Professional Documents

Culture Documents

Equipment Datasheet - Traveling Screen Backwash Pump

Uploaded by

ok59Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equipment Datasheet - Traveling Screen Backwash Pump

Uploaded by

ok59Copyright:

Available Formats

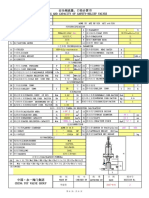

DOCUMENT NO.

文件号

TECHNICAL DATA SHEET SHEET NO. 页码 1 2 of 10

of 4 -

CENTRIFUGAL PUMP PROJECT NO.项目号

离心泵数据表 ITEM NO.位号 P10101A/B/C

NO. OFF数量 4

CLIENT 用户 GCB REV 版次 1 2 3 4

SERVICE 名称 Traveling screen backwash pump DATE 时间

LOCATION 位置 PREPARED 编制

PLANT CHECKED 校核

AREA NUMBER APPROVED 审核

DESCRIPTION 描述 UNITS 单位 DATA 数据 Iss

1 GENERAL 一般内容

2 MANUFACTURER 制造厂 ANDRITZ

3 MODEL / SIZE 型号/尺寸 ACP80-200

4 CONSTRUCTION CODE 标准 ISO5199

5 LOCATION 位置 室内 Indoor

6

7 OPERATING CONDITIONS 操作工况

8 OPERATION MODE 操作模式 Continuous 连续

9 HAZARDOUS AREA CLASSIFICATION 防爆区域划分 na

11 FLUID PUMPED泵送介质 海水 Seawater

12 FLUID CHARACTERISTICS介质特性

13 Corrosive 腐蚀 Yes Cl-=19700~20140mg/L

14 Erosive 磨蚀 No

15 Toxic 有毒 na

16

17 PUMPING TEMPERATURE 泵送温度 °C 14~30

18 DENSITY AT PUMPING TEMPERATURE 密度 kg/m³ 1030

19 VISCOSITY AT PUMPING TEMPERATURE 粘度 mPa.s 0.8007~1.1709

VAPOUR PRESSURE @ pumping temperature 泵送

20

温度下蒸气压 mmHg 11.99~31.85

21 SOLIDS CONTENT / SIZE固体含量/尺寸 wt%

22 Design Case设计工况

23 CAPACITY 流量 Normal 正常 m³/h 150

24 Max. 最大 m³/h

25

26 SUCTION PRESSURE 入口压力 Normal正常 MPa G

27 DISCHARGE PRESSURE出口压力 Normal正常 MPa G

28 DIFFERENTIAL PRESSURE 压差 At Normal Flow在正常 MPa

29 DIFFERENTIAL HEAD 扬程 At Normal Flow 在正常 m 50

30 NPSHA m

31

32 PERFORMANCE 性能

33

34 PUMP SPEED 泵速度 Normal正常 rev / min 2955

35 1st critical一阶临界转速 rev / min 4433

36 IMPELLER DIAMETE叶轮尺寸 Minimum最小 mm 163

37 Rated 额定 mm 202

38 Maximum 最大 mm 215

39 NUMBER OF STAGES 叶轮级数 1

40 NPSHR m 5.02

41 SUCTION SPECIFIC SPEED吸入比转速 m³/h.m.rpm 10791

42 MINIMUM CONTINUOUS FLOW Stable operation稳流 m³/h 80

43 最小连续流量 Thermal 热力 m³/h 50

44 EFFICIENCY 效率 Rated 额定 % 76.4

45 Maximum 最大 % 77.1

46

47 MAXIMUM HEAD 最大扬程 Rated Impeller 额定叶轮 m 57.2

48 Max. Impeller 最大叶轮 m 66

49 HEAD RISE TO MAX. Relative to duty flow % 131

50 上升到最大扬程 相对工作流量

51

52 ABSORBED POWER RATED IMPELLER Rated flow额定流量 kW 27.91

53 额定叶轮下的吸收功率 End of Curve曲线端部 kW 34.29

54 ABSORBED POWER MAX IMPELLER Rated flow额定流量 kW 32.5

55 最大叶轮下的吸收功率 End of Curve曲线端部 kW 44

56 PROPOSAL CURVE NO 曲线号 ACP80-200.5C

