Professional Documents

Culture Documents

ch8 5

ch8 5

Uploaded by

Dumisani SitholeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ch8 5

ch8 5

Uploaded by

Dumisani SitholeCopyright:

Available Formats

TC 9-524

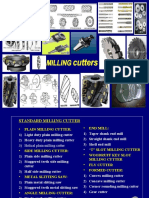

Side Milling Cutters After sharpening, a washer is placed between the two cutters

to compensate for the ground off metal. The staggered tooth

Side milling cutters are essentially plain milling cutters cutter is the most washer is placed between the two cutters to

with the addition of teeth on one or both sides. A plain side compensate for efficient type for milling slots where the depth

milling cutter has teeth on both sides and on the periphery. exceeds the width.

When teeth are added to one side only, the cutter is called a

half-side milling cutter and is identified as being either a End Milling Cutters

right-hand or left-hand cutter. Side milling cutters are

generally used for slotting and straddle milling. The end milling cutter, also called an end mill, has teeth on

the end as well as the periphery. The smaller end milling

Interlocking tooth side milling cutters and staggered tooth cutters have shanks for chuck mounting or direct spindle

side milling cutters are used for cutting relatively wide slots mounting. End milling cutters may have straight or spiral

with accuracy (Figure 8-6). Interlocking tooth side milling flutes. Spiral flute end milling cutters are classified as left-

cutters can be repeatedly sharpened without changing the hand or right-hand cutters depending on the direction of

width of the slot they will machine. rotation of the flutes. If they are small cutters, they may have

either a straight or tapered shank.

8-5

You might also like

- Milling MachineDocument14 pagesMilling MachineAqib ZamanNo ratings yet

- Aircraft ToolsDocument98 pagesAircraft ToolsAdrian Aquino100% (3)

- Basic WoodworkingFrom EverandBasic WoodworkingCheryl SobunRating: 4 out of 5 stars4/5 (7)

- ch8 4Document1 pagech8 4Dumisani SitholeNo ratings yet

- ch8 6Document1 pagech8 6Dumisani SitholeNo ratings yet

- Millng CutterDocument49 pagesMillng CuttersameekshaNo ratings yet

- Workshop MillingDocument12 pagesWorkshop Millinglyk zNo ratings yet

- Instructions How To Use A Milling Machine: Types of Milling MachinesDocument55 pagesInstructions How To Use A Milling Machine: Types of Milling MachinessureshkumarNo ratings yet

- Milling NotesDocument16 pagesMilling Notesvelavansu100% (1)

- Instructions How To Use A Milling MachineDocument7 pagesInstructions How To Use A Milling Machinerc94No ratings yet

- How To Use A Milling MachineDocument44 pagesHow To Use A Milling MachineGhazali ZuberiNo ratings yet

- Features of A Milling CutterDocument8 pagesFeatures of A Milling CutterAnuj KrNo ratings yet

- Instructions How To Use A Milling MachineDocument58 pagesInstructions How To Use A Milling MachineEng-Ramy El-MorsyNo ratings yet

- 1.plain Milling Cutter: Four Kinds of Cutting ToolsDocument2 pages1.plain Milling Cutter: Four Kinds of Cutting ToolsstanleypmanuelNo ratings yet

- Metal Cutting ToolsDocument12 pagesMetal Cutting ToolsRonald Vincent GonzalesNo ratings yet

- A Homeowner's Guide To Miter SawsDocument4 pagesA Homeowner's Guide To Miter SawsSilvia MassottoNo ratings yet

- Credit 2 Mill-2003Document26 pagesCredit 2 Mill-2003Gokul Prasad ChettiNo ratings yet

- Mod 7.03b Tools SlideshowDocument79 pagesMod 7.03b Tools Slideshowzaidkadiri9No ratings yet

- Table Saws Are Used For Straight Sawing. Depending On The Blade, They Cut Either Across (Crosscut) or With (Ripsaw) The Grain of The WoodDocument30 pagesTable Saws Are Used For Straight Sawing. Depending On The Blade, They Cut Either Across (Crosscut) or With (Ripsaw) The Grain of The WoodŽeljko Posavec50% (2)

- Madelaine Mina - Diana Castro - Zhaneil Limiac: Created byDocument51 pagesMadelaine Mina - Diana Castro - Zhaneil Limiac: Created byJerome PonceNo ratings yet

