Professional Documents

Culture Documents

73 - SOP - Utlisation of LD or GCP Sludge

Uploaded by

Mukesh SoniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

73 - SOP - Utlisation of LD or GCP Sludge

Uploaded by

Mukesh SoniCopyright:

Available Formats

Standard Operating Procedure and Checklist of Minimal Requisite

Facilities for utilization of hazardous waste under Rule 9 of the

Hazardous and Other Wastes (Management and Transboundary

movement) Rules, 2016

Utilization of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast

Furnace Flue Dust for manufacturing of L.D. Sludge agglomerates

y

e

ein

December, 2021

Central Pollution Control Board

(Ministry of Environment, Forest & Climate Change,

Government of India)

Parivesh Bhawan, East Arjun Nagar,

Shahdara, Delhi — 110032

Utilization of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust for

manufacturing of L.D. Sludge agglomerates

a ern

Procedure for grant of authorization by State Pollution Control Boards (SPCBs)/Polltion Control

Committees (PCCs) for utilization of Hazardous waste

1) While granting authorization for utilization of hazardous wastes, SPCBs/PCCs shall

ensure that authorization is given only to those wastes for which Standard Operating

Procedures (SoPs) for utilisation have been circulated by Central Pollution Control Board

(CPCB) ensuring the following:

a. The waste (intended for utilization) belongs to similar source of generation as

specified in SoP.

b. The utilization shall be similar to as described in SoP.

c. End-use/ product produced from the waste shall be same as specified in SoP.

d. Authorization shall be granted only after verification of details and minimum

requisite facilities as given in SoP.

e. Issuance of passbooks (similar to passbooks issued for recycling of used oil, waste

oil, non-ferrous scraps, etc.) for maintaining records of receipt of hazardous waste

for utilization.

2) After issuance of authorization, SPCBs/PCCs shall verify the compliance of checklist and

SoP on quarterly basis for initial 2 years; followed by random checks during subsequent

period for atleast once a year.

3) In-case of lack of requisite infrastructures with the SPCBs/PCCs, they may engage 3

party institutions or laboratories having EPA, 1986/NABL/ISO17025 accreditation /

recognition for monitoring and analysis of prescribed parameters in SoPs for verification

purpose.

4) SPCBs/PCCs shall provide half yearly updated list of units permitted under Rule 9 of

Hazardous & Other Wastes (Management & Transboundary Movement) Rules, 2016

(HOWM Rules, 2016) to CPCB and also upload the same on SPCB/PCC website,

periodically. Such updated list shall be sent to CPCB on half yearly basis i.e., by July and

January respectively.

5) Authorization for utilisation shall not be given to the units located in the State/Union

Territory where there is no Common TSDF, unless the unit ensures authorised captive

disposal of the hazardous waste (generated during utilisation) or its complete utilisation

or arrangement of sharing with any other authorised disposal facility.

6) In case of the utilization proposal is not similar with respect to source of generation or

utilization process or end-use as outlined in this SoP, the same may be referred to CPCB

for clarification /conducting trial utilization studies and developing SoPs thereof.

7) The source and work zone standards suggested in the SoP are based on E(P)A notified

and OSHA/NAAQ standard respectively, however, SPCBs/PCCs may impose more

stringent standards based on the location or process specific conditions.

Waste Management-II Division, CPCB, Delhi |Page

Utilization of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust for

manufacturing of L.D. Sludge agglomerates

Ean a EE SS ET SR EEE LE LEAD

73.0 Utilization of hazardous waste (H.W):

Type of H.W Source of generation Recovery/Product

Linz-Donawitz (L.D.)/ Gas | Generated as a result of | For manufacturing of L.D.

Cleaning Plant (GCP) Sludge, | cleaning the off gases | Sludge agglomerates (Used

L.D/GCP Classifier Sludge | during steel manufacturing | in steel making)

and Blast Furnace Flue Dust | process.

Category 35.1, Schedule I (of

HOWM Rules, 2016)

73.1 Source of H.W:

The LD/GCP Sludge, LD/GCP Classifier Sludge and Blast furnace flue dust of steel/ ferro alloy

plants is categorized as hazardous waste Category 35.1, Schedule I of HOWM Rules 2016.