1 UTILITY REQUIREMENTS 公用工程要求

2 SEAL FLUSH FLUID 密封冲洗液 Plan 11 3 of 10 -

3 REQUIRED FLOWRATE 需要流量 m³/h N/A

4 PRESSURE INLET / OUTLET 压力 入口/出口 barg N/A

5 TEMPERATURE INLET / OUTLET 温度 入口/出口 °C N/A

6 PUMP COOLING / HEATING FLUID 泵冷却/加热介质 N/A

7 REQUIRED FLOWRATE 需要流量 m³/h N/A

8 PRESSURE INLET / OUTLET 压力 入口/出口 barg N/A

9 TEMPERATURE INLET / OUTLET 温度 入口/出口 °C N/A

10

11 CONNECTIONS

12 LSLL TEVIB

OPENINGS FLANGED GB/T9119-2010 V (Note

TT 5) PG V TYPE 型式 PCV

RATING 等级 SIZE 尺寸 POSITION 位置

13 接口法兰为国标 GB/T9119-2010

14 SUCTION 入口 mm RF PN10 DN125 End

15 DISCHARGE 出口 mm RF PN10 DN80 TOP

16 DRAIN 泵壳排净 堵头 plug Bottom

17 CASING VENT 泵壳排气 N/A

18 JACKET INLET 夹套入口 N/A

19 JACKET OUTLET 夹套出口 N/A

20 JACKET DRAIN 夹套排净 N/A

21 JACKET VENT 夹套排气 N/A

22

23 MATERIALS OF CONSTRUCTION 结构材料

24 CASING 壳体 DIN 1.4469 / ASTM A995 Grade 5A

25 IMPELLER 叶轮 DIN 1.4469 / ASTM A995 Grade 5A

26 CASING WEAR RINGS 壳体耐磨环 DIN 1.4469 / ASTM A995 Grade 5A

27 IMPELLER WEAR RINGS 叶轮耐磨环 N/A

28 SHAFT 轴 DIN 1.4410 / ASTM A276 S32750

29 SLEEVE 轴套 N/A

30 SEAL PLATE 密封板 N/A

31 THROAT BUSH 截流衬套 N/A

32 GASKETS / SEALS 垫片 EPDM

33 JACKET 夹套 N/A

34 SEAL FLUSH PIPING 密封冲洗管 DIN 1.4469 / ASTM A995 Grade 5A

35 BEARING HOUSING 轴承箱 DIN 1561 / ASTM A48-03

36 COUPLING MEMBRANE 联轴器膜片 ASTM A276 321

37 DRIVE GUARD 联轴器护罩 DIN 17100 / ASTM-A36

38 BASEPLATE 底板 DIN 17100 / ASTM-A36

39 COOLING / HEATING PIPING 冷却/加热管 N/A

40 SEALANT COOLER 冷却换热器 N/A

41 COOLING COIL 冷却盘管 N/A

42

43 MECHANICAL SEAL 机械密封

44 STATIONARY SEAT 静环 Inboard / Outboard SiC

45 ROTATING FACE 动环 Inboard / Outboard SiC

46 METALLIC PARTS 金属部件 Inboard / Outboard DIN 1.4410 / ASTM A276 S32750

47

1 MECHANICAL DATA 机械数据

2 PUMP TYPE 泵的形式 端吸离心泵 end suction centrifugal 4 of 10 -

3

4 CASING DESIGN PRESSURE Max./Min. 最大/最小 barg 20.1

壳体设计压力

5 CASING DESIGN TEMPERATURE Max./Min. 最大/最小 °C 110/-25

壳体设计温度

6 CASING TEST PRESSURE 壳体试验压力 barg 30.15

7 JACKET DESIGN TEMPERATURE 夹套设计温度 °C N/A

8 JACKET DESIGN PRESSURE 夹套设计压力 barg N/A

9 JACKET TEST PRESSURE 夹套试验压力 barg N/A

10

11 CASING 泵壳 Mounting 安装 地脚 Foot

12 Split 剖分 径向 Radial

13 腐蚀裕量 Corrosion allowance mm 3

14 Type 形式 蜗壳 Volute casing

15 IMPELLER 叶轮 Type 形式 闭式离心叶轮 Closed centrifugal impeller

16 No. vanes 叶片数 5

17

18 ROTATION (facing coupling end) 旋转方向(面向联轴器端部) 从电机端看顺时针 Clockwise vew from motor

