Professional Documents

Culture Documents

The Waddington Effect Reliability Academy

Uploaded by

Awad AbdallaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Waddington Effect Reliability Academy

Uploaded by

Awad AbdallaCopyright:

Available Formats

Reliability Insights

The Waddington Effect

October 25, 2023

Is doing more maintenance ‘good’?

It’s common to think so. I mean, it makes sense

that the more maintenance you do… the less likely

your equipment is to fail.

Right?

But if that’s the case…

Why do we still suBer from poor reliability?

Why do we still struggle with emergency

breakdowns?

Why do we struggle with expensive maintenance

costs?

“Can’t we just do more maintenance to improve

reliability?”

Unfortunately, it’s not that easy. And research

shows otherwise. Waddington and his research

team proved just how wrong that conventional

thinking really is.

In this article, I talk about the ‘Waddington EBect’,

why it is important in today’s modern maintenance

programs, and what the implications are when it

comes to how we implement maintenance.

What is the Waddington

Effect?

In an article called “The Waddington E!ect”, Dr.

James P. Ignizio discusses the research work done

by C. H. Waddington during World War II.

He coined the term “Waddington EBect”, which

shows that preventive maintenance inspections of

British bombers increased the rate of breakdowns

immediately after their maintenance.

Figure 1. The Waddington EBect with Bomber

Command (Taken from the article: The Waddington

E!ect, C4 U-Compliance, and Subsequent Impact on

Force Readiness)

“As Waddington observed, the number of repairs

increased after maintenance, ultimately settling

down to roughly 6 repairs every 10 hours – at

about which time the next maintenance event

was scheduled.”

You can read the full article on Waddington’s work

here:

The Waddington E!ect, C4 U-Compliance, and

Subsequent Impact on Force Readiness

But to summarise…

Waddington and his team concluded that

maintenance inspections actually led to MORE

equipment malfunctions due to the disruption of

an otherwise satisfactory condition.

They argued that PMs were too frequent, and that

it could be the cause of, rather than the solution to,

emergency repairs.

To solve this, they proposed and ultimately

accepted improvements to the maintenance

schedule:

1. extending the time between repairs

2. identifying components that need to be included

or excluded in a particular maintenance event

3. better allocating and scheduling maintenance

staB

4. and developing clearer, more concise, and

unambiguous documentation.

Implementing these recommendations resulted in

a remarkable increase in airplane availability and

the eBectively increased the size of the British

Coastal Command air [eet by over 60%…

…but much less costly and time-consuming than

actually increasing the aircraft [eet.

What does this imply for our

preventive maintenance

programs?

The `ndings from Waddington’s research have

great implications for our modern maintenance

programs.

The Waddington EBect provides modern

maintenance programs with a blueprint for how to

approach asset management in a way that is

eacient, cost-eBective, and maximises equipment

lifespan. And to achieve that, there are three things

you need to understand and apply:

1) First, you can’t maintain your way to

reliability.

This is very evidently shown in Waddington’s

research.

In fact, he showed that doing more maintenance

actually results in more emergency repairs.

That’s because maintenance can only preserve

your equipment’s inherent design reliability and

performance. If the equipment’s inherent reliability

or performance is poor, doing more maintenance

will not help.

No amount of maintenance can raise the inherent

reliability of a design. To improve poor reliability or

performance that’s due to poor design, you need

to change the design. Simple.

When you encounter failures that relate to design

issues, you need to eliminate them. Sure, the more

proactive and more eacient approach is to ensure

that the design is right, to begin with. But all plants

startup with design defects. Even proactive plants.

And that’s why the most reliable plants in the world

have an eBective defect elimination program in

place.

2) Second, the more intrusive maintenance you

do, the more human errors you introduce.

Which results in more defects.

As I discussed in the article, Defect Elimination:

Why you can’t do without, up to 84% of all defects

are caused by careless work habits, which become

failures over random periods of time.

You see, we introduce defects at every stage of a

plant’s life cycle: during the design, construction,

and commissioning of our plants.

Including the operation and maintenance phases.

If you don’t tackle these defects, they will

eventually lead to failures.

3) And lastly, documentation is important.

Interestingly, the British Operational Research

team was particularly surprised at the signi`cant

impact that proper documentation had on

achieving these results.

I discuss in my course how documentations like job

plans and work instructions are key to your

success because they help you manage human

error, reduce variability, and improve safety.

Summary

The Waddington EBect suggests that more

maintenance is not always the solution to poor

reliability and emergency breakdowns. In fact, they

concluded that more maintenance inspections

actually led to more equipment malfunctions. And

that’s because of disruptions to an otherwise

satisfactory condition.

