Professional Documents

Culture Documents

73 - SOP - Utlisation of Aluminium Dross Silicon

Uploaded by

Mukesh SoniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

73 - SOP - Utlisation of Aluminium Dross Silicon

Uploaded by

Mukesh SoniCopyright:

Available Formats

990

23487/2021/WM-II-HO

Standard Operating Procedure and Checklist of Minimal

Requisite Facilities for utilization of hazardous waste under Rule 9

of the Hazardous and Other Wastes (Management and

Transboundary Movement) Rules, 2016

Pre-processing of Waste Silicon Carbide Refractory bricks from

Pot Lining Waste generated from primary Aluminium smelters

December, 2021

Central Pollution Control Board

(Ministry of Environment, Forest & Climate Change, Government of India)

Parivesh Bhawan, East Arjun Nagar,

Shahdara, Delhi - 110032

991

23487/2021/WM-II-HO

Pre-processing of waste Silicon Carbide Refractory bricks from Pot Lining Waste

generated from primary Aluminium smelters

Procedure for grant of authorization by State Pollution Control Boards

(SPCBs)IPollution Control Committee (PCCs) for utilization of Hazardous waste

1) While granting authorization for utilization of hazardous wastes, SP.CBsiPCCs shall

ensure that authorization is given only to those wastes for which Standard Operating

Procedures (SoPs) for utilization have been circulated by Central Pollution Control Board

(CPCB) ensuring the following :

a. The waste (intended for utilization) should have similar source of generation as

specified in SoP.

b. The utilization shall be similar to as described in SoP.

c. End-use I product produced form the waste shall be same as specified in SoP.

d. Authorisation shall be granted only after verification of details and minimum requisite

facilities as given in SoP.

e. Issuance of passbooks (similar to the passbooks issued for recycling of used oils, waste

oil, non-ferrous scraps, etc.) for maintaining records of receipt of hazardous wastes for

utilization.

2) After issuance of authorization, SPCB shall verify the compliance of checklist and SOPs

on quarterly basis for initial 02 years; followed by random checks in subsequent period for

at least once in every year.

3) In-case of lack of requisite infrastructures with the SPCBs/PCCs, they may engage 3rct

party institutions or laboratories having EPA, 1986/NABL/ISO 17025 accreditation/

recognition for monitoring and analysis of prescribed parameters in SoP for verification

purpose.

4) SPCBs/PCCs shall provide half yearly updated list of units permitted under Rule 9 of

Hazardous & Other Wastes (Management & Transboundary Movement) Rules, 2016

(HOWM Rules, 2016) to CPCB and also upload the same on SPCBIPCC website,

periodically. Such updated list shall be sent to CPCB on a half yearly basis i.e. by July and

January respectively.

5) Authorisation for utilization shall not be given to the units located in the State!UT where

there is no Common TSDF, unless the unit ensures authorised captive disposal of the

hazardous waste (generated during utilization) or its complete utilization or arrangement

of sharing with any other authorised disposal facility.

6) In case of the utilization proposal is not similar with respect to source of generation or

utilization process or end-use as outlined in this SoP, the same may be referred to CPCB

for clarification I conducting trial utilization studies and developing SoPs thereof.

7) The source and work zone standards suggested in the SoPs are based on the E(P)A notified

and OSHA standards respectively, however, SPCBsiPCCs may impose more stringent

~

standards based on the location or process specific conditions.

Waste Management Division, CPCB, Delhi

1 1 r 1 (~ r

992

23487/2021/WM-II-HO

Pre-processing of waste Silicon Carbide Refractory bricks from Pot Lining Waste

generated from primary Aluminium smelters

72.0 Pre-processing of waste Silicon Carbide Refractory bricks:

TypeofHW Source of Recovery /Product

generation

Silicon Carbide Refractory Primary Silicon carbide refractory powder

bricks from Pot lining Waste Aluminium for use as raw material for silicon

Category 11.2 of Schedule I smelters carbide and other refractory bricks

of HOWM Rules, 20 I 6) manufacturing.