19 COUPLINGS 联轴器 Manufacturer 制造厂 宁波伟隆 Ningbo Weilong

20 型号 JM1J4

21 Type 形式 膜片式 Flexible disc

22 Lubrication 润滑 N/A

23 Spacer length 短节长度 mm 140

24 Service factor 安全系数 1.72

25 Guard 护罩 Steel

26

27 BEARINGS 轴承 Radial 径向 滚珠轴承 Radial ball bearing

28 Thrust 止推 Rolling element bearing

29 Life L10 寿命 Hours 100,000

30 BEARING SEALS 轴承密封 Type 形式 迷宫油封Labyrinth seal

31 Manufacturer 制造厂 ANDRITZ

32 LUBRICATION 润滑 Method 方法 脂润滑 Grease lubrication

33 Lubricant 润滑剂 润滑脂 Grease

34

35 BASEPLATE 底座 Type 形式 公共底座 Common baseplate

36

37 SHAFT SEAL TYPE 轴密封形式 机械密封 Mechanical seal

38 MANUFACTURER 制造厂 Burgmann/John Crane/Chesterton/Sinoseal Holding

39 API CODE API标准号 TBA

40 MANUFACTURER CODE 制造厂标号 TBA

41 CIRCULATION / FLUSH PLAN API 冲洗方案 自冲洗/PLAN11 Self flushing/PLAN11

42

43 DRIVE ARRANGEMENT 驱动机

44 DRIVER TYPE 驱动形式 电机 motor

45 MANUFACTURER 制造厂 ABB

46 DRIVER SPECIFICATION 驱动机技术要求 IP55, fan cooled IC411

47 RATED POWER / SPEED 功率/转速 kW / rpm 37/3000

48 POWER SUPPLY 提供动力 400V/50Hz

49

50 SCOPE OF SUPPLY 供货范围

51 PUMP 泵 Required 需要

52 DRIVER 驱动机 Required 需要

53 VARIABLE SPEED DRIVE 变速器 Not Required 不需要

54 Pump And Motor Communal Baseplate 水泵电机公共底座 Required 需要

55 COUPLING & GUARD 联轴器及护罩 Required 需要

56 SEAL COOLER 密封冷却器 Not Required 不需要

57 SEAL FLUID FLUSH SYSTEM 密封液冲洗系统 Not Required 不需要

58 NOZZLE GASKETS & FASTENERS 接管垫片和紧固件 Required for non-interface connections 在接口连接处需要

59 COMMISSIONING SPARES 开车备件 Not

Required 需要不需要

Required

60 OPERATING SPARES 操作备件 Priced bid 需要

Required only 只报价

61 FIRST FILL OF LUBRICANT 首次润滑油 Not

Required 需要不需要

Required

62 HOLDING DOWN BOLTS 地脚螺栓 Required 需要

N/A

63

DESCRIPTION UNITS DATA Iss

1 WEIGHTS & DIMENSIONS 重量尺寸 5 of 10 -

2 WEIGHT OF PUMP 泵重量 kg 75

3 WEIGHT OF DRIVER 驱动机重量 kg 268

4 WEIGHT OF BASEPLATE 底座重量 kg 100

5 TOTAL WEIGHT 总重 kg 443

6 MAXIMUM MAINTENANCE LIFT 最大维修重量 kg 268

7 BASEPLATE FOOTPRINT LENGTH x WIDTH mm 1450*500

8 底座尺寸 长x宽

9 INSPECTION, TESTING AND CERTIFICATION 检验,试验和证书

10 QUALITY LEVEL质量等级:-

11

12 Inspection will take place at the Vendor's works against an approved Quality Plan. Refer to Specification, Shop Quality Control

13 Requirements, and General Project Equipment Specification.

14 根据批准的质量计划和项目规定,设备检验应在厂家的工厂完成。

15

16 GENERAL NOTES 备注

17 1. The motor is fan cooled (IC411) suitable for inverter operation as per the end user's specification.

