Professional Documents

Culture Documents

Ampco 21: Technical Data Sheet Continuous Cast

Uploaded by

dedosimoes0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

A21_HCC_E

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageAmpco 21: Technical Data Sheet Continuous Cast

Uploaded by

dedosimoesCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

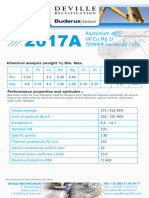

Technical Data Sheet

AMPCO® 21

Continuous Cast

Nominal composition:

Aluminium (Al) 13.1%

Iron (Fe) 4.4%

Others max. 2.5%

Copper (Cu) balance

Mechanical and physical properties Units Nominal Values

Tensile strength Rm MPa 703

Yield strength Rp 0.5 MPa 407

Elongation A5 % 1

Brinell hardness HBW 10/3000 302

Rockwell hardness HRC 32

Reduction of area ψ % 0.5

Compressive strength Rmc MPa 1227

Shear strength Rcm MPa 414

Modulus of elasticity E GPa 105

Charpy aK J 3

Izod aK J 3

Density ρ g / cm³ 7.2

Coefficient of expansion α 10 / K

-6

16.2

Thermal conductivity λ W /m ·K 42

Electrical conductivity γ m / Ω · mm² 6

Electrical conductivity % I.A.C.S. 10

Specific heat cp J/g·K 0.42

Assurances given with respect to properties or uses are subject to written approval from AMPCO METAL.

The increase in the Al and Fe content results in a material in which the hard gamma 2 phase (about 400 HB) is

present.

By proper metallurgical control this hard constituent is uniformly distributed giving this alloy its ability to resist

wear.

APPLICATIONS:

AMPCO® 21 is used for guide port bushings and wear strips replacing hardened steel and for some cams when

no impact is involved. However, the largest single use is as die rings, inserts, forming rolls etc. in forming,

bending or drawing operations, especially when stainless steel is the material being processed.

AMPCO® 21 is also widely used as work support blades for the centerless grinding of steel rods.

You might also like

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionNo ratings yet

- Ampco 22: Technical Data SheetDocument1 pageAmpco 22: Technical Data SheetdedosimoesNo ratings yet

- Ampco 22: Technical Data SheetDocument1 pageAmpco 22: Technical Data Sheetmarceloalves.dsNo ratings yet

- A21 Ex Rect eDocument1 pageA21 Ex Rect ededosimoesNo ratings yet

- Ampco 18.22: Technical Data SheetDocument1 pageAmpco 18.22: Technical Data SheetdedosimoesNo ratings yet

- Ampco 18: Technical Data Sheet Sand CastingsDocument1 pageAmpco 18: Technical Data Sheet Sand CastingsdedosimoesNo ratings yet

- Ampco 18: Technical Data SheetDocument1 pageAmpco 18: Technical Data SheetdedosimoesNo ratings yet

- Ampco 18: Technical Data SheetDocument2 pagesAmpco 18: Technical Data SheetAchilles AldaveNo ratings yet

- Ampco 18.23: Technical Data SheetDocument1 pageAmpco 18.23: Technical Data SheetdedosimoesNo ratings yet

- Ampco 18: Technical Data SheetDocument1 pageAmpco 18: Technical Data Sheetmarceloalves.dsNo ratings yet

- Ampco 8: Technical Data SheetDocument2 pagesAmpco 8: Technical Data SheetdedosimoesNo ratings yet

- Ampcoloy 83: Technical Data SheetDocument1 pageAmpcoloy 83: Technical Data SheetFilipe SantosNo ratings yet

- Ampcoloy 972: Technical Data SheetDocument1 pageAmpcoloy 972: Technical Data SheetmazaherramazaniNo ratings yet

- CuAl10Ni HCC EDocument1 pageCuAl10Ni HCC EDeepak DasNo ratings yet

- Ampco 45: Technical Data SheetDocument2 pagesAmpco 45: Technical Data Sheetmarceloalves.dsNo ratings yet

- Ampco 25: Technical Data SheetDocument1 pageAmpco 25: Technical Data Sheetmarceloalves.dsNo ratings yet

- Ampco 26: Technical Data SheetDocument1 pageAmpco 26: Technical Data SheetdedosimoesNo ratings yet

- A26 CCRM eDocument1 pageA26 CCRM ededosimoesNo ratings yet

- Ampco 18Document1 pageAmpco 18Gloria TouguinhaNo ratings yet

- Ampco 26: Technical Data SheetDocument1 pageAmpco 26: Technical Data SheetdedosimoesNo ratings yet

