Professional Documents

Culture Documents

2 Harajli2006

Uploaded by

Tú LêOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 Harajli2006

Uploaded by

Tú LêCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/279594470

Stress-strain model for fiber-reinforced polymer jacketed concrete columns

Article in Aci Structural Journal · September 2006

CITATIONS READS

119 951

3 authors, including:

Mohamed H. Harajli Elie G. Hantouche

American University of Beirut American University of Beirut

55 PUBLICATIONS 2,229 CITATIONS 49 PUBLICATIONS 511 CITATIONS

SEE PROFILE SEE PROFILE

All content following this page was uploaded by Elie G. Hantouche on 18 June 2018.

The user has requested enhancement of the downloaded file.

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

Title no. 103-S69

Stress-Strain Model for Fiber-Reinforced Polymer

Jacketed Concrete Columns

by Mohamed H. Harajli, Elie Hantouche, and Khaled Soudki

The stress-strain behavior of fiber-reinforced polymer (FRP) their relative complexity, analysis-oriented models are only

confined concrete columns was experimentally and analytically suitable for incorporation in numerical computer analysis.

investigated, with particular emphasis on rectangular column

Irrespective of their classification, most of the proposed

sections. A new design-oriented model of the stress-strain response

of FRP confined columns was developed and an experimental stress-strain relationships are based on the following

study was carried out for deriving the model characteristic confinement model proposed by Richart et al. (1928, 1929)

parameters. The test variables included the volumetric ratio of the from tests conducted on concrete specimens confined with

FRP jackets, the aspect ratio of the column section, and the area of hydrostatic pressure

longitudinal and lateral steel reinforcement. It was found that

jacketing rectangular column sections with FRP sheets increases

f′

their axial strength and ductility. In reinforced concrete columns, f cc′ = f c′ ⎛ 1 + k 1 ----l-⎞ (1)

the FRP jackets prevent premature failure of the concrete cover ⎝ f c′ ⎠

and buckling of the steel bars, leading to substantially improved

performance. The corresponding improvements become less

f cc′

ε cc = ε o ⎛ 1 + k 2 ⎛ ------

- – 1⎞ ⎞

significant as the aspect ratio of the column section increases. The

(2)

rate of increase in concrete lateral strain with axial strain is ⎝ ⎝ fc ′ ⎠⎠

influenced by the stiffness of the FRP jackets and aspect ratio of

the column sections. Based on the results of this investigation, the

main parameters that control the stress and strain characteristics where fcc′ and εcc are the confined concrete compressive

of FRP-confined rectangular column sections were discussed, and strength and corresponding strain, respectively; fc′ and εo are

a general design model of the stress-strain response of FRP- the compressive strength and corresponding strain for

confined concrete was generated. The results predicted by the

unconfined concrete; k1 is the confinement effectiveness

model showed very good agreement with the results of the current

experimental program and other test data of FRP-confined circular coefficient and fl′ is the lateral hydrostatic pressure. Based

and rectangular columns reported in the literature. on their test results, Richart et al. (1928, 1929) found values

for k1 = 4.1 and k2 = 5.

Keywords: columns; confined concrete; ductility; fiber-reinforced Among the well-known expressions for evaluating the

concrete; polymer; stress; strain. effect of confinement on the axial strength of concrete

columns is the one proposed by Mander et al. (1988) for steel

INTRODUCTION AND LITERATURE REVIEW confined concrete. In this expression, the confined concrete

Many experimental and analytical investigations have compressive strength fcc′ and corresponding strain εcc, calcu-

been conducted in recent years to evaluate the axial load lated at the onset of yielding of the transverse steel, are

capacity and stress-strain response of concrete confined with expressed as a function of the effective constant lateral

fiber-reinforced polymer (FRP) laminates (ACI Committee 440 confining pressure fl as follows

2002). These investigations have clearly demonstrated

that confining concrete with FRP jackets leads to

substantial improvement of the axial strength and energy ⎛ 7.94f f ⎞

f cc′ = f c′ ⎜ – 1.254 + 2.254 1 + --------------l – 2 ----l-⎟ (3)

absorption capacity of concrete columns under both ⎝ f c′ f c′ ⎠

static and cyclic loading.

Several confinement models were proposed in the literature

f cc′

to evaluate the axial strength and to describe the stress-strain ε cc = ε o 1 + 5 ⎛ ------

- – 1⎞ (4)

response of FRP jacketed columns. A comprehensive review ⎝ fc ′ ⎠

and assessment of existing models has been recently

presented by Teng and Lam (2004). According to Teng and

Lam, proposed stress-strain models of FRP-confined Different expressions were generated by Mander et al.

concrete can be classified mainly into two major categories: (1988) for calculating fl depending on the shape of the

design-oriented and analysis-oriented models. In the design- column section and configuration of longitudinal and

oriented models, the stress-strain curve is generated using a lateral steel.

simple closed form solution based on evaluation and

interpretation of experimental data. In the analysis-oriented ACI Structural Journal, V. 103, No. 5, September-October 2006.

models, the stress-strain curve is generated more rigorously MS No. 04-261 received September 6, 2005, and reviewed under Institute publication

policies. Copyright © 2006, American Concrete Institute. All rights reserved, including

using an iterative procedure by considering interaction the making of copies unless permission is obtained from the copyright proprietors. Pertinent

discussion including author’s closure, if any, will be published in the July-August

between the concrete core and the confining FRP. Because of 2007 ACI Structural Journal if the discussion is received by March 1, 2007.

672 ACI Structural Journal/September-October 2006

Table 1—Summary of proposed expressions for k1

ACI member Mohamed H. Harajli is a Professor of Civil Engineering at the American

University of Beirut, Beirut, Lebanon. He is a member of ACI Committees 408, Bond Reference k1

and Development of Reinforcement, and 440, Fiber Reinforced Polymer Reinforcement.

His research interests include the design and behavior of reinforced, prestressed, and Mander et al. (1998) 2.254 f

fiber-reinforced concrete members, and strengthening and repair of concrete structures. ----------------- 1 + 7.94 ----l- – 1 – 2.0

(for steel-confined concrete) ( f l ⁄ f c′ ) f c′

Elie Hantouche is a Consultant Engineer, Samir Khairalla and Partners, Lebanon.

He received his MS from the American University of Beirut.

Karbhari and Gao (1997) 2.1(fl /fc′ )–0.13

Samaan et al. (1998) 6.0(fl )–0.3

ACI member Khaled Soudki is the Professor and Canada Research Chair in Innovative

Structural Rehabilitation at the University of Waterloo, Waterloo, Ontario, Canada. Miyauchi et al. (1997) 2.98

He is a member of ACI Committees, 215, Fatigue of Concrete; 222, Corrosion of

Metals in Concrete; 440, Fiber Reinforced Polymer Reinforcement; and 546, Repair Saafi et al. (1999) 2.2(fl /fc′ )–0.16

of Concrete. He is also a member of Joint ACI-ASCE Committee 550, Precast Con-

crete Structures. His research interests include prestressed concrete, durability of Toutanji (1999) 3.5(fl /fc′ )–0.15

concrete, rehabilitation, and strengthening of concrete structures using fiber-rein-

Lam and Teng (2003a,b) 3.3

forced polymer composites.

Unlike confinement by steel hoops where the confinement

pressure becomes theoretically constant beyond yielding of

the hoops, the linear stress-strain behavior of the FRP causes

the confining pressure in FRP-confined concrete, associated

with concrete dilation, to increase continuously with

increasing lateral or axial strain. Provided there is a good

bond between the concrete surface and FRP, the lateral strain

in the FRP is often assumed to be equal to the lateral strain

in concrete. Consequently, for FRP-confined circular

column sections, the lateral confining pressure fl is calculated

as a function of the volumetric ratio ρ f and lateral strain εl of

the FRP using the requirements of lateral strain compatibility

and force equilibrium between the concrete and confining

FRP jacket as follows

ρ f E f⎞

f l = ⎛ ---------

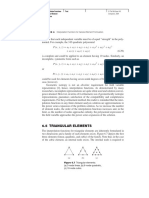

- ε (5) Fig. 1—Stress-strain model proposed by Lam and Teng

⎝ 2 ⎠ l (2003a,b).

where Whereas the stress-strain behavior of FRP confined

concrete in circular columns has been extensively studied

4n f t f (Saadatmanesh et al. 1994; Samaan et al. 1998; Spoelstra

ρ f = ----------

- (6) and Monti 1999; Toutanji 1999; Fam and Rizkalla 2001),

D because of the many unknowns associated with the behavior

of FRP-confined rectangular columns, only few analytical

in which nf is the number of applications (layers); tf is the models have been proposed to evaluate their stress-strain

design thickness of the FRP fabric; and D is the column response (Rochette and Labossiere 2000; Wang and

diameter. Whereas it does not recognize increases in strength Restrepo 2001; Lam and Teng 2003a,b).