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

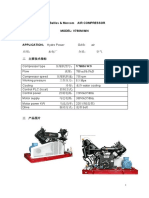

Item: P10101

Performance curve Traveling screen backwash pump

Pump name ACP80-200.5C

Pump description single-stage, single-flow, closed impeller

Head — 202

H/ m ∆p / MPaPump data

60 % 65 % Make

57,13 68 % 0,577

70 % ANDRITZ

56 72 % 0,56

DP 2 73 % Product group

74 %

75 % ACP ISO

52 76 %

0,52 Series

50,44 77 % 0,509 ACP

77,1%

77 %

48 DP 1 Size

0,48

80-200

76 % Speed

44 0,44

75 % 2955 1/min

74 %

73 % Frequency

40 72 % 0,4 50 Hz

39,14 0,395

DP 3 Stages

36 0,36 1

Impeller construction

32 Closed

0,32

Impeller type

Radial impeller

28 0,28 Impeller size

202 mm

24 0,24 Discharge size

DN 80

20 0,2 Free passage

[< POR >] 19,3 mm

Motor power

16 0,16 37 kW

[< AOR >]

Number of poles

P₂ / kW Shaft power P2 2

32,68

32

Customer data

28

27,91 Flow

150 m³/h

24

Head

20,91

20 50 m

Consistency

16 0%

12

Operating data

8 Flow

150,7 m³/h

4 Head

NPSH / m NPSH-values 50,44 m

Pump efficiency

12 76,4 %

11,63

11 Shaft power P2

27,91 kW

10

Max. shaft power

9 34,29 kW

8 NPSH

7 5,018 m

6

5,018

5

4 Impeller No.

3,479

3

Reserves to change any technical data.

0 20 40 60 80

80 100 120 140150,7160 180 200 216

220 240 Q / m³/h Diffuser No.

*) NPSHr tolerance +6% or +0.5m, the larger value to be considered

Selection is based on:

Addition

Sea water; 20°C; 1.029kg/m³; 1mm²/s

ISO 9906:2012 Class 2B Shaft power P2 < 10 kW acc. ISO9906:2012 Paragraph 4.4.2

Curve based on

Remarks

Pump serial number 1 Customer pos. No. Customer

Project No. (CRM) Project 2023-08-30 02:40:03.743

Reference 20221114_2.0_ACP80-200.5C_50_2 2023-08-30 Spaix® 5-2022.3 - 2023/07/20 (Build 551), 64 bit

fshzon05 Page 1 / 3

Performance curve

Pump name ACP80-200.5C

Pump description single-stage, single-flow, closed impeller

H/ m Head — 215 mm / 0° ∆p / MPaPump data

60 %65 68

— 205 mm / 0° Make

% %

70 72

%% — 190 mm / 0° ANDRITZ

64 7374%%

7576

%% — 182 mm / 0° 0,64 Product group

77 %

78 % — 169 mm / 0° ACP ISO

60 79 % — 163 mm / 0° 0,6 Series

Eff. 79,6% ACP

56

— 202

0,56 Size

50 % 80-200

52 0,52

50,44 77,5% 0,509 Speed

77,1% 2955 1/min

48 DP 1 0,48

Frequency

44 50 Hz

75,9% 0,44

Stages

40 0,4 1

74,4% Impeller construction

70 %

36 0,36 Closed

Impeller type

32 68 % 0,32 Radial impeller

72%

70,5% Impeller size

28 0,28 202 mm

Discharge size

24 65 % 0,24 DN 80

Free passage

20 0,2 19,3 mm

Motor power

16 0,16

37 kW

Number of poles

P₂ / kW Shaft power P2 2

40

Customer data

35 Flow

150 m³/h

30

27,91 Head

25 50 m

Consistency

20 0%

15

Operating data

10 Flow

150,7 m³/h

5

Head

NPSH / m NPSH-values 50,44 m

Pump efficiency

12 76,4 %

11 Shaft power P2

27,91 kW

10

Max. shaft power

9 34,29 kW

8 NPSH

7 5,018 m

6

5,018

5

4 Impeller No.

3

Reserves to change any technical data.

0 20 40 60 80 100 120 140150,7 160 180 200 220 240 260 Q / m³/h Diffuser No.

*) NPSHr tolerance +6% or +0.5m, the larger value to be considered

Selection is based on:

Addition

Sea water; 20°C; 1.029kg/m³; 1mm²/s

ISO 9906:2012 Class 2B Shaft power P2 < 10 kW acc. ISO9906:2012 Paragraph 4.4.2

Curve based on

Remarks

Pump serial number 1 Customer pos. No. Customer

Project No. (CRM) Project 2023-08-30 02:40:03.743

Reference 20221114_2.0_ACP80-200.5C_50_2 2023-08-30 Spaix® 5-2022.3 - 2023/07/20 (Build 551), 64 bit

fshzon05 Page 1 / 3

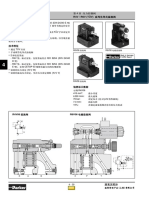

IEC LV Motors Technical Data Sheet - DOL

Project Location

Department/Author Customer name Customer ref Item name

1.00001

Our ref. Rev/Changed by Date of issue Saving ident Pages

A 2023/8/30 untitled.xlsm 1(3)

