Professional Documents

Culture Documents

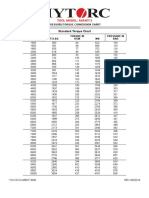

STEALTH 36 Torque Conversion Chart

STEALTH 36 Torque Conversion Chart

Uploaded by

chinedu0 ratings0% found this document useful (0 votes)

8 views2 pagesOriginal Title

STEALTH-36-Torque-Conversion-Chart

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesSTEALTH 36 Torque Conversion Chart

STEALTH 36 Torque Conversion Chart

Uploaded by

chineduCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

TOOL MODEL: STEALTH 36

PRESSURE/TORQUE CONVERSION CHART

Standard Torque Chart

PRESSURE IN TORQUE IN PRESSURE IN

PSI FT.LBS. KGM NM BAR

1500 4917 680 6665 104

1600 5255 727 7123 110

1800 5931 820 8040 124

2000 6607 914 8956 138

2200 7309 1011 9909 152

2400 8012 1108 10861 165

2600 8715 1205 11814 179

2800 9417 1302 12766 193

3000 10120 1400 13719 207

3200 10814 1496 14659 220

3400 11508 1592 15600 234

3600 12202 1688 16541 248

3800 12896 1784 17482 262

4000 13590 1879 18423 276

4200 14295 1977 19378 290

4400 14999 2074 20333 303

4600 15704 2172 21288 317

4800 16409 2269 22244 331

5000 17113 2367 23199 345

5200 17819 2464 24155 358

5400 18525 2562 25112 372

5600 19230 2660 26069 386

5800 19936 2757 27025 400

6000 20642 2855 27982 414

6200 21354 2953 28947 427

6400 22066 3052 29912 441

6600 22778 3150 30877 455

6800 23490 3249 31843 468

7000 24202 3347 32808 482

7200 24914 3446 33774 496

7400 25627 3544 34740 510

7600 26340 3643 35706 524

7800 27052 3741 36672 538

8000 27765 3840 37638 552

8200 28462 3936 38583 565

8400 29159 4033 39528 579

8600 29856 4129 40473 593

8800 30553 4225 41418 607

9000 31250 4322 42363 620

9200 31944 4418 43304 634

9400 32639 4514 44245 648

9600 33333 4610 45186 662

9800 34028 4706 46128 676

10000 34722 4802 47069 690

* ISO DOCUMENT 9000 REV. 08/04

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Your HYTORC TORQUE MACHINE is a power tool, and as with any power tool, certain safety precautions

should be observed to avoid accidents or personal injury. The following tips will assist you.

READ ALL INSTUCTIONS.

KEEP WORK AREA CLEAN AND WELL LIT.

CONSIDER WORK AREA ENVIRONMENT.Electrical Pumps should never be used in an atmosphere which

can be considered potentially volatile. If there is any doubt, use an air pump. Also Note: metal to metal contact

can cause sparks, precautions should be taken.

AVOID PREMATURE TOOL STARTING. The Pump Remote Control is for the TOOL OPERATOR only.

STAY CLEAR DURING OPERATION. In most cases, the tool will allow “hands free” operation. If the tool must

be held or steadied during operation, use alternative means of securing the tool to the application

GUARD AGAINS ELECTRIC SHOCK. Ensure the pump is properly grounded and the proper voltage is being

used

STORE IDLE TOOLS. When not in use, tool sand accessories should be properly stored to avoid deterioration

USE RIGHT TOOL. Don’t force small tools or attachments to do the job of a larger tool. Don’t use a tool for

purposes not intended.

PROPER SAFETY ATTIRE. When handling/operating hydraulic equipment use work gloves, hard hats, safety

shoes and other applicable clothing.

USE SAFETY GLASSES.

MOVING EQUIPMENT. Do not use hydraulic hoses, uni-swivels, pump power or remote cords as means of

moving the equipment.

MAINTAIN TOOLS WITH CARE. For top performance, inspect tools, powerpack and accessories for visual

damage frequently and always prior to use. Always follow instruction for proper tool and pump maintenance.

Refer to the Operations Maintenance Section for further clarification

STAY ALERT. Watch what you are doing. Use Common sense. Do not use power equipment under the

influence of any mood altering substances.

PRIOR TO OPERATION

Ensure that all hydraulic connections are securely connected and there is no leakage

Verify that the Hydraulic hoses are not kinked or otherwise damaged.

Ensure the square drive and its retainer are fully and securely engaged.

Be certain that all connectors, elbows, fitting and swivels are not bent, loose or damaged.

PRIOR TO USE.