for FRP-confined rectangular column sections, ACI Concerned in this study with the development of a design-

Committee 440 recommends evaluating the axial strength of oriented stress-strain model for FRP-confined concrete, to

FRP-jacketed circular columns using the expression of the best of the authors’ knowledge, the latest design-oriented

Mander et al. (1988) (Eq. (3)) in which the lateral confining model to describe the stress-strain response of FRP-jacketed

pressure fl is calculated using Eq. (5) corresponding to an circular or rectangular columns is the one proposed by Lam

effective lateral strain εl = εfe = 0.004 ≤ 0.75εfu, where εfu is the and Teng (2003a,b). Because of its relevance to the current

ultimate tensile strain of the FRP material. investigation and its simplicity in application, the model of

Numerous analytical and experimentally based confinement Lam and Teng is presented in this study for comparative

models were proposed to calculate the confinement purposes. Shown schematically in Fig. 1, the model is

effectiveness coefficient k1 (refer to Eq. (1)) for FRP composed of a parabolic first portion with its initial slope

confined concrete. A summary of some of the proposed being the elastic modulus of unconfined concrete Ec, and a

expressions, including the k1 equivalence of Eq. (3), is given linear second portion with a reduced slope E2 that intersects

in Table 1. Furthermore, whereas the confinement coefficient k2 the stress axis at fc = fc′ , where fc′ is the axial strength of

is constant for steel confined concrete (refer to Eq. (4)) in unconfined concrete. The model can be expressed in the

developing a stress-strain relationship for FRP-confined following general form

circular columns, Toutanji (1999) considered, based on the

experimental results of Rey (1997), that it varies in proportion to ( Ec – E2 ) 2

2

the lateral strain in the FRP as follows f cc = E c ε cc – ------------------------ε cc for 0 ≤ ε cc ≤ ε t

4f c′ (8)

k2 = 310.57εl + 1.9 (7) = f c′ + E 2 ε cc for ε t ≤ ε cc ≤ ε cu

ACI Structural Journal/September-October 2006 673

where εt is the axial strain at the intersection point between value of ks1 = fla /fc′ is less than 0.07. Lam and Teng verified

the first and second portions. The strain εt and the slope E2 the accuracy of their model by comparing with their own test

are calculated as data of rectangular column sections. Also, in its application

to circular columns, Teng and Lam (2004) concluded that

2f c′ their stress-strain model is more advantageous than the other

ε t = ----------------

- (9) available models in several aspects including accuracy and

Ec – E2 simplicity for direct use.

In this study, experimental and analytical investigations

f cu – f c′ were carried out for evaluating the stress-strain behavior of

E 2 = ----------------

- (10) FRP-jacketed columns with particular emphasis on the

ε cu

response of rectangular column sections. Based on the

results of this investigation, a new design-oriented stress-

in which fcu′ and εcu are the axial stress and corresponding strain model of FRP-confined concrete is proposed. The

axial strain at ultimate. For the general case of rectangular model, which represents an improvement over an earlier

columns, fcu′ and εcu are expressed taking into account the approximate stress-strain model proposed by the first author

reduced efficiency of rectangular sections as follows for evaluating the axial load-moment interaction capacity of

FRP-confined columns (Harajli 2005), takes into account

f cu′ f la most of the geometric and material properties that influence

-------- = 1 + k 1 k s1 ----

- (11) the stress-strain response. Verification of the model accuracy

f c′ f c′

has been made by comparing with the experimental results

obtained in this study and other experimental data reported

ε cu f la ⎛ ε h, rup⎞ 0.45 in the literature.

------- = 1.75 + k 2 k s2 ----

- ------------- (12)

εo f c′ ⎝ ε o ⎠

RESEARCH SIGNIFICANCE

The results of this experimental and analytical investigation

where

allow better understanding of the parameters that influence the

stress-strain response of rectangular column sections when

2E f n f t f confined with FRP laminates. The stress-strain model

- ε h, rup

fla = --------------- (13)

D developed in this study can be used for evaluating the axial

strength and deformation capacity of FRP-jacketed circular or

in which ks1 and ks2 are shape factors; k1 = 33 and k2 = 12.0; rectangular columns and can be employed for analyzing the

εo = 0.002; and εh,rup is the hoop rupture strain of the FRP. load-deformation response of FRP-confined concrete under

According to Lam and Teng (2003a,b), due to the effect of different types of load applications.

nonuniform stress distribution and curvature in the FRP

jacket, the rupture strain of the FRP confinement is lower THEORETICAL STRESS-STRAIN RELATIONSHIP

than the ultimate tensile strain determined from direct A two-stage relationship of the stress-strain (fcc-εcc)

coupon tests. Based on evaluation of experimental data, Lam response of FRP confined concrete is proposed. In the first

and Teng suggested using a value of εh,rup for CFRP, GFRP, stage, because the lateral strains and the consequent lateral

and AFRP equal, respectively, to 58.6, 62.4, and 85.1% of confinement pressure are small, the shape of the stress-strain

the ultimate tensile strain of the FRP material. For rectangular response can be described using the ascending branch of the

sections, the term D in Eq. (13) is the diameter of an equivalent stress-strain equations developed earlier for unconfined or

circular column given as D = h 2 + b 2 , where b is the short steel confined concrete (Sheikh and Uzumeri 1980, Scott

side and h is the long side of the section. Finally, the shape et al. 1982, and Mander et al. 1988). In this study, the stress-

factors are expressed as a function of the ratio of effectively strain response in the first stage is assumed, for simplicity, to

confined concrete area Ae to the cross sectional area Ag follow a second-degree parabola similar to the one suggested

by Sheikh and Uzumeri (1980) or Scott et al. (1982). The

corresponding two-stage fcc-εcc relationship, taking into

b 2A

k s1 = ⎛ ---⎞ -----e (14) account confinement by internal steel ties or hoops, can be

⎝ h⎠ A g

described in the following general form

h 0.5 A 2ε cc ⎛ ε cc⎞ 2

k s2 = ⎛ ---⎞ -----e (15) f cc = f co ---------

- – ------- for εcc ≤ εco (17)

⎝ b⎠ A g ε co ⎝ ε co⎠

A

2

1 – ( ( b ⁄ h ) ( h – 2r ) + ( h ⁄ b ) ( b – 2r ) ) ⁄ ( 3A g ) – ρ s

2 fcc = F ε cc = G ( ε l ), ρ f E f , ρ st fyt , section geometry (18)

-----e- = ---------------------------------------------------------------------------------------------------------------------------

- (16)

Ag 1 – ρs

≤ fcu for εcu ≥ εcc ≥ εco

in which r is the radius of the corner, and ρs is the ratio of

longitudinal steel reinforcement in the section. Note that for in which fco and εco are the stress and strain at the intersection

circular sections, the model remains exactly the same except point between the first stage (Eq. (17)) and the second stage

that the shape factors ks1 = ks2 = 1.0. According to Lam and (Eq. (18)); εcc = G(εl) is the relationship between the axial

Teng (2003b), in using the previous model for rectangular strain and lateral strain in the FRP sheets; εcu and fcu are the

sections, strength enhancement should not be expected if the maximum limiting concrete strain and corresponding stress,

674 ACI Structural Journal/September-October 2006

respectively; ρst and fyt are the volumetric ratio and yield

strength of transverse confining steel, respectively.

In the second stage of the response, including the intersection

point between the first and second stage (εcc = εco; fcc = fco),

which is assumed to correspond to a lateral strain in the FRP

sheets εl = εlo = 0.002 (Toutanji 1999), the confined concrete

compressive strength fcc and the relationship between the

axial strain and lateral FRP strain, εcc = G(εl ), can be expressed

explicitly as a function of the amount of reinforcement and

material properties by making use of the concept of Eq. (1)

and (2) as follows

Fig. 2—Confinement effectiveness coefficients: (a) using

FRP; and (b) using hoops.

A cc⎞

f cc = f c′ + k 1 ⎛ f lf + f ls ------- (19)

⎝ Ag ⎠

strength. Threshold values proposed by different investigators

for the effective FRP confinement above which the stress-

f cc ⎞

ε cc = ε o 1 + k 2 ⎛ ----- –1 (20) strain curve experiences ascending behavior were discussed

⎝ f c′ ⎠ by Lam and Teng (2003a).