No. Definition Data Unit Remarks

1 Product TEFC, 3-phase, squirrel cage induction motor

2 Product code 3GBA 201 420-ADFCN Calc. ref. 3GZC021020-267

3 Type/Frame M2BAX 200MLB 2

4 Mounting IM1001, B3(foot)

5 Rated output PN 37 kW

6 Service factor 1

7 Type of duty S1(IEC) 100%

8 Rated voltage UN 400 VD ± 5 % (IEC 60034-1)

9 Rated frequency fN 50 Hz ± 2 % (IEC 60034-1)

10 Rated speed nN 2951 r/min

11 Rated current IN 63.9 A

12 No-load current 19.5 A

13 Starting current Is/IN 10.5 Meet IEC 60034-12, NE

14 Nominal torque TN 120 Nm

15 Locked rotor torque TS/TN 4.2

16 Maximum torque Tmax/TN 4.1

17 Minimum torque Tmin/TN 2.7

18 Speed at minimum torque 1650 r/min

Load characteristics (IEC 60034-2-1:2014) Load % Current A Efficiency % Power factor

19 100 63.9 93.7 / IE3 0.89

20 75 49.6 93.9 0.86

21 50 36.2 93.3 0.79

22 Start 671 0.53

23 Maximum starting time from hot 19 s

24 Maximum starting time from cold 34 s

25 Insulation class / Temperature class F/B

26 Ambient temperature 45 °C

27 Altitude 1000 m.a.s.l.

28 Enclosure IP55

29 Cooling system IC411 self ventilated

30 Bearing DE/NDE 6212-2Z/C3 - 6209-2Z/C3

31 Type of Grease

32 Sound pressure level (LP dB(A) 1m) 78 dB(A)

33 Moment of inertia J = ¼ GD2 0.16 kg-m2

34 Balancing

35 Vibration class

36 Position of terminal box Top

37 Terminal box entries; no, dimens.

38 Number of power terminals

39 Direction of rotation CW or CCW

40 Weight of rotor 57 kg

41 Total weight of motor 268 kg

42 Dimension drawing no.

43

44

45

Ex-motors

46

47

48

Option Variant Codes / Definition

49

50

51

52

Remarks:

Data based on situation 10/13/2022

All data subject to tolerances in accordance with IEC

Guaranteed values on request

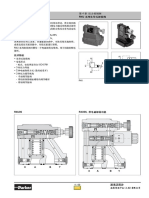

IEC LV Motors Starting Curves

Project Location

Department/Author Customer name Customer ref Item name

1.00001

Our ref. Rev/Changed byDate of issue Saving ident Pages

A 2023/8/30 untitled.xlsm 3(3)

Type of product TEFC, 3-phase, squirrel cage induction motor

Type/Frame M2BAX 200MLB 2 Calc. ref. 3GZC021020-267

Product code 3GBA 201 420-ADFCN Frequency (Hz) 50

Rated output PN 37 kW Rated current IN 63.9 A

Type of duty S1(IEC) 100%

Jmotor (kgm2) 0.16 Voltage (V) 100% 400 Voltage (V) 400V(100%)

Jload (kgm2) Tstart/TN 4.2 Tstart/TN 4.2

Speed (r/min) 2951 Starting time (s) Starting time (s)

TN (Nm) 120 Speed (r/min) Speed (r/min)

Tload (Nm) Is/In 10.5 Is/In 10.5

Nbr. of Consecutive Starts at UN Tmax/Tn 4.1 Tmax/Tn 4.1

6 12

5 10

4 8

Ts/Tn

Is/In

3 6

2 4

1 2

0 0

0 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750 3000 3250

Speed (r/min)

TMotorUn 400V TMotorU2 400V(100%)

IMotorUn 400V IMotorU2 400V(100%)

Load characteristics (IEC 60034-2-1:2014)

Data based on situation 10/13/2022

All data subject to tolerances in accordance with IEC

IEC LV Motors Load Curves

Project Location

Department/Author Customer name Customer ref Item name

1.00001

Our ref. Rev/Changed by Date of issue Saving ident Pages

A 2023/8/30 untitled.xlsm 2(3)