Check sockets for size, quality and flaws. (Do not use if questionable)

Cycle tool to ensure proper function.

Locate a solid, secure reaction point.

Be sure the reaction arm retaining clamp is fully engaged.

Be sure the hydraulic hoses are free of the reaction point.

Pressurize the system momentarily; if the tool tends to “ride up” or to “creep”, stop and re-adjust the

reaction arm to a more solid andsecure position.

NOTE: Remain clear of the reaction arm during operation and never put body parts between reaction arm and

reaction surfaces.

ALWAYS USE QUALITY ACCESSORIES. Always use top quality impact sockets in good condition which are

the correct size and fully engage the nut. Hidden flaws, however, remain a possibility which could cause

breakage, so stay clear of sockets during operation

DO NOR USE other equipment to enhance performance (Hammer on Socket/Tool)NOTE: Hytorc Pumps are

designed to operate Hytorc Tools only. Damage may occur to the pump or the product that is being operated

due to misuse.

SAVE THESE INSTRUCTIONS FOR FUTURE USE!

You might also like

- Ebook Developing Human 9Th Edition Moore Test Bank Full Chapter PDFDocument30 pagesEbook Developing Human 9Th Edition Moore Test Bank Full Chapter PDFStacieSharpnocje89% (9)

- Standard Torque Chart: Tool Model: MXT 1Document2 pagesStandard Torque Chart: Tool Model: MXT 1Wahyu WidiyantoNo ratings yet

- AVANTI 3 Torque Conversion ChartDocument2 pagesAVANTI 3 Torque Conversion ChartJovani SecrettiNo ratings yet

- ICE 1 Torque Conversion ChartDocument2 pagesICE 1 Torque Conversion ChartDeivid BezerraNo ratings yet

- Captura de Pantalla 2022-03-30 A La(s) 20.30.14Document2 pagesCaptura de Pantalla 2022-03-30 A La(s) 20.30.14Manuel CaipoNo ratings yet

- Tabla STEALTH 14Document2 pagesTabla STEALTH 14luz_cuellar_15No ratings yet

- mxt10 PDFDocument2 pagesmxt10 PDFTaufikNo ratings yet

- Hytorc Avanti 3 Torque ChartDocument2 pagesHytorc Avanti 3 Torque ChartDarwin Tovar ZuriqueNo ratings yet

- Tool Model: HY-3MXT: Pressure/Torque Conversion ChartDocument2 pagesTool Model: HY-3MXT: Pressure/Torque Conversion ChartBhavin GamiNo ratings yet

- XLCT 14Document2 pagesXLCT 14carlosNo ratings yet

- Tool Model: Hy-5Xlt: Standard Torque ChartDocument2 pagesTool Model: Hy-5Xlt: Standard Torque ChartFabioNo ratings yet

- RT10 Torque ChartDocument2 pagesRT10 Torque ChartRoy Ramos100% (1)

- RTX04 Torque ChartDocument1 pageRTX04 Torque ChartYang Kyo OhNo ratings yet

- Datasheet LR 13000Document13 pagesDatasheet LR 13000RasoolKhadibi100% (1)

- Stealth Torque Pressure ChartDocument3 pagesStealth Torque Pressure Chartnarft narftNo ratings yet

- 1 May 2019 Avocab New LP New March W.E.F - May 1stDocument1 page1 May 2019 Avocab New LP New March W.E.F - May 1stKaushal JhaNo ratings yet

- TableBookErrata PDFDocument4 pagesTableBookErrata PDFLutfi LailaNo ratings yet

- Hazen William Formula PDFDocument4 pagesHazen William Formula PDFMac ShaikNo ratings yet

- TableBookErrata PDFDocument4 pagesTableBookErrata PDFIbnuyusoff77No ratings yet

- Hazen-Williams Formula PDFDocument4 pagesHazen-Williams Formula PDFyehuoy100% (1)

- EDGE 6 - Torque - Conversion - ChartDocument1 pageEDGE 6 - Torque - Conversion - ChartindunilNo ratings yet

- General Testing and Adjusting InformationDocument3 pagesGeneral Testing and Adjusting InformationmkNo ratings yet

- DIN 2215 V Belt SpecificationDocument1 pageDIN 2215 V Belt SpecificationumeshNo ratings yet

- XLCTTorqueDocument4 pagesXLCTTorqueSebastin DrignyNo ratings yet

- 3MXT Torque ConversionDocument2 pages3MXT Torque ConversionRodrigo SanzNo ratings yet