For unconfined concrete or for the concrete cover of

where Acc is the area of the concrete core confined with sections confined only internally with ordinary steel and for

internal transverse hoops, measured to the centerline of the the purpose of validating the proposed model through

perimeter hoop, and εo is taken equal to 0.002. The terms flf comparisons with experimental data, the stress-strain

and fls are the effective lateral confining pressure exerted relationship in the descending branch of the unconfined

by FRP and ordinary transverse steel on the concrete concrete stress-strain response is assumed to follow the

section, respectively equation proposed by Scott et al. (1982)

k ef k vf ρ f E f⎞ fc = fc′ [1 – Z(εc – εo)] ≥ 0.2fc′ for εc ≥ εo (24)

f lf = ⎛ ----------------------

- εl (21)

⎝ 2 ⎠

where

k es k vs ρ st⎞

f ls = ⎛ -------------------- f (22) 0.5

Z = ---------------------------------------------------

- (25)

⎝ 2 ⎠ yt 3 + 0.29f c′

-------------------------------- – 0.002

145f c ′ – 1000

where

Using the previously proposed model, the stress-strain

ke(kef, kes) = Ae /Acc (23) response in the second stage of the response can be generated

by incrementally increasing the lateral strain beyond εl = εlo,

in which ρf is calculated using Eq. (6) where the equivalent and then calculating the compressive stress and corresponding

value of D for rectangular column sections is taken in strain from Eq. (19) and (20), respectively.

accordance with ACI Committee 440 (2002) as D = 2bh/(b + h). In this study, the characteristic parameters k1 and k2 of the

The terms ke (kef or kes) and kv (kvf or kvs) account for the proposed stress-strain model were determined using the test

effectiveness of the lateral reinforcement in confining the data of an experimental program designed specifically

concrete along the horizontal plane, and the concrete for the purpose of this investigation, as described in the

between transverse ties or FRP strips, respectively; and Ae is next section.

the effectively-confined concrete area. For circular columns,

kef = kes = 1.0. For columns confined with continuous FRP EXPERIMENTAL PROGRAM

sheets kvf = 1.0. Expressions for the coefficients ke and kv are Test parameters and test specimens

given in Fig. 2 for rectangular columns based on the Twenty-four small-scale column specimens of 300 mm

approach proposed by Sheikh and Uzumeri (1980), and more height were tested. Section dimensions, specimens designation,

recently by Mander et al. (1988) and ACI Committee 440 and reinforcement details are provided in Table 2 and Fig. 3.

(2002) (for evaluating the ductility of FRP confined The parameters investigated included the aspect ratio of the

sections). More details on the development of the expressions for column sections (h/b of 1, 1.7, and 2.7, respectively), the

kv and ke and also expressions for calculating kv for circular area of FRP jackets, and the area of longitudinal and lateral

column sections are described by Mander et al. (1988). steel reinforcement. The specimens were divided into

It should be noted that in the previously described theoretical three series depending on their aspect ratio. For each

stress-strain model, it is assumed that the stiffness of the FRP section aspect ratio, two groups of specimens were

jackets is sufficiently large to produce a monotonically tested, one group corresponding to plain concrete and

ascending stress-strain response until rupture of the FRP another group corresponding to reinforced concrete. In each

sheets. For insufficiently confined concrete, the stress-strain group, four specimens were tested, one control specimen

curve may experience a post-peak descending branch (without FRP) and three specimens with different areas of

whereby the ultimate compressive strength is reached before FRP jackets. While the specimens in the various test series

the FRP ruptures, producing only slight or no increase in have different aspect ratios, all column sections have

ACI Structural Journal/September-October 2006 675

Table 2—Summary of test parameters and axial load capacity results

Measured axial

Test series Column specimen Longitudinal steel As Transverse steel Ast No. of FRP layers nf ρf Ef ,* MPa ρst load capacity, kN

C1 — — — 0.0 0.0 323.1

C1FP1 — — 1 910 0.0 499.1

Series I C1FP2 — — 2 1820 0.0 689.4

b = 131.5 mm

h = 131.5 mm C1FP3 — — 3 2730 0.0 742.7

C1S 4φ8 mm φ6 mm — 0.0 0.0106 296.7

Aspect ratio

h/b = 1.0 C1SFP1 4φ8 mm φ6 mm 1 910 0.0106 557.3

C1SFP2 4φ8 mm φ6 mm 2 1820 0.0106 755.3

C1SFP3 4φ8 mm φ6 mm 3 2730 0.0106 931.0

C2 — — — 0.0 0.0 342.7

C2FP1 — — 1 926 0.0 420.4

Series II C2FP2 — — 2 1852 0.0 555.9

b = 102.0 mm

h = 176 mm C2FP3 — — 3 2778 0.0 653.4

C2S 4φ8 mm φ6 mm — 0.0 0.011 305.7

Aspect ratio

h/b = 1.7 C2SFP1 4φ8 mm φ6 mm 1 926 0.011 505.8

C2SFP2 4φ8 mm φ6 mm 2 1852 0.011 617.9

C2SFP3 4φ8 mm φ6 mm 3 2778 0.011 771.5

C3 — — — 0.0 0.0 359.3

C3FP1 — — 1 1036 0.0 468.7

Series III C3FP2 — — 2 2072 0.0 478.5

b = 79.0 mm

h = 214.0 mm C3FP3 — — 3 3108 0.0 512.7

C3S 4φ8 mm φ6 mm — 0.0 0.012 317.2

Aspect ratio

h/b = 2.7 C3SFP1 4φ8 mm φ6 mm 1 1036 0.012 432.3

C3SFP2 4φ8 mm φ6 mm 2 2072 0.012 490.2

C3SFP3 4φ8 mm φ6 mm 3 3108 0.012 607.1

*

ρf = 2nf tf (b + h)/bh.

epoxy resin. The design properties of the sheets as provided

by the manufacturer are as follows: tf = 0.13 mm per layer,

Ef = 230,000 MPa, rupture strain εfu = 0.015, and ultimate

strength ffu = 3500 MPa. Preparation of the concrete surface,

mixing of the epoxy resin, and application of the epoxy

soaked FRP sheets were all carried out in accordance with

the manufacturer specifications. Each FRP sheet was

wrapped transversely around the circumference of the

section with 100 mm overlap.

The longitudinal reinforcement in all the reinforced

specimens consisted of four φ8 mm deformed Grade 60

steel (actual yield strength of 596 MPa), producing a

longitudinal reinforcement ratio in the column sections of

approximately 1.0%. The concrete cover over the longitudinal

bars was maintained at 20 mm in all specimens. The

transverse reinforcement in the same specimens consisted of

plain 6 mm Grade 40 bars spaced at 100 mm, with the first

tie located 50 mm from the top of the specimen, producing

volumetric ratio ρst of the transverse steel (volume of ties per

spacing to volume of concrete core measured to outside of

Fig. 3—Specimen dimensions, reinforcement details, and

tie) equal to approximately 1.1% for all specimens. The

instrumentation.

modulus of elasticity of both the longitudinal and the

approximately identical areas. Also, in conformity with transverse steel is estimated at 2 × 105 MPa.

ACI 440.2R-02 (2002) recommendations, round corners The plain concrete specimens and the reinforced specimens

of 15 mm radius were provided in all specimens for FRP were cast together in two separate batches. The concrete

applications. Note that while the effect of corner radius on mixture consisted of coarse aggregate having 10 mm

the stress-strain response is accounted for in the analytical maximum size, beach sand, and portland cement (Type I).

modeling, the influence of this parameter on the test results The concrete compressive strength determined using three

was not evaluated in the current experimental program. 150 x 300 mm cylinders for each batch was 18.3 MPa for the

The FRP system consisted of monofilament carbon fiber- plain concrete specimens and 15.2 MPa for the reinforced

reinforced polymer (CFRP) flexible sheets with impregnating specimens. Note that the selection of a relatively low

676 ACI Structural Journal/September-October 2006

Fig. 4—Typical mode of failure of specimens.

concrete strength is necessitated by the limitation of the

available test facilities.

All specimens were capped using a 5 mm thick sulfur

layer. The average axial strain was measured using two linear

variable differential transformers (LVDTs) attached on

either side over a 200 mm gauge length in the middle portion

of the specimens (refer to Fig. 3). The average longitudinal

strain was also measured using one LVDT connected

between the actuator head and base of the specimens.

Average lateral concrete strains were measured using two

LVDTs attached on either side parallel to the long dimension at

the midheight of the specimens. The gauge lengths of the

LVDTs were 75, 115, 150 mm for the specimens of aspect Fig. 5—Typical stress or axial load versus strain of specimens.

ratio 1.0, 1.7, and 2.7, respectively.

Discussion of experimental results confined with three FRP wraps, the axial strength attained a

All specimens mobilized monotonically increasing stress- sizable 330, 252, and 190% increase for the specimens with

strain response until fracture of the FRP sheets, except aspect ratio of 1.0, 1.7, and 2.7, respectively.