- AMPCO 18 SandDocument1 pageAMPCO 18 SandS BHATTACHARYYANo ratings yet

- Ampcoloy 95: Technical Data SheetDocument1 pageAmpcoloy 95: Technical Data Sheetmarceloalves.dsNo ratings yet

- Stainless Steel 1.4404Document1 pageStainless Steel 1.4404Alexandra PetreNo ratings yet

- Accc/Tw London (780) : Data SheetDocument1 pageAccc/Tw London (780) : Data SheetkmiqdNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Accc/Tw Paris (800) : Data SheetDocument1 pageAccc/Tw Paris (800) : Data SheetkmiqdNo ratings yet

- CuZn30 PDFDocument2 pagesCuZn30 PDFavinashchauhan2695No ratings yet

- AmuDocument2 pagesAmuavinashchauhan2695No ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- Accc/Tw Dublin (520) : Data SheetDocument1 pageAccc/Tw Dublin (520) : Data SheetkmiqdNo ratings yet

- Accc/Tw Stockholm (460) : Data SheetDocument1 pageAccc/Tw Stockholm (460) : Data SheetkmiqdNo ratings yet

- CuZn40 01 2019 PDFDocument7 pagesCuZn40 01 2019 PDFMisaelNo ratings yet

- (Al Cu MG 1) 2017a - RemovedDocument1 page(Al Cu MG 1) 2017a - RemovedZo StevanovicNo ratings yet

- AluminiumHE15 PropertiesDocument3 pagesAluminiumHE15 PropertiesPrashanthNo ratings yet

- Accc/Tw Prague (700) : Data SheetDocument1 pageAccc/Tw Prague (700) : Data SheetkmiqdNo ratings yet

- Accc/Tw Hamburg (550) : Data SheetDocument1 pageAccc/Tw Hamburg (550) : Data SheetkmiqdNo ratings yet

- Accc/Tw Warsaw (510) : Data SheetDocument1 pageAccc/Tw Warsaw (510) : Data SheetkmiqdNo ratings yet

- Accc/Tw Brussels (415) : Data SheetDocument1 pageAccc/Tw Brussels (415) : Data Sheetkmiqd0% (1)

- BrusselsDocument1 pageBrusselskmiqdNo ratings yet

- GTP ACSR Tern Conductor 22.05.2018Document1 pageGTP ACSR Tern Conductor 22.05.2018Avinash LalNo ratings yet

- Aluminium ADC12Document1 pageAluminium ADC12Gowtham Raj KNo ratings yet

- Aluminium 7075 SpecDocument2 pagesAluminium 7075 Specadam.el.polaco7881No ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- Fracture and Fatigue of Commercial Grade API Pipeline Steels in Gaseous Hydrogen B.P. SomerdayDocument17 pagesFracture and Fatigue of Commercial Grade API Pipeline Steels in Gaseous Hydrogen B.P. SomerdayPhoenix RomeoNo ratings yet

- Bab 03 - Materials PropertiesDocument29 pagesBab 03 - Materials Propertiesfauzi ganiNo ratings yet

- Accc/Tw Lisbon (310) : Data SheetDocument1 pageAccc/Tw Lisbon (310) : Data SheetkmiqdNo ratings yet

- Accc/Tw Lisbon (310) : Data SheetDocument1 pageAccc/Tw Lisbon (310) : Data SheetkmiqdNo ratings yet

- M. Farhan Alfarabi. (4318218004)Document2 pagesM. Farhan Alfarabi. (4318218004)Farhan AlfarabiNo ratings yet

- SNI 4658-2008-Pelek Kategori LDocument2 pagesSNI 4658-2008-Pelek Kategori LDimazNugraha100% (1)

- Carbofil Crmo9 (G Crmo9)Document1 pageCarbofil Crmo9 (G Crmo9)brunizzaNo ratings yet

- Cathodic Calculation RuleDocument8 pagesCathodic Calculation RulegtomehNo ratings yet

- Steel-1 7131Document1 pageSteel-1 7131H. BeatsNo ratings yet

- Bronze c54400 SpecificationsDocument3 pagesBronze c54400 SpecificationsRam Parimalam100% (1)

- 6061 T6 MaterialDocument2 pages6061 T6 Materialtravis8zimmermannNo ratings yet

- 2024-O ASM Material Data SheetDocument2 pages2024-O ASM Material Data SheetAnonymous mq0U43UsPNo ratings yet

- 2 ACCC®LINNET-RevFDocument1 page2 ACCC®LINNET-RevFraulNo ratings yet

- Accc/Tw Helsinki (160) : Data SheetDocument1 pageAccc/Tw Helsinki (160) : Data SheetkmiqdNo ratings yet