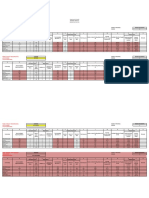

Table I. Typical Characteristics of hazardous waste are given below:

SI. Parameter Unit LD sludge | LD/GCP Blast Furnace

No. classifier sludge | Flue Dust

1 Iron as Fe g/kg 206.4 257.9 143.82

2 Zinc as Zn mg/kg 477.5 65.17 390

3 Manganese as Mn__| mg/kg 290 806 184

4 Copper as Cu mg/kg <1.0 <1.0 <1.0

5 Cadmium as Cd mg/kg 9.2 <1.0 <1.0

6 Cobalt as Co mg/kg <1.0 <1.0 <1.0

7 Lead as Pb mg/kg 218.5 183.4 167.8

8 Nickel as Ni mg/kg <1.0 <1.0 <1.0

9 Arsenic as As mg/kg <0.5 <0.5 <0.5

10 Vanadium as V mg/kg 18.6 19.2 10.7

jl Chromium as Cr mg/kg 40.7 39.7 9.6

12 Moisture Content | % 11.81 5.81 6.1

13 Mercury as Hg mg/kg <1.0 <1.0 <1.0

73.2 Utilization Process

The LD/GCP Sludge, LD/GCP Classifier Sludge and Blast furnace flue dust collected from steel/

ferro alloy plants are mixed with other raw materials such as lime and cement in proportion. The

mixed raw materials are fed in the Pelletizing Disc. The moisture content in the raw materials

helps in binding and nodulizing the green agglomerates

The green agglomerates are loaded inside the chamber kiln and heated at 110° C for 3-4 hours.

Then dry LD sludge agglomerates are pulled out from the chamber kiln and cooled in normal

temperature under shed. After cooling the final product is ready for dispatching or stocking in

stockyard.

Waste Management-II Division, CPCB, Delhi 2 |/P

oD

©

oQ

Utilization of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust for

manufacturing of L.D. Sludge agglomerates

LD/ GCP Sludge +

LD/ GCP Classifier Sludge +

Blast Furnace flue Dust

Mixing and briquetting

¥

Agglomeration Stack

v

Drying in chamber | APCD

kiln "|

!

Natural cooling

Vv

Finished Product

(LD Sludge Agglomerate)

Figure: 1-Process flow diagram for utilization of hazardous waste.

73.3 Product Usage / Utilization

LD/GCP Sludge, LD/GCP Classifier Sludge and Blast furnace flue dust is utilized in the

manufacturing of L.D. Sludge agglomerates which is used in steel making.

73.4 Standard Operating Procedure for utilization

This SoP is applicable only for Utilization of LD/GCP Sludge, LD/GCP Classifier Sludge and

Blast Furnace Flue Dust for manufacturing L.D. Sludge agglomerates.

1) LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust shall be procured

only in wet form having moisture not less than 15% by weight so as to avoid fugitive dust

emission during handling/ loading/ transportation/ unloading/ mixing etc. The said wastes

shall, however, be not procured in slurry form.

2) LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust shall be procured

only in SPCB/PCC authorized barrels/closed tanks mounted over vehicles fitted with

requisite safeguards ensuring no emissions/spillages.

3) LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust shall be stored in

dedicated storage area with impervious floor under covered storage shed within premises.

Waste Management-II Division, CPCB, Delhi Se, age

Utilization of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust for

manufacturing of L.D. Sludge agglomerates

Further, storage sheds shall have proper slope and seepage collection pit to collect seepage /

floor washing. The collected seepage / floor washing shall be utilized in the process.

4) The unit shall ensure that while mixing with other raw materials, that no dust formation takes

place by maintaining >15% moisture in the LD/GCP Sludge, LD/GCP Classifier Sludge and

Blast Furnace Flue Dust.

5) Material transfer / handling in entire utilization process shall be equipped with canopy /hood

system or done in closed system. Manual handling shall be restricted.

6) The unit shall ensure control of emissions in process area through dust extraction system

with APCD such as bag filter followed by stack.

7) The gases from kiln shall pass through APCD like Cyclone separator/ Bag filter/ Electro

static precipitators to meet the prescribe standards.

