Professional Documents

Culture Documents

Moldflow Course

Uploaded by

nx.reversecadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Moldflow Course

Uploaded by

nx.reversecadCopyright:

Available Formats

Plastic Injection Moulding using Autodesk Moldflow

Instructor-Led Online Training

Autodesk Authorised Certified Course

Plastic Injection

Moulding using Autodesk Moldflow (10).pdf

Course Title Plastic Injection Moulding using Autodesk Moldflow

Duration 3 Days (18 Hrs)

Schedule Only on weekends: we will announce soon

Mode of Training Instructor-Led Online Training

At least up to 60% products are manufactured with plastic material in

Automotive & related

Autodesk Moldflow simulation is a replication of Injection moulding process.

It’s a faster virtual process to get an idea about an effects of different process

Why Moldflow? condition on products.

It helps to know critical regions in the parts which are prone to risk due to part

design, process parameters etc.

This tool can be effectively used during new product development phase,

during production phase, during cost cutting projects.

Autodesk Moldflow: Plastic injection and compression mould simulation

Engineers and analysts use Moldflow® software for plastic injection moulding

simulation to improve plastic part designs, injection mould designs and manufacturing

processes. Moldflow has two core products: Moldflow Adviser providing

About Autodesk manufacturability guidance and directional feedback for standard part and mold design

Moldflow Software and Moldflow Insight which provides definitive results for flow, cooling, and warpage

along with support for specialized molding processes. In addition, Autodesk produces

Moldflow Design, Moldflow CAD Doctor, Moldflow Magics STL Expert, and Moldflow

Structural Alliance that serve as connectivity tools for other CAD and CAE software.

They also have a free results viewer, Moldflow Communicator.

User can able to perform various types of analysis In order to evaluate Part & Mold. It

Course Outcome

will help user to convince the customer for the betterment of design.

Day 1 (8 hours duration):

Introduction to plastics

Introduction to the injection molding process

Course Contents

Prerequisites to kick off Simulation

Introduction to software Interface

Model Building for Simulation

Material selection, Mesh type by mold flow

Gate location analysis

Molding window analysis

The shear rate for gate dimension

Day 2 (8 hours duration):

Part evaluation (Fill + Pack analysis)

Polymer Flow & Molding Conditions

Runner Balancing / Flow leaders / Flow deflectors

Mold evaluation (Cooling analysis)

Result Interpretation & Common Defects

COV Coefficient of Variance

Report generation from a customer perspective

Day 3 (2 hours duration):

Q&A, Assignments and Case Study discussions

Assignments, Case

Guidance & Support will be provided during course.

Studies & Projects

Test 1-hour objective type test.

Plastics and Polymer Engineering senior professional with 10+ years of industrial

Faculty Profile

experience.

Certification Autodesk Authorised Certificate of Completion.

Course Fees INR 17,700 including GST per participant

Course fees should be paid 100% advance. Once fees is paid, you have to send us an

email to training@ifsacademy.org with following details.

Name as per HSC

Mobile No

Admission Procedure Email ID

Educational Qualification

Brief Work Experience

Specific Training outcome which you are looking at. (We will share this

information with our Faculty in advance.)

Account: IFS Academy

Bank and Branch: Axis Bank Ltd., Kothrud Branch, Pune-411038

Account Number: 104010200009058

Payment Mode: To Account Type: Current

be paid 100% Branch Code: 000104

advance IFSC Code: UTIB0000104

RTGS Code: Same as above

MICR Code: 411211004

Swift Code: AXISINBB037

Note: After successful transaction, you are requested to send following details to: training@ifsacademy.org

Name of the Student:

Course Title:

Amount (Rs./-):

Transaction ID:

If you have any questions, please don’t hesitate to get in touch with us by emailing at

training@ifsacademy.org or calling +91-98228 49628 / 99224 40102.

