Professional Documents

Culture Documents

5 Lec 6-7 Turning Operation

5 Lec 6-7 Turning Operation

Uploaded by

Rahmat ali0 ratings0% found this document useful (0 votes)

1 views22 pagesA workpiece is to be turned down from 4 inches to 3.5 inches diameter using two passes on a lathe. The total cycle time to complete the turning operation will be calculated.

A second workpiece is to be turned on an automatic lathe to create a tapered surface from 100mm to 200mm diameters over 750mm length. The time required and starting/ending rotational speeds will be determined.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA workpiece is to be turned down from 4 inches to 3.5 inches diameter using two passes on a lathe. The total cycle time to complete the turning operation will be calculated.

A second workpiece is to be turned on an automatic lathe to create a tapered surface from 100mm to 200mm diameters over 750mm length. The time required and starting/ending rotational speeds will be determined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views22 pages5 Lec 6-7 Turning Operation

5 Lec 6-7 Turning Operation

Uploaded by

Rahmat aliA workpiece is to be turned down from 4 inches to 3.5 inches diameter using two passes on a lathe. The total cycle time to complete the turning operation will be calculated.

A second workpiece is to be turned on an automatic lathe to create a tapered surface from 100mm to 200mm diameters over 750mm length. The time required and starting/ending rotational speeds will be determined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 22

Also find the Power

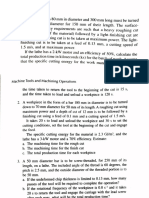

A 4.00-in-diameter work piece that is 25 in long is to be

turned down to a diameter of 3.50 in, using two passes on

an engine lathe using a cutting speed = 300 ft/min, feed

= 0.015 in/rev, and depth of cut = 0.125 in. The bar will

be held in a chuck and supported on the opposite end in a

live center. With this work holding setup, one end must be

turned to diameter for 15 in length; then the bar must be

reversed to turn the other end. Using an overhead crane

available at the lathe, the time required to load and unload

the bar is 5.0 minutes, and the time to reverse the bar is

3.0 minutes. For each turning cut an allowance must be

added to the cut length for approach and overtravel. The

total allowance (approach plus overtravel) = 0.50 in.

Determine the total cycle time to complete this turning

operation.

A tapered surface is to be turned on an automatic

lathe. The work piece is 750 mm long with

minimum and maximum diameters of 100 mm

and 200 mm at opposite ends. The automatic

controls on the lathe permit the surface speed to

be maintained at a constant value of 200 m/min

by adjusting the rotational speed as a function of

work piece diameter. Feed = 0.25 mm/rev and

depth of cut = 3.0 mm. The rough geometry of

the piece has already been formed, and this

operation will be the final cut. Determine (a) the

time required to turn the taper and (b) the

rotational speeds at the beginning and end of the

cut.

You might also like

- Faculty of Mechanical and Industrial Engineering (2011 E.C.)Document2 pagesFaculty of Mechanical and Industrial Engineering (2011 E.C.)Roha Engineering0% (1)

- PE-II Numerical Assignment 2Document3 pagesPE-II Numerical Assignment 2Waqas Ud-din0% (1)

- Sheet 1 Pelton WheelDocument2 pagesSheet 1 Pelton WheelAbdelmoneimFawzy100% (1)

- 3 End of Chapter3 Problems BULKDocument6 pages3 End of Chapter3 Problems BULKqusayNo ratings yet

- 414 TutorialsDocument2 pages414 TutorialsAMOS SIFUNANo ratings yet

- Problem Sheet Metal Machining and Cutting Conditions 2016Document3 pagesProblem Sheet Metal Machining and Cutting Conditions 2016Muhammad imranNo ratings yet

- Tutorial-2: Manufacturing Science and Technology-II (ME - 322)Document2 pagesTutorial-2: Manufacturing Science and Technology-II (ME - 322)Deepam ShyamNo ratings yet

- Class 11Document2 pagesClass 11KIRAN P ABRAHAMNo ratings yet

- Turbomachine Example QuestionDocument4 pagesTurbomachine Example QuestionSteven MilwardNo ratings yet

- Class 11Document4 pagesClass 11BINAYAK DATTA ROYNo ratings yet

- Tutorial Problems in Machining TimeDocument2 pagesTutorial Problems in Machining TimeDHANASEKAR K IV A 9023No ratings yet

- Manufacturing Engineering Assignment Thapar UniversityDocument5 pagesManufacturing Engineering Assignment Thapar UniversitySaurav Kumar0% (1)

- TUTORIALS 1 (1) - MergedDocument23 pagesTUTORIALS 1 (1) - MergedRUGERO KeslyneNo ratings yet

- HW4 2013 Solution Heat TransferDocument5 pagesHW4 2013 Solution Heat TransferAlbert StarkNo ratings yet

- MEC 4106 Pumps Tutorial SheetDocument6 pagesMEC 4106 Pumps Tutorial SheetleitchNo ratings yet

- UTA026 Manufacturing Processes Work SheetDocument3 pagesUTA026 Manufacturing Processes Work SheetGUNJAN KHULLARNo ratings yet

