Professional Documents

Culture Documents

Ampco 18.22: Technical Data Sheet

Ampco 18.22: Technical Data Sheet

Uploaded by

dedosimoesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ampco 18.22: Technical Data Sheet

Ampco 18.22: Technical Data Sheet

Uploaded by

dedosimoesCopyright:

Available Formats

Technical Data Sheet

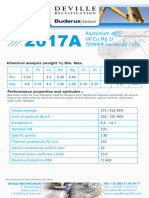

AMPCO® 18.22

Sand Castings

Nominal composition:

Aluminium (Al) 10.5%

Iron (Fe) 3.5%

Others max.0.5%

Copper (Cu) balance

Mechanical and physical properties Units Nominal Values

Tensile strength Rm MPa 724

Yield strength Rp 0.5 MPa 379

Elongation A5 % 8

Brinell hardness HBW 10/3000 223

Rockwell hardness HRB 97

Reduction of area ψ % 6

Compressive strength Rmc MPa 1069

Proportional limit in compression Rpc MPa 345

Shear strength Rcm MPa 414

Modulus of elasticity E GPa 110

Charpy aK J 8

Izod aK J 13.5

Fatigue (100'000'000 cycles) σN MPa 248

Density ρ g / cm³ 7.45

-6

Coefficient of expansion α 10 / K 16.2

Thermal conductivity λ W / m ·K 59

Electrical conductivity γ m / Ω · mm² 7.5

Electrical conductivity % I.A.C.S. 13

Specific heat cp J / g ·K 0.42

Assurances given with respect to properties or uses are subject to written approval from AMPCO METAL.

By varying the heat treatment and by close control of all operations, the characteristic duplex structure of

® ®

AMPCO 18 is refined to produce a material AMPCO 18.22 having substantially higher ultimate strength, yield

strength and hardness.

APPLICATIONS:

®

AMPCO 18.22 has been developed to meet the exact requirements of the aircraft industry for an alloy having

increased physical properties, hardness and sufficient elongation to withstand important impacts and loads. It

is recommended for use as bushings, bearings liners, inserts, piston parts, nuts and slides, etc.

You might also like

- SNI 4658-2008-Pelek Kategori LDocument2 pagesSNI 4658-2008-Pelek Kategori LDimazNugraha100% (1)

- R2-MCGM SP Schedule of Rates 2018-R2Document28 pagesR2-MCGM SP Schedule of Rates 2018-R2Deepanshu GargNo ratings yet

- Ampco 18: Technical Data Sheet Sand CastingsDocument1 pageAmpco 18: Technical Data Sheet Sand CastingsdedosimoesNo ratings yet

- Ampco 18.23: Technical Data SheetDocument1 pageAmpco 18.23: Technical Data SheetdedosimoesNo ratings yet

- Ampco 18: Technical Data SheetDocument1 pageAmpco 18: Technical Data SheetdedosimoesNo ratings yet

- Ampco 18: Technical Data SheetDocument2 pagesAmpco 18: Technical Data SheetAchilles AldaveNo ratings yet

- Ampco 18: Technical Data SheetDocument1 pageAmpco 18: Technical Data Sheetmarceloalves.dsNo ratings yet

- Ampco 22: Technical Data SheetDocument1 pageAmpco 22: Technical Data Sheetmarceloalves.dsNo ratings yet

- Ampco 21: Technical Data Sheet Continuous CastDocument1 pageAmpco 21: Technical Data Sheet Continuous CastdedosimoesNo ratings yet

- Ampco 22: Technical Data SheetDocument1 pageAmpco 22: Technical Data SheetdedosimoesNo ratings yet

- Ampco 8: Technical Data SheetDocument2 pagesAmpco 8: Technical Data SheetdedosimoesNo ratings yet

- Ampco 45: Technical Data SheetDocument2 pagesAmpco 45: Technical Data Sheetmarceloalves.dsNo ratings yet

- Ampco 18Document1 pageAmpco 18Gloria TouguinhaNo ratings yet

- Ampco 25: Technical Data SheetDocument1 pageAmpco 25: Technical Data Sheetmarceloalves.dsNo ratings yet

- A26 CCRM eDocument1 pageA26 CCRM ededosimoesNo ratings yet

- Ampco 26: Technical Data SheetDocument1 pageAmpco 26: Technical Data SheetdedosimoesNo ratings yet

- AMPCO 18 SandDocument1 pageAMPCO 18 SandS BHATTACHARYYANo ratings yet

- A21 Ex Rect eDocument1 pageA21 Ex Rect ededosimoesNo ratings yet

- Ampco 26: Technical Data SheetDocument1 pageAmpco 26: Technical Data SheetdedosimoesNo ratings yet

- Ampcoloy 83: Technical Data SheetDocument1 pageAmpcoloy 83: Technical Data SheetFilipe SantosNo ratings yet

