Professional Documents

Culture Documents

Chimei Brochure Combined

Uploaded by

Artiom SîrbuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chimei Brochure Combined

Uploaded by

Artiom SîrbuCopyright:

Available Formats

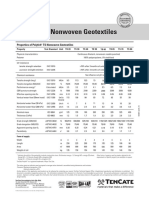

Chimei ABS Polylac Properties

Typical General Purpose High Flow Electroplating

ISO Condition Units

Properties PA-707 PA-757 PA-717C PA-726 PA-747 PA-709 PA-737 PA-716 PA-757H PA-746 PA-746H PA-756 PA-756H PA-756S PA-726M PA-727

MVR 1133 220°C x 10kg ml/10min 20 18 16 17 13 5.0 29 33 30 28 40 40 80 62 23 19

Mass Density 1183 23°C g/cm 3

1.06 1.05 1.04 1.04 1.03 1.03 1.04 1.04 1.04 1.03 1.03 1.05 1.05 1.05 1.04 1.05

50mm/min,

MPa 50 47 44 44 40 40 39 42 40 40 37 45 44 41 42 46

Tensile yield

527

Strength 50mm/min,

MPa 36 34 33 33 30 31 32 31 31 29 27 32 33 31 32 34

break

Tensile

527 50mm/min % 30 30 30 40 35 35 20 25 40 30 25 30 35 35 20 25

Elongation

Flexural

178 2mm/min MPa 79 76 69 64 58 58 60 65 61 60 54 72 65 61 63 71

Strength

Flexural

178 2mm/min GPa 2.3 2.2 1.9 2.1 1.8 1.8 1.9 1.9 2.0 1.8 1.7 2.1 2.2 2.0 2.1 2.0

Modulus

Izod 180/1 23°C, Notched KJ/m2 14 19 25 24 34 40 24 25 27 28 27 16 9 15 20 24

Impact A -30°C, Notched KJ/m2 7 9 12 11 23 27 10 11 - 12 12 8 5 7 9 11

Charpy 23°C, Notched KJ/m 2

15 21 27 26 36 42 25 26 29 30 29 17 10 16 22 25

179

Impact -30°C, Notched KJ/m 2 8 10 13 12 25 29 11 12 - 14 14 9 5 8 10 12

Vicat 50°C/hr; 5kg °C 104 104 103 104 104 105 103 104 105 103 102 104 102 102 103 105

Softening 306

Temperature 50°C/hr; 5kg °C 100 100 98 96 96 97 96 96 101 94 94 96 95 95 95 98

1.8MPa,

Heat

0C 83 83 82 83 82 82 81 83 83 82 81 83 82 82 81 83

unannealed

Deflection 75/A

Temperature 1.8MPa, 0C 98 98 97 98 97 98 96 97 98 96 96 98 97 97 96 100

annealed

CTE 11359 - - 8.4 × 10⁻5 8.6 × 10⁻5 8.8 × 10⁻5 9.1 × 10⁻5 9.3 × 10⁻5 9.3 × 10⁻5 9.0 × 10⁻5 9.1 × 10⁻5 8.6 × 10⁻5 9.2 × 10⁻5 9.2 × 10⁻5 8.9 × 10⁻5 8.9 × 10⁻5 8.8 × 10⁻5 8.7 × 10⁻5 8.8 × 10⁻5

1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm

Flammability - UL-94 -

HB HB HB HB HB HB HB HB HB HB HB HB HB HB HB HB

Mold

294-4 - % 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7

Shrinkage

Symbol 1043 - - >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS<

High gloss, High gloss, Medium Medium High Super High flow, High flow, High flow, High flow, Super high High Super high Super high Auto- Medium

High Medium impact flow, impact impact Medium Medium Medium Medium flow, High rigidity, flow flow, motive flow,

Product Description rigidity impact Medium impact impact impact impact impact High flow Medium parts, Medium

impact impact electro- impact

plating

All tests were run under laboratory conditions testing procedures. The test results obtained with respect to the products are for reference only. The above information should not be used as a warranty of any kind. Buyers must run their own tests and assume all risks of use. Chi Mei Corporation assumes no liability for any

advice furnished by it, its employees and representatives. Chi Mei Corporation makes no warranties, whether express or implied, and assumes no liability in connection with any use of above information.