Specimens C3FP1, C3FP2, C3FP3, and CS3FP1. Because of One of the most important observations in the current

their high aspect ratio, these specimens experienced a post- experimental study, which will be analyzed in more detail, is

peak descending branch before tensile breaking of the FRP that the rate of increase of the measured average lateral strain

sheets. Fracturing of the FRP sheets, which took place with the axial strain tended to decrease as the aspect ratio of

mostly at the junction between the corners and the flat sides the column section and also as the area or stiffness of the

of the specimens (refer to Fig. 4), resulted in a sudden and FRP jacket increased. This observation, which is similar to

almost total loss of axial strength. Typical load or stress the observation reported earlier by Chaallal et al. (2003) and

versus axial strain and average lateral strain responses are which has been disregarded in the development of earlier

given in Fig. 5. It should be indicated that because of the stress-strain models, has a substantial implication on the

large curvature of the FRP sheets at the corners, it is likely derivation of the characteristic parameters k1 and k2 of the

that the actual FRP strains at the location where the sheets proposed stress-strain model as illustrated in the following.

fractured (at the corners) are lower than the ultimate material

tensile strain. This observation is even true for circular PROPOSED EXPRESSIONS FOR k1 AND k2

column sections and represent the basis upon which the Using the experimentally measured axial stress and lateral

design-oriented model proposed by Lam and Teng (2003a,b) strains, values of k1 for the various FRP-confined specimens

is developed (Eq. (8) to (16)). were estimated in the second stage of the response (beyond

Some of the important and direct observations that can be εl = εlo = 0.002) from Eq. (19) as a function of the proposed

drawn from the test results are: a) increasing the area of FRP confinement parameters flf and fls(k1 = [fcc – fc′]/[flf + flsAcc /Ag])

reinforcement increased the axial stress and axial strain that and plotted as a function of fl/fc′= ([flf + flsAcc /Ag]/fc′) , as

can be mobilized at failure of the column sections; b) shown in Fig. 6. Shown also in Fig. 6, for the purpose of

improvements in axial strength and strain were most significant comparison, are the predictions of the various expressions

for square columns and tended to decrease as the aspect ratio summarized in Table 2. For the equation proposed by

of the column section increased (refer to Table 2). For Samaan et al. (1998), a value of fc′ = 18.3 MPa, to correspond to

instance, considering the plain concrete specimens confined the plain concrete specimens in the current investigation,

with three FRP wraps, the stress attained a 230, 190, and is assumed.

143% increase for the column sections with aspect ratios of It can be observed in Fig. 6 that the magnitude of k1

1.0, 1.7, and 2.7, respectively; and c) For the steel reinforced decreases consistently from a relatively high value in the

specimens, external confinement by FRP prevented spalling early stage of the response during which the effective lateral

of the concrete cover and premature buckling of the longitudinal confining pressure is low, to a value close to 2.0 as the

steel bars that would otherwise occur, leading to superior confining pressure increases. Note that the magnitudes of k1

improvements of the axial load and axial strain capacities at low values of fl /fc′ were slightly lower for the reinforced

when compared with the control unconfined specimens in specimens in comparison with the plain concrete specimens.

the same test series. For the steel reinforced columns Part of this difference may be attributed to the fact that the

ACI Structural Journal/September-October 2006 677

Fig. 6—Variation of confinement parameter k1 with lateral

strain.

Fig. 8—Variation of confinement parameter k2 with lateral

strain: (a) h/b = 1.0; (b) h/b = 1.7; and (c) h/b = 2.7.

and Teng (2002) based on statistical analysis of experimental

data, particularly at high values of fl /fc′ .

The use of regression analysis of the data presented in

Fig. 6 produced a best-fit expression for k1 given by k1 =

1.13( fl /fc′ )–0.69 with a coefficient of correlation of 0.88 for

the plain specimens, and k1 = 1.3(fl /fc′ )–0.41 with a coefficient of

correlation of 0.63 for the reinforced specimens. Based on

regression analysis of all the data combined, the following

equation is proposed for calculating the confinement

effectiveness coefficient k1 (refer to Fig. 6)

f lf + f ls A cc ⁄ A g⎞ –0.5

k 1 = 1.25 ⎛ ---------------------------------

- (26)

⎝ f c′ ⎠

Fig. 7—Axial strain versus lateral strain: (a) h/b = 1.0; (b) where 2 ≤ k1 ≤ 7.

h/b = 1.7; and (c) h/b = 2.7. Figure 7 shows a variation of measured concrete lateral

strain with axial strain and Fig. 8 shows a variation of k2

values of fcc for the plain specimens are extracted directly calculated from the experimental results using Eq. (20) (k2 =

from the experimental data, while the values of fcc for the [εcc /εco – 1]/[fcc /fc′ – 1]) with measured lateral strain beyond

reinforced specimens had to be estimated indirectly by εlo = 0.002 for the specimens with different section

taking into account the force carried by the longitudinal aspect ratios.

steel. It can also be seen in Fig. 6 that, while the experimental The results presented in Fig. 7 show that, irrespective of

data falls well within the range of the predictions of the the aspect ratio of the column sections or area of the FRP

various expressions proposed in the technical literature, it jackets, the rate of increase of lateral strain with axial strain

agrees best with the value of k1 = 2.0 derived earlier by Lam (slope of the εl-εcc relationship) was small in the early stage

678 ACI Structural Journal/September-October 2006

of the response but experienced a large increase and,

consequently, a change of behavior beyond a lateral strain of

approximately 0.002. Hence, the selection of a lateral strain

εl = εlo = 0.002 to correspond to the intersection point

between the two stages of the stress-strain response as

suggested in the study of Toutanji (1999) and as adopted in

this study appears to be reasonably validated. Beyond a

lateral strain of 0.002, all specimens, including the control

unconfined specimens, mobilized an approximately linear

(εl-εcc) relationship. Because the FRP confinement curtails

the dilation rate of concrete (Mirmiran and Shahawy 1997),

however, the rate of increase in lateral strain with axial strain

tended to decrease as the area of FRP jackets increased

(mostly evident for the specimens with h/b = 1 and 1.7).

Another interesting observation in Fig. 7 is that while the rate

of increase in lateral strain with axial strain for the unconfined

control specimens was not influenced by the shape of the

column section, it dropped noticeably for the FRP confined

specimens as the aspect ratio of the section increased.

Similar to the (εl-εcc) behavior shown in Fig. 7, the results

in Fig. 8 clearly demonstrate that the magnitude of k2

increases almost linearly with the increase in lateral strain.

Also, it can be seen in Fig. 8 that the rate of increase in k2

with lateral strain tends to decrease with increase in the

volumetric ratio of the FRP jackets but increases significantly

with increase in the aspect ratio of the column section. Based

on these observations, accurate evaluation of the stress-strain

response or ultimate load capacity of FRP confined columns

should take into account that the confinement coefficient k2 Fig. 9—Comparison of model predictions with current test

is not constant or only a function of the lateral strain as results of plain concrete specimens.

suggested in Eq. (7) but also a function of the volumetric

ratio and modulus of elasticity of the FRP jackets, and most fcc/fc′ (28)

importantly, the aspect ratio h/b of the column section. At

present and until more data becomes available to develop a

more accurate relationship between the axial strain and ( k ef ρ f E f ⁄ 2 )ε l + ( k es k vs ρ st A cc ⁄ 2A g )f yt

= 1 + 1.25 -------------------------------------------------------------------------------------------

-

lateral strain as a function of the stiffness of the FRP jacket f c′

and aspect ratio of the column section, the trend of the

experimental results presented in Fig. 8 is only consistent

enough to allow the generation of the following approximate, ⎛ 25,800e 1.17h ⁄ b ⎞ f cc ⎞

- ε l + 2.0⎟ ⎛ -----

ε cc = ε o 1 + ⎜ --------------------------------- –1 (29)

⎠ ⎝ f c′ ⎠

mathematically simple, and yet reasonably accurate expression

⎝ ( ρf Ef ) 0.83

for estimating k2 as a function of the control parameters

⎛ 25,800e 1.17h ⁄ b⎞ Because of the limitation imposed on the value of k1 in

-⎟ ε l + 2.0

k 2 = ⎜ --------------------------------- (27) Eq. (26), the value of (fcc/fc′ – 1) calculated using Eq. (28) shall

⎝ ( ρ f E f) 0.83 ⎠ not be taken less than 2.0[flf + fls]/fc′ or more than 7.0[flf +

fls]/fc′ . The stress-strain curve in the second stage can be

generated by incrementally increasing εl and calculating fcc

In which Ef is expressed in MPa. Note that Eq. (27) is from Eq. (28), and then calculating the corresponding εcc

applicable within the range of values of the experimental from Eq. (29). Because it is well established that the actual

parameters used in this investigation, that is, h/b ≤ 2.7 and is rupture strain in FRP is lower than the ultimate tensile strain

assumed to be applicable for circular column sections for of the FRP materials (Lam and Teng 2003a), it is recommended

values of h/b = 1.0. It is interesting to point out that for to estimate the ultimate axial stress fcu and corresponding

circular sections (h/b = 1), and for a value of ρf Ef = 840 MPa, ultimate axial strain εcu using Eq. (28) and (29) by substituting a