- Ampcoloy 972: Technical Data SheetDocument1 pageAmpcoloy 972: Technical Data SheetmazaherramazaniNo ratings yet

- CuAl10Ni HCC EDocument1 pageCuAl10Ni HCC EDeepak DasNo ratings yet

- Ampcoloy 95: Technical Data SheetDocument1 pageAmpcoloy 95: Technical Data Sheetmarceloalves.dsNo ratings yet

- AluminiumHE15 PropertiesDocument3 pagesAluminiumHE15 PropertiesPrashanthNo ratings yet

- Aluminium 7075 SpecDocument2 pagesAluminium 7075 Specadam.el.polaco7881No ratings yet

- 6061 T6 MaterialDocument2 pages6061 T6 Materialtravis8zimmermannNo ratings yet

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFanne smithNo ratings yet

- Accc/Tw Paris (800) : Data SheetDocument1 pageAccc/Tw Paris (800) : Data SheetkmiqdNo ratings yet

- 2024-O ASM Material Data SheetDocument2 pages2024-O ASM Material Data SheetAnonymous mq0U43UsPNo ratings yet

- Accc/Tw Stockholm (460) : Data SheetDocument1 pageAccc/Tw Stockholm (460) : Data SheetkmiqdNo ratings yet

- Accc/Tw London (780) : Data SheetDocument1 pageAccc/Tw London (780) : Data SheetkmiqdNo ratings yet

- Accc/Tw Prague (700) : Data SheetDocument1 pageAccc/Tw Prague (700) : Data SheetkmiqdNo ratings yet

- 2024-T3 ASM Material Data Sheet PDFDocument2 pages2024-T3 ASM Material Data Sheet PDFAnonymous mq0U43UsPNo ratings yet

- Accc/Tw Lisbon (310) : Data SheetDocument1 pageAccc/Tw Lisbon (310) : Data SheetkmiqdNo ratings yet

- Accc/Tw Lisbon (310) : Data SheetDocument1 pageAccc/Tw Lisbon (310) : Data SheetkmiqdNo ratings yet

- Accc/Tw Dublin (520) : Data SheetDocument1 pageAccc/Tw Dublin (520) : Data SheetkmiqdNo ratings yet

- AmuDocument2 pagesAmuavinashchauhan2695No ratings yet

- CuZn30 PDFDocument2 pagesCuZn30 PDFavinashchauhan2695No ratings yet

- Aluminum6061DataSheet PDFDocument2 pagesAluminum6061DataSheet PDFhardik033No ratings yet

- Aluminum 7075 SpecsDocument3 pagesAluminum 7075 SpecsZakaria MuhammadNo ratings yet

- Accc/Tw Brussels (415) : Data SheetDocument1 pageAccc/Tw Brussels (415) : Data Sheetkmiqd0% (1)

- BrusselsDocument1 pageBrusselskmiqdNo ratings yet

- Data Sheet TI-6AL-4VDocument3 pagesData Sheet TI-6AL-4VMarcionilo NeriNo ratings yet

- Cusn8 Industrial RolledDocument4 pagesCusn8 Industrial RolledPrakash MakadiaNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Accc/Tw Hamburg (550) : Data SheetDocument1 pageAccc/Tw Hamburg (550) : Data SheetkmiqdNo ratings yet

- Accc/Tw Warsaw (510) : Data SheetDocument1 pageAccc/Tw Warsaw (510) : Data SheetkmiqdNo ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- AluminaDocument1 pageAluminaSreesanNo ratings yet

- ASM Material Data Sheet Titanium AlloyDocument2 pagesASM Material Data Sheet Titanium AlloyAdriano100% (1)

- Accc/Tw Helsinki (160) : Data SheetDocument1 pageAccc/Tw Helsinki (160) : Data SheetkmiqdNo ratings yet

- Accc/Tw Helsinki (160) : Data SheetDocument1 pageAccc/Tw Helsinki (160) : Data SheetkmiqdNo ratings yet

- Accc Bittern Data SheetDocument1 pageAccc Bittern Data SheetHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Metal-Matrix Composites For Space ApplicationsDocument8 pagesMetal-Matrix Composites For Space Applicationslakshmigsr6610No ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data SheetMECHA ENGINEEERINGNo ratings yet

- Accc/Tw Vienna (620) : Data SheetDocument1 pageAccc/Tw Vienna (620) : Data SheetkmiqdNo ratings yet

- SRBP-P3 DatasheetDocument1 pageSRBP-P3 DatasheetnaveenupadyaNo ratings yet

- Technical Data Sheet Gpo-3 (Glass Polymer Laminate)Document1 pageTechnical Data Sheet Gpo-3 (Glass Polymer Laminate)macNo ratings yet

