Professional Documents

Culture Documents

ROHACELL HERO 2022 April EN 243522

Uploaded by

c.breckonsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ROHACELL HERO 2022 April EN 243522

Uploaded by

c.breckonsCopyright:

Available Formats

Product Information

Technical Information

ROHACELL® HERO

ROHACELL® HERO

Innovative ROHACELL® HERO delivers the latest in WE CAN HELP YOU SHAPE THE FUTURE

materials technology for composite aircraft

Let our Shapes Department supply you with finished,

structures that are lightweight, durable over their

ready-to-use net-shape ROHACELL® HERO parts.

lifetime and less expensive to produce.

Your cores will be delivered ready for immediate use

It’s the new standard in aircraft structural core in your next processing step.

material!

• Eliminate waste

• Reduce in-house production time

KEEPING IT LIGHT

• Up to 30 % cost savings

Sandwich technology is an excellent way to reduce

weight and thanks to its outstanding mechanical

properties and low density, ROHACELL® HERO

sandwich cores offer the most weight saving

potential of all structural foams.

Featuring a closed cell structure, ROHACELL® HERO

minimizes added weight by taking up resin only in

the cut surface cells – resulting in a lighter finished

part weight compared with traditional honeycomb

structures.

LONG HAUL DURABILITY

Offering excellent elongation at break properties,

ROHACELL® HERO remains robust and durable for

the lifetime of the aircraft. ROHACELL® HERO IN FLIGHT

Surface impact damage is easily visible during ROHACELL® HERO is a recommended grade for core

inspections and rework/repair is simple since the material in sandwich structures for aircraft wings,

core damage does not extend beyond the initial landing gear doors, radomes, vertical and horizontal

impact location and there is no water ingress as can stabilizers, ailerons and other areas subject to

occur with honeycomb core structures. surface impact damage.

IT CAN TAKE THE HEAT

With heat resistance of up to 210 °C (428 °F),

processing or curing temperatures can be increased

higher than other core materials allow (e.g., typical

cure cycle at 180 °C/356 °F with maximum pressure

dependent upon density). This results in significant

reductions in total cycle time and faster part

manufacturing.

No other core material offers such ease of

processing in a wide variety of processes, including

autoclave, resin infusion, RTM and VARTM.

Evonik Operations GmbH | ROHACELL® HERO | April 2022

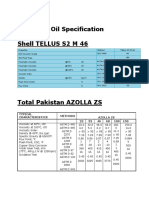

Property Test Method* Unit ROHACELL® ROHACELL® ROHACELL® ROHACELL®

51 HERO 71 HERO 110 HERO 200 HERO

Density ISO 845 kg/m³ 52 75 110 205

ASTM D 1622 lbs/ft³ 3.25 4.68 6.87 12.80

ISO 844 MPa 0.6 1.1 2.5 7.1

Compressive Strength ASTM D 1621 psi 87 160 363 1,030

Compressive Modulus ISO 844 MPa 32 48 83 180

ASTM D 1621 psi 4,640 6,960 12,000 26,100

ISO 527-2 MPa 2.6 4.1 6.3 12.3

Tensile Strength ASTM D 638 psi 377 595 914 1,780

Tensile Modulus ISO 527-2 MPa 82 123 189 389

ASTM D 638 psi 11,900 17,800 27,400 56,400

ISO 527-2

Elongation at Break ASTM D 638 % 8 9.5 9.9 10.8

Shear Strength DIN 53294 MPa 0.7 1.3 2.3 5.2

ASTM C 273 psi 102 189 334 754

DIN 53294 MPa 22 28 50 109

Shear Modulus ASTM C 273 psi 3,190 4,060 7,250 15,800

Maximum Shear Strain DIN 53294 % 7.0 7.2 7.2 7.2

ASTM C 273

Glass Transition °C 207 203 200

Temperature °F N/A 405 397 392

Coefficient of Thermal 1/K*10E-5 3.76 3.77 3.72 4.26

Expansion

Technical data values presented above are typical for nominal density, subject to normal manufacturing variations. *Data values are based on ISO & DIN

standard test methods, however ASTM values can be confirmed upon request. All ROHACELL® products are closed-cell rigid foams based on

polymethacrylimide (PMI) chemistry and contain no CFC's.

Disclaimer Evonik Operations GmbH │ Smart Materials

ROHACELL® is a registered trademark of Evonik Industries and its subsidiaries. High Performance Polymers

Performance Foams

This information and all technical and other advice are based on Evonik’s present knowledge and 64293 Darmstadt, Germany

experience. However, Evonik assumes no liability for such information or advice, including the Phone +49 6151 18-1005

extent to which such information or advice may relate to third party intellectual property rights.