Aug 2016 wahsin.com

Chimei ABS Polylac Properties

Typical Extrusion Flame Retardant High Heat

ISO Condition Units

Properties PA-747R PA-747F PA-747H PA-747S PA-709S PA-77SD PA-763 PA-764 PA-764B PA-765 PA-765A PA-765B PA-777B PA-777C PA-777D PA-777E PA-77NB

ml/10mi

MVR 1133 220°C x 10kg n 2.5 3.5 3.0 6.0 4.0 0.5 27 30 28 50 46 38 8.5 7.0 5.5 4.5 10

Mass Density 1183 23°C g/cm3 1.04 1.05 1.05 1.03 1.03 1.06 1.19 1.19 1.16 1.19 1.17 1.16 1.03 1.06 1.06 1.07 1.06

50mm/min,

yield

MPa 41 46 46 40 37 45 38 37 38 37 38 38 44 44 45 45 45

Tensile

527

Strength 50mm/min,

break

MPa 30 33 35 30 29 - 29 28 29 28 29 29 34 35 33 32 -

Tensile

Elongation

527 50mm/min % 25 25 25 40 30 30 15 10 10 10 10 10 40 44 34 29 50

Flexural

Strength

178 2mm/min MPa 61 66 63 57 51 70 58 55 57 55 56 57 67 69 73 74 70

Flexural

Modulus

178 2mm/min GPa 1.7 1.9 1.8 1.7 1.5 2.2 2.0 1.7 1.8 1.8 1.8 1.8 2.2 2.2 2.3 2.3 2.2

Izod 23°C, Notched KJ/m2 37 30 33 34 40 22 21 13 14 22 23 24 21 18 13 12 23

180/1A

Impact -30°C, Notched KJ/m 2

26 20 22 23 28 - 11 7 7 9 10 11 11 9 7 6 -

Charpy 23°C, Notched KJ/m2 39 32 35 36 42 20 22 13 13 23 24 26 22 17 14 13 21

179

Impact -30°C, Notched KJ/m2 28 21 24 25 30 - 12 7 7 10 10 11 11 9 7 6 -

Vicat 50°C/hr; 5kg °C 106 106 106 103 104 125 103 101 102 91 93 94 114 119 124 129 115

Softening 306

Temperature 50°C/hr; 5kg °C 101 101 101 98 98 115 96 90 90 78 79 80 106 112 117 121 108

1.8MPa,

Heat unannealed

0 C 83 84 84 81 81 95 86 82 83 74 76 77 86 92 97 101 86

Deflection 75/A

Temperature 1.8MPa,

annealed

0 C 99 100 100 96 96 115 96 92 93 83 84 85 106 112 117 121 106

CTE 11359 - - 9.1 × 10⁻5 8.7 × 10⁻5 8.7 × 10⁻5 9.2 × 10⁻5 9.5 × 10⁻5 8.3 × 10⁻5 8.5 × 10⁻5 8.5 × 10⁻5 8.6 × 10⁻5 8.4 × 10⁻5 8.5 × 10⁻5 8.6 × 10⁻5 8.4 × 10⁻5 8.2 × 10⁻5 8.3 × 10⁻5 8.2 × 10⁻5 8.4 × 10⁻5

1.0mmV-1 1.5mmV-1 1.5mmV-2

1.5mmV-0 2.5mmV-0

1.5mm 1.5mm 1.0mm 1.5mm 1.5mm 1.5mm 1.5mmV-0 1.5mm V-0 2.1mm V-0 2.5mm V-0 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm

Flammability - UL-94 - 2.5mm 5VA

1.5mm 5VB 2.5mm 5VB

1.5mm 5VB 2.1mm 5VB 2.5mm 5VB

HB HB HB HB HB HB 2.5mm 5VA 3.0mm 5VA HB HB HB HB HB

2.5mm 5VA 2.5mm 5VA 3.0mm 5VA

Mold

294-4 - % 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.4 〜 0.7 0.3 〜 0.6 0.3 〜 0.6 0.3 〜 0.6 0.3 〜 0.6 0.3 〜 0.6 0.3 〜 0.6 0.3 〜 0.6 0.3 〜 0.6 0.3 〜 0.6 0.3 〜 0.6 0.3 〜 0.6 0.3 〜 0.6

Shrinkage

>ABS >ABS >ABS >ABS >ABS >ABS

Symbol 1043 - - >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS< >ABS<

-FR(17)< -FR(17)< -FR(17)< -FR(17)< -FR(17)< -FR(17)<

Extrusion Refrigerator, Refrigerator, High Super High heat, F.R, High F.R, F.R, F.R, Medium High heat, Low

Extrusion Extrusion impact, impact, Extrusion, heat, Weather Weather F.R, High F.R, High Medium heat, High High Super high Ultra high emission,

Product Description Extrusion Extrusion Blow Weather resistant resistant flow flow impact impact impact heat heat Low odor,

resistant Low gloss

All tests were run under laboratory conditions testing procedures. The test results obtained with respect to the products are for reference only. The above information should not be used as a warranty of any kind. Buyers must run their own tests and assume all risks of use. Chi Mei Corporation assumes no liability for any

advice furnished by it, its employees and representatives. Chi Mei Corporation makes no warranties, whether express or implied, and assumes no liability in connection with any use of above information.