Eq. (27) coincides with the experimentally-based equation value for the lateral strain εl = Fεfu, where F is a strain

(Eq. (7)) used by Toutanji (1999) to derive a stress-strain reduction factor equal to 0.6 for CFRP and GFRP and 0.85

model for circular columns. for AFRP in accordance with the values derived by Lam and

Replacing the values of k1 and k2 from Eq. (26) and (27) Teng (2003a).

and the values of flf and fls from Eq. (21) and (22), respectively,

into Eq. (19) and (20) leads to the following general expressions COMPARISON OF PROPOSED MODEL

for generating the stress-strain relationship of FRP-confined WITH EXPERIMENTAL RESULTS

concrete in the second stage of the response, including the The predictions of the proposed stress-strain model were

intersection point between the first and second stage (εl = compared with the experimental data of the current investigation

εlo = 0.002; εcc = εco; fcc = fco) as well as the predictions of the design-oriented model of Lam and

ACI Structural Journal/September-October 2006 679

Table 3—Experimental data for circular and

rectangular columns

Column Concrete

Section dimension, strength Fiber ρf Ef ,

Reference Specimen type mm fc′ , MPa type MPa

Nanni et al. A1 Circular 150 41 Aramid 4274

(1994) A2 Circular 150 41 Aramid 914

Harmon et al. — Circular 50 64.0 Glass 2760

(1995)

Pitcher et al. — Circular 152 39.7 Carbon 786

(1996)

GE Circular 76 31.0 Glass 917

Toutanji C1 Circular 76 31.0 Carbon 2670

(1999)

C5 Circular 76 31.0 Carbon 6475

1CFRP1/1 Square* 180 21 Carbon 860

Cole and 1GFRP1/1 Square 180 21 Glass 563

Belarbi

(2001) 2GFRP1/1 Square 180 21 Glass 1126

3GFRP1/1 Square 180 21 Glass 1689

Series I Circular 152 † Carbon 1140

Teng and 39.0

Lam (2002) Series II Circular 152 37.7† Carbon 800

‡

Lam and S2R25 Square 150 33.7† Carbon 2260

Teng (2003b) S3R15 Square§ 150 24.0† Carbon 3390

*

Corner radius for FRP application = 22.5 mm; As = four No. 4 (Grade 40); ρst = 0.006.

†

Cylinder strength fc′ is assumed equal to 80% of reported cube strength fcu.

‡

Corner radius for FRP application is equal to 25 mm.

§

Corner radius for FRP application is equal to 15 mm.

reproducing the experimental results when compared with

the design-oriented model developed in this study.

CONCLUSIONS

The stress-strain response of FRP-confined rectangular

concrete column sections was experimentally and analytically

investigated. A theoretical stress-strain model is developed and

an experimental study was carried out to derive the model

characteristic parameters. Based on this investigation, the

following conclusions and observations can be drawn:

1. Confining rectangular columns with FRP jackets leads

Fig. 10—Comparison of model predictions with current test

to substantial improvement in the axial strength and ductility

results of steel-reinforced concrete specimens.

of compression failure of the columns. For square column

sections without longitudinal reinforcement (plain

Teng (2003a,b) presented in Eq. (8) corresponding to the plain specimens), the increases in axial strength were 154, 213,

concrete specimens. Results are shown in Fig. 9 and 10. and 230% for the specimens confined with one, two, or three

Despite some discrepancy, the analytical results predicted CFRP wraps, respectively;

using the proposed model are generally in good agreement 2. The improvement of column axial strength and ductility

with the experimental stress-strain response of the specimens in due to FRP confinement becomes less significant as the

the current investigation. Because the FRP-confined plain aspect ratio (h/b) of the column section increases. For the

concrete specimens with aspect ratio h/b = 2.7 experienced a plain column sections with aspect ratio of 2.7, the increases

post-peak descending branch before fracturing of the FRP in axial strength were 133, 133, and 143% for the specimens

sheets, the agreement between the analytical predictions and confined with one, two, or three CFRP wraps, respectively;

the test data was not as good in comparison with the 3. For reinforced concrete columns, external confinement

by FRP jackets prevents premature compression failure of

remaining specimens.

the concrete cover and buckling of the longitudinal steel bars

The analytical model was also compared with test results that normally occur in steel confined concrete, leading to

of circular column specimens and rectangular specimens substantial improvement in axial strength. For the square

reported in the technical literature as shown in Fig. 11. A steel reinforced columns, the increase in axial strength in

summary of test parameters for the specimens is provided in comparison with the control unconfined specimen in the same

Table 3. It can be seen from the comparisons that the series attained a sizable 188, 255, and 310% increase for

proposed model was able to reproduce other test data with the specimens confined with one, two, or three CFRP

reasonable accuracy. Note that while the model of Lam and wraps, respectively;

Teng (Eq. (8)) is easier to apply and allows more direct use 4. For a given aspect ratio of rectangular column section,

for design applications, it was generally less accurate in the rate of increase in lateral strain with axial strain decreases

680 ACI Structural Journal/September-October 2006

Fig. 11—Comparison of model predictions with experimental data.

as the stiffness ρf Ef of the FRP jackets increases. Also, for a influence the stress and strain behavior were derived and a

given ρf Ef of the FRP jackets, the rate of increase of lateral general analytical model for generating the stress-strain

strain with axial strain decreases with increase in the aspect response and evaluating the ultimate axial strength and

ratio of the section; and deformation capacity of FRP-jacketed columns was

5. Irrespective of the h/b of the column section or ρf Ef of developed. The model takes into account almost all the

the FRP jackets, the stress-strain response of FRP confined design variables that control the axial stress and strain

columns experiences a considerable increase in lateral strain, characteristics of FRP-confined columns. Results

and, consequently, a distinct change in behavior, beyond a predicted by the model were generally in good agreement

confined lateral strain of approximately 0.002. with the experimental results of the current investigation

Based on the results of the experimental investigation, and other test data of FRP-confined circular and rectangular

analytical expressions for the characteristic parameters that column sections reported in the literature.

ACI Structural Journal/September-October 2006 681

ACKNOWLEDGMENTS Journal of Composites for Construction, ASCE, V. 9, No. 1, pp. 4-14.

This research was supported by the Lebanese National Council for Scientific Harmon, T.; Slattery, K.; and Ramakrishnan, S., 1995, “The Effect of

Research (LNCSR). The authors are grateful for that support and to the Faculty Confinement Stiffness on Confined Concrete,” Non-Metallic (FRP)

of Engineering and Architecture at the American University of Beirut for Reinforcement for Concrete Structures, Proceedings of the 2nd International

providing the test facilities. RILEM Symposium (FRPRCS-2), pp. 584-592.

Karbhari, V. M., and Gao, Y., 1997, “Composite Jacketed Concrete

Under Uniaxial Compression—Verification of Simple Design Equations,”

NOTATION Journal of Materials in Civil Engineering, ASCE, V. 9, No. 4, pp. 185-193.

Acc = area of concrete core

Lam, L., and Teng, J. G., 2002, “Strength Models for Fiber-Reinforced

Ae = area of effectively confined concrete section

Plastic-Confined Concrete,” Journal of Structural Engineering, ASCE,

Ag = area of gross section

V. 128, No. 5, May, pp. 612-623.

As = area of column longitudinal reinforcement

Lam, L., and Teng, J. G., 2003a, “Design-Oriented Stress-Strain Model

b = section short dimension

for FRP-Confined Concrete,” Construction and Building Materials, V. 17,

D = diameter or equivalent diameter of column section

pp. 471-489.

