Professional Documents

Culture Documents

Aceptance Criteria For Visual-2

Uploaded by

ayu0 ratings0% found this document useful (0 votes)

26 views2 pagesOriginal Title

ACEPTANCE CRITERIA FOR VISUAL-2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views2 pagesAceptance Criteria For Visual-2

Uploaded by

ayuCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

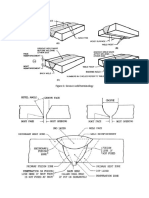

ACEPTANCE CRITERIA FOR VISUAL AND MACRO TESTING

(*FOR EDUCATION PURPOSE ONLY)

No Defect type Acceptance criteria of visual inspection for plate and pipe Acceptance for

macro only

Remarks Maximum allowance Remarks

1 Excess weld At no point shall the excess weld Excess weld metal will not exceed H = 3 As for plate and

metal metal fall below the outside surface mm in any area on the base metal, pipe

of the bases metal. showing smooth transition at weld toes.

All weld runs shall blend smoothly.

2 Inclusion Slag inclusions are defined as non- The length of the slag inclusion shall not Slag and silica

metallic inclusions trapped in the exceed 50 mm continuous or inclusion are not

weed metal or between the weld intermittent. permitted.

metal and the base metal Accumulative total shall not exceed 50

mm.

3 Undercut Undercut is defined as groove No sharp indications, smooth blend No sharp

melted into the parent metal, at the required. indications.

toes of the weld excess metal, root The length of any undercut shall not Smooth blend

or adjacent weld metal exceed 50 mm continuous or required.

intermittent.

Accumulative totals shall not exceed 50

mm.

Max depth D=1 mm for the capping

weld metal.

Root undercut is not permitted.

4 Gas cavities or Trapped gas, in weld metal, Individual pores ≤ 1.5 mm, max. Cluster porosity

porosity elongated, individual pores, cluster Cluster porosity maximum 50 mm2 total not permitted.

porosity, piping or wormhole area. Individual pores

porosity. Elongated, piping or wormholes 15 mm are acceptable.

max length continuous or intermittent.

5 Cracks or Transverse, longitudinal, star or Not permitted. Not permitted

laminations crater cracks.

6 Incomplete Incomplete fusion between the weld Surface breaking incomplete fusion Not permitted

fusion metal and base metal, incomplete continuous or intermittent not to exceed

fusion between weld metal. 15 mm.

Accumulative totals not to exceed 15

mm over a 300 mm length of weld.

7 Arc strikes Damage to the base metal or weld Not permitted Not permitted

metal, from an unintentional

touchdown of electrode or arcing

from poor connections in the

welding circuit.

8 Mechanical Damage to the base metal or weld No stray tacks weld permitted. Not permitted

damage metal, internal or external resulting Base metal must be smoothly blended.

from any activities. General corrosion permitted.

Max depth D=1.5mm.

Only 1 location allowed.

9 Misalignment Mismatch between the welded or Max H = 1.5 mm As for plate and

unwelded joint. pipe

10 Excessive Excess weld metal, above the base Max H ≤ 3 mm As for plate and

penetration metal in the root of the joint. pipe

11 Incomplete The absence of weld metal in the Not permitted. Not permitted

penetration root area, two root faces showing.

Inadeguate cross penetration of one

root face

12 Burn through Excessive penetration, collapse of Not permitted Not permitted

the weld root

13 Angular Distortion due to weld contraction. Max 5 mm. Plate only. Accept

distortion

14 Root concavity Weld metal below the surface of Max length L=50 mm, max depth D=3 Accept

both base metals. mm.

You might also like

- WIS5 - Appendix 2Document86 pagesWIS5 - Appendix 2Reza Fakhrizal100% (1)

- Acceptence CriteriaDocument1 pageAcceptence CriteriaPraviBeetlesNo ratings yet

- Acceptance CriteriaDocument1 pageAcceptance CriteriaRamzi Dol Abdul Wahid50% (2)

- Acceptance Level TWI SampleDocument1 pageAcceptance Level TWI SampleFadhlan D Luffy100% (1)

- Acceptance Criteria For CSWIP 3.1Document19 pagesAcceptance Criteria For CSWIP 3.1Muhammed Abo-Fandood100% (5)

- Acceptance CriteriaDocument19 pagesAcceptance CriteriaAnonymous 5iv0i3cZNo ratings yet

- 008rtfi Notes Okdoc CompressDocument19 pages008rtfi Notes Okdoc CompressShahid IqbalNo ratings yet

- 008.rtfi Notes - OkDocument19 pages008.rtfi Notes - OkVivekanandan JNo ratings yet

- Operating Instructions For Eclipse Refractometer - 2013 - EnglishDocument16 pagesOperating Instructions For Eclipse Refractometer - 2013 - Englisharavindan100% (1)

- Weld Imperfection Examination StandardDocument4 pagesWeld Imperfection Examination StandardMohd Akmal ShafieNo ratings yet