Aug 2016 wahsin.com

Chimei MABS Polylac Properties & PMMA Acryrex Properties

Typical Transparent Typical PMMA Acryrex

ISO Condition Units ISO Condition Units

Properties PA-758 PA-758R Properties CM-205 CM-205M CM-207 CM-211

MVR 1133 200°C x 5kg ml/10min 3.0 2.2 MVR 1133 230°C x 3.8kg ml/10min 1.9 3.2 8.5 16

Mass Density 1183 23°C g/cm 3

1.08 1.08 Mass Density 1183 23°C g/cm 3

1.19 1.19 1.19 1.19

50mm/min, yield MPa 42 45 5mm/min, yield MPa 70 70 67 65

Tensile Tensile

527 527

Strength Strength

50mm/min,break MPa 33 33 5mm/min,break MPa 70 70 67 65

Tensile Tensile

Elongation

527 50mm/min % 40 60 Elongation

527 5mm/min % 12 12 8 6

Flexural Flexural

Strength

178 2mm/min MPa 57 62 Strength

178 2mm/min MPa 103 103 97 95

Flexural Flexural

Modulus

178 2mm/min GPa 1.9 2.1 Modulus

178 2mm/min GPa 2.8 2.8 2.7 2.7

23°C, Notched KJ/m2 14 15

180/1A 180/1A 23°C, Notched KJ/m2 2 2 2 2

Izod -30°C, Notched KJ/m 2

7 8 Izod

Impact Impact

23°C,Unnotched KJ/m2 55 58

180/1C 180/1C 23°C,Unnotched KJ/m2 21 21 18 17

-30°C,Unnotched KJ/m2 40 41

23°C, Notched KJ/m2 14 15

23°C, Notched KJ/m2 2 2 2 2

Charpy -30°C, Notched KJ/m2 7 8 Charpy

179 179

Impact Impact

23°C,unnotched KJ/m2 58 62

23°C,unnotched KJ/m2 26 26 20 19

-30°C,unnotched KJ/m 2

45 48

Vicat 50°C/hr; 1kg °C 104 102 50°C/hr; 1kg °C 115 115 107 103

Vicat Softening

Softening 306 306

Temperature

Temperature 50°C/hr; 5kg °C 96 94 50°C/hr; 5kg °C 107 107 99 96

Heat 1.8MPa, unannealed 0C 87 85 1.8MPa, unannealed 0C 95 95 89 78

Heat Deflection

Deflection 75/A 75/A

Temperature

Temperature 1.8MPa, annealed 0C 97 95 1.8MPa, annealed 0C 104 104 100 98

CTE 11359 - - 9.0 × 10⁻5 8.7 × 10⁻5 CTE 11359 - - 6.0 × 10⁻5 6.0 × 10⁻5 6.0 × 10⁻5 6.0 × 10⁻5

1.5mm 1.5mm 1.5mm 1.5mm 1.5mm 1.5mm

Flammability - UL-94 - Flammability - UL-94 -

HB HB HB HB HB HB

Mold

294-4 - % 0.3 〜 0.7 0.3 〜 0.7 Mold Shrinkage 294-4 - % 0.2 〜 0.6 0.2 〜 0.6 0.2 〜 0.6 0.2 〜 0.6

Shrinkage

Symbol 1043 - - >MABS< >MABS< Symbol 1043 - - >PMMA< >PMMA< >PMMA< >PMMA<

Transparent Transparent, High viscosity

Product Description Chemical resistant Product Description High viscosity

High flow

Medium viscosity Low viscosity

All tests were run under laboratory conditions testing procedures. The test results obtained with respect to the products are for reference only. The above information should not be used as a warranty of any kind. Buyers must run their own tests and assume all risks of use. Chi Mei Corporation assumes no liability for any

advice furnished by it, its employees and representatives. Chi Mei Corporation makes no warranties, whether express or implied, and assumes no liability in connection with any use of above information.