Ec = modulus of elasticity of unconfined concrete

Lam, L., and Teng, J. G., 2003b, “Design-Oriented Stress-Strain Model

Ef = modulus of elasticity of transverse FRP

for FRP-Confined Concrete in Rectangular Columns,” Journal of Reinforcing

fc = stress in unconfined concrete

Plastics and Composites, V. 22, No. 13, pp. 1149-1186.

fc′ = compressive strength of unconfined concrete

Mander, J. B.; Priestley, M. J. N.; and Park, R., 1988, “Theoretical

fcc = stress in confined concrete

Stress-Strain Model for Confined Concrete,” Journal of Structural

fcc′ = compression strength of confined concrete Engineering., ASCE, V. 114, No. 8, Aug., pp. 1804-1826.

fco = stress at intersection point between first and second stage of

Mirmiran, A., and Shahawy, M., 1997, “Behavior of Concrete Columns

stress-strain curve

Confined by Fiber Composites,” Journal of Structural Engineering, ASCE,

fcu = stress corresponding to a limiting strain εcu V. 123, No. 5, May, pp. 583-590.

ffu = rupture stress of FRP sheets

Miyauchi, K.; Nishibayashi, S.; and Inoue, S., 1997, “Estimation of

fl = effective lateral confining pressure

Strengthening Effects with Carbon Fiber Sheet for Concrete Column,”

fl′ hydrostatic confining pressure Non-Metallic (FRP) Reinforcement for Concrete Structures, Proceedings of

flf = effective lateral confining pressure provided by FRP the 3rd International RILEM Symposium, Sapparo, Japan, V. 1, pp. 217-224.

fls = effective lateral confining pressure provided by steel hoops Nanni, A.; Norris, M. S.; and Bradford, N. M., 1994, “Lateral Confinement

fyt = yield stress of transverse hoops of Concrete Using FRP Reinforcement,” Fiber-Reinforced Plastic

h = section long dimension Reinforcement for Concrete Structures, SP-138, A. Nanni and C. W. Dolan,

k1, k2, eds., American Concrete Institute, Farmington Hills, Mich., pp. 193-209.

ke , kv = confinement effectiveness coefficients Picher, F.; Rochette, P.; and Labossiere, P., 1996, “Confinement of Concrete

nf = number of transverse FRP layers Cylinders with CFRP,” Fiber Composites in Infrastructure, Proceedings of the

r = corner radius 1st International Conference on Composites in Infrastructure, H. Saadetmanesh

s′ = clear spacing between transverse hoops and M. R. Ehsani, eds., University of Arizona, Tucson, Ariz., pp. 829-841.

tf = thickness of one FRP layer Rey, F. J., 1997, “Durability and Long Performance of Concrete Structural

w = clear distance between adjacent longitudinal bars Elements Strengthened with FRP Sheets,” MS thesis, University of Puerto

wxi, wyi = i-th clear distance between adjacent longitudinal bars along Rico, Mayaguez, Puerto Rico.

horizontal x- and y-dimensions, respectively Richart, F. E.; Brandtzaeg, A.; and Brown, R. L., 1928, “A Study of the

x, y = concrete core dimensions to center line of peripheral hoop Failure of Concrete Under Combined Compressive Stresses,” Bulletin 185,

εc = axial strain in unconfined concrete University of Illinois Engineering Experimental Station, Champaign, Ill.

εcc = axial strain in confined concrete Richart, F. E.; Brandtzaeg, A.; and Brown, R. L., 1929, “The Failure of

εco = concrete strain at intersection point between first and second Plain and Spirally Reinforced Concrete in Compression,” Bulletin 190,

stage of stress-strain curve University of Illinois Engineering Experimental Station, Champaign, Ill.

εcu = limiting concrete strain Rochette, P., and Labossiere, P., 2000, “Axial Testing of Rectangular

εfe = effective lateral strain in FRP Column Models Confined with Composites,” Journal of Composites for

εfu = ultimate tensile strain of FRP material Construction, ASCE, V. 4, No. 3, pp. 129-136.

εh,rup = hoop rupture strain of FRP sheets Saadatmanesh, H.; Ehsani, M. R.; and Li, M. W, 1994, “Strength and

εl = lateral concrete strain Ductility of Concrete Columns Externally Confined with Fiber Composite

εlo = lateral concrete strain at intersection point between first and Straps,” ACI Structural Journal, V. 94, No. 1, Jan.-Feb., pp. 434-447.

second stage of stress-strain curve Saafi, M.; Toutanji, H. A.; and Li, Z., 1999, “Behavior of Concrete Columns

εo = strain at maximum stress for unconfined concrete Confined with Fiber Reinforced Polymer Tubes,” ACI Materials Journal,

εyt = yield strain of transverse hoops V. 96, No. 4, July-Aug., pp. 500-509.

ρcc = steel ratio relative to concrete core section Samaan, M.; Mirmiran, A.; and Shahawy, M., 1998, “Model for Concrete

ρf = volumetric ratio of FRP reinforcement Confined by Fiber Composites,” Journal of Structural Engineering,

ρs = ratio of column longitudinal reinforcement ASCE, V. 124, No. 9, pp. 1025-1931.

ρst = volumetric ratio of hoop reinforcement Scott, B. D.; Park, R.; and Priestley, M. J. N., 1982, “Stress-Strain

Behavior of Concrete Confined by Overlapping Hoops at Low and High

REFERENCES Strain Rates,” ACI JOURNAL , Proceedings V. 79, No. 1, Jan., pp. 13-27.

ACI Committee 440, 2002, “Design and Construction of Externally Sheikh, S. A., and Uzumeri, S. M., 1980, “Strength and Ductility of Tied

Bonded FRP Systems for Strengthening Concrete Structures (ACI 440.2R-02),” Concrete Columns,” Journal of the Structural Division, ASCE, V. 106, No. 5,

American Concrete Institute, Farmington Hills, Mich., 45 pp. pp. 1079-1102.

Chaallal, O.; Shahawy, M.; and Hassan, M., 2003, “Performance of Axially Spoelstra, M. R., and Monti, G., 1999, “FRP-Confined Concrete

Loaded Short Rectangular Columns Strengthened with Carbon Fiber- Model,” Journal of Composites for Construction, ASCE, V. 3, No. 3, Aug.,

Reinforced Polymer Wrapping,” Journal of Composites for Construction, pp. 143-150.

ASCE, V. 7, No. 3, pp. 200-208. Teng, J. G., and Lam, L., 2002, “Compressive Behavior of Carbon Fiber

Cole, C., and Belarbi, A., 2001, “Confinement Characteristics of Rectangular Reinforced Polymer-Confined Concrete in Elliptical Columns,” Journal of

FRP-Jacketed Columns,” Proceedings of the 5th International Conference Structural Engineering, ASCE, V. 128, No. 12, Dec., pp. 1535-1543.

on Fiber-Reinforced Plastics for Reinforced Concrete Structures, Cambridge, Teng, J. G., and Lam, L., 2004, “Behavior and Modeling of Fiber

UK, July 16-18, pp. 823-832. Reinforced Polymer-Confined Concrete,” Journal of Structural Engineering,

Elwi, A. A., and Murray, D. W., 1979, “A 3D Hypoelastic Concrete ASCE, V. 130, No. 11, pp. 1713-1723.

Constitutive Relationship,” Journal of Engineering Mechanics, ASCE, Toutanji, H. A., 1999, “Stress-Strain Characteristics of Concrete Column

V. 105, No. 4, pp. 623-641. Externally Confined with Advanced Fiber Composite Sheets,” ACI Materials

Fam, A. Z., and Rizkalla, S. H., 2001, “Confinement Model for Axially Journal, V. 96, No. 3, May-June, pp. 397-404.

Loaded Concrete Confined by Circular Fiber-Reinforced Polymer Tubes,” Wang, Y. C., and Restrepo, J. I., 2001, “Investigation of Concentrically

ACI Structural Journal, V. 98, No. 4, July-Aug., pp. 451-461. Loaded Reinforced Concrete Columns Confined with Glass Fiber

Harajli, M. H., 2005, “Behavior of Gravity Load-Designed Rectangular Reinforced Polymer Jackets,” ACI Structural Journal, V. 98, No. 3, Mar.-

Concrete Columns Confined with Fiber Reinforced Polymer Sheets,” Apr., pp. 377-385.