Product TEFC, 3-phase, squirrel cage induction motor

Type/Frame M2BAX 200MLB 2 Calc. ref. 3GZC021020-267

Product code 3GBA 201 420-ADFCN

Rated output PN 37 kW

Type of duty S1(IEC) 100%

Voltage (V) 400 Current IN (A) 63.9 Power factor at PN 0.89

Frequency (Hz) 50 Speed (r/min) 2951 Efficiency (%) at PN 93.7

1.4

1.3

1.2

1.1

1

PF / Efficiency,Current%(*100)

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1 1.2 1.3 1.4

P2/Pn

Current Efficiency Cosinus

Load characteristics (IEC 60034-2-1:2014)

Data based on situation 10/13/2022

All data subject to tolerances in accordance with IEC

You might also like

- 管線工程Document127 pages管線工程Eason HuangNo ratings yet

- XE215C Crawler Excavator Technical SpecificationDocument4 pagesXE215C Crawler Excavator Technical SpecificationKevin Andrian100% (1)

- XE215C Crawler Excavator Technical SpecificationDocument4 pagesXE215C Crawler Excavator Technical SpecificationJhoan Mendoza RinconNo ratings yet

- PW2 0VK+++220-240V+50 60Hz+M LBPDocument9 pagesPW2 0VK+++220-240V+50 60Hz+M LBPtrieutuyenhoang100% (1)

- Safety Relief ValveDocument1 pageSafety Relief ValveMrinal Kanti BhaduriNo ratings yet

- 1400 Me DTS 009Document2 pages1400 Me DTS 009ssmith2007No ratings yet

- Gree-Lamda Qxa-E232rh050 Article 1604089090511295 en SsDocument15 pagesGree-Lamda Qxa-E232rh050 Article 1604089090511295 en SsYui HdzNo ratings yet

- 452-Aqc Boiler (Equipment List) 5000Document2 pages452-Aqc Boiler (Equipment List) 5000Tan VuNo ratings yet

- MPV 80F最小压力阀Document1 pageMPV 80F最小压力阀Сергей КолесниковNo ratings yet

- PH310M2CS 4kuhDocument18 pagesPH310M2CS 4kuhsidahmed latsameniaNo ratings yet

- A46F-150LB Safety Valve Size and Capacity CalculationDocument2 pagesA46F-150LB Safety Valve Size and Capacity Calculationpriyanka GNo ratings yet

- 04-08 - RE06M^W 电磁比例溢流阀Document4 pages04-08 - RE06M^W 电磁比例溢流阀ZHOUNo ratings yet

- QD91H V4Document2 pagesQD91H V4daniel180778No ratings yet

- 02-12 - D^P 液动方向阀Document11 pages02-12 - D^P 液动方向阀ZHOUNo ratings yet

- KMC PTRDocument3 pagesKMC PTRRaj DhuriNo ratings yet

- A10vso PDFDocument40 pagesA10vso PDF江柄宏No ratings yet

- 14 50061-Mr-003-Zk-ds Instrument Data SheetsDocument8 pages14 50061-Mr-003-Zk-ds Instrument Data SheetsPhucChuVanNo ratings yet

- HVM70MTa Technical-Specification PolorhouseDocument23 pagesHVM70MTa Technical-Specification PolorhouseJulius ApigoNo ratings yet

- Block QiangshengDocument13 pagesBlock QiangshengtrieutuyenhoangNo ratings yet

- PH215X2C-4FT Comp SpecificationDocument17 pagesPH215X2C-4FT Comp SpecificationZimmy ZizakeNo ratings yet

- 1200 PR DTS 020Document2 pages1200 PR DTS 020zsmithNo ratings yet

- PE250 MVE-压缩机-苏州双仕丰Document9 pagesPE250 MVE-压缩机-苏州双仕丰周然No ratings yet

- 1200 PR Dts 021Document2 pages1200 PR Dts 021zsmithNo ratings yet

- QDZH91G MXDocument8 pagesQDZH91G MXDiego CachaguaNo ratings yet

- 04-07 - R4V-R6V TUV 先导式及电磁溢流阀Document9 pages04-07 - R4V-R6V TUV 先导式及电磁溢流阀ZHOUNo ratings yet

- Grundfosliterature 1191152Document47 pagesGrundfosliterature 1191152sf wNo ratings yet