8) The treated gases shall comply with emission norms prior to dispersion into atmosphere

through stack. The stack height shall be minimum of 30m from ground level or as prescribed

by the concerned SPCB/PCC, whichever is higher.

9) Treatment and disposal of wastewater: Wastewater generated from floor-washings,

spillages, reactor washing, scrubber bleed shall be reused in the process while mixing raw

materials or treated Physico-Chemically in an Effluent Treatment Plant (ETP) or may be

sent to Common Effluent Treatment Plant (CETP) for final disposal or be treated further in

a captive facility to comply with surface water discharge standards.

In case of zero discharge, the treated waste water from ETP may be managed as per

conditions stipulated by the concerned SPCB/PCC.

10) The treated effluent shall be discharged in accordance with the conditions stipulated in the

Consent to Operate issued by concerned SPCB/PCC under the Water (Prevention and

Control of Pollution) Act, 1974.

11) The unit shall maintain proper ventilation in the work zone and process areas. All personnel

involved in the plant operation shall wear proper personal protective equipment (PPE)

specific to the process operations involved and type of chemicals handled as per Material

Safety Data Sheet (MSDS). The safety precautions of the worker shall be in accordance with

the Factory Act, 1948, as amended from time to time.

12) The hazardous wastes generated during utilization of LD/GCP Sludge, LD/GCP Classifier

Sludge and Blast Furnace Flue Dust (namely APCD dust etc.) during manufacturing process

of unit, shall be captively utilized with in the process or collected and temporarily stored in

non-reactive drums/ bags under a dedicated hazardous waste storage area and be sent to

authorized common TSDF or other authorized facility within 90 days from generation of the

waste in accordance with the authorization issued by the concerned SPCB/PCC.

13) The unit shall ensure that the LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace

Flue Dust is procured from authorized industries as required under HOWM Rules, 2016.

14) Transportation of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust

shall be carried out by sender (generator) or receiver (utilizer) only after obtaining

authorization from the concerned SPCB/PCC under HOWM Rules, 2016. Requisite manifest

document shall be followed as laid down under the said Rules.

15) Prior to utilization of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue

Dust, the unit shall obtain authorization for storage, utilization and disposal of LD/GCP

Waste Management-II Division, CPCB, Delhi 4|Page

Utilization of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust for

manufacturing of L.D. Sludge agglomerates

Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust from the concerned

SPCB/PCC under HOWM Rules, 2016.

16) In case of environmental damages arising due to improper handling of hazardous wastes

including accidental spillage during generation, storage, processing, transportation and

disposal, the occupier (sender or receiver, as the case may be) shall be liable to implement

immediate response measures, environmental site assessment and remediation of

contaminated soil/ groundwater/ sediment etc. as per the “Guidelines on Implementing

Liabilities for Environmental Damages due to Handling & Disposal of Hazardous Wastes

and Penalty” published by CPCB.

17) The unit shall provide suitable fire safety arrangements and flame proof electrical fittings.

18) During the process of utilization and handling of hazardous waste the unit shall comply with

requirement in accordance with the Public Liability Insurance Act, 1991 as amended,

wherever applicable.

73.5 Record/Returns Filing

1) The unit shall maintain a passbook issued by concern SPCB/PCC and maintain details ofeach

procurement of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust as

mentioned below:

- Address of the sender

- Date of dispatch

- Quantity procured

- Sealand signature ofthe sender

- Date ofReceptin the premises

2) A log book with information on source and date of procurement of LD/GCP Sludge, LD/GCP

Classifier Sludge and Blast Furnace Flue Dust, date wise utilization of the same, hazardous

waste generation and its disposal, etc. shall be maintained including analysis report of

fugitive emission monitoring & effluent discharged, as applicable.

3) The unit shall maintain record of hazardous waste generated, utilized and disposed as per

Form-3 & also file an annual return in Form-4 as per Rule 20 (1) and (2) of HOWM Rules,

2016, to concerned SPCB/PCC.

4) The unit shall submit quarterly and annual information on hazardous wastes consumed, its

source, products generated or resources conserved (specifying the details like, type and

quantity of resources conserved) to the concerned SPCB/PCC.