682 ACI Structural Journal/September-October 2006

View publication stats

You might also like

- RCS4099مشروع 1Document12 pagesRCS4099مشروع 1malek malekNo ratings yet

- Pstruct 2019 111459Document11 pagesPstruct 2019 111459Mn HmoodNo ratings yet

- Strength of Short Concrete Columns Confined with CFRP SheetsDocument9 pagesStrength of Short Concrete Columns Confined with CFRP SheetsSaddam Abdulrahman AlazzaniNo ratings yet

- Axial Behavior of Circular CFFT Long Columns Internally Reinforced With Steel or Carbon and Glass FRP Longitudinal BarsDocument12 pagesAxial Behavior of Circular CFFT Long Columns Internally Reinforced With Steel or Carbon and Glass FRP Longitudinal BarsZhi Ming CheahNo ratings yet

- 1 s2.0 S0263822321013994 MainDocument19 pages1 s2.0 S0263822321013994 MainAli BenzaamiaNo ratings yet

- What Do We Know About Confinement in Reinforced Concrete Columns-Sakai-SheikhDocument16 pagesWhat Do We Know About Confinement in Reinforced Concrete Columns-Sakai-SheikhAlberto Ezequiel León TamayoNo ratings yet

- Engineering Structures: Ran Feng, Yanwen Li, Ji-Hua Zhu, Feng XingDocument15 pagesEngineering Structures: Ran Feng, Yanwen Li, Ji-Hua Zhu, Feng XingEng mohammadNo ratings yet

- J Cemconcomp 2006 12 003Document12 pagesJ Cemconcomp 2006 12 003Ambika SubediNo ratings yet

- Confinement Model For Circular Concrete Columns Transversely Reinforced With GFRP Spirals and HoopsDocument6 pagesConfinement Model For Circular Concrete Columns Transversely Reinforced With GFRP Spirals and HoopsAbdullah tahaNo ratings yet

- Seismic Design Basis For Internally-Braced RC Frames: M.R. Maheri and H. GhaffarzadehDocument8 pagesSeismic Design Basis For Internally-Braced RC Frames: M.R. Maheri and H. Ghaffarzadehhlong123123No ratings yet

- Retrofit of Square Concrete Columns With Carbon Fiber Reinforced Polymer For Seismic ResistanceDocument11 pagesRetrofit of Square Concrete Columns With Carbon Fiber Reinforced Polymer For Seismic Resistanceanne marieNo ratings yet

- 1 s2.0 S0141029617323829 MainDocument17 pages1 s2.0 S0141029617323829 MainAnonymous cKV7P2magXNo ratings yet

- Experimental Investigation On Eccentric Compression Behavior of FRP-confined Concrete-Encased Cross-Shaped Steel ColumnsDocument15 pagesExperimental Investigation On Eccentric Compression Behavior of FRP-confined Concrete-Encased Cross-Shaped Steel ColumnsXin HuangNo ratings yet

- Parametric Study of Beams With Externally Bonded FRP ReinforcementDocument9 pagesParametric Study of Beams With Externally Bonded FRP ReinforcementpicottNo ratings yet

- A Study of Reinforced Concrete Bridge Columns RetrDocument11 pagesA Study of Reinforced Concrete Bridge Columns Retrnattanai kuangmiaNo ratings yet

- Modelling of Frp&Steel-Confined Circular RC Sections: R R C CDocument4 pagesModelling of Frp&Steel-Confined Circular RC Sections: R R C CDamian KowalskiNo ratings yet

- Petersen 2018Document10 pagesPetersen 2018Suvendu ParidaNo ratings yet

- Axial Load LevelDocument17 pagesAxial Load Levelnikhil bembadeNo ratings yet

- Retrofitting of Reinforced Concrete Beam-Column Joints by Composites-Part II: Analytical StudyDocument10 pagesRetrofitting of Reinforced Concrete Beam-Column Joints by Composites-Part II: Analytical Study'Willi Orozco'No ratings yet

- Composite Structures: SciencedirectDocument12 pagesComposite Structures: Sciencedirectanis suhailiNo ratings yet

- Near Surface Mounted FRP MaterialDocument26 pagesNear Surface Mounted FRP MaterialMuhammad AjmalNo ratings yet

- Displacement Based Design of Reinforced Concrete Columns For ConfinementDocument9 pagesDisplacement Based Design of Reinforced Concrete Columns For ConfinementbrahmabulNo ratings yet

- Seismic Performance of Concrete-Filled Steel Tubular (CFST) StructuresDocument8 pagesSeismic Performance of Concrete-Filled Steel Tubular (CFST) StructuresPatel TosifNo ratings yet

- Confining Reinforcement for High StrengtDocument2 pagesConfining Reinforcement for High StrengtArthur DahokloryNo ratings yet

- 15-Performance of Concrete-Filled Thin-Walled Steel Tubes Under Pure Torsion 2007 PDFDocument13 pages15-Performance of Concrete-Filled Thin-Walled Steel Tubes Under Pure Torsion 2007 PDFHendrik TaupanNo ratings yet

- Proposed Design of High-Strength Spiral Reinforcement in Compression MembersDocument12 pagesProposed Design of High-Strength Spiral Reinforcement in Compression MembersTavio TavioTavioNo ratings yet

- Thin-Walled Structures: An He, Jian Cai, Qing-Jun Chen, Xinpei Liu, Jin XuDocument15 pagesThin-Walled Structures: An He, Jian Cai, Qing-Jun Chen, Xinpei Liu, Jin XuParth DaxiniNo ratings yet

- 1 s2.0 S0263822317328350 MainDocument15 pages1 s2.0 S0263822317328350 MainArthur DahokloryNo ratings yet

- Confinementreinforcement RCcolumns ICJAug2011Document10 pagesConfinementreinforcement RCcolumns ICJAug2011joshuaNo ratings yet

- Cao (2019) ADocument12 pagesCao (2019) AFRP ItuNo ratings yet

- Confinementreinforcement RCcolumns ICJAug2011 PDFDocument10 pagesConfinementreinforcement RCcolumns ICJAug2011 PDFSamuel megersaNo ratings yet

- Kadhim 2023 IOP Conf. Ser. Earth Environ. Sci. 1232 012034Document9 pagesKadhim 2023 IOP Conf. Ser. Earth Environ. Sci. 1232 012034engraslam39No ratings yet

- Compressive Characteristics of Damaged Circular Hollow Section (CHS) Steel Columns Repaired by CFRP or Grout JacketingDocument11 pagesCompressive Characteristics of Damaged Circular Hollow Section (CHS) Steel Columns Repaired by CFRP or Grout Jacketingnomigamer99No ratings yet

- Strengthening of The Self-Compacted Reinforced Concrete Corbels Using NSM Steel Bars and CFRP Sheets TechniquesDocument18 pagesStrengthening of The Self-Compacted Reinforced Concrete Corbels Using NSM Steel Bars and CFRP Sheets Techniquesmohamme.arif63No ratings yet

- 3D Modelling and Analysis of Encased Steel-Concrete Composite ColumnDocument10 pages3D Modelling and Analysis of Encased Steel-Concrete Composite ColumnTasktareaNo ratings yet

- 2005 (A Colori) TAHER - Strenghtening of Critically Designed Girders With Dapped EndsDocument31 pages2005 (A Colori) TAHER - Strenghtening of Critically Designed Girders With Dapped EndsEleonora InghelleriNo ratings yet

- Analytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceDocument14 pagesAnalytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceAndres NaranjoNo ratings yet

- Damage PlasticityDocument12 pagesDamage PlasticityVibhanshu Mishra100% (1)

- Analytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceDocument14 pagesAnalytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceAndres NaranjoNo ratings yet

- An Accurate Method For The Calculation of UltimateDocument12 pagesAn Accurate Method For The Calculation of UltimateManoj KumarNo ratings yet

- Shear Strength of RC Jacketed Interior Beam-Column Joints Without Horizontal Shear ReinforcementDocument17 pagesShear Strength of RC Jacketed Interior Beam-Column Joints Without Horizontal Shear ReinforcementPaul KohanNo ratings yet

- Ductility of Prefabricated Cage Reinforced Concrete Beams: Analytical StudyDocument9 pagesDuctility of Prefabricated Cage Reinforced Concrete Beams: Analytical StudymagdyamdbNo ratings yet

- Retrofitting of Reinforced ConDocument11 pagesRetrofitting of Reinforced ConForsythe LearningNo ratings yet

- Seismic Retrofit Using Continuous Fiber SheetsDocument8 pagesSeismic Retrofit Using Continuous Fiber SheetsMohit KohliNo ratings yet

- Improvement in Properties of Circular Columns Using Welded Wire Mesh WWM An Experimental StudyDocument7 pagesImprovement in Properties of Circular Columns Using Welded Wire Mesh WWM An Experimental StudyEditor IJTSRDNo ratings yet

- Fibers: Combined Transverse Steel-External FRP Confinement Model For Rectangular Reinforced Concrete ColumnsDocument25 pagesFibers: Combined Transverse Steel-External FRP Confinement Model For Rectangular Reinforced Concrete ColumnsjasimabdNo ratings yet

- Experimental Study On Concrete Columns Reinforced by Hyb - 2017 - Construction ADocument10 pagesExperimental Study On Concrete Columns Reinforced by Hyb - 2017 - Construction AAliNo ratings yet

- RC Corbels-SimplifiedDocument6 pagesRC Corbels-SimplifiedSRINIVASAN TNo ratings yet

- Three-dimensional finite element analysis of reinforced concreteDocument14 pagesThree-dimensional finite element analysis of reinforced concreteArthur DahokloryNo ratings yet

- ACI 108 s34 PDFDocument11 pagesACI 108 s34 PDFSoveasna ChanNo ratings yet

- Performance of RFP Wrapped RC Column Under Combined Axial Flexural LoadingDocument10 pagesPerformance of RFP Wrapped RC Column Under Combined Axial Flexural LoadingCu ToànNo ratings yet