- Appendix 1 - Visual Inspection PlateDocument4 pagesAppendix 1 - Visual Inspection PlateLaith Salman100% (1)

- Welding TolerancesDocument3 pagesWelding Tolerancessaeedsaeed31No ratings yet

- 10 Welding Defect (LSNG PRINT)Document45 pages10 Welding Defect (LSNG PRINT)rahmad musliadiNo ratings yet

- Acceptance Criteria in Welding TableBDocument1 pageAcceptance Criteria in Welding TableBanishk6336No ratings yet

- Figure 1: Groove Weld TerminologyDocument28 pagesFigure 1: Groove Weld TerminologyAmyNo ratings yet

- Welding DefectsDocument122 pagesWelding DefectsqaNo ratings yet

- Visual Inspection Acceptance CriteriaDocument2 pagesVisual Inspection Acceptance CriteriaJohn TerryNo ratings yet

- Acceptable Weld ProfilesDocument14 pagesAcceptable Weld ProfilesMark Miano100% (1)

- VT Acceptance Criteria PDFDocument10 pagesVT Acceptance Criteria PDFKalaivel ThandavarayanNo ratings yet

- Tolerance As Per AWS D1.1Document3 pagesTolerance As Per AWS D1.1milind bedarkarNo ratings yet

- Welding FLAWSDocument86 pagesWelding FLAWSrohitbhat2345100% (1)

- 3 Welding Imperfections (Edited)Document80 pages3 Welding Imperfections (Edited)PraviBeetlesNo ratings yet

- Welding Defects Ala'aDocument48 pagesWelding Defects Ala'asbmmlaNo ratings yet

- Significance of Defects in WeldsDocument9 pagesSignificance of Defects in Weldsssk48100% (1)

- GR 11 ReportDocument14 pagesGR 11 ReportVanessa HadJeanxNo ratings yet

- Visual Inspection of Defects and DiscontinuitiesDocument21 pagesVisual Inspection of Defects and Discontinuitiessanketpavi21No ratings yet

- D 11.1 KPTMDocument6 pagesD 11.1 KPTMNayan RamyaNo ratings yet

- A L F I: Cceptance Imit OR MperfectionsDocument29 pagesA L F I: Cceptance Imit OR MperfectionsDavid MacatangayNo ratings yet

- Weld Defects TrainingDocument77 pagesWeld Defects TrainingQC apollohx100% (1)

- Bs4872 Visual ApprovalDocument1 pageBs4872 Visual Approvalkjmcbain100% (1)

- Acceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Document4 pagesAcceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Lipika Gayen100% (1)

- Shielded Metal Arc Welding (SMAW) NC II: Worksheet Week 4Document9 pagesShielded Metal Arc Welding (SMAW) NC II: Worksheet Week 4Tommy Dela CruzNo ratings yet

- 1104 Acceptance Criteria For NDTDocument6 pages1104 Acceptance Criteria For NDTMd faizan AlamNo ratings yet

- Welding DefectDocument14 pagesWelding DefectAfewerk RedaNo ratings yet

- Weld DefectsDocument47 pagesWeld DefectsPratikNo ratings yet

- Grade 12: Shielded Metal Arc WeldingDocument10 pagesGrade 12: Shielded Metal Arc WeldingDarry BlanciaNo ratings yet

- Visual Weld Inspection Work InstructionDocument8 pagesVisual Weld Inspection Work InstructionAgustín Antonio Flores RomeroNo ratings yet

- Cross Over The Root Centerline: Longitudinal Cracks Transverse Cracks Crater Cracks Base Metal CracksDocument1 pageCross Over The Root Centerline: Longitudinal Cracks Transverse Cracks Crater Cracks Base Metal CracksjavierNo ratings yet

- Bolted ConnectionsDocument10 pagesBolted ConnectionsAbhi ANo ratings yet

- Defect ID: Lack of Fusion (LOF)Document5 pagesDefect ID: Lack of Fusion (LOF)Amit HasanNo ratings yet

- Welding DefectDocument33 pagesWelding DefectabdoNo ratings yet

- Radiographic DefectsDocument20 pagesRadiographic DefectsUsman AhmedNo ratings yet

- Welding ImpuritiesDocument11 pagesWelding ImpuritiesapNo ratings yet

- Defects in Fusion WeldingDocument83 pagesDefects in Fusion WeldingBalakumar100% (1)

- C ASingDocument3 pagesC ASingGabriela MotaNo ratings yet

- Acceptance Criteria To TR1826Document1 pageAcceptance Criteria To TR1826Adisak Aumpiem0% (1)

- Effect of Elemental Sulfur On Pitting Corrosion of SteelsDocument8 pagesEffect of Elemental Sulfur On Pitting Corrosion of SteelsGovindan KrishnamoorthybashyamNo ratings yet

- Bolted Connection (Wk7-Wk10)Document20 pagesBolted Connection (Wk7-Wk10)Ma. Angelica TamayaoNo ratings yet

- ConnectorsDocument36 pagesConnectorsSherif El Sayed100% (2)

