Professional Documents

Culture Documents

IDCON CMS 104R Coupling Thomas (With Watermark)

Uploaded by

javeriaamin02Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IDCON CMS 104R Coupling Thomas (With Watermark)

Uploaded by

javeriaamin02Copyright:

Available Formats

Coupling Thomas

CMS104R

Condition Monitoring Standards

Basic Principle

The function of the Thomas® coupling, or any coupling, is to connect two shafts. A coupling must also be able

to handle shock loads due to changing operating conditions. Many coupling vendors claim that their couplings

can handle misalignment well. Often this is true, but remember that the driving and driven equipment is usually

the expensive items, and the driving and driven equipment usually have bearings that are very sensitive to

misalignment.

Thomas® couplings are non-lubricated, metal flexing couplings, utilizing non-wearing parts for the transmission

of torque and the accommodation of unavoidable shaft misalignment. The flex element is a series of precision

stamped discs with uniquely designed cross sections that flex without causing the metal-to-metal wear problems

associated with lubricated couplings. The flexible disc packs are engineered for very long life when applied

within the published ratings and environmental guidelines.

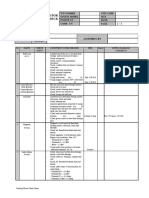

KEY WHAT WHY

Check for abnormal noise. Noise could be due to

loose bolts, a loose shaft

Noise

key or broken flex

elements.

www.idcon.com © IDCON, INC. 2006 CMS 104R Page 1 of 4

919-847-8764 Do Not Copy

KEY WHAT WHY

Use stroboscope to check disc pack for broken flex-elements. Broken elements could

be caused by:

Overload

Excessive vibration

Shaft misalignment

Strobe Light

Check flex elements

Strobe light causes rotating objects to appear stopped. Do not

touch coupling or shaft.

Use strobe to check coupling bolts for looseness or corrosion.

Bolts

Use strobe to check bolts.

Strobe light causes rotating objects to appear stopped. Do not

touch coupling or shaft.

www.idcon.com © IDCON, INC. 2006 CMS 104R Page 2 of 4

919-847-8764 Do Not Copy

KEY WHAT WHY

Check coupling temperature with Infrared temperature meter through safe Any substantial change in

opening in guard. The temperature of the coupling should not exceed 10°C temperature usually

(50°F) ambient temperature. indicates some fault:

Coupling damage

Overload

Excessive vibration

Temperature

Shaft misalignment

Scan flex-elements

for temperature.

Use a stroboscope and make sure the coupling appears to be stopped. The radius of keyways

Inspect shaft key for damage, cracks, corrosion and looseness. could be sharp. Sharp

edges create stress

concentration;

therefore, carefully

check around keys and

keyways when

inspecting shaft

Keyway

keyways.

Stress

concentration

Inspect key and keyway for

damage, cracks, corrosion

and looseness.

www.idcon.com © IDCON, INC. 2006 CMS 104R Page 3 of 4

919-847-8764 Do Not Copy

KEY WHAT WHY

The guard has to have an inspection opening to enable an on-the-run Guard modification is a

inspection of the coupling. Some guards must be modified. Inspection ports prerequisite for

with wire mesh metal or inspection lids with a hinge are examples of guard performing safe and

modifications that will enable coupling inspection. Paint mesh matte black effective condition

to increase visibility. monitoring on-the-run.

Guards

When modifying guards, refer to OSHA standard 1910.212 (for USA). The

allowed size of the wire mesh depends on the distance from the coupling to

the mesh. For example, a 1-inch (25.4 mm) wire mesh must be at least 1.5

inches (38.1 mm) away from the coupling. If your plant applies higher

standards than OSHA, make a wire mesh according to OSHA standard, then

apply a hinged lid over the wire mesh.

www.idcon.com © IDCON, INC. 2006 CMS 104R Page 4 of 4

919-847-8764 Do Not Copy

You might also like

- Rigging & Slinging SafetyDocument477 pagesRigging & Slinging SafetySHIJAD SRAJU100% (1)

- Anchor DesignDocument68 pagesAnchor Designroshansm1978100% (1)

- Lifting Supervisor Training: Slinging SAFETYDocument614 pagesLifting Supervisor Training: Slinging SAFETYSHIJAD SRAJU100% (3)