73.6 Standards

1) Source emissions from the stack connected to reactors/process unit shall comply with the

following Emission standards or as prescribed by the concerned SPCB/PCC, whichever

is stringent;

Particulate Matter 50 mg/Nm?

NOx 150 mg/Nm?

SO2 250 me/Nm3

Waste Management-II Division, CPCB, Delhi | Page

Utilization of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust for

manufacturing of L.D. Sludge agglomerates

2) Fugitive emission in the work zone area shall comply with the following standards:

PMio 40 mg/m}

NOx 150 g/m}

SO2 200 g/m?

3) Monitoring of the above specified parameters for source emission shall be carried out

quarterly for first year followed by at least annually in the subsequent year of utilization.

Fugitive emission for specified parameters shall be carried out quarterly. The monitoring

shall be carried out by ISO 17025 accredited or EPA, 1986 approved laboratories and the

results shall be submitted to the concerned SPCB/PCC on a quarterly basis.

4) Standard for wastewater discharge: Treated effluent shall be discharged in accordance

with the conditions stipulated in Consent to Operate issued by concerned SPCB/PCC

under the Water (Prevention and Control of Pollution) Act, 1974. In case of zero

discharge or no discharge condition stipulated in the consent or non-availability of the

common Effluent Treatment Plant (CETP), zero discharge shall be met.

73.7 Siting of Industry

Facilities for utilization of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue

Dust shall be preferably located in a notified industrial area or industrial park/estate/cluster and

in accordance with Consent to Establish issued by the concerned SPCB/PCC.

73.8 Size of Plant and Efficiency of Utilisation

The yield of the product is around 90 % by using the raw materials during the trial run (L.D.

Sludge, L.D. Classifier Sludge and Blast Furnace Flue Dust in the proportion 40%, 30% and 25%

respectively).

73.9 On-line Detectors / Alarms / Analyzers

In case of continuous process operations, online emission analyzers for PM, SO2, NOx in the

stack shall be installed and the online data be connected to the server of the concerned SPCB /

PCC.

73.10 Checklist of Minimal Requisite Facilities:

SI. No Particulars

1. Cool, dry well-ventilated covered sheds for LD/GCP Sludge, LD/GCP Classifier

Sludge & Blast Furnace Flue Dust, process activities within premises and dedicated

hazardous storage area for temporary storage of hazardous waste generated during

utilization process

Mixer, Pelletizer and Kiln.

35 APCD like Bag filters/ Cyclone for fugitive emissions.

4. |APCD like Cyclone /Bag filter/ Electro static precipitators connected to kiln.

Waste Management-II Division, CPCB, Delhi 6|Page

Utilization of LD/GCP Sludge, LD/GCP Classifier Sludge and Blast Furnace Flue Dust for

manufacturing of L.D. Sludge agglomerates

5. Stack to have sampling port, platform, access to the platform etc. as per the guidelines

on methodologies for source emission monitoring published by CPCB under Laboratory

Analysis Techniques LATS/80/2013-14. -

6. | Online analyzers for PM, SO2 & NOx emission monitoring in the stack, in case of

continuous process operations.

Waste Management-II Division, CPCB, Delhi 7[Page

You might also like

- Topa CTO 2018Document5 pagesTopa CTO 2018nikhil ranjanNo ratings yet

- CTO Rohini 2023Document6 pagesCTO Rohini 2023environment NK AreaNo ratings yet

- SOP for Utilization of Gasifier Slag and Spent Catalyst in Steel ProductionDocument7 pagesSOP for Utilization of Gasifier Slag and Spent Catalyst in Steel ProductionManish PatelNo ratings yet

- Flue Gas Desulfurization Systems PDFDocument53 pagesFlue Gas Desulfurization Systems PDFsenthil031277No ratings yet

- Flue Gas Desulfurization Systems PDFDocument53 pagesFlue Gas Desulfurization Systems PDFnamdq-1No ratings yet

- Guidelines on Refuse Derived Fuel UsageDocument153 pagesGuidelines on Refuse Derived Fuel Usagepavnitkiran02100% (1)

- Jharkhand State Pollution Control BoardDocument5 pagesJharkhand State Pollution Control BoardANJANI KUMAR SINGHNo ratings yet

