,i]T to In this section, we perform the simulation for the tracking

control of two-links rigid-link robot manipulators including

driveS1 � 0 : motor dynamics (seen in Fig. 2) to demonstrate the validity

X2 = -K]S 1 +qd K] >0 (13) of the proposed control algorithm.

Then, to obtain a filtered virtual System parameters are chosen as: link mass

control X2f = diag[xz fr,xz/J]T , we passed x2 through a m] =4kg,mz = 2kg ,link lengthsr; =Yz = lm,acceleration

first-order filter by using time constants of gravity g = 9.8mI sZ .

112 = diag[112,l ...112,i]T > 0 as follows:

j,

11ZX2f+x2f = Xz X2f (0) = xz(O) (14)

Step 2: Using the Eq. (7), defmed 2nd error

surface S2 = Xz - X2f ' then differentiated:

S2=Ar (Xj)[K"rX3 -CeXj,.\2).\2 -G(Xj)-F(.\2)]+4x,i-X;f (15)

Chose virtual control variable X3 = diag[x3,1'.,x3,i]T and

K; >0 to driveSz � 0 :

ij=i0q4��4)+i\�}t-i¢j(��-t{-'2--'2f)�] (16)

11 DC motor I

Combined with Eq. (10), the unknown parameter vector VI

()a,; is updated by Figure 2, The two-linkss planar robot manipulators driven by de motors

Oa,; = ra,;�a,;S2,; -crura,;Oa,; (17) The parameters for the motor dynamics are chosen:

with a gain matrix ra,i =ra; T =diaalu,l"ru,;1T >0 and a L = diag[0.048 0.048]H, R = diag[1.6 1.6]0,

gain constant (J a > 0 . Ke =diag[0.19 0.19]V · s l rad .

Then, through a first-order filter by using time constants Important parameters that affect the control performance

113=diag1131, ' ..113i, ]T >0 to obtain X3f = diag[ x3/,l"· x3f ,i]T of the robotic system are the external joint torque

disturbance TL =[O.2sin�.27U) O.lcoS().27r1)]T,and the

113X 3f+ X3f = X3 X3f (0) = X3 (0) (18)

Step 3: Using the Eq. (8), defmed 3rd error external voltage disturbance TE =[O.lsinQ.27tt) O.05cosQ.27tt)t .

surface S 3 = X3 - X3f ' then differentiated: The friction term isF(xz)=0.5sgn�z)' The desired

-1 - -

S3 = r [U -RX3 -Kexz] +�p,i -x3f (19) trajectories for the system to be tracked are

•

Designed the ultimated control law U to drive S 3 � 0: givenqd =[2sin(!).27r1) 2coS().27r1)]T. The initial angular

u=i.[�+(ij-.:\jf)/T];-.\J+�+ih �>O (20) position is% =[0.5 O.5]T.

Similarity, the unknown parameter vector ()p,i is updated RBFNN used in proposed adaptive DSC control algorithm

has six inputs and two outputs. There are 21 neurons in the

by

hidden layer. Central positions of Gaussian function ci are

Op,i = rp,i�p,;S3,; -crprp,;Op,; (21)

selected from -10 to 10.

with a gain matrix rp,; =rp,;T =diaalp,] ..rp,i]T >0 and a The controller parameters and adaptation gains are chosen

gain constant (J p > 0. as:

Remark1: In comparison with the backstepping design K; =lQKz =6,K3=4,112/3= diag[ O.Ol O.Ol]T,

systems for robot manipulators reported in [8J and [9J, the

ru/fJ; = diag[lx10-6 1x1O-6]T ,cru/p = 0.0010 O=L 2)

proposed control algorithm can not only overcome the

"explosion of complexity" problem [lOJ by using the first- Tracking position,tracking errors are shown in Fig. 3-4

order filters with x2' X3 as the inputs instead of x2' x3' respectively. As seen in Fig. 3, the control system has

excellent robust performances. The joint positions track the

but also solve the unmatched & uncertainties of the system

by using RBFNN. Consequently, the burdensome desired trajectory. Tracking errors converge to zero quickly

computation of the algorithm can be reduced dramatically (see Fig. 4).

and it is simpler and easy to be implemented in applications.

54

� REFERENCES

" [1] M. C. Good, L. M. Sweet and K. L. Strobel, "Dynamic models for

/' . '\ control system design of integrated robot and drive systems,"

\

Transactions of the ASME on Dynamic Systems, Measurement and

/ Control, vol. 107, Mar.l985, pp. 53-59 ,.