- Overlap: Weld ProfileDocument8 pagesOverlap: Weld ProfilejoNo ratings yet

- TWI Training CSWIP 3.1 PlateDocument8 pagesTWI Training CSWIP 3.1 PlateSepthian DS100% (2)

- Welding Defects Causes & SolutionsDocument30 pagesWelding Defects Causes & SolutionsAkshay Kumar100% (1)

- 10 Welding Defects & RemediesDocument12 pages10 Welding Defects & RemediesvilukNo ratings yet

- Door Frame MethodologyDocument8 pagesDoor Frame Methodologychhaya BhardwajNo ratings yet

- Welding Is The Process of Permanently Joining Two or More Metal Parts, by Melting BothDocument3 pagesWelding Is The Process of Permanently Joining Two or More Metal Parts, by Melting BothSuleman KhanNo ratings yet

- Xample Program in C++ Using File Handling To Perform Following OperationsDocument6 pagesXample Program in C++ Using File Handling To Perform Following OperationsNamita SahuNo ratings yet

- ValvesDocument1 pageValvesnikhilNo ratings yet

- Prince CPVC Pipes and Fittings Pricelist1Document1 pagePrince CPVC Pipes and Fittings Pricelist1Dee Raja38% (8)

- Manual M810Document38 pagesManual M810romiyuddinNo ratings yet

- Mechanical and Micro Structure of MDF Processed MaterialDocument8 pagesMechanical and Micro Structure of MDF Processed MaterialSharath P CNo ratings yet

- Operating Check List For Disel Generator: Date: TimeDocument2 pagesOperating Check List For Disel Generator: Date: TimeAshfaq BilwarNo ratings yet

- AIS - 007 - Rev 5 - Table - 1Document21 pagesAIS - 007 - Rev 5 - Table - 1Vino Joseph VargheseNo ratings yet

- Set-1-Index001-ERA - ERTMS - 003204 v500 Functional Requirements SpecificationDocument98 pagesSet-1-Index001-ERA - ERTMS - 003204 v500 Functional Requirements SpecificationShauna MooreNo ratings yet

- Bio GasDocument4 pagesBio GasRajko DakicNo ratings yet

- Spring Setting of Piping Connected To A CompressorDocument4 pagesSpring Setting of Piping Connected To A CompressorSharun SureshNo ratings yet

- TravelerSafe ReadMe PDFDocument17 pagesTravelerSafe ReadMe PDFnatadevxNo ratings yet

- DataDocument85 pagesDataMyk Twentytwenty NBeyond100% (1)

- Troubleshooting: Fully Automated Urine Particle AnalyzerDocument108 pagesTroubleshooting: Fully Automated Urine Particle Analyzerjw lNo ratings yet

- Understanding ZTPFDocument41 pagesUnderstanding ZTPFsanjivrmenonNo ratings yet

- Final Exam Review Questions Funds of SecurityDocument65 pagesFinal Exam Review Questions Funds of Securityidk80% (5)

- McGraw-Hill (Level 1) PDFDocument41 pagesMcGraw-Hill (Level 1) PDFDarpan GajjarNo ratings yet

- DatasheetDocument2 pagesDatasheetTesfay Zemuy GebrekidanNo ratings yet

- Tubewell Energy Audit PDFDocument172 pagesTubewell Energy Audit PDFshaheerdurrani100% (1)

- Dokumen - Tips Cfm56 7 B AnswerbookDocument75 pagesDokumen - Tips Cfm56 7 B AnswerbookOnur YayNo ratings yet

- Aadhaar Application FormDocument4 pagesAadhaar Application Formpan cardNo ratings yet

- 3.1 Turbine and GoverningDocument90 pages3.1 Turbine and GoverningYudo Heru PribadiNo ratings yet

- DC GenDocument66 pagesDC Genjonathan_awayan733286% (71)

- Clean Energy Council Installers Checklist PDFDocument3 pagesClean Energy Council Installers Checklist PDFAndre SNo ratings yet

- Relay Performance Testing: Jay Gosalia Vice President of Engineering and Marketing Doble Engineering Company, USADocument40 pagesRelay Performance Testing: Jay Gosalia Vice President of Engineering and Marketing Doble Engineering Company, USArashid rahmanNo ratings yet

- Sorona - Product InformationDocument4 pagesSorona - Product InformationchristianNo ratings yet

- fmx4 PartsDocument1 pagefmx4 PartsФедя ФедяNo ratings yet

- Oem National 14-P-220 7500psiDocument9 pagesOem National 14-P-220 7500psiandrew0% (1)

- Munday CH 5.3-5.3.1 Skopos TheoryDocument11 pagesMunday CH 5.3-5.3.1 Skopos TheoryEvelina Tutlyte100% (1)

- Patch Apply Instructions 19852360.HTMLDocument60 pagesPatch Apply Instructions 19852360.HTMLdineshNo ratings yet

- 15ME11E - Solar PV - Question BankDocument15 pages15ME11E - Solar PV - Question BankvigneshNo ratings yet