- (ENG) Journal-Paint Sludge On IndiaDocument10 pages(ENG) Journal-Paint Sludge On IndiaSoebowo AdjinegoroNo ratings yet

- Environmental Issues and Control - Position Paper 2021Document12 pagesEnvironmental Issues and Control - Position Paper 2021abubakarNo ratings yet

- 2021-12-29-10-16-c3b43d7a06e4441035e32252b4b7c1faDocument79 pages2021-12-29-10-16-c3b43d7a06e4441035e32252b4b7c1fa359degrees.359No ratings yet

- CTO Bokaro General HospitalDocument5 pagesCTO Bokaro General HospitalAnonymous Shbwruff4rNo ratings yet

- An Insight Review On Textile Effluent Treatment Using NanoparticlesDocument33 pagesAn Insight Review On Textile Effluent Treatment Using NanoparticlesRajalakshmiNo ratings yet

- EPA R06 OAR 2017 0129 0011 - Attachment - 2Document25 pagesEPA R06 OAR 2017 0129 0011 - Attachment - 2muhammad farisNo ratings yet

- URS - Tanauan Factory WWTP Upgrade PDFDocument23 pagesURS - Tanauan Factory WWTP Upgrade PDFVer AmorosoNo ratings yet

- Low Carbon Marine Technology Focus: Hydrogen EnergyDocument21 pagesLow Carbon Marine Technology Focus: Hydrogen EnergyTamal MukherjeeNo ratings yet

- Air Quality StandardDocument10 pagesAir Quality Standardसुनिल बाबु खत्रीNo ratings yet

- CCPC Summary by Iea CCCDocument23 pagesCCPC Summary by Iea CCCProcess EngineerNo ratings yet

- CO2 Post Combustion Capture TechnologyDocument17 pagesCO2 Post Combustion Capture TechnologywiboonwiNo ratings yet

- Opportunities For CO Mineralisation in Indian Waste-Based Manufactured ProductsDocument8 pagesOpportunities For CO Mineralisation in Indian Waste-Based Manufactured Productspradhith kattaNo ratings yet

- AG2 Index of Preferred Methods May2021 v4Document75 pagesAG2 Index of Preferred Methods May2021 v4nureNo ratings yet

- 3 China VCM PresentationDocument26 pages3 China VCM PresentationfatjonNo ratings yet

- Influence of Compaction On Copper SlagDocument82 pagesInfluence of Compaction On Copper SlagakashNo ratings yet

- Municipal2BWaste2BConsiderations2BChecklistDocument4 pagesMunicipal2BWaste2BConsiderations2BChecklistSecret secretNo ratings yet

- Apar Silvassa LubesDocument8 pagesApar Silvassa LubesROOPDIP MUKHOPADHYAYNo ratings yet

- AbdchtrDocument5 pagesAbdchtrkooolsumitNo ratings yet

- Thailand Water QualityDocument26 pagesThailand Water QualityMohammad Syahir JamaluddinNo ratings yet

- Guidelines on Using Refuse-Derived Fuel Across IndustriesDocument104 pagesGuidelines on Using Refuse-Derived Fuel Across Industriessaravanan gNo ratings yet

- Session3-2 DR B SenguptaDocument50 pagesSession3-2 DR B SenguptaRaja Rao KamarsuNo ratings yet

- High-yield preparation of graphene oxide from small graphite flakesDocument9 pagesHigh-yield preparation of graphene oxide from small graphite flakeswidyaNo ratings yet

- 2.B.7 Soda Ash Production 2019Document8 pages2.B.7 Soda Ash Production 2019Itamar HiteNo ratings yet

- Kogut 2021Document11 pagesKogut 2021naruse10No ratings yet

- 2.7 Particulate Cems For Wet and Dry FGD ApplicationsDocument11 pages2.7 Particulate Cems For Wet and Dry FGD Applicationsjitendrashukla10836No ratings yet

- BR 1944 Salt Drying Technology For Zero Liquid DischargeDocument13 pagesBR 1944 Salt Drying Technology For Zero Liquid DischargeOscar Alvitez DominguezNo ratings yet

- An Environmental Control Plan (Ecp)Document21 pagesAn Environmental Control Plan (Ecp)Kumar SilNo ratings yet