72.1 Source of Waste

In aluminium smelting process, there is a refractory liner between the carbon layer and steel

casing of melting pot for insulation. After the end of pot life, the liners are discarded as pot liner

waste, which is classified as hazardous waste due to high leaching potential for fluoride, cyanide

and release of harmful gases in reaction with water. The refractory layers including silicon

carbide bricks are categorized as hazardous waste - category 11.2 of Schedule I of HOWM

Rules, 2016 which is required to be disposed in authorized disposal facility in accordance with

authorization condition, when not utilized for resource/energy recovery.

There is a possibility of utilising waste refractory material for producing renewed refractory

material, especially the silicon carbide bricks, DIM (Alz03 castable refractory), calcium silicate

bricks, insulating bricks (both refractory and clay bricks), etc.

72.1.1 Steps to identify and segregate silicon carbide from refractory layers of SPL

Carbon Portion :

l. Cathode Block

Feeder 2. Anode Rod

Refractory Portion :

3. Shell+ Side Lining

4. Ramming Paste

5. Refractory Layer

Bath

Side Ljdgel

Shell 3

Side Lmmg l.;l

Ramming Pa~

Co!leetor Bar

Heatlnaulltion

[]

Refr-actory l.ayer

Figure 1: Silicon Carbide refractory bricks are mainly installed in (3) Shell+ Side lining of

Refractory portion

Waste Management Division, CPCB, Delhi

2 1 Page

993

23487/2021/WM-II-HO

Pre-processing of waste Silicon Carbide Refractory bricks from Pot Lining Waste

generated from primary Aluminium smelters

ock

Installation

Thennal

ltlSulation insulation

material

Figure 2: Fresh Silicon Carbide bricks installation Figure 3: Silicon Carbide brick

in Side Wall of Pot. location in refractory layer of pot

References:

Fig. 1: https://www. lightmetalar:e. c om/newslindustrv~newslsme lting:/the -spl- waste-management -challenr:e-in-

primarv-aluminuml

Fig. 2: http://know1edgeplatform. in/wp-content/up/oads/20 15110/Sma/1-Group-Activitv-on-Pat-bv-Sesa-

Ster/i te-Limited-Jharsumda. pd(

Fig. 3: Feng-qin LIU, Ming-zhuang X I£, Wei L/U, Hong-liang ZHAO, Footprint ofharmful substances in spent

reduction cell.

1) Waste silicon carbide refractory bricks shall only be procured from primary aluminium

smelting industries excluding carbon portion and other refractory liners of cathode residue

(pot liner waste). Separation of other refractory parts shall be done at generator premises

before transportation to the pre-processor.

2) It is the responsibility of cathode residue generator (Primary Aluminium Smelters) and

pre-processors to ensure proper segregation of waste Silicon carbide bricks from other

refractory layers which should not exceed 5% of total quantity.

Table 1:- Typical Characteristics ofwaste Silicon carbide refractory bricks:

s. Parameters Results Unit s. Parameters Results Unit

no. no.