You might also like

- Online Exam: Project Using J2EEDocument27 pagesOnline Exam: Project Using J2EEDanielSitumorangNo ratings yet

- The Online Examination SystemDocument15 pagesThe Online Examination Systemtamkeen begumNo ratings yet

- Autocad Project Report (Without Notes)Document13 pagesAutocad Project Report (Without Notes)Harpreet Harry0% (1)

- MITS5002 Software Engineering Methodologies: Final Assessment June 2020Document4 pagesMITS5002 Software Engineering Methodologies: Final Assessment June 2020tamanna sharmaNo ratings yet

- Project Guideline For BCA-6th SemDocument8 pagesProject Guideline For BCA-6th SemNitin PatelNo ratings yet

- MITS5002 Software Engineering Methodologies: Final Assessment June 2020Document4 pagesMITS5002 Software Engineering Methodologies: Final Assessment June 2020tamanna sharmaNo ratings yet

- SupriyaDocument20 pagesSupriyasunnyNo ratings yet

- SecondDocument8 pagesSecondIshrat FatimaNo ratings yet

- Introduction To Moldflow: Cad-It Consultants (Asia) Pte LTDDocument1 pageIntroduction To Moldflow: Cad-It Consultants (Asia) Pte LTDmouadNo ratings yet

- For 100% Result Oriented IGNOU Coaching and Project Training Call CPD: 011-65164822, 08860352748Document8 pagesFor 100% Result Oriented IGNOU Coaching and Project Training Call CPD: 011-65164822, 08860352748Tejendra PachhaiNo ratings yet

- SE2022 Lecture-06 CaseStudyDocument40 pagesSE2022 Lecture-06 CaseStudythành nguyễn quốcNo ratings yet

- 2 - Moldflow Adviser 2019 BrochureDocument4 pages2 - Moldflow Adviser 2019 BrochureAhmedBraham100% (1)

- CETPA Workshop ProposalDocument17 pagesCETPA Workshop ProposalAnurag MishraNo ratings yet

- Mca Vtu ThesisDocument4 pagesMca Vtu ThesisWriteMyBiologyPaperCanada100% (4)

- SE ReportDocument43 pagesSE ReportKen Adams100% (1)

- 3 - Moldflow Insight 2019 BrochureDocument4 pages3 - Moldflow Insight 2019 BrochureAhmedBrahamNo ratings yet

- BCS 051 Solved AssignmentsDocument11 pagesBCS 051 Solved AssignmentsAmit GuptaNo ratings yet

- Major Project BCA Guidelines 10062020Document8 pagesMajor Project BCA Guidelines 10062020medicalpushpa8No ratings yet

- Project Report On Website ProjectDocument24 pagesProject Report On Website ProjectSandeepThakurNo ratings yet

- Project ReportDocument149 pagesProject ReportArun sharmaNo ratings yet

- Aeb4101 Engineering and Design: Module - 3Document14 pagesAeb4101 Engineering and Design: Module - 3saiNo ratings yet

- Fin Irjmets1655988916Document8 pagesFin Irjmets1655988916SociaLinks SupportNo ratings yet

- NotepadDocument4 pagesNotepadBhagyashri RagitNo ratings yet

- CMT4440 CMT4440 Is About:: The BookDocument6 pagesCMT4440 CMT4440 Is About:: The BookMagued A HannaNo ratings yet

- Autodesk Moldflow 2012 Technical Whats New BrochureDocument8 pagesAutodesk Moldflow 2012 Technical Whats New BrochurebmyertekinNo ratings yet

- Pega Arch 1Document5 pagesPega Arch 1Cricket Live StreamingNo ratings yet

- Automotive Plastic Product DesignDocument3 pagesAutomotive Plastic Product Designravanlegend22No ratings yet

- Product Development Life Cycle - 21-12-2012 BLAZE AutomationDocument22 pagesProduct Development Life Cycle - 21-12-2012 BLAZE AutomationBlaze_HydNo ratings yet

- Computer-Aided Casting Design and Simulation PDFDocument9 pagesComputer-Aided Casting Design and Simulation PDFmonish KrishnaNo ratings yet

- Empirical Study of Software Development Life Cycle and Its Various ModelsDocument11 pagesEmpirical Study of Software Development Life Cycle and Its Various ModelsAI Coordinator - CSC JournalsNo ratings yet

- Software Analysis and Design Case Study - EditedDocument13 pagesSoftware Analysis and Design Case Study - EditedCruzmartin OfficialNo ratings yet

- Advanced Diploma in CADDocument3 pagesAdvanced Diploma in CADSHUBHAM ADEPNo ratings yet

- BankDocument18 pagesBankAbhijit BaghsinghNo ratings yet

- CV_Swapnali+Chandrakant+Patil (1)Document6 pagesCV_Swapnali+Chandrakant+Patil (1)database.mnrsolutionsNo ratings yet