Aug 2016 wahsin.com

You might also like

- Technical Data SheetDocument16 pagesTechnical Data SheetChakkaravarthiEr100% (1)

- CKB TDSDocument2 pagesCKB TDSmonik manuelNo ratings yet

- FRPC Properties EN-RUDocument1 pageFRPC Properties EN-RUVahNo ratings yet

- 25-35NB Datasheet - Rev 17 PDFDocument2 pages25-35NB Datasheet - Rev 17 PDFAnonymous nw5AXJqjdNo ratings yet

- Data Sheet For ESUN 3D Filament-201411Document1 pageData Sheet For ESUN 3D Filament-201411Russhs HourNo ratings yet

- File Rock Lab (Latihan)Document8 pagesFile Rock Lab (Latihan)Rizky PratamaNo ratings yet

- File Rock Lab (Latihan)Document8 pagesFile Rock Lab (Latihan)dr.rizkypmNo ratings yet

- Evalene HDPE Grade SlateDocument1 pageEvalene HDPE Grade Slatepalani.djpNo ratings yet

- YEE70G30HSLNCDocument2 pagesYEE70G30HSLNCRanjan GnanaoliNo ratings yet

- Tds - Macgrid BiaxialDocument1 pageTds - Macgrid BiaxialLiliana Ribeiro100% (2)

- Principal Stresses: Minor Principal Stress (Mpa)Document6 pagesPrincipal Stresses: Minor Principal Stress (Mpa)Edgardo O. Osses PonsNo ratings yet

- Euro-Composites Panel Datasheet EC-PA Aviation PanelsDocument1 pageEuro-Composites Panel Datasheet EC-PA Aviation PanelsWurstNo ratings yet

- Spheroidal GraphiteDocument1 pageSpheroidal GraphiteS.Mohana sundaramNo ratings yet

- Tdk-B41692a5158q001 C428910Document19 pagesTdk-B41692a5158q001 C428910СергейВойчукNo ratings yet

- File Rock Lab (Latihan)Document8 pagesFile Rock Lab (Latihan)Andre febrianNo ratings yet

- Current Kmax HRC Fuse Current A K Max HRC Fu Construction Approx. Area in MMDocument5 pagesCurrent Kmax HRC Fuse Current A K Max HRC Fu Construction Approx. Area in MMDilum GunathilakaNo ratings yet

- Apc Materials Properties PDFDocument1 pageApc Materials Properties PDFnamyefNo ratings yet

- Desmodur MAX-T MOCADocument2 pagesDesmodur MAX-T MOCAFrench CorvetteNo ratings yet

- Delpet 70 NHDocument1 pageDelpet 70 NHAccounts AVG PolymersNo ratings yet

- Physical and Piezoelectric Properties of APC MaterialsDocument2 pagesPhysical and Piezoelectric Properties of APC MaterialsTrương Anh DuyNo ratings yet

- Glass Fiber Reinforced Polypropylene Composite Pipes: Safe and Practical For All Hot Water and Heating ApplicationsDocument2 pagesGlass Fiber Reinforced Polypropylene Composite Pipes: Safe and Practical For All Hot Water and Heating Applicationskhaled redaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 pageAspen Exchanger Design and Rating Shell & Tube V9MAYANK AGRAWALNo ratings yet

- Product Manual: Characters of Mold Silicone RubberDocument3 pagesProduct Manual: Characters of Mold Silicone RubbershennoNo ratings yet

- تخفيض عمليDocument8 pagesتخفيض عمليAbd elrahman SwilamNo ratings yet

- Dynamic Cone Penetrometer (DCP) Test Bs 1377:part 9:1990Document1 pageDynamic Cone Penetrometer (DCP) Test Bs 1377:part 9:1990inno musiimeNo ratings yet

- Honeycomb Beam & Panel Calculations XLV1 - 2Document29 pagesHoneycomb Beam & Panel Calculations XLV1 - 2Krishant Krishant Krishant0% (1)

- J Integral Based Failure Assessment Diagram Assessment of A Cylinder With A Surface CrackDocument22 pagesJ Integral Based Failure Assessment Diagram Assessment of A Cylinder With A Surface CrackAsraff Ahmedul KabirNo ratings yet

- SGL Datasheet SIGRAFINE Materials For Mechanical Applications ENDocument2 pagesSGL Datasheet SIGRAFINE Materials For Mechanical Applications ENMayur PattanshettiNo ratings yet