Evonik reserves the right to make any changes to information or advice at any time, without prior Evonik Corporation

or subsequent notice. EVONIK DISCLAIMS ALL REPRESENTATIONS AND WARRANTIES, WHETHER Theodore, Alabama USA

EXPRESS OR IMPLIED, AND SHALL HAVE NO LIABILITY FOR, MERCHANTABILITY OF THE PRODUCT Phone +1 866 764-6235

OR ITS FITNESS FOR A PARTICULAR PURPOSE (EVEN IF EVONIK IS AWARE OF SUCH PURPOSE), OR

OTHERWISE. EVONIK SHALL NOT BE RESPONSIBLE FOR CONSEQUENTIAL, INDIRECT OR Evonik Specialty Chemicals

INCIDENTAL DAMAGES (INCLUDING LOSS OF PROFITS) OF ANY KIND. It is the customer’s sole (Shanghai) Co., Ltd.

responsibility to arrange for inspection and testing of all products by qualified experts. Reference Shanghai, China

to trade names used by other companies is neither a recommendation, nor an endorsement of Phone +86 21 6119 3788

the corresponding product, and does not imply that similar products could not be used.

Evonik Operations GmbH | ROHACELL® HERO | April 2022

You might also like

- OLUCHUKWUDocument30 pagesOLUCHUKWUOluchukwuGolden100% (5)

- FS 600 Data SheetDocument1 pageFS 600 Data SheetNguyen Hong67% (3)

- C827 PDFDocument5 pagesC827 PDFRam Kumar JaiswalNo ratings yet

- Prokon TutorialsDocument48 pagesProkon TutorialsAhmed Faraz95% (19)

- ROHACELL A 2022 April EN 243400Document2 pagesROHACELL A 2022 April EN 243400c.breckonsNo ratings yet

- Rohacell Ig F 2022 April en 243534Document2 pagesRohacell Ig F 2022 April en 243534c.breckonsNo ratings yet

- Properties IG-FDocument1 pageProperties IG-FsmartNo ratings yet

- Hdpe Me8000 (En)Document1 pageHdpe Me8000 (En)Judith Casstañeda AgurtoNo ratings yet

- Hydroflux Ep tcm14-62558Document1 pageHydroflux Ep tcm14-62558Azis GPBNo ratings yet

- Rohacell HF 2022 April en 243298Document2 pagesRohacell HF 2022 April en 243298c.breckonsNo ratings yet

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Document2 pagesEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNo ratings yet

- HDPE Blow Ineos-G50-100Document2 pagesHDPE Blow Ineos-G50-100luisalbertolvNo ratings yet

- Wepp bpzs8fDocument2 pagesWepp bpzs8fArthur Sanda LayukNo ratings yet

- InnoPlus HD8100MDocument1 pageInnoPlus HD8100MLe Minh TuanNo ratings yet

- Bel Ray Hyperion Synthetic Blend CK-4Document1 pageBel Ray Hyperion Synthetic Blend CK-4Daniel Salazar CruzNo ratings yet

- Castrol Aircol SR RangeDocument2 pagesCastrol Aircol SR RangeJeremias UtreraNo ratings yet

- Ficha Tecnica Castrol Hyspin AWS RangeDocument2 pagesFicha Tecnica Castrol Hyspin AWS Rangeel pro jajaja GonzalezNo ratings yet

- Technical Data Sheet: Premium AW Hydraulic FluidDocument1 pageTechnical Data Sheet: Premium AW Hydraulic FluidDiegoNo ratings yet

- Castrol Hyspin AWS HX RangeDocument2 pagesCastrol Hyspin AWS HX RangeGunco TirNo ratings yet

- PEADM5372Document2 pagesPEADM5372nicolas yoris marcoglieseNo ratings yet

- Castrol Hyspin AWS RangeDocument2 pagesCastrol Hyspin AWS RangeVusal HasanovNo ratings yet

- Pds-Aegle 7000 D 15w-40-Api Ci-4Document1 pagePds-Aegle 7000 D 15w-40-Api Ci-4agnovNo ratings yet

- Specifications For Hydraulic OilDocument3 pagesSpecifications For Hydraulic OilAliya NaseemNo ratings yet

- Bpxe B6ctalDocument2 pagesBpxe B6ctalVusal HasanovNo ratings yet

- Dural Fast Epoxy Gel EuclidDocument3 pagesDural Fast Epoxy Gel Euclidpayaso1973No ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- Icr-1454 - United Gold Sae 5w40 SN (Ua5161)Document2 pagesIcr-1454 - United Gold Sae 5w40 SN (Ua5161)dnoaisapsNo ratings yet