- GMB Water Pump +fan - 2007 PDFDocument483 pagesGMB Water Pump +fan - 2007 PDFAnton ShvidunNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- NRG2.Types of Crane and Components PDFDocument107 pagesNRG2.Types of Crane and Components PDFMaza LufiasNo ratings yet

- Master Locksmithing: An Expert's Guide to Master Keying, Intruder Alarms, Access Control Systems, High-Security Locks...From EverandMaster Locksmithing: An Expert's Guide to Master Keying, Intruder Alarms, Access Control Systems, High-Security Locks...Rating: 3 out of 5 stars3/5 (1)

- Belt Failure AnalysisDocument4 pagesBelt Failure AnalysisTamer EmamNo ratings yet

- Poster Fallas de RodamientosDocument1 pagePoster Fallas de RodamientosRepositorio MantenimientoNo ratings yet

- Hoist Pre-Operational Inspection Check ListDocument1 pageHoist Pre-Operational Inspection Check ListMohd Shareen Ezzry Mohd SomNo ratings yet

- 01 Samss 034Document18 pages01 Samss 034aamirtec301100% (1)

- Damage Analysis Chart 2Document1 pageDamage Analysis Chart 2NuM NaNo ratings yet

- Rigger Training: Slings SafetyDocument340 pagesRigger Training: Slings SafetySHIJAD SRAJU100% (1)

- WB - Bearings - Poster - FINAL - US SizeDocument1 pageWB - Bearings - Poster - FINAL - US SizeAditya Shiva AppallaNo ratings yet

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- 5R110W Low QualityDocument66 pages5R110W Low QualityScott Noel100% (1)

- General Information: Wire Rope SlingsDocument7 pagesGeneral Information: Wire Rope Slingsegy pureNo ratings yet

- Techs Up Insert Wear Hand OutDocument2 pagesTechs Up Insert Wear Hand OutShahed FacebookNo ratings yet

- Optical GlassDocument55 pagesOptical GlassLambert StrongNo ratings yet

- Super Fishing Jar: Instruction Manual 4100Document21 pagesSuper Fishing Jar: Instruction Manual 4100Foros IscNo ratings yet

- Welding Types and Positions and DefectsDocument10 pagesWelding Types and Positions and Defectssam_antony2005No ratings yet

- Miller Lanyard Inspection and Maintenance Proceedure PDFDocument2 pagesMiller Lanyard Inspection and Maintenance Proceedure PDFUlviyye ElesgerovaNo ratings yet

- Sagot Sa Potanginang PhysicsDocument8 pagesSagot Sa Potanginang PhysicsVargas, Cristine Joy D.100% (1)

- Fundamental University Physics Vol III QDocument615 pagesFundamental University Physics Vol III QLudimila Iara de Andrade AlvesNo ratings yet

- Denure Base ResinDocument94 pagesDenure Base ResinVishnu S Pattath100% (1)

- IDCON CMS 102R Coupling Sure Flex TOC (With Watermark)Document3 pagesIDCON CMS 102R Coupling Sure Flex TOC (With Watermark)javeriaamin02No ratings yet

- IDCON CMS 101R Coupling Tire (With Watermark)Document3 pagesIDCON CMS 101R Coupling Tire (With Watermark)javeriaamin02No ratings yet

- IDCON CMS 103R Coupling Grid (With Watermark)Document4 pagesIDCON CMS 103R Coupling Grid (With Watermark)javeriaamin02No ratings yet

- Job Safety Analysis: Burning UnderwaterDocument2 pagesJob Safety Analysis: Burning UnderwaterEarl alboNo ratings yet

- Nord-Lock Brochure En2Document32 pagesNord-Lock Brochure En2MarekNo ratings yet

- How To Inspect Your Wire Ropes: Focus On Your Rope'S Critical PointsDocument2 pagesHow To Inspect Your Wire Ropes: Focus On Your Rope'S Critical PointskaloordenisNo ratings yet

- Fluid Film Bearing Damage Poster 1668361770Document1 pageFluid Film Bearing Damage Poster 1668361770Amna YahyaNo ratings yet

- Fluid Film Bearing Damage-1Document1 pageFluid Film Bearing Damage-1Hafiz HarunNo ratings yet