- Cembrit Cembonit: Exterior CladdingDocument2 pagesCembrit Cembonit: Exterior CladdingIrina SanduNo ratings yet

- CLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)Document4 pagesCLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)PeterWayNo ratings yet

- PT Tension GuideDocument8 pagesPT Tension GuideA.i. StergianosNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoNo ratings yet

- Formosa Ldpe Data SheetDocument5 pagesFormosa Ldpe Data SheetBasant AGarwalNo ratings yet

- DSAHI00050866Document17 pagesDSAHI00050866Pavel LaurinecNo ratings yet

- Lexan™ Exell™ D - Sheet DatasheetDocument3 pagesLexan™ Exell™ D - Sheet DatasheetAmritraj CharlesNo ratings yet

- Battery BSB 55AHDocument2 pagesBattery BSB 55AHfandiebedil4No ratings yet

- Slab Design: Initial ConditionsDocument6 pagesSlab Design: Initial ConditionscathalboweNo ratings yet

- Condenser 7.5 (RATING)Document1 pageCondenser 7.5 (RATING)Madelyn BelbesNo ratings yet

- Technical Specification 18Document2 pagesTechnical Specification 18sarvan shivaNo ratings yet

- Thermal Cracking CalcDocument1 pageThermal Cracking Calcbogdan_danuletNo ratings yet

- TenCate Polyfelt TS Nonwoven GeotextilesDocument6 pagesTenCate Polyfelt TS Nonwoven GeotextilesChee Soon LeeNo ratings yet

- PA717CDocument1 pagePA717Cjdstore99No ratings yet

- Propiedades ZamakDocument5 pagesPropiedades ZamakMNNo ratings yet

- Cromax 280X: Hard Chrome BarDocument4 pagesCromax 280X: Hard Chrome BarpeterNo ratings yet

- IFB 2300 - BNZ MaterialsDocument2 pagesIFB 2300 - BNZ Materialsmiltone87No ratings yet

- Geomembrane HDPE Smooth Black PDFDocument1 pageGeomembrane HDPE Smooth Black PDFandriarisetiawan0% (1)

- New Atlanta Permaline 2021 0Document2 pagesNew Atlanta Permaline 2021 0Kerr Nell AsuncionNo ratings yet

- CLC 17-13-5LN: A 317LN Modified Mo 4% Austenitic Stainless Steel (317LNM)Document4 pagesCLC 17-13-5LN: A 317LN Modified Mo 4% Austenitic Stainless Steel (317LNM)PeterWayNo ratings yet

- Classification 14009Document2 pagesClassification 14009Sayyid AbulkhairNo ratings yet

- Cable ELEXOR BT-MTDocument4 pagesCable ELEXOR BT-MTespiripitiberto espiripitiflauticoNo ratings yet

- 05 00944tdsDocument1 page05 00944tdsTobNo ratings yet

- TDS-MY-MacTex MXC, Feb2020Document1 pageTDS-MY-MacTex MXC, Feb2020CHEONG WEI HAONo ratings yet

- BS EN 1992-3:2006, Table 7.105 - Classification of TightnessDocument13 pagesBS EN 1992-3:2006, Table 7.105 - Classification of TightnessEuniceNo ratings yet

- Bubbledeck: View of Standard Deck TypesDocument0 pagesBubbledeck: View of Standard Deck Typesgrifoo7No ratings yet

- Awg Metric ComparisonDocument2 pagesAwg Metric ComparisonmirjithNo ratings yet

- Overall SummaryDocument1 pageOverall SummaryTIPAZONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9: File: Printed: 24-08-2019 at 10:29:26 PM Overall SummaryDocument1 pageAspen Exchanger Design and Rating Shell & Tube V9: File: Printed: 24-08-2019 at 10:29:26 PM Overall Summarymohit kumarNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- Overall SummaryDocument1 pageOverall SummaryMayank AgrawalNo ratings yet

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Air To Fuel Ratio ControlDocument68 pagesAir To Fuel Ratio Controlvivek_genx4737100% (2)

- Temperature of 17000C To Room Temperature of 250C. Take The Fusion Temperature From Any Reference BookDocument2 pagesTemperature of 17000C To Room Temperature of 250C. Take The Fusion Temperature From Any Reference BookAshok PradhanNo ratings yet

- Review of Related Literature and StudiesDocument9 pagesReview of Related Literature and StudiesJay-Ar S. SungaNo ratings yet