- Impeller STD Resin - Dion 9800 PDFDocument5 pagesImpeller STD Resin - Dion 9800 PDFWilmer AndresNo ratings yet

- Repsol Telex E 46,68Document2 pagesRepsol Telex E 46,68ibrahim maulanaNo ratings yet

- Castrol Perfecto XEP RangeDocument3 pagesCastrol Perfecto XEP Rangeanibal_rios_rivasNo ratings yet

- Repsol Telex HVLP 32Document2 pagesRepsol Telex HVLP 32ibrahim maulanaNo ratings yet

- L-TSE Turbine OilDocument3 pagesL-TSE Turbine OilYoong TanNo ratings yet

- Polyethylene 2EDocument25 pagesPolyethylene 2EJohn SuperdetalleNo ratings yet

- Hyspin AWS 15Document2 pagesHyspin AWS 15nargueNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Brayco Micronic™ SV/B: DescriptionDocument5 pagesBrayco Micronic™ SV/B: DescriptionAlfonsus W.M.No ratings yet

- Repsol Hydroflux Ep PDFDocument1 pageRepsol Hydroflux Ep PDFrandiNo ratings yet

- Halene - H : Technical Data SheetDocument1 pageHalene - H : Technical Data SheetIshah KaziNo ratings yet

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Document2 pagesHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- Repsol Merak VDL PDFDocument1 pageRepsol Merak VDL PDFrandiNo ratings yet

- Perfecto X RangeDocument2 pagesPerfecto X RangekronthNo ratings yet

- L-TSA Classic Turbine OilDocument3 pagesL-TSA Classic Turbine OilQuy NguyenNo ratings yet

- Eurol Super Lite 5W40 Full SyntheticDocument1 pageEurol Super Lite 5W40 Full SyntheticDanilo DamianNo ratings yet

- Braskem CP 741 Blow Molding PolypropyleneDocument2 pagesBraskem CP 741 Blow Molding PolypropyleneRonaldo CamargoNo ratings yet

- PDS Perfecto XEP (2)Document3 pagesPDS Perfecto XEP (2)邢焕震No ratings yet

- Aircol HC 7, HC 10Document2 pagesAircol HC 7, HC 10Vladislav TrempoletsNo ratings yet

- Futong Ism Tds SCG Hdpe h2001wc 20jul20Document3 pagesFutong Ism Tds SCG Hdpe h2001wc 20jul20Aung Thein OoNo ratings yet

- SABICs P6006NDocument2 pagesSABICs P6006NroybharggavNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Alathon®: ApplicationsDocument2 pagesAlathon®: ApplicationsCarlos Revilla FloresNo ratings yet

- DoW LDPE 2685GDocument4 pagesDoW LDPE 2685Gtariquekhan143No ratings yet

- Repsol Maker Hydroflux EP 32,46,68Document1 pageRepsol Maker Hydroflux EP 32,46,68ibrahim maulanaNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- Elite Cosmos A5 b5 5w-30 enDocument1 pageElite Cosmos A5 b5 5w-30 enAnderson MatioliNo ratings yet

- FOB Extra Duty Gear Oil TDSW 815913 - 815914Document3 pagesFOB Extra Duty Gear Oil TDSW 815913 - 815914Elwin arifinNo ratings yet

- Eurol Cirturo ISO-VG 46: Ashless Mineral Turbine and Circulation Oil / R&O OilDocument1 pageEurol Cirturo ISO-VG 46: Ashless Mineral Turbine and Circulation Oil / R&O OilHamdi Al-sarooryNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- ALLEN 8300FR Technical Data SheetDocument2 pagesALLEN 8300FR Technical Data SheetRachit RanjanNo ratings yet

- 5010 5020 5030 5040 5070 5100 5090 2110 HYDRAULIC OIL AW PDS Vesion 3Document2 pages5010 5020 5030 5040 5070 5100 5090 2110 HYDRAULIC OIL AW PDS Vesion 3tauhidrockNo ratings yet

- Manufacturing Technology for Aerospace Structural MaterialsFrom EverandManufacturing Technology for Aerospace Structural MaterialsRating: 5 out of 5 stars5/5 (2)

- Rohacell MSDSDocument3 pagesRohacell MSDSc.breckonsNo ratings yet

- ROHACELL HERO 2022 April EN 243522Document2 pagesROHACELL HERO 2022 April EN 243522c.breckonsNo ratings yet

- Working With ROHACELL - September 2021Document4 pagesWorking With ROHACELL - September 2021c.breckonsNo ratings yet