- Gaurav Bhonsule: SR.D EDocument5 pagesGaurav Bhonsule: SR.D EgauvNo ratings yet

- CSY3010 Assignment BriefDocument4 pagesCSY3010 Assignment Briefanishgajurel7No ratings yet

- AEES ReportDocument23 pagesAEES ReportGagana PNo ratings yet

- Simulation Thesis PDFDocument6 pagesSimulation Thesis PDFkarenhenningssiouxfalls100% (2)

- Expertshub - Automotive Styling Boot CampDocument5 pagesExpertshub - Automotive Styling Boot CampKirubakaran ReddyNo ratings yet

- Deepak ResumeDocument4 pagesDeepak ResumeDeepakkarmaNo ratings yet

- MITS5002 Software Engineering Methodologies: Final Assessment June 2020Document5 pagesMITS5002 Software Engineering Methodologies: Final Assessment June 2020tamanna sharmaNo ratings yet

- BIT Baroda Institute of Technology: Creo (Pro/ENGINEER) Training atDocument4 pagesBIT Baroda Institute of Technology: Creo (Pro/ENGINEER) Training atNIRALINo ratings yet

- Project Report On Banking Management SystemDocument27 pagesProject Report On Banking Management SystemVipul KumarNo ratings yet

- Mukul JainDocument4 pagesMukul JainShailenderNo ratings yet

- Industry Internship Summary Report Web Page Automation Using SeleniumDocument28 pagesIndustry Internship Summary Report Web Page Automation Using SeleniumKANIKA RAINo ratings yet

- c7 Sen 11 Exam PaperDocument5 pagesc7 Sen 11 Exam PaperSnr Berel ShepherdNo ratings yet

- Hà Minh Chí (BKC12327) - Assignment 1 lần 1 - SDLCDocument19 pagesHà Minh Chí (BKC12327) - Assignment 1 lần 1 - SDLCChí Hà MinhNo ratings yet

- Online Test Engine: A Project ReportDocument30 pagesOnline Test Engine: A Project ReportMayank JainNo ratings yet

- MITS5002 Software Engineering Methodologies: Final Assessment June 2020Document4 pagesMITS5002 Software Engineering Methodologies: Final Assessment June 2020tamanna sharmaNo ratings yet

- GATE Software Engineering & Web Technology BookDocument12 pagesGATE Software Engineering & Web Technology BookMims12No ratings yet

- Student Details Management SystemDocument86 pagesStudent Details Management SystemMohamed AhmedNo ratings yet

- AutoCAD 2019: A Problem - Solving Approach, Basic and Intermediate, 25th EditionFrom EverandAutoCAD 2019: A Problem - Solving Approach, Basic and Intermediate, 25th EditionNo ratings yet

- Multimedia Software Life Cycle: What Can You Infer From This Chart?Document19 pagesMultimedia Software Life Cycle: What Can You Infer From This Chart?flor-calderaro-6219No ratings yet

- sp3d Training Course 1122Document5 pagessp3d Training Course 1122api-269727505No ratings yet

- Module Code & Module Title CS5002NI Software Engineering Examination Weightage & Type 45% Exam Wieght Year and Semester 2020-21 SpringDocument15 pagesModule Code & Module Title CS5002NI Software Engineering Examination Weightage & Type 45% Exam Wieght Year and Semester 2020-21 SpringMandip MandalNo ratings yet

- SDLC ModelsDocument65 pagesSDLC ModelsGarima DabasNo ratings yet

- Software EngineeringDocument129 pagesSoftware EngineeringGuruKPO92% (26)

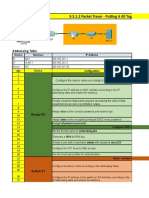

- 9.5.1.2 Packet Tracer - Putting It All Together: Addressing TableDocument6 pages9.5.1.2 Packet Tracer - Putting It All Together: Addressing TableGaz ArtimisNo ratings yet

- Analysys Mason ExpertiseDocument10 pagesAnalysys Mason ExpertiseAndrey PritulyukNo ratings yet

- Algo122 Assignment2 JohnsonsAlgorithmDocument5 pagesAlgo122 Assignment2 JohnsonsAlgorithmkaushik81190No ratings yet