1 Carbon 5.50 % 17 Lead as Pb 2.78 ppm

2 Silica as Si02 74.25 % 18 Manganese as Mn 40.88 ppm

".) Alumina as Ab03 15.75 % 19 Beryllium as Be <0.10 ppm

4 Iron as Fe 0.60 % 20 Mercury as Hg <0.10 ppm

5 Magnesium as Mg 0.13 % 21 Nickel as Ni 14.42 ppm

6 Phosphorus as P 0.22 % 22 Zinc as Zn 639.3 ppm

7 Potassium as K 0.95 % 23 Total Fluoride 49.68 mg/Kg

8 Sodium as Na 1.23 % 24 Leachable Fluoride 6.93 mg/L

9 Titanium as Ti 0.38 % 25 Total cyanide <0.10 mg/Kg

10 Cadmium as Cd <0.10 ppm 26 Leachable Cyanide <0.10 mg/L

11 Antimony as Sb <0.10 ppm 27 Fe203 8.58 %

12 Chromium as Cr 14.32 ppm 28 Volatile Matter 0.88 %

13 Copper as Cu 21.21 ppm 29 Fixed Carbon 0.44 %

14 Cobalt as Co 2.57 ppm 30 Gross calorific value <200 Kcal/Kg

15 Arsenic as As <0.10 ppm

16 Boron as B 20.78 ppm

Waste Management Division, CPCB, Delhi

3I Page

994

23487/2021/WM-II-HO

Pre-processing ofwaste Silicon Carbide Refractory bricks from Pot Lining Waste

generated from primary Aluminium smelters

72.2 Pre-processing of waste silicon carbide refractory bricks

The waste silicon carbide refractory bricks procured from primary Aluminium smelting

industries are charged into crusher preferably jaw crusher manually. The crushed material

passed through separator to collect in different sizes ( <5 mm). This powdered form of pre-

processed Silicon Carbide is packed and sold to authorized users for manufacturing of

refractory bricks.

Collection ofwaste silicon carbide

refractory bricks from refractory

portion of pot liner waste

Stack

i

Cyclone r---. Bag filter

Separator

<5 mm size

To refractory bricks

manufacturers

Figure 4: Process flow diagram for pre-processing of waste silicon carbide refractory bricks

72.3 Product Usage I Utilization

The product (Silicon Carbide powder) shall be utilized as raw material in manufacturing of

silicon carbide and other refractory bricks only.

72.4 Standard Operating Procedure for utilization

This SoP is applicable only for Pre-processing of waste silicon carbide refractory bricks

generated from primary Aluminium smelters.

1) The waste silicon carbide refractory bricks shall be transported in covered container

mounted on vehicles fitted with requisite safeguards ensuring no spillage of waste m

accordance with provisions stipulated under HO WM Rules, 2016. ~

Waste Mana.5ement Division, CPCB, Delhi

4 IPd !~ ('

995

23487/2021/WM-II-HO

Pre-processing of waste Silicon Carbide Refractory bricks from Pot Lining Waste

generated from primary Aluminium smelters

2) The unit shall store waste silicon carbide refractory bricks in a designated storage area

having concrete flooring with shed and proper ventilation ensuring no rain water intrusion.

3) The transfer of waste silicon carbide refractory bricks to crusher as well as separator shall

be through mechanised system i.e. covered conveyer belt with minimal manual

intervention. In case of manual transfer proper personal protective equipment (PPEs) such

as mask, gloves, safety shoes and helmet shall be provided to the workers.

4) Dust is expected to be formed at crusher and mechanical separator. Therefore, near crusher

and separator the unit shall provide dust cyclone with proper suction and bag filter

followed by stack of height 30 m or as prescribed by concerned SPCB/PCC.

5) The entire system of operation i.e. crusher and separator shall be in a closed system.

6) The unit shall earmarked all machineries, storage areas and APCDs with sign board.

7) The unit shall ensure that hazardous waste i.e. waste silicon carbide refractory bricks

procured as well as product i.e. silicon carbide after pre-processing shall comply with

cyanide and fluoride concentration of <0.1 0 and 7 mg/L respectively based on Toxicity

Characteristic Leaching Procedure (TCLP)/Soluble Threshold Limit Concentration

(STLC). Silicon carbide shall not exceeds concentration limit as specified in Schedule II

ofHOWM Rules, 2016

Cyanide - 20 mg/L [Based on TCLP]

Fluoride- 180 mg/L [Based on STLC]

In case the TCLP and STLC values of grinded silicon carbide refractory exceeds the

prescribed standard for Cyanide and Fluoride, the material shall not be sent for further

processing and the same shall be treated as hazardous waste and sent to TSDF for disposal.