- Ilovepdf MergedDocument53 pagesIlovepdf Merged208048022No ratings yet

- Saws and Screwdrivers Keian CompressedDocument23 pagesSaws and Screwdrivers Keian CompressednikkamgalauraNo ratings yet

- Lecture No. 10: Milling MachinesDocument70 pagesLecture No. 10: Milling MachinesMuhammad IrfanNo ratings yet

- ACCT ITM 6 SheetMetalCuttingToolsPowerPointDocument11 pagesACCT ITM 6 SheetMetalCuttingToolsPowerPointZwingCAD AcademyNo ratings yet

- WS Expt8Document4 pagesWS Expt8shwetaNo ratings yet

- Cutting ToolsDocument5 pagesCutting ToolsBhavdeep SinghNo ratings yet

- Machining ProcessDocument54 pagesMachining ProcesskaushiksoniNo ratings yet

- ch8 9Document1 pagech8 9Dumisani SitholeNo ratings yet

- SawsDocument10 pagesSawsconnor haberechtNo ratings yet

- Milling: Prepared By: Dinbandhu Singh 1Document23 pagesMilling: Prepared By: Dinbandhu Singh 1Dino SinghNo ratings yet

- Unit 3a4 Sawing 180328125446Document29 pagesUnit 3a4 Sawing 180328125446Gilang RestuNo ratings yet

- 2832-Saws & How To Use ThemDocument1 page2832-Saws & How To Use ThemSandra Barnett CrossanNo ratings yet

- Deck Maintenance Equipment & ToolsDocument28 pagesDeck Maintenance Equipment & ToolsGerona CruzNo ratings yet

- Milling Machine Report DelyDocument10 pagesMilling Machine Report DelyFazdly Azilan0% (2)

- Mapúa University: Shop Exercise No. 1Document15 pagesMapúa University: Shop Exercise No. 1Eriane GarciaNo ratings yet

- Engine Room ToolsDocument121 pagesEngine Room ToolsILHAM MUKTI WIBOWONo ratings yet

- Hand InstrumentsDocument59 pagesHand Instrumentssanket pandey100% (1)

- A Milling Machine Is A Machine Tool Used To Machine Solid MaterialsDocument7 pagesA Milling Machine Is A Machine Tool Used To Machine Solid MaterialsMD Mahmudul Hasan MasudNo ratings yet

- m7 Common Hand ToolsDocument119 pagesm7 Common Hand ToolsSweta ThakurNo ratings yet

- Mod 7 Book 2 ToolsDocument83 pagesMod 7 Book 2 Toolsranjit prasad100% (1)

- ch8 8Document1 pagech8 8Dumisani SitholeNo ratings yet

- 2 Ball Peen HammerDocument16 pages2 Ball Peen HammerCHESTER JAN BOSONGNo ratings yet

- Machining HAND TOOLS ANDDocument2 pagesMachining HAND TOOLS ANDGene EyasNo ratings yet

- JJ 104 Workshop Technology 1 MillingDocument44 pagesJJ 104 Workshop Technology 1 MillingHusaini Zamzury0% (1)

- Carpentry ToolsDocument2 pagesCarpentry ToolsJill Catherine CabanaNo ratings yet

- Nomenclature of Face and End Milling CutterDocument4 pagesNomenclature of Face and End Milling CutterIsmael AibisNo ratings yet

- Turning Aluminium Alloys: DrillingDocument2 pagesTurning Aluminium Alloys: DrillingandyalwayshugsNo ratings yet

- Hand Tools: HandsawDocument23 pagesHand Tools: HandsawJozueuNo ratings yet

- MillingDocument37 pagesMillingKemba DonyeNo ratings yet

- Tools and Machines Used in Carpentry Lab Part 5Document10 pagesTools and Machines Used in Carpentry Lab Part 5Lo M'hNo ratings yet

- Hand Tools: Safety FirstDocument20 pagesHand Tools: Safety FirstJeff WebberNo ratings yet

- CuttingDocument5 pagesCuttingsand@ashiqNo ratings yet

- Bridgeport Milling Machine OperationDocument40 pagesBridgeport Milling Machine OperationALLEN FRANCIS100% (3)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- Paper-Cutting Machines: A Primer of Information about Paper and Card Trimmers, Hand-Lever Cutters, Power Cutters and Other Automatic Machines for Cutting PaperFrom EverandPaper-Cutting Machines: A Primer of Information about Paper and Card Trimmers, Hand-Lever Cutters, Power Cutters and Other Automatic Machines for Cutting PaperNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- The Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolFrom EverandThe Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolNo ratings yet