- PSPC Q&As - and - CIs - (Common - Interpretation)Document10 pagesPSPC Q&As - and - CIs - (Common - Interpretation)totoq51No ratings yet

- Density of Cargoes: Name Equivalent Cor. Fact. Sp. Grav IMO UN Poll. Com Stow Cat. PT For 1 C at 30 CDocument4 pagesDensity of Cargoes: Name Equivalent Cor. Fact. Sp. Grav IMO UN Poll. Com Stow Cat. PT For 1 C at 30 CJeet SinghNo ratings yet

- Assembly of Very Fine Pitches Infrared Focal Plane Array With Indium Micro BallsDocument6 pagesAssembly of Very Fine Pitches Infrared Focal Plane Array With Indium Micro BallsaaronNo ratings yet

- Acids and BasesDocument5 pagesAcids and BasesalandagocNo ratings yet

- KGL ManualDocument47 pagesKGL ManualAaron Shane IrvinNo ratings yet

- Personal Care: Industrial & Consumer SpecialtiesDocument17 pagesPersonal Care: Industrial & Consumer Specialtiescontentdrive4 drive4No ratings yet

- Fatigue Analysis W - CIIDocument10 pagesFatigue Analysis W - CIInaeandNo ratings yet

- Filter DataDocument6 pagesFilter DataJohnNo ratings yet

- Materials of Construction and Selection: Faculty of Chemical Engineering Universiti Teknologi MaraDocument80 pagesMaterials of Construction and Selection: Faculty of Chemical Engineering Universiti Teknologi MaraAisyah Addia AzizanNo ratings yet

- Lesson 3 - Respiratory SystemDocument6 pagesLesson 3 - Respiratory SystemlarraNo ratings yet

- Specifications: Specifications & Material Safety Data Sheet Xyz General Cleaner LemonDocument3 pagesSpecifications: Specifications & Material Safety Data Sheet Xyz General Cleaner LemonnicholasyudhistiraNo ratings yet

- Well Testing PresentationDocument24 pagesWell Testing PresentationSaid71% (7)

- PPIIDocument1,106 pagesPPIIVineeta SharmaNo ratings yet

- Journal of Radiation Research and Applied Sciences: Abdullah Al Naim, Nisrin Alnaim, Sobhy S. Ibrahim, S.M. MetwallyDocument7 pagesJournal of Radiation Research and Applied Sciences: Abdullah Al Naim, Nisrin Alnaim, Sobhy S. Ibrahim, S.M. MetwallySarifatul HidayahNo ratings yet

- Kobel CoDocument4 pagesKobel CoCesar ZarateNo ratings yet

- Experiment 1: Determination of Corrosion Rate of Metals: ObjectiveDocument3 pagesExperiment 1: Determination of Corrosion Rate of Metals: Objective041Mir QazimNo ratings yet

- The Complexometric Determination of Calcium and Magnesium in The Same SampleDocument3 pagesThe Complexometric Determination of Calcium and Magnesium in The Same SampleRieska foni YuniarNo ratings yet

- Buchner J., Kiefhaber T. (Eds.) - Protein Folding Handbook, 5-Volume Set - Wiley (2005) PDFDocument2,590 pagesBuchner J., Kiefhaber T. (Eds.) - Protein Folding Handbook, 5-Volume Set - Wiley (2005) PDFhasrettolgaNo ratings yet

- (De Dios) Science ProjectDocument22 pages(De Dios) Science ProjectRoucyzle Ynnah AcidoNo ratings yet

- Epoxy Curing Agents and ModifiersDocument3 pagesEpoxy Curing Agents and ModifiersNissim Hazar CasanovaNo ratings yet

- MSDS All DNA RNA Purification KitsDocument6 pagesMSDS All DNA RNA Purification Kitsjusman sadorraNo ratings yet

- ECE 6401: MEMS Design & Micromachining: Working Principle of MicrosystemsDocument11 pagesECE 6401: MEMS Design & Micromachining: Working Principle of MicrosystemsAbcNo ratings yet

- Lasers For Industrial Applications - 56850 - 12Document15 pagesLasers For Industrial Applications - 56850 - 12ΈλσαΟγκρένιNo ratings yet

- Chlorine Institute Manual 2000Document68 pagesChlorine Institute Manual 2000Misael RamírezNo ratings yet

- XII PT-1 Phy KeyDocument9 pagesXII PT-1 Phy KeyRoshini SNo ratings yet

- Sedimentation and Sedimentation TanksDocument43 pagesSedimentation and Sedimentation TanksDevendra Sharma80% (10)