- Satuan GDocument1 pageSatuan GWoro IndrianiNo ratings yet

- Price List For LT Aluminium Cables: May - 2021Document5 pagesPrice List For LT Aluminium Cables: May - 2021Sandeep GMNo ratings yet

- Measurements For Anchor-Chain and AccessoriesDocument4 pagesMeasurements For Anchor-Chain and AccessoriesOzata TersanesiNo ratings yet

- HTL DS Series Torque Pressure ChartDocument1 pageHTL DS Series Torque Pressure ChartElmo JuiceNo ratings yet

- Pressure Versus Torque - S-Series Torque WrenchesDocument5 pagesPressure Versus Torque - S-Series Torque WrenchesManga MinNo ratings yet

- Marine Chain DataDocument7 pagesMarine Chain DataIrwan SyahNo ratings yet

- Catalogo Generadores SincronosDocument11 pagesCatalogo Generadores SincronosMirko Yanque TomasevichNo ratings yet

- Spinlock Conversion ChartDocument1 pageSpinlock Conversion ChartjmairadoNo ratings yet

- Flow, KV Values and Zeta Values For Gate Valves, Resilient Seated Appendix 6Document3 pagesFlow, KV Values and Zeta Values For Gate Valves, Resilient Seated Appendix 6Imtiyaz KhanNo ratings yet

- GC-3000 Torque ChartDocument1 pageGC-3000 Torque Chartgerryocnahron86No ratings yet

- WKT/WKTR/WKB 6 Design Data: 6.1 WeightsDocument6 pagesWKT/WKTR/WKB 6 Design Data: 6.1 WeightsWibowo ArieNo ratings yet

- KEI AEC Wires Cables Full Price List 28 February 2022Document6 pagesKEI AEC Wires Cables Full Price List 28 February 2022anirban 007No ratings yet

- RR KABEL Price List - LT HT Cables - 01st February 2023Document4 pagesRR KABEL Price List - LT HT Cables - 01st February 2023threephase electricNo ratings yet

- Atlas Copco TFX08 Torque ChartDocument1 pageAtlas Copco TFX08 Torque Chartgauthamac07No ratings yet

- Generator KVA KW Amp ChartDocument2 pagesGenerator KVA KW Amp ChartSajid MahmoodNo ratings yet

- Generator kVA-kW-Amp Chart PDFDocument2 pagesGenerator kVA-kW-Amp Chart PDFAEE MHCH Sub Div 1stNo ratings yet

- VF730 & VF733 - AGA ApprovedDocument8 pagesVF730 & VF733 - AGA ApprovedJamyansuren TseveendorjNo ratings yet

- Auditorium TX - Dimensions - and - Capacity - GuideDocument2 pagesAuditorium TX - Dimensions - and - Capacity - GuideChong Hong RuiNo ratings yet

- Load Inertia TablesDocument7 pagesLoad Inertia TablesgabrielaNo ratings yet

- FLOWTITE Handling and StorageDocument13 pagesFLOWTITE Handling and StorageMohammed khaleelNo ratings yet

- Br. Naziv Prostorije Gubici (W) Tip Radijatora Dužina (CM) Izaberi Tip 0 Temp (°C) Površina (m2) Po Radijatoru Protok Grijanje (KG/H)Document5 pagesBr. Naziv Prostorije Gubici (W) Tip Radijatora Dužina (CM) Izaberi Tip 0 Temp (°C) Površina (m2) Po Radijatoru Protok Grijanje (KG/H)Damir ĆavarNo ratings yet

- Powersoft TN005 PeakOutVoltage en v1.0Document2 pagesPowersoft TN005 PeakOutVoltage en v1.0victor mogajane100% (1)

- Rezistoare-Valori Standard de SerieDocument1 pageRezistoare-Valori Standard de SerieRobert ViorelNo ratings yet

- Hydraulic Torque Wrench Operation ManualDocument18 pagesHydraulic Torque Wrench Operation Manualahmad fahmeyNo ratings yet

- PH Hydraulic Torque Wrench Instruction ManualDocument23 pagesPH Hydraulic Torque Wrench Instruction ManualLikLiek WahahaNo ratings yet

- Duzina Kabla Na DobosimaDocument3 pagesDuzina Kabla Na DobosimaDe RNo ratings yet

- TFX02 Torque ChartDocument1 pageTFX02 Torque ChartArnulfo SánchezNo ratings yet

- Face-To-Face Valve Dimensions - EN-558-1: DN Basic SeriessDocument3 pagesFace-To-Face Valve Dimensions - EN-558-1: DN Basic Seriessdona_001No ratings yet