Processed samples shall be tested every month for leaching concentration of CN and F and

the records of the same shall be maintained for verification.

8) The hazardous wastes generated (if any) during utilization process shall be collected and

temporarily stored in non-reactive drums under a dedicated hazardous waste storage area

and be sent to authorized common TSDF or other authorized facility within 90 days from

generation of the waste in accordance with the authorization issued by the concerned

SPCB/PCC. Such storage shall be done under covered storage area with proper ventilation.

9) Prior to pre-processing of waste silicon carbide refractory bricks, the unit shall obtain

authorization for transportation, storage and pre-processing of silicon carbide from the

concerned SPCB/PCC under the HOWM Rules 2016.

10) The unit shall maintain proper ventilation in the work zone and process areas. All

personnel involved in the plant operation shall wear proper PPEs specific to the process

operations involved and type of chemicals handled as per MSDS. The safety precautions

~~~e worker shall be in accordance with the Factory Act, 1948, as amende~eto

Waste Management Division, CPCB, Delhi

Sl

996

23487/2021/WM-II-HO

Pre-processing of waste Silicon Carbide Refractory bricks from Pot Lining Waste

generated from primary Aluminium smelters

11) In case of environmental damages arising due to improper handling of hazardous wastes

including accidental spillage during generation, storage, processing, transportation and

disposal , the occupier (sender or receiver, as the case may be) shall be liable to implement

immediate response measures, environmental site assessment and remediation of

contaminated soil/groundwater/sediment etc. as per the "Guidelines on Implementing

Liabilities for Environmental Damages due to Handling & Disposal of Hazardous Wastes

and Penalty" published by CPCB.

12) The unit shall provide suitable fire safety arrangements and flame proof electrical fittings.

13) During the handling and pre-processing of hazardous waste, the unit shall comply with

requirements in accordance with the Public Liability Insurance Act, 1991 as amended,

wherever applicable.

72.5 Record/Returns Filing

1) The unit shall maintain a passbook issued by the concern SPCB/PCC and maintain details

of each procurement of silicon carbide as mentioned below:

- Address of the sender

- Date of dispatch

-Quantity procured

- Seal and signature of the sender

- Date of Receipt in the premises

2) A log book with information on source. and date of generation/procurement of silicon

carbide, quantity, date wise utilization of the same, quantity of product manufactured,

hazardous waste generation and its disposal, etc. shall be maintained including analysis

report of emission monitoring & effluent discharged, as applicable.

3) The unit shall maintain record of hazardous waste generated, utilized and disposed as per

Form 3 & also file annual returns in Form 4 as per Rule 20 (1) and (2) of the HOWM

Rules, 2016, to concerned SPCB/PCC.

4) The unit shall submit quarterly and annual information on hazardous wastes consumed, its

source, products generated or resources conserved (specifying the details like, type and

quantity of resources conserved) to the concerned SPCB.

72.6 Standards

1) Source emissions from the stack connected to APCD shall comply with the following