- Button Not Functioning ReportDocument14 pagesButton Not Functioning ReportninjaNo ratings yet

- Avensis 2006 tns600Document19 pagesAvensis 2006 tns600Expobiro Srbija100% (1)

- Basic Mechanical Seal Installation: By: Dewi Tri HandayaniDocument9 pagesBasic Mechanical Seal Installation: By: Dewi Tri HandayaniPermana DediNo ratings yet

- Care in Use Wire Rope SlingsDocument1 pageCare in Use Wire Rope SlingsEhsan Bahrami Gol SorkhdanNo ratings yet

- Brochure OP Vs or GBDocument2 pagesBrochure OP Vs or GBjojoNo ratings yet

- TNS600 RHD PZ445-00331-00 Aim 000 766-1 PDFDocument19 pagesTNS600 RHD PZ445-00331-00 Aim 000 766-1 PDFAndreiPopoviciNo ratings yet

- SM006 642E Service ManualDocument16 pagesSM006 642E Service ManualAlexandra JanicNo ratings yet

- 4 Common Coupling Issues and How To Prevent ThemDocument6 pages4 Common Coupling Issues and How To Prevent ThemApple StarkNo ratings yet

- Guia TronzadoraDocument35 pagesGuia TronzadoraKatherine VergaraNo ratings yet

- عیوب بکسلDocument2 pagesعیوب بکسلjahel2002No ratings yet

- HARDLOCK NUT Presentation (English) 2015.10.30 - コピーDocument32 pagesHARDLOCK NUT Presentation (English) 2015.10.30 - コピーJayden BarnesNo ratings yet

- Assembly Fip Electical: JakartaDocument5 pagesAssembly Fip Electical: Jakartaeko sunaryoNo ratings yet

- Led Signal Light Model 280 Instruction Sheet 6542790b 2016Document1 pageLed Signal Light Model 280 Instruction Sheet 6542790b 2016braulio jimenezNo ratings yet

- Brochure Orbit Valvula Vástago AscendenteDocument28 pagesBrochure Orbit Valvula Vástago AscendenteMiguel SoteloNo ratings yet

- Enercon Achieve A Perfect SealDocument4 pagesEnercon Achieve A Perfect SealRakesh BeheraNo ratings yet

- How To Use This Manual: Type A10Document5 pagesHow To Use This Manual: Type A10dparoNo ratings yet

- 5.SMP Drag Chain Feeder (DCF)Document5 pages5.SMP Drag Chain Feeder (DCF)Abdullatif umatiyaNo ratings yet

- KB InstructionsDocument2 pagesKB Instructionssd731No ratings yet

- Moore Fans Maintenance and Operation ManualDocument10 pagesMoore Fans Maintenance and Operation ManualVivian AnastasyaNo ratings yet

- InsertWearHandout 1 PDFDocument2 pagesInsertWearHandout 1 PDFks1226No ratings yet

- Chain InspectionDocument4 pagesChain Inspectionadhi nrNo ratings yet

- Assy STARTING MOTORDocument3 pagesAssy STARTING MOTORErik dwi KurniawanNo ratings yet

- Ecoline User Guide 25-300Document8 pagesEcoline User Guide 25-300eduardo roqueNo ratings yet

- FB Series: Flexure Base Floor ScalesDocument14 pagesFB Series: Flexure Base Floor ScalesManuel DsfilmNo ratings yet

- Grinding Operation JSA HSE ProfessionalsDocument1 pageGrinding Operation JSA HSE ProfessionalsSamadov 13No ratings yet

- Orbit Valves Brochure PDFDocument28 pagesOrbit Valves Brochure PDFHendi RofiansyahNo ratings yet

- Shaft Voltages and Rotating MachineryDocument8 pagesShaft Voltages and Rotating MachineryDavid MendozaNo ratings yet

- Remy Warranty Aware Trifold 4 15Document2 pagesRemy Warranty Aware Trifold 4 15Eric KenyaNo ratings yet

- NORD-LOCK CatalogDocument14 pagesNORD-LOCK CatalogThái Mai ĐìnhNo ratings yet

- Manual de Instalação 442 LargeDocument12 pagesManual de Instalação 442 LargeDanilo D'AmatoNo ratings yet

- Manual Esmeril Black & Decker BT3600 6Document9 pagesManual Esmeril Black & Decker BT3600 6Argenis MarinNo ratings yet