To solve this, they proposed improvements to the

maintenance schedule, such as extending the time

between repairs, identifying components that need

to be included or excluded in a particular

maintenance event, better allocating and

scheduling maintenance staB, and developing

clearer, more concise, and unambiguous

documentation.

The `ndings from Waddington’s research have

implications for modern maintenance programs.

To achieve this, three things need to be

understood and applied: 1) you cannot maintain

your way to reliability; 2) more intrusive

maintenance introduces more human errors,

which results in more defects. Careless work habits

cause up to 84% of all defects, which eventually

lead to failures.

Lastly, proper documentation is important. Job

plans and work instructions help manage human

error, reduce variability, and improve safety. By

implementing these recommendations, modern

maintenance programs can achieve more eacient,

cost-eBective, and maximised equipment lifespan.

Now, with that said…

Is your PM program optimised to follow these

principles?

If not, then there’s room for improvement.

If you want to train your team to do LESS

maintenance but still improve your overall

reliability…

If you want to avoid intrusive maintenance tasks so

you introduce less human error…

If you need tools and templates to properly

implement and document your preventive

maintenance process…

Then schedule a call with me.

Let’s discuss how we can train your team in

optimising and developing your preventive

maintenance program.

SHARE THIS ON :

Related Articles

Reliability Insights

9 November 2023 Erik Hupje

Why standardising your

process is a crucial 3rst

step before automation

Many of our tasks are automated. But just

imagine that you need to manually do some

of those. For example, collect and process

data from ...

LEARN MORE

Planning & Scheduling

16 October 2023 Erik Hupje

How to stay reliable

DESPITE maintenance

budget cuts

How’s your maintenance budget? Chances

are you think it’s not enough. And you

resent that it’s been cut back for the

umpteenth time. Every organisation ...

LEARN MORE

Reliability Insights

4 October 2023 Erik Hupje

Why do we reward poor

behaviour?

When it comes to building a culture of

reliability, what you say is important. What

you do is even more important. But what you

reward ...

LEARN MORE

We train and coach your team

to help you escape the vicious

cycle of reactive maintenance

and create a Reliable Plant.

How can we help?

Improve Reliability

Planning & Scheduling

Preventive Maintenance

Defect Elimination

Leadership & Culture

Online Training

Online Training

Planning & Scheduling Online Training

Preventive Maintenance Online Training

Scholarship Program

Reliability Resources

Articles & Blogs

Resources

Glossary & FAQ’s

Webinars

About Us

Success Stories

About Us

Contact Us

Our Approach

© 2017-2023 R2 Reliability Pty Ltd.

All Rights Reserved. | Privacy Policy |

Terms of Use | Cookie Settings

You might also like

- Operator Driven Reliability Transcript PDFDocument13 pagesOperator Driven Reliability Transcript PDFMohamadSyahmiNo ratings yet

- Facility Maintenance Series: Types of Maintenance ProgramsFrom EverandFacility Maintenance Series: Types of Maintenance ProgramsRating: 5 out of 5 stars5/5 (1)

- Control RoomDocument24 pagesControl Roomsarsan nedumkuzhi maniNo ratings yet

- World Class Reliability PerformanceDocument142 pagesWorld Class Reliability Performancemasgraha100% (12)

- Reactive Maintenance To Preventive MaintenanceDocument16 pagesReactive Maintenance To Preventive MaintenancematshonaNo ratings yet

- Maintenance StrategyDocument9 pagesMaintenance Strategyganeshji@vsnl.comNo ratings yet

- EWM Transaction CodesDocument22 pagesEWM Transaction CodesChuks Osagwu100% (1)

- Troubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingFrom EverandTroubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingRating: 4.5 out of 5 stars4.5/5 (3)

- MaintenanceDocument9 pagesMaintenanceKumar GaneshNo ratings yet

- Agal-8mkqdm r0 enDocument16 pagesAgal-8mkqdm r0 enCldResendeNo ratings yet

- Keysight Software ExamplesDocument66 pagesKeysight Software ExamplesAkshaya HegdeNo ratings yet

- Why Are We So Bad at Maintenance ManagementDocument16 pagesWhy Are We So Bad at Maintenance ManagementMasoud AmirzadehfardNo ratings yet

- Total Productive Maintenance For Organisational EffectivenessFrom EverandTotal Productive Maintenance For Organisational EffectivenessRating: 4 out of 5 stars4/5 (4)

- Nebosh Igc Openbook Students Answer December 2020Document7 pagesNebosh Igc Openbook Students Answer December 2020Nathan Tankwal86% (7)