Emission standards or as prescribed by the concerned SPCB/PCC, whichever is stringent;

Particulate Matter 50 mg/Nm3

Total Fluoride 25 mg/Nm3

Waste Management Division, CPCB, Delhi

GI P<tgf'

997

23487/2021/WM-II-HO

Pre-proc~essing of waste Silicon Carbide Refractory bricks from Pot Lining Waste

generated from primary Aluminium smelters

2) Fugitive emission in the work zone shall comply with the following standards:

PMIO 5.0 mg/m3 TWA*

Total Fluoride 2.5 mg/m 3 TWA*

Cyanide 5 mg/m3 TWA*

*time-weighted average (TWA) - measured over a penod of 8 hours of operat1on ofprocess.

3) Monitoring of the specified parameters for source emission shall be carried out quarterly

for the first year followed by at least annually in the subsequent year of utilization.

Fugitive emission for specified parameters shall be carried out quarterly. The monitoring

shall be carried out by ISO 17025 accredited or EPA, 1986 approved laboratories and the

results shall be submitted to the concerned SPCB/PCC on a quarterly basis.

72.7 Siting of Industry

..

Facilities for pre-processing of waste silicon carbide refractory bricks shall be located in a

notified industrial area or industrial park/estate/cluster and in accordance with Consent to

Establish issued by the concerned SPCB/PCC.

72.8 Size nf Plant & Efficiency of utilization

99 % recovery of material shall be achieved during pre-processing of waste silicon carbide

refractory bricks. i.e. I MT ofwaste silicon carbide refractory may generate 990Kg of product

(silicon carbide refractory powder).

Therefore, requisite facilities of adequate size of storage shed and other plants & machineries

as given in para 72.9 below shall be installed accordingly.

72.9 Checklist of Minimal Requisite Facilities

Sl. No Particulars

Cool, dry, well-ventilated storage areas (separate for hazardous wastes and product)

1.

earmarked with signs and concrete flooring & shed.

2. Mechanized and closed system for transfer of waste silicon carbide refractory bricks.

3. Closed system of operation i.e. crusher & separator

4. Crusher and Separator

Cyclone with bag filter followed with stack of height 30m or as prescribed by

5.

SPCB/PCC.

*****

~

Waste Management Division, CPCB, Delhi

7l ragP

You might also like

- Procedure For Grant of Authorisation by Spcbs/Pccs For Utilization of Hazardous WasteDocument7 pagesProcedure For Grant of Authorisation by Spcbs/Pccs For Utilization of Hazardous WasteManish PatelNo ratings yet

- Tunsgten - Scrap - Metal - Cutting - 13.04.17utilization of Tungsten Scrap (Tungsten Carbide Insert Tips) Generated From Metal Cutting OperationsDocument8 pagesTunsgten - Scrap - Metal - Cutting - 13.04.17utilization of Tungsten Scrap (Tungsten Carbide Insert Tips) Generated From Metal Cutting OperationsManish PatelNo ratings yet

- 73 - SOP - Utlisation of Aluminium DrossDocument10 pages73 - SOP - Utlisation of Aluminium DrossMukesh SoniNo ratings yet

- Al Dross HandlingDocument12 pagesAl Dross Handlingusha22No ratings yet

- Draft: Is No. TitleDocument8 pagesDraft: Is No. TitleRajeshkumar ElangoNo ratings yet

- UNSATURATEDocument10 pagesUNSATURATEHani KirmaniNo ratings yet

- Pollution Control Mechanism in Iron & Steel PlantDocument89 pagesPollution Control Mechanism in Iron & Steel PlantMohit Kumar DasNo ratings yet

- 73 - SOP - Utlisation of LD or GCP SludgeDocument8 pages73 - SOP - Utlisation of LD or GCP SludgeMukesh SoniNo ratings yet