- Environmental Statement Form V Tata Steel Limited Hooghly Metcoke Division Haldia Yearly April 2021 To March 2022Document8 pagesEnvironmental Statement Form V Tata Steel Limited Hooghly Metcoke Division Haldia Yearly April 2021 To March 2022Mohit Kumar DasNo ratings yet

- What Are The Precautionary Measures Taken by ENGRO Fertilizers Industry To Overcome The Environmental Hazards?Document3 pagesWhat Are The Precautionary Measures Taken by ENGRO Fertilizers Industry To Overcome The Environmental Hazards?ahmad farazNo ratings yet

- Guide To Diesel Exhaust Emissions Control of No, SO, Particulates, Smoke and CODocument36 pagesGuide To Diesel Exhaust Emissions Control of No, SO, Particulates, Smoke and COKarim Sowley DelgadoNo ratings yet

- Combustion Process Operators - Spreadsheet Tool For Reporting Emissions To AirDocument15 pagesCombustion Process Operators - Spreadsheet Tool For Reporting Emissions To AiraalfanNo ratings yet

- NOx Reduction using RDF in cement kilnsDocument8 pagesNOx Reduction using RDF in cement kilnsIzaz Ulhaq YousafziNo ratings yet

- Rashtriya Ispat Nigam LTD.: Visakhapatnam Steel PlantDocument15 pagesRashtriya Ispat Nigam LTD.: Visakhapatnam Steel PlantAnjiNo ratings yet

- "Alternate Refrigerants": J.IlangumaranDocument61 pages"Alternate Refrigerants": J.Ilangumaranapi-25999517No ratings yet

- Stack HT FGDDocument8 pagesStack HT FGDKiranNo ratings yet

- 73 - SOP - Utlisation of Aluminium Dross SiliconDocument8 pages73 - SOP - Utlisation of Aluminium Dross SiliconMukesh SoniNo ratings yet

- EMP Raheja MindspaceDocument5 pagesEMP Raheja MindspaceJohn SharonNo ratings yet

- 6 Tech Spec AMOC Final V2Document26 pages6 Tech Spec AMOC Final V2bvdbNo ratings yet

- Pollution Control Mechanism in Iron & Steel PlantDocument89 pagesPollution Control Mechanism in Iron & Steel PlantMohit Kumar DasNo ratings yet

- CFP JuteDocument29 pagesCFP JuteArnab ChakrabartiNo ratings yet

- Alternate Fuel and Raw Material FacilityDocument5 pagesAlternate Fuel and Raw Material FacilityRAHUL MATHURNo ratings yet

- Sciencedirect: Lead and Cadmium Removal From Aqueous Solution Using An Industrial Gypsum By-ProductDocument8 pagesSciencedirect: Lead and Cadmium Removal From Aqueous Solution Using An Industrial Gypsum By-ProductSoumya Ranjan MishraNo ratings yet

- Coke Oven PlantDocument45 pagesCoke Oven PlantSameer Shekhar100% (1)

- Philippines Clean Air Act of 1999 (Group 1 ME22FB1)Document9 pagesPhilippines Clean Air Act of 1999 (Group 1 ME22FB1)Boris Lorenzo LimpahanNo ratings yet

- Pollution Control Guidelines for Conversion to Solid FuelsDocument24 pagesPollution Control Guidelines for Conversion to Solid FuelsdurgamadhabaNo ratings yet

- Cement Plant Wast Processing Guidelines-CPCB-07!07!2017Document35 pagesCement Plant Wast Processing Guidelines-CPCB-07!07!2017tsrinivasan5083No ratings yet

- STP Proposal for 5 m3/hr Sewage Treatment PlantDocument15 pagesSTP Proposal for 5 m3/hr Sewage Treatment PlantShah Newaz KabirNo ratings yet

- SBB Energy Canada Emissions InventoryDocument1 pageSBB Energy Canada Emissions InventoryRufus D SNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- The Electrochemistry and Characteristics of Embeddable Reference Electrodes for ConcreteFrom EverandThe Electrochemistry and Characteristics of Embeddable Reference Electrodes for ConcreteNo ratings yet

- Fentanyl Epidemic Ravaging WisconsinDocument2 pagesFentanyl Epidemic Ravaging WisconsinMike MaybayNo ratings yet