- Project ReportDocument61 pagesProject Reportlove goyal100% (2)

- Key Brand Elements: How-To GuideDocument7 pagesKey Brand Elements: How-To GuideDemand MetricNo ratings yet

- 10 Reasons Why Mntnce FailsDocument7 pages10 Reasons Why Mntnce FailsCyrix.OneNo ratings yet

- How To Improve Your Preventive Maintenance ProgramDocument16 pagesHow To Improve Your Preventive Maintenance Programvepaula50% (2)

- Preventive Maintenance2Document22 pagesPreventive Maintenance2Shivaji ThubeNo ratings yet

- Github Markdown CheatsheetDocument2 pagesGithub Markdown CheatsheetBramanthyo AndrianNo ratings yet

- Preventive Maintenance Optimization Through FMEADocument3 pagesPreventive Maintenance Optimization Through FMEAHugoCabanillasNo ratings yet

- Top Five Maintenance Reliability Enablers For Improved Operational PerformanceDocument10 pagesTop Five Maintenance Reliability Enablers For Improved Operational PerformanceElvis DiazNo ratings yet

- Mean Deviation of Grouped Data - LPDocument4 pagesMean Deviation of Grouped Data - LPKishi Nissi Dela CruzNo ratings yet

- Inspection of Heat ExcahngeDocument32 pagesInspection of Heat ExcahngeAfetNo ratings yet

- MPS Day1 World Class Reliability PerformanceDocument142 pagesMPS Day1 World Class Reliability Performancemelator100% (1)

- Huawei LTE ENodeB CabinetsDocument41 pagesHuawei LTE ENodeB CabinetsSyed Mohsin Ghani100% (1)

- What Constitutes WorldDocument10 pagesWhat Constitutes WorldDiah Indriani KusbandariNo ratings yet

- 10 Things Your Management Needs To Know Now - Reliabilityweb - A Culture of ReliabilityDocument5 pages10 Things Your Management Needs To Know Now - Reliabilityweb - A Culture of ReliabilityyaserNo ratings yet

- Managing Mill Maintenance - Maintenance Options and ChallengesDocument7 pagesManaging Mill Maintenance - Maintenance Options and ChallengesMilling and Grain magazineNo ratings yet

- Preventive Maintenance ThesisDocument6 pagesPreventive Maintenance ThesisKaela Johnson100% (2)

- Human Error: Causes and PreventionDocument4 pagesHuman Error: Causes and PreventionretalfouadNo ratings yet

- Research Papers On HseDocument6 pagesResearch Papers On Hsetdqmodcnd100% (3)

- Availability-Based Maintenance Within An Asset Management ProgrammeDocument12 pagesAvailability-Based Maintenance Within An Asset Management Programmeignite182No ratings yet

- How To Build An Electrical Maintenance ProgramDocument5 pagesHow To Build An Electrical Maintenance ProgramJayson Jonson AraojoNo ratings yet

- Ammj July Ricky Smith Article W CoverDocument5 pagesAmmj July Ricky Smith Article W CoverSrđan KrsteljNo ratings yet

- Manufacturing Maintenance ExcellenceDocument3 pagesManufacturing Maintenance Excellencemintek2009No ratings yet

- Business Continuity Plan DissertationDocument8 pagesBusiness Continuity Plan DissertationWriteMyPaperOnlineCanada100% (1)

- TPM-How To Implement Total Productive MaintenanceDocument2 pagesTPM-How To Implement Total Productive MaintenanceGiovani AmorinNo ratings yet

- MBTF vs. OeeDocument10 pagesMBTF vs. OeeyoratenallNo ratings yet

- Conduct "Toolbox Talks" by Site Execution Team and Workers Along With Safety PersonalsDocument4 pagesConduct "Toolbox Talks" by Site Execution Team and Workers Along With Safety PersonalsvipinNo ratings yet

- 5 Time Wasters For Reliability Engineers To AvoidDocument3 pages5 Time Wasters For Reliability Engineers To AvoidfahazumeeNo ratings yet

- 3 Simple Ideas To Improve Equipment ReliabilitDocument7 pages3 Simple Ideas To Improve Equipment ReliabilitPedro Augusto Ribeiro MartinsNo ratings yet

- What Is Maintenance Management?Document7 pagesWhat Is Maintenance Management?Leo UrbančićNo ratings yet

- Schedule "Toolbox Talks" by Site Execution Team and Workers Along With Safety PersonalsDocument4 pagesSchedule "Toolbox Talks" by Site Execution Team and Workers Along With Safety PersonalsvipinNo ratings yet

- Rima Anggraini 6mc Review JournalingDocument14 pagesRima Anggraini 6mc Review JournalingMuhammad Khatammi AzharNo ratings yet