- Quicklime, Hydrated Lime, and Limestone For Environmental UsesDocument3 pagesQuicklime, Hydrated Lime, and Limestone For Environmental UsesDIAZCORDOBANo ratings yet

- Bentonite Absorber Block (BAB) : Summary of Technical SpecificationsDocument3 pagesBentonite Absorber Block (BAB) : Summary of Technical SpecificationsTharanga RoxNo ratings yet

- SNF InspectionDocument7 pagesSNF InspectionTitik SundariNo ratings yet

- Influence of Compaction On Copper SlagDocument82 pagesInfluence of Compaction On Copper SlagakashNo ratings yet

- Grout Selection Criteria and Recommendation For The OU 7 4 3/14 in Situ Grouting Early Action ProjectDocument32 pagesGrout Selection Criteria and Recommendation For The OU 7 4 3/14 in Situ Grouting Early Action ProjectAyman ElMawardyNo ratings yet

- Research ArticleDocument6 pagesResearch ArticleleogggNo ratings yet

- Fosroc SP495Document8 pagesFosroc SP495John PaulsyNo ratings yet

- Environmental Display Board2Document2 pagesEnvironmental Display Board2laxman8793_587619166100% (1)

- Application of Supported Perovskite-Type Catalysts For Vehicular Emission ControlDocument10 pagesApplication of Supported Perovskite-Type Catalysts For Vehicular Emission ControlKirti GadeNo ratings yet

- Jharkhand State Pollution Control BoardDocument5 pagesJharkhand State Pollution Control BoardANJANI KUMAR SINGHNo ratings yet

- PW - KZ B Èku DH JK (K Fof'kf"v: HKKJRH EkudDocument16 pagesPW - KZ B Èku DH JK (K Fof'kf"v: HKKJRH EkuddivithNo ratings yet

- CIGRE Field & Laboratory Assessment of Room Temperature Vulcanizing Coated Insulators in Harsh Desert EnvironmentDocument12 pagesCIGRE Field & Laboratory Assessment of Room Temperature Vulcanizing Coated Insulators in Harsh Desert EnvironmentMalik Shoaib khalidNo ratings yet

- G - Writereaddata FormB EC Additional Report 13032020M8AI7TH7AmbicaEDSreplyDocument57 pagesG - Writereaddata FormB EC Additional Report 13032020M8AI7TH7AmbicaEDSreplyHardik VavdiyaNo ratings yet

- Application Guide Phenoline Tank ShieldDocument10 pagesApplication Guide Phenoline Tank ShieldNaveed AhmedNo ratings yet

- Feldspar ProcessingDocument4 pagesFeldspar ProcessingaltipatlarNo ratings yet

- Pollution Control Implementation - IIDocument25 pagesPollution Control Implementation - IIMann MehtaNo ratings yet

- Sop For Precious MetalDocument5 pagesSop For Precious MetalChirag JainNo ratings yet

- CTO Rohini 2023Document6 pagesCTO Rohini 2023environment NK AreaNo ratings yet

- Ban BekasDocument13 pagesBan BekasNur Arifin AkbarNo ratings yet

- Pilot Plant Evaluation of Hydrotreating Catalysts For Heavy Gas Oil ConversionDocument3 pagesPilot Plant Evaluation of Hydrotreating Catalysts For Heavy Gas Oil ConversionIan MannNo ratings yet

- PW - KZ B Èku DH JK (K Fof'kf"v: HKKJRH EkudDocument16 pagesPW - KZ B Èku DH JK (K Fof'kf"v: HKKJRH EkudqweqweNo ratings yet

- Frauscher Marcella - 2019 - Capillary GC-EI-MS and Low Energy Tandem MS of Base..Document9 pagesFrauscher Marcella - 2019 - Capillary GC-EI-MS and Low Energy Tandem MS of Base..Leila safiddineNo ratings yet

- Boron Chemicals Pre Feasibility SummaryDocument25 pagesBoron Chemicals Pre Feasibility SummaryDrMohammed KhanNo ratings yet

- JEA Ash Handling Systems Topical Report Rev 1Document22 pagesJEA Ash Handling Systems Topical Report Rev 1Sarfaraz KhanNo ratings yet

- Understanding Refractory API 936 ReadingDocument77 pagesUnderstanding Refractory API 936 ReadingRadi Gohar100% (1)