- 167 Manuscript 193 1 10 20210107Document4 pages167 Manuscript 193 1 10 20210107Hundessa Daba100% (1)

- BETA VitaHop CaseSty R2Document1 pageBETA VitaHop CaseSty R2ALEJANDRO AstudilloNo ratings yet

- PG Diploma in Psychotherapy Course InfoDocument1 pagePG Diploma in Psychotherapy Course InfoSabitri SanyalNo ratings yet

- Regional Family Planning Inventory FormsDocument2 pagesRegional Family Planning Inventory FormsRANDY BAOGBOGNo ratings yet

- I Want To Generate New Ideas: by Thinking DifferentlyDocument4 pagesI Want To Generate New Ideas: by Thinking DifferentlyJohn Michael SomorostroNo ratings yet

- 1.1, 1.2, 1.3, 1.5 Paediatric Nursing Presentation - 1-1Document54 pages1.1, 1.2, 1.3, 1.5 Paediatric Nursing Presentation - 1-1Christina YounasNo ratings yet

- TTP vs HUS: Distinguishing Features and TreatmentDocument21 pagesTTP vs HUS: Distinguishing Features and TreatmentHanif ullahNo ratings yet

- Mapeh 10 Curriculum MapDocument9 pagesMapeh 10 Curriculum MapJoshua LamzonNo ratings yet

- Lewinsohn 1975Document3 pagesLewinsohn 1975serenadenightNo ratings yet

- Chapter 6. Operation: Before Operation, Prepare The Ventilator As Instructed inDocument18 pagesChapter 6. Operation: Before Operation, Prepare The Ventilator As Instructed indeboraNo ratings yet

- PHL Ad 17 01 Operationalguidance 2017 Eng Ops Manual Adolescent Health Development ProgramDocument111 pagesPHL Ad 17 01 Operationalguidance 2017 Eng Ops Manual Adolescent Health Development ProgramJoanne G Haw GetidaNo ratings yet

- Orthotic Intervention For The Hand and Upper Extremity Splinting PrinciplesDocument61 pagesOrthotic Intervention For The Hand and Upper Extremity Splinting Principleskevin.smart540No ratings yet

- AL Ehsan Welfare Eye Hospital Volunteer ReportDocument21 pagesAL Ehsan Welfare Eye Hospital Volunteer ReportKaamla BajwaNo ratings yet

- DA MayDocument1 pageDA MayMingNo ratings yet

- FlowerhornDocument10 pagesFlowerhornPaul Michael P. GarciaNo ratings yet

- OmniTurn Manual g3Document210 pagesOmniTurn Manual g3CESAR MTZNo ratings yet

- Food Defense Plan RequirementsDocument4 pagesFood Defense Plan RequirementsRodolfoNo ratings yet

- Standrad For Hospital: ReferenceDocument74 pagesStandrad For Hospital: ReferenceHasib MohammadNo ratings yet

- KPI Study on Middle Management PerceptionsDocument5 pagesKPI Study on Middle Management Perceptionsjigisha234100% (1)

- Case StudyDocument3 pagesCase StudyNovelyn B. PlaniaNo ratings yet

- Aster RV Hospital BangloreDocument47 pagesAster RV Hospital BangloreAkhil Hb100% (1)

- KistokelDocument4 pagesKistokelIntan PermataNo ratings yet

- Nature of Conflict ExplainedDocument24 pagesNature of Conflict ExplainedJabrail AminNo ratings yet

- Summative Test (Health)Document3 pagesSummative Test (Health)Diego ConopioNo ratings yet

- Crisis Assessment Intervention and Prevention 2nd Edition Cherry Test BankDocument22 pagesCrisis Assessment Intervention and Prevention 2nd Edition Cherry Test Bankdolium.technic.1i5d67100% (30)

- Lydia Hall Nursing TheoryDocument1 pageLydia Hall Nursing TheoryJohn Patrick Bernada100% (1)

- Gender EuphoriaDocument25 pagesGender EuphoriaillaritzaNo ratings yet

- Skin Assessment FormDocument2 pagesSkin Assessment FormOng KarlNo ratings yet

- Healing Through LandscapeDocument28 pagesHealing Through LandscapeShinsha SaleemNo ratings yet