- OM Script ReportDocument8 pagesOM Script ReportThreeGee JoseNo ratings yet

- 58-Reliability Centered MaintenanceDocument32 pages58-Reliability Centered MaintenanceAlejandro Bartolo Yañez100% (1)

- ProdMngt - 5 - Details of The ReportDocument63 pagesProdMngt - 5 - Details of The ReportNico PaoloNo ratings yet

- Term Paper Contingency Planning in ActionDocument8 pagesTerm Paper Contingency Planning in Actionea86yezd100% (1)

- Term Paper About Safety ManagementDocument7 pagesTerm Paper About Safety Managementafdtakoea100% (1)

- Journal Review: On Sustainable Approaches To Maintenance Practice in The Apparel IndustryDocument6 pagesJournal Review: On Sustainable Approaches To Maintenance Practice in The Apparel IndustryanishaNo ratings yet

- Assignment For The Module Maintenance Management - VishwajeetDocument7 pagesAssignment For The Module Maintenance Management - VishwajeetVishwajeet KumarNo ratings yet

- 7 - Mansor Et AlDocument10 pages7 - Mansor Et Algroovercm15No ratings yet

- Reliability Centered Maintenance Literature ReviewDocument5 pagesReliability Centered Maintenance Literature Reviewfvehwd96No ratings yet

- Complete Guide To Incident Management Part 1 22EB09Document13 pagesComplete Guide To Incident Management Part 1 22EB09nttrials3027No ratings yet

- PM and PDM ConceptsDocument6 pagesPM and PDM ConceptsMagoroku D. YudhoNo ratings yet

- Research Paper On Quality Assurance PDFDocument8 pagesResearch Paper On Quality Assurance PDFafnkwiytzcpszv100% (1)

- How To Audit Your Preventive MaintenanceDocument12 pagesHow To Audit Your Preventive MaintenanceFran jimenezNo ratings yet

- IMChap 014 SDocument14 pagesIMChap 014 STroy WingerNo ratings yet

- Kpi Question (1) ZXZXZXDocument14 pagesKpi Question (1) ZXZXZXTrash mailNo ratings yet

- Topic Eight and NineDocument14 pagesTopic Eight and Nineswizz PaulNo ratings yet

- Maintenance Planning Is To Hard To My WorklplaceDocument4 pagesMaintenance Planning Is To Hard To My WorklplaceFery HartantoNo ratings yet

- Reducing Human ErrDocument3 pagesReducing Human ErrrwillestoneNo ratings yet

- Introduction and Evaluation of ReliabilityDocument15 pagesIntroduction and Evaluation of ReliabilityRebbyno Deendri Andika100% (1)

- Planning and Scheduling MaterialDocument4 pagesPlanning and Scheduling MaterialIrete FemiNo ratings yet

- Maintenance Planning Is Too Hard in My WorkplaceDocument4 pagesMaintenance Planning Is Too Hard in My WorkplaceambiabaNo ratings yet

- Punchlist ProcessDocument14 pagesPunchlist ProcessReem Sabry100% (1)

- Awadelkarem Abdallah Mohgoub Mechanical Maintenance TEAM LEADER Khartoum Sudan Phone (+249) 912505873 Mobile (+249) 912951728Document3 pagesAwadelkarem Abdallah Mohgoub Mechanical Maintenance TEAM LEADER Khartoum Sudan Phone (+249) 912505873 Mobile (+249) 912951728Awad AbdallaNo ratings yet

- LECTURENOTE Mech HMIFDocument231 pagesLECTURENOTE Mech HMIFAwad AbdallaNo ratings yet

- Fandi Setia - Vibration Level 2 Certificate - MobiusDocument1 pageFandi Setia - Vibration Level 2 Certificate - MobiusfandisetiaNo ratings yet

- Maintenance Management An Overview Reliable PL 2Document2 pagesMaintenance Management An Overview Reliable PL 2Awad AbdallaNo ratings yet

- Awadelkarem Ali CompressedDocument2 pagesAwadelkarem Ali CompressedAwad AbdallaNo ratings yet

- Maintenance Management An Overview Reliable PL 2Document2 pagesMaintenance Management An Overview Reliable PL 2Awad AbdallaNo ratings yet

- Awadelkarem Abdallah Mohgoub Mechanical Maintenance TEAM LEADER Khartoum Sudan Phone (+249) 912505873 Mobile (+249) 912951728Document3 pagesAwadelkarem Abdallah Mohgoub Mechanical Maintenance TEAM LEADER Khartoum Sudan Phone (+249) 912505873 Mobile (+249) 912951728Awad AbdallaNo ratings yet