- Removal of Polyacrylonitrile Oligomers From Acrylic Fiber Wastewater Using Two-Stage FlotationDocument7 pagesRemoval of Polyacrylonitrile Oligomers From Acrylic Fiber Wastewater Using Two-Stage Flotationcarlosalfredo35No ratings yet

- Cte Ongc SpecDocument21 pagesCte Ongc SpecMohamed HushainNo ratings yet

- 2.C.7.b Nickel Production 2019Document11 pages2.C.7.b Nickel Production 2019farizpanghegarNo ratings yet

- KOC-P-004 Part 5Document23 pagesKOC-P-004 Part 5Hari KrishnanNo ratings yet

- Home Land Retex CTE OrderDocument5 pagesHome Land Retex CTE Orderrohith adariNo ratings yet

- Nobuhiro Tanigaki Latest Results of Bottom Ash Handling in JapanDocument23 pagesNobuhiro Tanigaki Latest Results of Bottom Ash Handling in JapanMiuwthNo ratings yet

- CFB Refractory Repair: Power January 2006Document10 pagesCFB Refractory Repair: Power January 2006num0067No ratings yet

- Astm C1529Document3 pagesAstm C1529adolfo camayoNo ratings yet

- Evaluation of Compatibility of Neutron-Shielding Boron Aggregates With Portland Cement in MortarDocument8 pagesEvaluation of Compatibility of Neutron-Shielding Boron Aggregates With Portland Cement in MortarSÜLEYMAN ÖZENNo ratings yet

- Ultramarine Specialty Chemicals - CFE-30-10-2021Document9 pagesUltramarine Specialty Chemicals - CFE-30-10-2021APIIC EENo ratings yet

- 13 - PPSS Plant Design For Waste-To-Energy Ash Valorization 2023 v1Document7 pages13 - PPSS Plant Design For Waste-To-Energy Ash Valorization 2023 v1yohannearachchi2001No ratings yet

- Research Article: Novel Photocatalytic Reactor Development For Removal of Hydrocarbons From WaterDocument8 pagesResearch Article: Novel Photocatalytic Reactor Development For Removal of Hydrocarbons From WaterhusseinhshNo ratings yet

- TechnicalscopeDocument24 pagesTechnicalscopeAhmed YounisNo ratings yet

- 2 YDK 669.1:622.267 O. P Baidin, V. I. Rostovsky, D.E EsezoborDocument11 pages2 YDK 669.1:622.267 O. P Baidin, V. I. Rostovsky, D.E EsezoborROWHEITNo ratings yet

- Astm C1529Document2 pagesAstm C1529SilviaMonica100% (1)

- gsr546 (E)Document7 pagesgsr546 (E)Vinod SaleNo ratings yet

- KEPCO's First 5000 MW of Flue Gas Desulfurization: Babcock & Wilcox Barberton, Ohio, U.S.ADocument6 pagesKEPCO's First 5000 MW of Flue Gas Desulfurization: Babcock & Wilcox Barberton, Ohio, U.S.AVishal RastogiNo ratings yet

- Lombardi 2016Document10 pagesLombardi 2016barti koksNo ratings yet

- Dust Leaching and Copper CementationDocument5 pagesDust Leaching and Copper CementationMaysam MohamNo ratings yet

- Techno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteDocument9 pagesTechno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteTech MongerNo ratings yet

- Refractories: Standard Terminology Relating ToDocument5 pagesRefractories: Standard Terminology Relating ToPrakash MakadiaNo ratings yet

- The Vitrification of High-Level Wastes in FranceDocument10 pagesThe Vitrification of High-Level Wastes in FranceLejing ZhangNo ratings yet

- Refractories: Standard Terminology Relating ToDocument5 pagesRefractories: Standard Terminology Relating ToAnh MinhNo ratings yet

- Topa CTO 2018Document5 pagesTopa CTO 2018nikhil ranjanNo ratings yet

- MCC Comments 1 TechDocument55 pagesMCC Comments 1 TechSUDDHA CHAKRABARTYNo ratings yet

- Ceramic Materials for Energy Applications VIFrom EverandCeramic Materials for Energy Applications VIHua-Tay LinNo ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Code of Practice For Licensed General Waste CollectorsDocument33 pagesCode of Practice For Licensed General Waste CollectorsAizen Myo-o AcitNo ratings yet