- Using A Conformity Matrix To Align Processes To ISO 9001 - 2015Document4 pagesUsing A Conformity Matrix To Align Processes To ISO 9001 - 2015esivaks2000No ratings yet

- Estimate Distance Measurement Using Nodemcu Esp8266 Based On Rssi TechniqueDocument5 pagesEstimate Distance Measurement Using Nodemcu Esp8266 Based On Rssi TechniqueBrendo JustinoNo ratings yet

- Data Communications Networks Network Types Protocol LayeringDocument48 pagesData Communications Networks Network Types Protocol LayeringiotNo ratings yet

- Greedy AlgorithmDocument20 pagesGreedy AlgorithmMohammedNo ratings yet

- The Basics of Protecting Against Computer HackingDocument8 pagesThe Basics of Protecting Against Computer HackinggynxNo ratings yet

- Jim Highsmith, Linda Luu, David Robinson - EDGE - Value-Driven Digital Transformation-Addison-Wesley Professional (2019)Document254 pagesJim Highsmith, Linda Luu, David Robinson - EDGE - Value-Driven Digital Transformation-Addison-Wesley Professional (2019)gangadhar krishnamoorthyNo ratings yet

- Final Summer Training ReportDocument24 pagesFinal Summer Training ReportHarish NaiduNo ratings yet

- 27 41 32 Ip-Based Television System (Iptv)Document30 pages27 41 32 Ip-Based Television System (Iptv)Mohamed Abou El hassanNo ratings yet

- Manual of Fish Sclerochronology-Ifremer PDFDocument466 pagesManual of Fish Sclerochronology-Ifremer PDFDaniela Mariana RosioruNo ratings yet

- Quickstart Guide of OpenVox GSM Gateway VS-GW1600-20G Connect With 3CX Server PDFDocument6 pagesQuickstart Guide of OpenVox GSM Gateway VS-GW1600-20G Connect With 3CX Server PDFJeandelaSagesse100% (1)

- CSF-429 - L7 Word Vectors - GloveDocument24 pagesCSF-429 - L7 Word Vectors - GloveManan PopatNo ratings yet

- AVS Security Requirements-V1 - 2Document2 pagesAVS Security Requirements-V1 - 2Sigma PigsNo ratings yet

- Pierce Theory CommunicationDocument19 pagesPierce Theory CommunicationditurreguiNo ratings yet

- AP Computer Science - Exploring Boolean Expressions and Conditional StatementsDocument4 pagesAP Computer Science - Exploring Boolean Expressions and Conditional StatementsAnish BuddollaNo ratings yet

- AD250 Wireless Datasheet WebDocument12 pagesAD250 Wireless Datasheet WebArumugam RajendranNo ratings yet

- Chapter 3 - Understanding Markets, Market Demand, and The Marketing EnvironmentDocument34 pagesChapter 3 - Understanding Markets, Market Demand, and The Marketing EnvironmentArman100% (1)

- RET - 521 - 2.3 Technical - Reference - Manual PDFDocument455 pagesRET - 521 - 2.3 Technical - Reference - Manual PDFelo_elo_elo_eloNo ratings yet

- ComptiaDocument90 pagesComptiakvsrvzmNo ratings yet

- Template - 20.1 - 1682176095Document2 pagesTemplate - 20.1 - 1682176095Salman OmarNo ratings yet

- EE311 Lecture OneDocument18 pagesEE311 Lecture OneĤmăđę HmNo ratings yet

- Building Backbone - JsDocument23 pagesBuilding Backbone - JsFarid HidayatNo ratings yet

- Information ManagementDocument18 pagesInformation ManagementorchuchiNo ratings yet

- CV Yaumil FirdausDocument3 pagesCV Yaumil FirdausYaumil FirdausNo ratings yet

- Printable Resume For Mechanical EngineerDocument5 pagesPrintable Resume For Mechanical EngineerSachin PintoNo ratings yet

- Rudolf R2 Users ManualDocument44 pagesRudolf R2 Users ManualGleen AlamillaNo ratings yet

- API Certification Exam Dates & Deadlines 2015Document2 pagesAPI Certification Exam Dates & Deadlines 2015slxantoNo ratings yet

- Object Relational Interactions With OracleDocument16 pagesObject Relational Interactions With OraclefacultyniitNo ratings yet