- Working With ROHACELL - September 2021Document4 pagesWorking With ROHACELL - September 2021c.breckonsNo ratings yet

- A Model Study of Thermal Characteristics of Decarburization Annealing Furnace For Silicon Steel Strip PDFDocument8 pagesA Model Study of Thermal Characteristics of Decarburization Annealing Furnace For Silicon Steel Strip PDFد. علا محمد حداويNo ratings yet

- ROMPOS (Rumania Position Determination System)Document49 pagesROMPOS (Rumania Position Determination System)raulNo ratings yet

- Technical Data Sheet Hifax CA 10 ADocument2 pagesTechnical Data Sheet Hifax CA 10 AafidyusufNo ratings yet

- Assessment of Man's Thermal Comfort - Fanger 1973Document12 pagesAssessment of Man's Thermal Comfort - Fanger 1973haniskamis82No ratings yet

- Essay - Seli AnrianaDocument2 pagesEssay - Seli AnrianaShely AndhrianyNo ratings yet

- Module 8.1 - B1B2 - Rev 00 (Full Permission)Document24 pagesModule 8.1 - B1B2 - Rev 00 (Full Permission)Ahsan MalikNo ratings yet

- Propulsion: EASA Part-66 Cat-B2 Module-14 Shahzad KhalilDocument56 pagesPropulsion: EASA Part-66 Cat-B2 Module-14 Shahzad KhalilSK91% (11)

- An Experimental Study On Vibration Isolation Performance of Weft-Knitted Spacer FabricsDocument11 pagesAn Experimental Study On Vibration Isolation Performance of Weft-Knitted Spacer FabricshawNo ratings yet

- Lab Manual Foundation EngineeringDocument39 pagesLab Manual Foundation Engineeringartiraha100% (1)

- FlenderTechnicalHandbook PDFDocument79 pagesFlenderTechnicalHandbook PDFWagner OliveiraNo ratings yet

- Mozzle Repad Design ToolDocument2 pagesMozzle Repad Design ToolSiddiqui Muhammad AshfaqueNo ratings yet

- Practice Test Questions - Fluid MechanicsDocument25 pagesPractice Test Questions - Fluid MechanicsMehrozNo ratings yet

- Painting & Powder Coating ProcessesDocument5 pagesPainting & Powder Coating ProcessesdramiltNo ratings yet

- 1 EN0721 A Vane Troubleshooting GuideDocument65 pages1 EN0721 A Vane Troubleshooting Guidergg_135292No ratings yet

- Science Q4 Summative TestsDocument5 pagesScience Q4 Summative TestsPJ BARREONo ratings yet

- M0803e Pressure Membrane Apparatus Ad8dbbnDocument20 pagesM0803e Pressure Membrane Apparatus Ad8dbbnRosario Ramirez MNo ratings yet

- GDJP UNIT - I Two MarksDocument4 pagesGDJP UNIT - I Two MarksjuanNo ratings yet

- Dielectric HeatingDocument2 pagesDielectric HeatingPallavi JainNo ratings yet

- Bending Moment and Shear Force Diagram Theory (40chDocument39 pagesBending Moment and Shear Force Diagram Theory (40chVenkatesh KakhandikiNo ratings yet

- Pripol Dimer Acids: Flexibility and HydrophobicityDocument4 pagesPripol Dimer Acids: Flexibility and Hydrophobicitymaged_abdnaghoNo ratings yet

- Dokumen - Tips - Weir Plate CalculationDocument1 pageDokumen - Tips - Weir Plate CalculationNathachai LeewathanakijNo ratings yet

- Vol. 2: MaDocument1 pageVol. 2: Magad480No ratings yet

- Inverse Square LawDocument16 pagesInverse Square Lawfushiguro megumiNo ratings yet

- First and Second Order Linear Ordinary Differential Equations With Constant CoefficientsDocument11 pagesFirst and Second Order Linear Ordinary Differential Equations With Constant CoefficientsSiddhant SardanaNo ratings yet

- WRDTHDSHFJEJEVEJEIDocument21 pagesWRDTHDSHFJEJEVEJEIAshleyNo ratings yet

- Indian PatentDocument6 pagesIndian PatentCHANDANNo ratings yet

- 003-INT-INSP-CPF1-PP1-BUFFER VESSEL (XX76) - AUG-2022 (REV0.0) - SignedDocument11 pages003-INT-INSP-CPF1-PP1-BUFFER VESSEL (XX76) - AUG-2022 (REV0.0) - SignedVignesh PanchabakesanNo ratings yet