- Tds Tasnee 100 Black Revised in 2022Document2 pagesTds Tasnee 100 Black Revised in 2022Amir NawazNo ratings yet

- Classification of Different Welding Processes With PDFDocument4 pagesClassification of Different Welding Processes With PDFMadhu NNo ratings yet

- Internship ReportDocument20 pagesInternship ReportMikiyas KibebewNo ratings yet

- Different Types of CementDocument19 pagesDifferent Types of Cementtuyisabe jean boscoNo ratings yet

- Nomenclature of Face and End Milling CutterDocument4 pagesNomenclature of Face and End Milling CutterIsmael AibisNo ratings yet

- UNIT 3 c.COMPRESSIVE STRENGTH OF CONCRETE HOLLOW BLOCKSDocument12 pagesUNIT 3 c.COMPRESSIVE STRENGTH OF CONCRETE HOLLOW BLOCKSFaher Gaosel WatamamaNo ratings yet

- Tds Protite Fibreglas Clear Casting ResinDocument2 pagesTds Protite Fibreglas Clear Casting ResinLinton EckertNo ratings yet

- Talon Drill Chuck ArborDocument8 pagesTalon Drill Chuck ArborSugeng Ciko DarmintoNo ratings yet

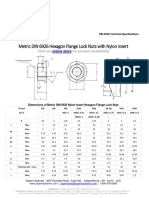

- Metric DIN 6926 SpecDocument4 pagesMetric DIN 6926 Spec叶开No ratings yet

- Research Data SpecsDocument7 pagesResearch Data SpecssahilNo ratings yet

- Recycling MythsDocument6 pagesRecycling MythsvanessaNo ratings yet

- Metal ReferatDocument8 pagesMetal ReferatIordana-Paula ManoleNo ratings yet

- 2075-102-200-A Cameras and LightsDocument1 page2075-102-200-A Cameras and LightsBurak YıldırımNo ratings yet

- The F990 Has Smooth Flow Characteristics, Abrasion, Erosion and Corrosion Resistance With A Crevice Free Internal ContourDocument4 pagesThe F990 Has Smooth Flow Characteristics, Abrasion, Erosion and Corrosion Resistance With A Crevice Free Internal ContourRobi KeiNo ratings yet

- 2022 Electrical Steel NO Catalog - Eng - FinalDocument14 pages2022 Electrical Steel NO Catalog - Eng - Final雨庵우암No ratings yet

- DS Tarkett Iq - Natural en - INTLDocument1 pageDS Tarkett Iq - Natural en - INTLabdulazeem703No ratings yet

- Catalogue Dai ADocument16 pagesCatalogue Dai AHD TalababuNo ratings yet

- 紧固件常用英语Document12 pages紧固件常用英语里差No ratings yet

- QC MAGUDESH CV Updated 28-03-2023Document4 pagesQC MAGUDESH CV Updated 28-03-2023BaraneedharanNo ratings yet

- Problem 7.2 General-Purpose Equipment (Gpe)Document9 pagesProblem 7.2 General-Purpose Equipment (Gpe)Lưu Gia BảoNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- Project Name: Optimize The Mould Operation at Ekala Tires Division by Transfering From Traditional Processes To Agile and Intigrated Operation SystemDocument60 pagesProject Name: Optimize The Mould Operation at Ekala Tires Division by Transfering From Traditional Processes To Agile and Intigrated Operation SystemTharindu MadumalNo ratings yet

- Prospekt 100D EnglischDocument2 pagesProspekt 100D EnglischAbdoOmarNo ratings yet

- India Import Iron ScrapDocument9 pagesIndia Import Iron ScrapdheeruyadavNo ratings yet

- Leancafe09 SlidesDocument64 pagesLeancafe09 SlidesTon DorchainNo ratings yet

- Chapter 4 Exercises 1-8Document9 pagesChapter 4 Exercises 1-8deniz turkbayragiNo ratings yet

- Indian Forging Core MembersDocument9 pagesIndian Forging Core MemberskijekaNo ratings yet

- VW 50134 en 2015-09Document13 pagesVW 50134 en 2015-09xu zhangNo ratings yet

- KP Magnetic FilmDocument4 pagesKP Magnetic FilmCésar GNo ratings yet