- Polycab22 3Document2 pagesPolycab22 3Velu SNo ratings yet

- Nozzle Load TableDocument27 pagesNozzle Load TableRamuAlagappanNo ratings yet

- Pressure Vs Torque Conversion Chart: Titan T Series ToolsDocument1 pagePressure Vs Torque Conversion Chart: Titan T Series ToolsHanselPerezAguirreNo ratings yet

- Ax Contactor Catalogue 1524473646Document40 pagesAx Contactor Catalogue 1524473646Sami SalmanNo ratings yet

- Stored Energy Solutions For A Demanding World: SpecificationsDocument2 pagesStored Energy Solutions For A Demanding World: SpecificationsALEX ALEXNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- King S Bride Chronicles Beck MichaelsDocument492 pagesKing S Bride Chronicles Beck MichaelsMeylinNo ratings yet

- Distal Tibia Paper 2Document6 pagesDistal Tibia Paper 2Rajib DebnathNo ratings yet

- 34 Pilates ExercisesDocument7 pages34 Pilates ExerciseskerryNo ratings yet

- Rehabilitation of Lateral Ankle Sprains in SportsDocument13 pagesRehabilitation of Lateral Ankle Sprains in SportsEmilio RobledoNo ratings yet

- Vocabulary Basic Unit6 Without Answers PDFDocument1 pageVocabulary Basic Unit6 Without Answers PDFMiguel SoaresNo ratings yet

- Pediatric Injury Manual 2019Document176 pagesPediatric Injury Manual 2019smith.kevin1420344No ratings yet

- Lime Standard PDFDocument7 pagesLime Standard PDFJose SalazarNo ratings yet

- Jsa For Cable PullingDocument9 pagesJsa For Cable Pullingshaibaz chafekarNo ratings yet

- Summary Boxes Tables Illustrated Figures of Bailey Love's Surgery (27thDocument304 pagesSummary Boxes Tables Illustrated Figures of Bailey Love's Surgery (27thrauga dragoNo ratings yet

- Portrait SculptingDocument10 pagesPortrait SculptingadrianNo ratings yet

- Health Problems and RemediesDocument2 pagesHealth Problems and RemediesLuisaNo ratings yet

- Arnica Montana: Spheres of ActionDocument5 pagesArnica Montana: Spheres of ActionSuhas Ingale50% (2)

- BERNARDINO JIMENEZ v. CITY OF MANILADocument2 pagesBERNARDINO JIMENEZ v. CITY OF MANILAGellomar AlkuinoNo ratings yet

- Thermolator Heatrac User GuideDocument98 pagesThermolator Heatrac User GuideValeria SarahiNo ratings yet

- First Aid: By: Sem. Winmark S. PerdiganDocument18 pagesFirst Aid: By: Sem. Winmark S. PerdiganWinsley RazNo ratings yet

- Hazard Sheet 14: Manual HandlingDocument3 pagesHazard Sheet 14: Manual HandlingcerajibNo ratings yet

- Fractures of The HipDocument198 pagesFractures of The HipPutri habna100% (1)

- Chapter 9Document25 pagesChapter 9Wonderful TechnologiesNo ratings yet

- Survey of The VictimDocument52 pagesSurvey of The VictimLodi PetmaluNo ratings yet

- Toshiba Xario XG User ManualDocument25 pagesToshiba Xario XG User ManualMonica Fajardo100% (1)

- Government Safety Engineer'S Accident Investigation ReportDocument1 pageGovernment Safety Engineer'S Accident Investigation ReportDon Aries EidosNo ratings yet

- Module 6Document22 pagesModule 6Jhoanna Lovely OntulanNo ratings yet

- Cerebral PalsyDocument96 pagesCerebral PalsyRahini PaniNo ratings yet

- Upper Limb OrthosesDocument29 pagesUpper Limb OrthosesMaryam KhalidNo ratings yet

- TT15 Knee Full S - 636512664914290776Document88 pagesTT15 Knee Full S - 636512664914290776CARLOSNo ratings yet

- Clase de Ingles Sesión 11Document5 pagesClase de Ingles Sesión 11trafaelNo ratings yet

- Criminal Law Ii Notes: Non-Fatal Offences Affecting Human BodyDocument43 pagesCriminal Law Ii Notes: Non-Fatal Offences Affecting Human BodyWai LingNo ratings yet

- Coc Preparation Question: Prepared by Tammirat B. True Knowledge Has No Measure !!!Document16 pagesCoc Preparation Question: Prepared by Tammirat B. True Knowledge Has No Measure !!!habtamuNo ratings yet

- SP HseDocument157 pagesSP HseDie HArdNo ratings yet