- S1 AM019 C DenisonDocument25 pagesS1 AM019 C DenisonEmerson MazzaroloNo ratings yet

- Physical Chemistry II (TKK-1237) : Review ReviewDocument7 pagesPhysical Chemistry II (TKK-1237) : Review ReviewUlvatus Sa' DiyahNo ratings yet

- Rotary Screw Compressor Units: MODELS 12 - 101Document68 pagesRotary Screw Compressor Units: MODELS 12 - 101jorge castilloNo ratings yet

- 100 - 2 Electromagnetics C3.2Document11 pages100 - 2 Electromagnetics C3.2Hassan AbdelmoamenNo ratings yet

- L125Document15 pagesL125Gilorie RuizNo ratings yet

- Brezina Etal 2021Document8 pagesBrezina Etal 2021Syed MubashirhussainNo ratings yet

- Visco Test Blade Model 301: Testing Equipment For Quality ManagementDocument2 pagesVisco Test Blade Model 301: Testing Equipment For Quality ManagementFadi MagdyNo ratings yet

- Physics Ss1 Edidot - 081647Document6 pagesPhysics Ss1 Edidot - 081647Raymy ConceptsNo ratings yet

- 1st M.SC SyllabusDocument24 pages1st M.SC SyllabusShilpendu GhoshNo ratings yet

- Chapter 17 - CorrosionDocument11 pagesChapter 17 - CorrosionmuthuhcuNo ratings yet

- The LengthDocument1 pageThe LengthRAIZZ67% (3)

- Differences Between Solids and FluidsDocument4 pagesDifferences Between Solids and FluidsgknindrasenanNo ratings yet

- Using The Eulerian Granular Multiphase Model With Heat TransferDocument36 pagesUsing The Eulerian Granular Multiphase Model With Heat TransferFábio NascimentoNo ratings yet

- Surface Chemistry QuestionsDocument4 pagesSurface Chemistry QuestionssingamroopaNo ratings yet

- Spinner Manual 950 PNEUMATIC Serial Numbers 1 To 80Document81 pagesSpinner Manual 950 PNEUMATIC Serial Numbers 1 To 80Andres BernalNo ratings yet

- Supplementary Information A.: A.1. Overview of Elements Used in Structural and Acoustic CalculationsDocument11 pagesSupplementary Information A.: A.1. Overview of Elements Used in Structural and Acoustic CalculationsDanNo ratings yet

- Investigating The Properties of Rejuvenated Asphalt With The Modified Rejuvenator Prepared by Waste Cooking Oil and Waste Tire Crumb RubberDocument9 pagesInvestigating The Properties of Rejuvenated Asphalt With The Modified Rejuvenator Prepared by Waste Cooking Oil and Waste Tire Crumb RubberNur AthirahNo ratings yet

- 22 - Fracture Toughness & Toughening MechDocument30 pages22 - Fracture Toughness & Toughening MechMd. Rafiqul IslamNo ratings yet

- IGCSE Combined Science (0654) - Chemistry ChecklistDocument4 pagesIGCSE Combined Science (0654) - Chemistry ChecklistHồ Liên KhảiNo ratings yet

- Black Liquor Evaporation3-2Document21 pagesBlack Liquor Evaporation3-2isosicaNo ratings yet

- Electrorheological Materials and Potential Applications in TextilesDocument4 pagesElectrorheological Materials and Potential Applications in TextilesArt PlanteurNo ratings yet

- Hydrology Module 5.BASIC SUBSURFACE FLOWDocument12 pagesHydrology Module 5.BASIC SUBSURFACE FLOWJona OraaNo ratings yet

- Reologia Páginas Desde - Physical - PharmacyDocument23 pagesReologia Páginas Desde - Physical - PharmacyEvelyn K MazoNo ratings yet

- Jun Liu, Yuchen Wang, Baoshuang Shi, Daoming Wang, Liquan Wang, Xiangjuan XuDocument10 pagesJun Liu, Yuchen Wang, Baoshuang Shi, Daoming Wang, Liquan Wang, Xiangjuan Xunarendar.1No ratings yet

- Micromachines 13 01615 v2Document36 pagesMicromachines 13 01615 v2Sing SamNo ratings yet