- Accc/Tw Helsinki (160) : Data SheetDocument1 pageAccc/Tw Helsinki (160) : Data SheetkmiqdNo ratings yet

- Data Sheet TI-6AL-4VDocument3 pagesData Sheet TI-6AL-4VMarcionilo NeriNo ratings yet

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- SpecificationDocument6 pagesSpecificationMOHAMAD AMIR BIN HALIDNo ratings yet

- Hodge JM Orehoski MA Trans AIME 1946 167 502 PDFDocument11 pagesHodge JM Orehoski MA Trans AIME 1946 167 502 PDFPablo CollantesNo ratings yet

- Flexible Waterproofing With Sika Membrane Technologies-SMLDocument5 pagesFlexible Waterproofing With Sika Membrane Technologies-SMLAgung RahmadiNo ratings yet

- Is 191Document9 pagesIs 191Saravana Kumar100% (1)

- Series 1700 PDFDocument27 pagesSeries 1700 PDFmukndpandeyNo ratings yet

- Cement Plant Operations Handbook - 7thDocument40 pagesCement Plant Operations Handbook - 7thJackson VuNo ratings yet

- SCGC Brochure PVC Resins CompressedDocument12 pagesSCGC Brochure PVC Resins CompressedWW LeongNo ratings yet

- Hyperzone Presentation SPE 2019Document17 pagesHyperzone Presentation SPE 2019phu nghiaNo ratings yet

- Written ReportDocument14 pagesWritten ReportHansel TayongNo ratings yet

- Cembrit Patina Installation Instructions2016Document34 pagesCembrit Patina Installation Instructions2016Petre EnescuNo ratings yet

- Welcome To CE 413: Lecture-03Document16 pagesWelcome To CE 413: Lecture-03Md Tanvir Haider 191-47-915No ratings yet

- Gunung Gahapi BaharaDocument6 pagesGunung Gahapi BaharamagiNo ratings yet

- Monthly Ahead PlanDocument3 pagesMonthly Ahead PlanPoru ManNo ratings yet

- Plumbing ReviewDocument22 pagesPlumbing ReviewsherylNo ratings yet

- Sulzer MaterialGuide 06.2010aDocument132 pagesSulzer MaterialGuide 06.2010aatfrost4638No ratings yet

- Sonagage IVDocument2 pagesSonagage IVRushikesh JoshiNo ratings yet

- Sami Icme2017 00013 PDFDocument10 pagesSami Icme2017 00013 PDFSam AlalimiNo ratings yet

- Use of Plastic Waste in Bituminous PavementDocument19 pagesUse of Plastic Waste in Bituminous Pavementparvezahamed563No ratings yet

- QP10-Q-611 Rev0 Typical Cross Section For Roads and TrafficDocument1 pageQP10-Q-611 Rev0 Typical Cross Section For Roads and TrafficnawajhaNo ratings yet

- Sweeper & Vacuum TruckDocument8 pagesSweeper & Vacuum TruckAfryanto BuliNo ratings yet

- TangkiDocument7 pagesTangkiReza Fadhila0% (1)

- Shalimar Superlac Hi Gloss Enamel PaintsDocument2 pagesShalimar Superlac Hi Gloss Enamel PaintsitbhuNo ratings yet

- 2G +5GDocument1 page2G +5GRahul Moottolikandy0% (1)

- en-GB - Flo-Grout 2.03012016065544 PDFDocument2 pagesen-GB - Flo-Grout 2.03012016065544 PDFHassan SleemNo ratings yet

- Sampling and Sample Preparation of Aluminum and Aluminum Alloys For Determination of Chemical Composition by Spark Atomic Emission SpectrometryDocument6 pagesSampling and Sample Preparation of Aluminum and Aluminum Alloys For Determination of Chemical Composition by Spark Atomic Emission SpectrometryAdriene SantosNo ratings yet

- Toilet Layout Details PDFDocument1 pageToilet Layout Details PDFVetrivel AjanNo ratings yet

- CUI III Tech Paper Fundamentals Layout - EN - 201901 - f2 - WebDocument24 pagesCUI III Tech Paper Fundamentals Layout - EN - 201901 - f2 - WebVarlyvarlyanNo ratings yet

- Film PropertiesDocument22 pagesFilm PropertiescattausNo ratings yet

- Alloys - Definition, Composition, Properties and Uses - GeeksforGeeksDocument1 pageAlloys - Definition, Composition, Properties and Uses - GeeksforGeeksrvinNo ratings yet

- Astm B 316 Acero InoxidableDocument9 pagesAstm B 316 Acero InoxidableMajo BárcenasNo ratings yet