- Maintenance Management An Overview Reliable PLDocument2 pagesMaintenance Management An Overview Reliable PLAwad AbdallaNo ratings yet

- 5M Maintenance Planning ModelDocument1 page5M Maintenance Planning ModelAwad AbdallaNo ratings yet

- My WalletDocument1 pageMy WalletAwad AbdallaNo ratings yet

- Best Efficiency Point & Performance Curves Pumps & SystemsDocument1 pageBest Efficiency Point & Performance Curves Pumps & SystemsAwad AbdallaNo ratings yet

- Best Efficiency Point & Performance Curves Pumps & SystemsDocument1 pageBest Efficiency Point & Performance Curves Pumps & SystemsAwad AbdallaNo ratings yet

- Oil Consumbtion PDFDocument7 pagesOil Consumbtion PDFAwad AbdallaNo ratings yet

- Fuel Dilution of Engine Oi PDFDocument4 pagesFuel Dilution of Engine Oi PDFAwad AbdallaNo ratings yet

- Piston Ring Clearance Sheet Allen 2000 V2 PDFDocument1 pagePiston Ring Clearance Sheet Allen 2000 V2 PDFAwad AbdallaNo ratings yet

- Process Safety Management Initial TrainingDocument20 pagesProcess Safety Management Initial TrainingAwad AbdallaNo ratings yet

- God The Myth: by 6litchDocument4 pagesGod The Myth: by 6litchAnonymous nJ1YlTWNo ratings yet

- Managed Fortiswitch 604Document110 pagesManaged Fortiswitch 604Netsys BilisimNo ratings yet

- MVC Interview Questions AnswersDocument12 pagesMVC Interview Questions AnswersKapil SharmaNo ratings yet

- ESD Short Sleeve SmocksDocument12 pagesESD Short Sleeve Smocksbeach_lover_1970No ratings yet

- Punching Report - Unikl MsiDocument9 pagesPunching Report - Unikl MsiRudyee FaiezahNo ratings yet

- Vision: Electricity Bill Management SystemDocument25 pagesVision: Electricity Bill Management SystemDiyaN IrfaN sketcher and cartooning artNo ratings yet

- BK Vibro - DDAU3 - Wind - BrochureDocument12 pagesBK Vibro - DDAU3 - Wind - BrochurePedro RosaNo ratings yet

- C++ Practicle FileDocument39 pagesC++ Practicle Filekhushi birlaNo ratings yet

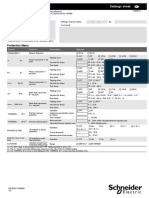

- VIP400 Settings Sheet NRJED311208ENDocument2 pagesVIP400 Settings Sheet NRJED311208ENVăn NguyễnNo ratings yet

- SOP For CPU CCP-521Document5 pagesSOP For CPU CCP-521Mehtab AhmedNo ratings yet

- OMD-425 O2 AnalyzerDocument1 pageOMD-425 O2 Analyzerindra irawanNo ratings yet

- Kisi-Kisi Web Technologies 2023Document36 pagesKisi-Kisi Web Technologies 2023Erhamna noor riskiNo ratings yet

- MongoDB ManualDocument1,320 pagesMongoDB ManualEliceo Choque AndradeNo ratings yet

- 701MRF de PDFDocument92 pages701MRF de PDFPetros TsenesNo ratings yet

- Advanced High-Capacity Synchronization Solution: Your BenefitsDocument6 pagesAdvanced High-Capacity Synchronization Solution: Your BenefitsTuan MANo ratings yet

- Growth Marketing Final PresentationDocument17 pagesGrowth Marketing Final PresentationAmna AhmedNo ratings yet

- Assignment 4 CSE 205Document8 pagesAssignment 4 CSE 205Dewank SainiNo ratings yet

- Unit 8: Future Outlook: Central Business Configuration For SAP S/4HANA CloudDocument9 pagesUnit 8: Future Outlook: Central Business Configuration For SAP S/4HANA CloudKarina San MartinNo ratings yet

- How To Register The HospitalDocument55 pagesHow To Register The HospitalAkhilesh Dwivedi0% (1)

- Hatch Mott Proposal - FINAL REVISEDDocument82 pagesHatch Mott Proposal - FINAL REVISEDbubbles82No ratings yet

- Chapter 12Document34 pagesChapter 12Thanh Van DaoNo ratings yet

- Data Entry Operator Key Punch Operator (BS-08) Session BDocument3 pagesData Entry Operator Key Punch Operator (BS-08) Session BRao M. YasirNo ratings yet