- Mechanical Behavior of Circular and Square Concrete Filled Steel Tube Stub Columns Under Local Compression, 2015 (Fa-Xing Ding)Document12 pagesMechanical Behavior of Circular and Square Concrete Filled Steel Tube Stub Columns Under Local Compression, 2015 (Fa-Xing Ding)Phan Đào Hoàng HiệpNo ratings yet

- 1 s2.0 S0950061818310663 MainDocument10 pages1 s2.0 S0950061818310663 Mainliuwei.feaNo ratings yet

- Strengthening of RC Chimneys With FRP Composites 0Document6 pagesStrengthening of RC Chimneys With FRP Composites 0andyhrNo ratings yet

- 5905 13961 1 PBDocument7 pages5905 13961 1 PBNhật KhaNo ratings yet

- Sobrevega-Seismic Performance C-SMRFDocument9 pagesSobrevega-Seismic Performance C-SMRFFrance Mico SobrevegaNo ratings yet

- PVC Plastic Tube With Concrete Infill Strengthened With FRP: A State-Of-The-Art ReviewDocument9 pagesPVC Plastic Tube With Concrete Infill Strengthened With FRP: A State-Of-The-Art ReviewCelina Birta SantosoNo ratings yet

- Composites Part B: SciencedirectDocument15 pagesComposites Part B: SciencedirectAli petekNo ratings yet

- Materials and Design: H. Akbarzadeh, A.A. MaghsoudiDocument18 pagesMaterials and Design: H. Akbarzadeh, A.A. MaghsoudiQudrati Al WasiewNo ratings yet

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Pages From 30.fundamentals of Finite Element Analysis-5Document8 pagesPages From 30.fundamentals of Finite Element Analysis-5Tú LêNo ratings yet

- Kolonda Köşeleri Pahlama Yarıçapının Eksenel Yük Kapasitesine Etkisi Wang 2008Document13 pagesKolonda Köşeleri Pahlama Yarıçapının Eksenel Yük Kapasitesine Etkisi Wang 2008aygunbayramNo ratings yet

- 1D CNNs Survey Applications Neural Networks Signal ProcessingDocument21 pages1D CNNs Survey Applications Neural Networks Signal ProcessingRoberto HolNo ratings yet

- 3 Rousakis2007Document11 pages3 Rousakis2007Tú LêNo ratings yet

- Pages From 30.fundamentals of Finite Element Analysis-4Document3 pagesPages From 30.fundamentals of Finite Element Analysis-4Tú LêNo ratings yet

- Kolonda Köşeleri Pahlama Yarıçapının Eksenel Yük Kapasitesine Etkisi Wang 2008Document13 pagesKolonda Köşeleri Pahlama Yarıçapının Eksenel Yük Kapasitesine Etkisi Wang 2008aygunbayramNo ratings yet

- CCENG-1056 p1Document10 pagesCCENG-1056 p1Tú LêNo ratings yet

- A T R C M C C: Xial Esting of Ectangular Olumn Odels Onfined With Omposites by Pierre Rochette and Pierre Labossie'reDocument8 pagesA T R C M C C: Xial Esting of Ectangular Olumn Odels Onfined With Omposites by Pierre Rochette and Pierre Labossie'reCelil OrakNo ratings yet

- 3 Rousakis2007Document11 pages3 Rousakis2007Tú LêNo ratings yet

- Compressive Behaviour of CFRP-confined Rectangular Concrete ColumnsDocument11 pagesCompressive Behaviour of CFRP-confined Rectangular Concrete Columnsz.taouws.edu.auNo ratings yet

- 4 Lam2003Document38 pages4 Lam2003Tú LêNo ratings yet

- Editorial Board 2021 Mechanical Systems and Signal ProcessingDocument1 pageEditorial Board 2021 Mechanical Systems and Signal ProcessingTú LêNo ratings yet

- Size Effects in Axially Loaded Square-Section Concrete Prisms Strengthened Using Carbon Fibre Reinforced Polymer WrappingDocument13 pagesSize Effects in Axially Loaded Square-Section Concrete Prisms Strengthened Using Carbon Fibre Reinforced Polymer WrappingGanesh PadmanabanNo ratings yet

- CCENG-1056 p1Document10 pagesCCENG-1056 p1Tú LêNo ratings yet

- Zenit Milling ToolsDocument12 pagesZenit Milling ToolsPeter NomikosNo ratings yet

- Cucrzr c18160 Pna 372 - enDocument2 pagesCucrzr c18160 Pna 372 - enSulistyo widiatmokoNo ratings yet

- Stress Release Properties of Orthodontic AlignersDocument8 pagesStress Release Properties of Orthodontic AlignersLady SolarteNo ratings yet

- HILTI Chemical Injection AnchoringDocument6 pagesHILTI Chemical Injection AnchoringBaden Lim-bonautNo ratings yet

- Materials Selection For Hot Section Aircraft Engine ComponentDocument7 pagesMaterials Selection For Hot Section Aircraft Engine ComponentCaio Fazzioli TavaresNo ratings yet

- En DP DPL 2022Document6 pagesEn DP DPL 2022Zvonimir AračićNo ratings yet

- Wall Is A Structure and A Surface That Defines An AreaDocument2 pagesWall Is A Structure and A Surface That Defines An Areakuganrp-wv22No ratings yet

- Advanced PP 1102KDocument1 pageAdvanced PP 1102KLaxman AhirNo ratings yet

- CCDC Chemicals Brand Name Compared With Baker Hughes, MI Swaco, HalliburtonDocument30 pagesCCDC Chemicals Brand Name Compared With Baker Hughes, MI Swaco, Halliburtonahsanmunir2107No ratings yet

- FORTHRESSDocument25 pagesFORTHRESSMaria Aiza Maniwang CalumbaNo ratings yet

- Does Wood Conduct Electrical Energydcmxa PDFDocument2 pagesDoes Wood Conduct Electrical Energydcmxa PDFEvansMayo4No ratings yet

- AdmixtureDocument3 pagesAdmixtureArafat RahmanNo ratings yet

- Date of Test: Non-Destructive Testing (NDT) / Ultrasonic Pulse Velocity (UPV) & Compressive Testing Strenght (CTM)Document65 pagesDate of Test: Non-Destructive Testing (NDT) / Ultrasonic Pulse Velocity (UPV) & Compressive Testing Strenght (CTM)GaneshNo ratings yet

- Engineering Materials Assignment Strengthening MechanismsDocument11 pagesEngineering Materials Assignment Strengthening MechanismsArsalan Rafique100% (1)

- 101 (2006)Document2 pages101 (2006)Eng-Mahmoud AtiaNo ratings yet

- API 5L Pipe SpecificationDocument23 pagesAPI 5L Pipe SpecificationGalo AyalaNo ratings yet

- OK Flux 10.62: Classifications: ApprovalsDocument3 pagesOK Flux 10.62: Classifications: ApprovalsJaison JoseNo ratings yet

- Complete The de-WPS OfficeDocument3 pagesComplete The de-WPS OfficeIntan MaharaniNo ratings yet

- TDS Polyvest MA 75Document3 pagesTDS Polyvest MA 75Fairmont Ind Quality DivisionNo ratings yet

- Introducing The New Generation Hardox Wear PlateDocument2 pagesIntroducing The New Generation Hardox Wear PlateAndré Luiz NogueiraNo ratings yet

- Fabrication and Testing of Fiber Reinforced Composite MaterialDocument10 pagesFabrication and Testing of Fiber Reinforced Composite Materialsuba vNo ratings yet

- Unit 1 Cement and ConcreteDocument130 pagesUnit 1 Cement and Concretehamshini100% (1)

- Organic sand binders reduce emissions and improve core performanceDocument1 pageOrganic sand binders reduce emissions and improve core performanceanudattNo ratings yet

- 2018 Skandia Catalog Email Version PDFDocument147 pages2018 Skandia Catalog Email Version PDFDiego MartinezNo ratings yet

- Estimating The Percentage of Wood Failure in Adhesive Bonded JointsDocument4 pagesEstimating The Percentage of Wood Failure in Adhesive Bonded Jointsارفع راسك فوق انت يمنيNo ratings yet

- Boom Construction and Materials PDFDocument1 pageBoom Construction and Materials PDFFernandoNo ratings yet

- Thumb 20180521C775Document2 pagesThumb 20180521C775Alle LunagNo ratings yet

- Study On Fiber Reinforced Concrete Using AsbestosDocument6 pagesStudy On Fiber Reinforced Concrete Using AsbestosIJRASETPublicationsNo ratings yet

- Cell Filled Concrete PavementDocument23 pagesCell Filled Concrete PavementDEVIKA ANIL79% (14)

- Glass As A BLDG MaterialDocument21 pagesGlass As A BLDG Materialmegha rajNo ratings yet