- (Al Cu MG 1) 2017a - RemovedDocument1 page(Al Cu MG 1) 2017a - RemovedZo StevanovicNo ratings yet

- Domestic - MTD SilentDocument6 pagesDomestic - MTD SilentVan Vinh NguyenNo ratings yet

- Hemp Buildings FoundationsDocument48 pagesHemp Buildings FoundationsMarekNo ratings yet

- Alternatif Perencanaan Struktur Atas Gedung Apartemen Begawan Malang Menggunakan SRPM Dan Dinding GeserDocument11 pagesAlternatif Perencanaan Struktur Atas Gedung Apartemen Begawan Malang Menggunakan SRPM Dan Dinding GeserJeson TjowariNo ratings yet

- Design of Isolated Footing (Calculation Sheet) EGYPTION CODEDocument23 pagesDesign of Isolated Footing (Calculation Sheet) EGYPTION CODECivil SanamNo ratings yet

- 04 MASONRY HandoutDocument9 pages04 MASONRY HandoutZabeth villalonNo ratings yet

- Liebert Minimate2 Brochure PDFDocument12 pagesLiebert Minimate2 Brochure PDFjeisson alejandro franco torresNo ratings yet

- 5.2 - Design of Axially Loaded ColumnDocument10 pages5.2 - Design of Axially Loaded Columnron thombareNo ratings yet

- L-Shape Wall Mar13Document2 pagesL-Shape Wall Mar13Wan MahiramNo ratings yet

- VBR 50-30-2 Water Heating BattDocument4 pagesVBR 50-30-2 Water Heating BattCsiszer RobertNo ratings yet

- Mep Design Engineer: Mohammad Rijaullah Phone: +91-8983868548Document6 pagesMep Design Engineer: Mohammad Rijaullah Phone: +91-8983868548Rija UllahNo ratings yet

- Material Contract Work - Agreement Dated 19 Sep-2021 - CsDocument8 pagesMaterial Contract Work - Agreement Dated 19 Sep-2021 - Cssureshkumar0% (1)

- 18.Ms Slab Concrete Finishing WorkDocument4 pages18.Ms Slab Concrete Finishing WorkShenbagaraja PandianNo ratings yet

- Compression Test of BrickDocument3 pagesCompression Test of BrickShiela SorinoNo ratings yet

- VSL SlabDocument12 pagesVSL SlabhazemNo ratings yet

- Structure Design Report #117, 8-ADocument5 pagesStructure Design Report #117, 8-AAarti VatsNo ratings yet

- Glass Embedding: Safe and Fast Glass Embedding Solution For Glass BalustradesDocument4 pagesGlass Embedding: Safe and Fast Glass Embedding Solution For Glass BalustradesGiri DharanNo ratings yet

- SEMIINARDocument15 pagesSEMIINARabcdNo ratings yet

- Amvic ICF Pool 10 Step Construction GuideDocument2 pagesAmvic ICF Pool 10 Step Construction GuidedanNo ratings yet

- SE3M ExamDocument7 pagesSE3M ExamMariel UNo ratings yet

- Reporte Carga Termica TotalDocument3 pagesReporte Carga Termica TotalJulian Camilo IbarraNo ratings yet

- Trump Tower ManilaDocument8 pagesTrump Tower ManilaRiFTzCuTLeR -YTNo ratings yet

- ACI 517 2 1992 Accelerated Curing of Concrete at Atmospheric Pressure PDFDocument17 pagesACI 517 2 1992 Accelerated Curing of Concrete at Atmospheric Pressure PDFHaniAminNo ratings yet

- Schedule of RC Footings (M25:Fe500) : Client Key Plan MR - Chetan PatelDocument2 pagesSchedule of RC Footings (M25:Fe500) : Client Key Plan MR - Chetan PatelNiraj ShindeNo ratings yet

- Sustainable Architecture and Green Architecture: Environmental ControlDocument26 pagesSustainable Architecture and Green Architecture: Environmental ControlAseel HussienNo ratings yet

- Project Report On Fiber Reinforced ConcrDocument60 pagesProject Report On Fiber Reinforced ConcrAmanuel TekalignNo ratings yet

- Health ManagementDocument10 pagesHealth Managementpurvakul10No ratings yet

- Volume-2a Roads Work Specifications (Final)Document425 pagesVolume-2a Roads Work Specifications (Final)Samwel TarimoNo ratings yet

- Project: Proposed Residential/ Commercial Development On Plot No. DONYO Sabuk/Komarock Block 1/25878Document12 pagesProject: Proposed Residential/ Commercial Development On Plot No. DONYO Sabuk/Komarock Block 1/25878Austin AnindoNo ratings yet

- 21 Types of Beams in ConstructionDocument11 pages21 Types of Beams in ConstructionMayank KumarNo ratings yet