[2] T. 1. Tam, A. K. Bejczy, X. Yun and Z. Li, "Effect of motor

dynamics on nonlinear feedback robot arm control," IEEE

Transactions on Robotics and Automation, vol. 7, Feb. 1991, pp. 114-

122.

. . . [3] Hwee Choo Liaw, Shirinzadeh B, Smith J, Alici G, "Motion tracking

control of piezo-driven flexure-based mechanism based on sliding

'\ .. � mode strategy," Proc. IEEE International Conference on Advanced

�/'

B'\

.

Intelligent Mechatronics, IEEE Press, Sept. 2007, pp. 1-6.

[4] Bor-Sen Chen, Huey-Jian Uang and Chung-Shi Tseng, "Robust

�

tracking enhancement of robot systems including motor dynamics: a

....!----+--+--!--+----:f---i---!----l---!----l

fuzzy-based dynamic game approach," IEEE Transactions on Fuzzy

Systems, vol. 6, Nov. 1998, pp. 538 -552.

Figure 3. Tracking position of two-link robot manipulators

[5] S.N. Huang, K.K. Tan, T.H. Lee, "Adaptive neural network algorithm

for control design of rigid-link electrically driven robots,"

r- --;======:;I

1 -----

--ql'--q2'sstratraijeedolYer

dory'elTOro:rl

o. r -�-�-�-�-�-�-

Neurocomputing, vol. 71, Jan. 2008, pp. 885-894.

[6] Chun-Yi Su and Y. Stepanenko, "Backstepping based hybrid adaptive

B' O.S ; control of robot manipulators incorporating actuator dynamics," Proc.

�

'I::"0.4 : IEEE International Conference on Industrial Electronics, Control, and

� !

o.,

Instrumentation, IEEE Press, Aug. 1996, pp.l258-1263.

I!� 0.2

[7] A. Lotfazar, M. Eghtesad, M. Mohseni, "A Integrator backstepping

.� 0.1 control of a 5 DoF robot manipulator incorporating actuator

dynamics," Proc. IEEE International Conference on Control

-O. 10!--.;----

- -;---+----;---7,;----c,'c-, ----:-

:- ---7

,'- ---7,;"-----;!20 Applications, IEEE Press, Jun. 2003 pp.1007-1012.

timo:sec) [8] C. Kwan, F. L. Lewis and D. M. Dawson, " Robust Neural-Network

Figure 4. Tracking errors Control of Rigid-Link Electrically Driven Robots," IEEE

Transactions on Neural Networks, vol. 9, July 1998, pp. 581-588.

[9] Rong-Jong Wai and Kuan-Yun Hsieh, " Tracking control design for

V. CONCLUSION robot manipulator via fuzzy neural network," Proc. IEEE

International Conference on Fuzzy Systems. IEEE Press, May 2002,

A novel developed trajectory tracking control algorithm pp. 1422-1427.

for rigid-link robot manipulators was proposed using the [10] Y.T. Kim, "Decentralized adaptive fuzzy backstepping control of

concept of dynamic surface control (DSC) to overcome the rigid-link electrically driven robots," Proc. IEEE International

problem of "explosion of items" in this paper. The highly Conference on Systems, Man and Cybernetics. IEEE Press, Oct. 2005

pp. 2061-2066.

nonlinear dynamic behavior of motor was incorporated in the

[11] D. Swaroop, 1. C. Gerdes, P. P. Yip and 1. K. Hedrick, " Dynamic

control algorithm design. Furthermore, to deal with the surface control of nonlinear systems," Proc. American Control

unmatched & uncertainties in the system, the control Conference, June 1997, pp. 3028-3034.

algorithm was augmented with a number of adaptation laws. [12] D. Wang and Huang Jie, "Neural network-based adaptive dynamic

Simulation was carried out and validated the performance surface control for a class of uncertain nonlinear systems in strict

and effectiveness of the proposed control algorithm. feedback form," IEEE Transactions on Neural Networks, vol.16, Jan.

2005, pp. 195-202.

ACKNOWLEDGMENT [13] Bong Seok Park, Sung Jin Yoo, Jin Bae Park and Yoon Ho Choi,

"Adaptive tracking control of nonholonomic mobile robots

The research is supported by the National Science considering actuator dynamics: Dynamic surface design approach,"

Foundation (506770l3) and "863" project (2007AA04Z214) Proc. American Control Conference, June 2009, pp. 3860-3865.

of China.

55