- For reference only: 客户名称/Customer:Document16 pagesFor reference only: 客户名称/Customer:piyuNo ratings yet

- 04-17 Vmy 电液比例减压阀Document8 pages04-17 Vmy 电液比例减压阀ZHOUNo ratings yet

- JFSB116Z12 Specification 4000 RPMDocument7 pagesJFSB116Z12 Specification 4000 RPMRafael Antonio Santana GarciaNo ratings yet

- ASM93V11VDZDocument14 pagesASM93V11VDZpant.vk8514No ratings yet

- 1904-FG-ME-LST-0003 BAC-Utility Consumption ListDocument5 pages1904-FG-ME-LST-0003 BAC-Utility Consumption Listmahan moradiNo ratings yet

- BOSCH中频焊机现场培训资料Document11 pagesBOSCH中频焊机现场培训资料Teo de los SantosNo ratings yet

- 000 in DTS 301Document5 pages000 in DTS 301zsmithNo ratings yet

- 04-12 Vbyk 滑阀型电液比例溢流阀Document6 pages04-12 Vbyk 滑阀型电液比例溢流阀ZHOUNo ratings yet

- UntitledDocument6 pagesUntitledZHOUNo ratings yet

- ICP BrochureDocument7 pagesICP Brochurelee victorNo ratings yet

- Inverter Type AC CompressorDocument12 pagesInverter Type AC CompressorPrudzNo ratings yet

- 04-03 - VBY 系列滑阀型先导式溢流阀Document5 pages04-03 - VBY 系列滑阀型先导式溢流阀ZHOUNo ratings yet

- 24V 18CC CompressorDocument4 pages24V 18CC CompressorYAKOVNo ratings yet

- 04-06 - R4V-R6V 先导式及电磁溢流阀Document9 pages04-06 - R4V-R6V 先导式及电磁溢流阀ZHOUNo ratings yet

- 流體輸送設備設 計Document112 pages流體輸送設備設 計bill100% (1)

- 02-13 - D1VA NG06气动方向阀Document4 pages02-13 - D1VA NG06气动方向阀ZHOUNo ratings yet

- SolenoidDocument50 pagesSolenoidRajan BediNo ratings yet

- 04-09 - RE06M^T 电磁比例溢流阀 OBEDocument6 pages04-09 - RE06M^T 电磁比例溢流阀 OBEZHOUNo ratings yet

- Atlas Copco APE - 空压机大机-中高风压Document4 pagesAtlas Copco APE - 空压机大机-中高风压NunoNo ratings yet

- V780M-WN TEC. FileDocument5 pagesV780M-WN TEC. FileTriệu Tử LongNo ratings yet

- 50X3H93M 5AMD 01 (DW AS 6609) A版 - 新表格 - 凝结温度 - 2021Document17 pages50X3H93M 5AMD 01 (DW AS 6609) A版 - 新表格 - 凝结温度 - 2021pant.vk8514No ratings yet

- 日立螺杆压缩机培训资料Document18 pages日立螺杆压缩机培训资料anbang wangNo ratings yet

- Atlas Copco APE - 空压机大机-钻探专家Document4 pagesAtlas Copco APE - 空压机大机-钻探专家NunoNo ratings yet

- 04-02 - VB 滑阀型直动式溢流阀Document5 pages04-02 - VB 滑阀型直动式溢流阀ZHOUNo ratings yet

- FM0515Document4 pagesFM0515mustafaNo ratings yet

- Thermal MechanicalDocument58 pagesThermal MechanicalLương Đình HuyNo ratings yet

- 454 455 - Cooling Tower &circulating Water Pump StationDocument2 pages454 455 - Cooling Tower &circulating Water Pump StationTan VuNo ratings yet

- 03-13 D1feDocument6 pages03-13 D1feZHOUNo ratings yet

- 立式热虹吸再沸器HTRI优化设计 PDFDocument34 pages立式热虹吸再沸器HTRI优化设计 PDFaaaNo ratings yet

- 04-13 r4u 先导式及电磁卸荷阀Document6 pages04-13 r4u 先导式及电磁卸荷阀ZHOUNo ratings yet

- 采油工程课程设计任务书 新Document4 pages采油工程课程设计任务书 新jiv24No ratings yet

- 04-15 - VM 直动式减压阀Document5 pages04-15 - VM 直动式减压阀ZHOUNo ratings yet

- B38H CopperDocument28 pagesB38H Coppergago tvNo ratings yet