- Machining Process - I: Lathe Machine Operations and CalculationDocument40 pagesMachining Process - I: Lathe Machine Operations and CalculationNajshhsNo ratings yet

- Exercise 1Document4 pagesExercise 1Rekawt RashedNo ratings yet

- Stevens ME 560 HW 4Document4 pagesStevens ME 560 HW 4Dominique SmoyerNo ratings yet

- Man ProDocument2 pagesMan ProlividiveNo ratings yet

- Problems Sheet Machine Tools 2015 16Document9 pagesProblems Sheet Machine Tools 2015 16Shafiq AhmadNo ratings yet

- Problem Set ADocument3 pagesProblem Set AAldrich BaldonadoNo ratings yet

- Assignment IIDocument3 pagesAssignment IIPawan SubediNo ratings yet

- L7 Readings&SelectedProblemsDocument1 pageL7 Readings&SelectedProblemspoojana semalNo ratings yet

- Mm216 Eigenvalue EigenvalueDocument4 pagesMm216 Eigenvalue EigenvalueFurkan ŞahinNo ratings yet

- 2 Problems Sheet Machine ToolsDocument9 pages2 Problems Sheet Machine ToolsALOKSRK0% (1)

- Assignment 1 2Document2 pagesAssignment 1 2Jeevan GNo ratings yet

- Chapter 5 Milling Machine-Calculation Problems-11 May 2022Document11 pagesChapter 5 Milling Machine-Calculation Problems-11 May 2022ShuhadaNo ratings yet

- Types of Operation: Facing OperationDocument9 pagesTypes of Operation: Facing OperationSai KiranNo ratings yet

- LATHEDocument60 pagesLATHEKanchan KumariNo ratings yet

- Plate No RaDocument5 pagesPlate No RaEdelleNo ratings yet

- Hydraulic TurbinesDocument2 pagesHydraulic TurbinesmartinNo ratings yet

- Adama Science and Technology University: Department of Thermal and Aerospace EngineeringDocument13 pagesAdama Science and Technology University: Department of Thermal and Aerospace Engineeringregassa rajiNo ratings yet

- Coal Cutting MachineDocument62 pagesCoal Cutting MachineSaiNo ratings yet

- Assignment 4Document2 pagesAssignment 4sujay nayakNo ratings yet

- B.E. Degree Examination, 2020: (Electrical AND Electronics Engineering) Eeec-306: Fluid Mechanics and Fluid MachineryDocument2 pagesB.E. Degree Examination, 2020: (Electrical AND Electronics Engineering) Eeec-306: Fluid Mechanics and Fluid MachineryR.KathiravanNo ratings yet

- 4 5881846313305247595Document2 pages4 5881846313305247595Mulugeta DefaruNo ratings yet

- 2 Numericals On Energy Transfer in TMDocument2 pages2 Numericals On Energy Transfer in TMRahulNo ratings yet

- Solution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minDocument11 pagesSolution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minwoihoNo ratings yet

- Lathe - PPT 0Document74 pagesLathe - PPT 0AcidoMexNo ratings yet

- Turning Dan DrillingDocument13 pagesTurning Dan DrillingAzmi Muhammad AzmiNo ratings yet

- AQ Fluid Machinery-1Document3 pagesAQ Fluid Machinery-1Sourabh BelladNo ratings yet

- 14 MarksDocument4 pages14 MarksmohanNo ratings yet

- Unit 5Document8 pagesUnit 5Narendra YadavNo ratings yet

- Force Momentum 2Document6 pagesForce Momentum 2lasitha chandima jayasingheNo ratings yet

- Turbines NumericalsDocument14 pagesTurbines NumericalsPremKumar0% (1)

- Assignment 4 Due: May 15, 2020 MachiningDocument1 pageAssignment 4 Due: May 15, 2020 MachiningngouoNo ratings yet

- Problem Set 1Document5 pagesProblem Set 1riyaNo ratings yet

- Ch23 Machining Processes Turning and Hole Making2Document72 pagesCh23 Machining Processes Turning and Hole Making2Muhammad YusufNo ratings yet

- Tutorial - Topic 4Document2 pagesTutorial - Topic 4Kavish CserNo ratings yet

- Hydraulic Machines Tutorial Section-ADocument1 pageHydraulic Machines Tutorial Section-AhasanNo ratings yet

- 6-2 Machining Processes IDocument44 pages6-2 Machining Processes IOmar Ahmed100% (1)

- Tutorial (Individuals) Dateline: 15/12/2011 at 5.00 PMDocument2 pagesTutorial (Individuals) Dateline: 15/12/2011 at 5.00 PMrandyooiNo ratings yet

- 3-12-22 ManufacturingDocument25 pages3-12-22 ManufacturingPiyush KumarNo ratings yet

- Assignment 1Document4 pagesAssignment 1antonushany52No ratings yet

- Material and Metal Processing Mid Semester: NADIRA AFRA RASHEESA 04211941000011Document9 pagesMaterial and Metal Processing Mid Semester: NADIRA AFRA RASHEESA 04211941000011Aldy FairuzNo ratings yet

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet