Professional Documents

Culture Documents

Stainless Steel 1.4404

Uploaded by

Alexandra Petre0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

Stainless-steel-1.4404

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageStainless Steel 1.4404

Uploaded by

Alexandra PetreCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Data Sheet

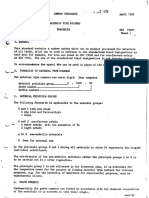

Stainless Steel 316L / 1.4404 /

X2CrNiMo17-12-2

Alternative Designations Key Features

X2CrNiMo17-12-2 (ISO) | 316L (AISI/SAE) | S31603 Good heat resistance • Corrosion resistance • High

(UNS) | Z2CND17.12 (AFNOR) | 316S12 (BS) | weldability

2343/2348/2553 (SIS) | X2CrNiMo1712 (UNI) |

SUS316 (JIS)

Description

It is an austenitic chromium-nickel alloy that contains molybdenum and nitrogen. This combination of

elements makes it durable and provides it with a number of other desirable properties. The addition of

molybdenum results in improved corrosion resistance with good stability against chloric and non-

oxidizing acid. It has good heat resistance which reduces in continuous use at 425 – 861°C in water. It

can be readily formed into different products. It has good machinability and is used in food processing

equipment, boat fittings, bolts, nuts, and springs.

Mechanical Properties Chemical Composition

Yield strength 260 – 270 MPa Al - N 0.1%

Tensile strength 520 – 680 MPa Bi - Nb -

Elongation at break ≥ 45% C 0.03% Ni 10 – 13%

Hardness 215 Cd - O -

Module of elasticity 200 GPa Co - P 0.045%

Cr 16.5 – 18.5% Pb -

Physical Properties Cu - S 0.03%

Density 8 g/cm³ Fe - Si 1%

1.33 m/Ω · mm² H - Sn -

Electrical conductivity

Mg - Ti -

Coefficient of thermal expansion 16.5 K-1 · 10-6

Mn 2% V -

Thermal conductivity 15 W/m · K

Mo 2 – 2.5 % Zn -

Specific heat capacity 500 J/kg · K

Reference Datasheets provided by Xometry contain materials sourced through trusted

OEMs, material distributors, and databases. Please visit Materialdatacenter.com

for further information on this material.

CNC Machining • Sheet Metal • 3D Printing • Injection Moulding • Die Casting | xometry.eu

You might also like

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Steel-1 0570Document1 pageSteel-1 0570Klemen KavčičNo ratings yet

- Steel-1 7131Document1 pageSteel-1 7131H. BeatsNo ratings yet

- Steel 1.1191 XC48H1 C45EDocument1 pageSteel 1.1191 XC48H1 C45EAmirhossein Shahidi NejadNo ratings yet

- Data-Sheet_-Aluminum-EN-AW-5754 (1)Document1 pageData-Sheet_-Aluminum-EN-AW-5754 (1)MarkoNo ratings yet

- Zamak-3 XometryDocument1 pageZamak-3 XometryFrancisco BocanegraNo ratings yet

- Aluminium 2017A 3.1325 Al Cu4MgDocument1 pageAluminium 2017A 3.1325 Al Cu4Mgk.d.oliveira.lucasNo ratings yet

- Aluminium ADC12Document1 pageAluminium ADC12Gowtham Raj KNo ratings yet

- Inox 316 L: (Stainless Steel, Austenitic, AISI 316L, Annealed)Document3 pagesInox 316 L: (Stainless Steel, Austenitic, AISI 316L, Annealed)Hamid AZZOUZINo ratings yet

- Lecture 10Document24 pagesLecture 10spsu2010No ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFMuhammad Asif IqbalNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKMuhammad Asif IqbalNo ratings yet

- Cored Wires for High Toughness Welding of C-Mn and Low-Alloy SteelsDocument1 pageCored Wires for High Toughness Welding of C-Mn and Low-Alloy SteelsCristian BoselliNo ratings yet

- Albromet-W 240: Data Sheet High-Conductivity CopperDocument1 pageAlbromet-W 240: Data Sheet High-Conductivity CopperPaolo MilaniNo ratings yet

- Ampco 21: Technical Data Sheet Continuous CastDocument1 pageAmpco 21: Technical Data Sheet Continuous CastdedosimoesNo ratings yet

- Ampcoloy 972: Technical Data SheetDocument1 pageAmpcoloy 972: Technical Data SheetmazaherramazaniNo ratings yet

- CuAl10Ni HCC EDocument1 pageCuAl10Ni HCC EDeepak DasNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Steel PropertiesDocument22 pagesSteel PropertiesMOHD SALMANNo ratings yet

- Ficha Técnica CarborodDocument1 pageFicha Técnica CarborodAndres NuñezNo ratings yet

- Carbofil Crmo9 (G Crmo9)Document1 pageCarbofil Crmo9 (G Crmo9)brunizzaNo ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- GBTDocument1 pageGBTRaviTeja BhamidiNo ratings yet

- 6030P Daiko CuMn13AlDocument1 page6030P Daiko CuMn13AlAris WicaksonoNo ratings yet

- Ppte Acier Fiablement AllierDocument3 pagesPpte Acier Fiablement AllierConception & Fabrication MécaniqueNo ratings yet

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- Ampco 22: Technical Data SheetDocument1 pageAmpco 22: Technical Data SheetdedosimoesNo ratings yet

- A22_EX_EDocument1 pageA22_EX_Emarceloalves.dsNo ratings yet

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Steel 316 LDocument5 pagesSteel 316 LManjunatha VNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- PNA282 - C51900 - CuSn6 - PB103 - Technical Data SheetDocument2 pagesPNA282 - C51900 - CuSn6 - PB103 - Technical Data Sheetstrip1No ratings yet

- MG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetDocument7 pagesMG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetAbdulrahman AlabdanNo ratings yet

- Dual Shield 9000-B3 Flux Cored Wire for 2.25% Cr-1% Mo SteelsDocument1 pageDual Shield 9000-B3 Flux Cored Wire for 2.25% Cr-1% Mo SteelsqaNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Alloy 254SMO Long & Flat Products Corrosion ResistanceDocument1 pageAlloy 254SMO Long & Flat Products Corrosion ResistancequalityNo ratings yet

- Automig FC 71 T1Document1 pageAutomig FC 71 T1Sushil BhansaliNo ratings yet

- c95500 Spec SheetDocument2 pagesc95500 Spec SheetOrnella MancinelliNo ratings yet

- 303-Cruicible SteelDocument2 pages303-Cruicible SteelARUNKANNANNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- Union MV Mo and RV 71 Flux Cored WiresDocument1 pageUnion MV Mo and RV 71 Flux Cored WiresAnghelache RazvanNo ratings yet

- Material Datasheet Cu-OFDocument2 pagesMaterial Datasheet Cu-OFmohsen_267No ratings yet

- Bohler-Welding-Germany 207Document1 pageBohler-Welding-Germany 207Anghelache RazvanNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- Miginox 307: Classification: en Iso 14343-ADocument1 pageMiginox 307: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- CuZn30 Brass Sheet: Properties and Applications of 70/30 Copper Zinc AlloyDocument2 pagesCuZn30 Brass Sheet: Properties and Applications of 70/30 Copper Zinc Alloyavinashchauhan2695No ratings yet

- AmuDocument2 pagesAmuavinashchauhan2695No ratings yet

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocument2 pagesMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62No ratings yet

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- BS1400 HTB1Document2 pagesBS1400 HTB1Atul KulkarniNo ratings yet

- JIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelDocument1 pageJIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelPuji RiatnoNo ratings yet

- Copper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument7 pagesCopper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webboydoc inspectionNo ratings yet

- Maraging Steel Material Spec for 3D PrintingDocument1 pageMaraging Steel Material Spec for 3D Printingmartinm3tNo ratings yet

- Filcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- Characterization of Pulsed MIG Welded Modified P91 SteelDocument42 pagesCharacterization of Pulsed MIG Welded Modified P91 SteelSanthosh ManoharanNo ratings yet

- AUTOMIG 80S Ni1 - TIGFIL 80S Ni1Document1 pageAUTOMIG 80S Ni1 - TIGFIL 80S Ni1Kalyan Chakravathi A GNo ratings yet

- High Strength Steel Welding Wire for Cr-Ni-Mo AlloysDocument1 pageHigh Strength Steel Welding Wire for Cr-Ni-Mo Alloysrusf123No ratings yet

- Flatwise Compressive Properties of Sandwich Cores: Standard Test Method ForDocument7 pagesFlatwise Compressive Properties of Sandwich Cores: Standard Test Method ForAlexandra PetreNo ratings yet

- AFP TankDocument17 pagesAFP TankAlexandra PetreNo ratings yet

- Carbon HTDocument1 pageCarbon HTAlexandra PetreNo ratings yet

- D3039 - 3039M (Tensile Properties of Composites)Document12 pagesD3039 - 3039M (Tensile Properties of Composites)Azmul FadhliNo ratings yet

- Din 17007Document8 pagesDin 17007Aditya Pratap100% (1)

- Hastelloy alloys corrosion resistant metal trademarkDocument3 pagesHastelloy alloys corrosion resistant metal trademarktalparadipakNo ratings yet

- A 391 - A 391M - 98 Qtm5ms9bmzkxts1sruqDocument6 pagesA 391 - A 391M - 98 Qtm5ms9bmzkxts1sruqClaudia Patricia Magaña RabanalesNo ratings yet

- Answers For Metal Reactivity SeriesDocument3 pagesAnswers For Metal Reactivity SeriespenguinpowerrrrNo ratings yet

- (Lertffi Y: (Typ - I) Iffi "Eq0Document6 pages(Lertffi Y: (Typ - I) Iffi "Eq0supremeNo ratings yet

- Dogal LAD High Strength Low Alloy Steels For Cold Forming: GeneralDocument2 pagesDogal LAD High Strength Low Alloy Steels For Cold Forming: Generalchristos032No ratings yet

- Ceramic Materials I: Asst - Prof. Dr. Ayşe KALEMTAŞDocument38 pagesCeramic Materials I: Asst - Prof. Dr. Ayşe KALEMTAŞŞebnem Gül İlarslanNo ratings yet

- Materials Guide for Over 50 AlloysDocument8 pagesMaterials Guide for Over 50 AlloysMark RomeroNo ratings yet

- Seminar On Jigs & FixtureDocument30 pagesSeminar On Jigs & FixturesnagareddyNo ratings yet

- Valbruna UK LTD - Stainless Steels - Nickel Alloys and Titaniums - Round Bar Tolerances (DIN 1013)Document7 pagesValbruna UK LTD - Stainless Steels - Nickel Alloys and Titaniums - Round Bar Tolerances (DIN 1013)hamid razaNo ratings yet

- Corrosion and Its ControlDocument29 pagesCorrosion and Its Controlomer faruqeNo ratings yet

- Titanium and Titanium Alloy Forgings: Standard Specification ForDocument7 pagesTitanium and Titanium Alloy Forgings: Standard Specification ForjenishjsNo ratings yet

- Steel Making Processes: Dr. Laraib Sarfraz KhanzadaDocument23 pagesSteel Making Processes: Dr. Laraib Sarfraz KhanzadaAsher AhmedNo ratings yet

- Sa 395Document12 pagesSa 395Widya widyaNo ratings yet

- Evaluation of High-Strength Steel Castings for Improved WeldabilityDocument14 pagesEvaluation of High-Strength Steel Castings for Improved WeldabilityShivam SrivastavaNo ratings yet

- Cobalt (22221) PDFDocument23 pagesCobalt (22221) PDFKhder DayubNo ratings yet

- Art 2 Stimation of Hardness During Heat Treatment of EN8 and C25 SteelsDocument12 pagesArt 2 Stimation of Hardness During Heat Treatment of EN8 and C25 SteelsEdwinMedinaBejaranoNo ratings yet

- Element Word SearchDocument2 pagesElement Word Searchpepac4140% (1)

- A193 A193M 2011aDocument13 pagesA193 A193M 2011aJohn HollandNo ratings yet

- Monthly Production and ConsumptionDocument6 pagesMonthly Production and ConsumptionjekiranNo ratings yet

- Welding Alloys Technical CatalogueDocument15 pagesWelding Alloys Technical CatalogueThanh TamNo ratings yet

- CS Pipes Installation CostDocument12 pagesCS Pipes Installation Costrajkamal_e100% (2)

- Yo BankDocument130 pagesYo BankAnonymous 0BpXe7RMNo ratings yet

- Materials: Prediction of The Work-Hardening Exponent For 3104 Aluminum Sheets With DiDocument12 pagesMaterials: Prediction of The Work-Hardening Exponent For 3104 Aluminum Sheets With DiSavalia HardikNo ratings yet

- B16 Case 5 Nickel Alloy UNS N06230 ASTM B564 N06230 (ASME B16.34 Material Group 3.19) Ni-22Cr-14W-2Mo-La Material ASME B16.34 ValvesDocument12 pagesB16 Case 5 Nickel Alloy UNS N06230 ASTM B564 N06230 (ASME B16.34 Material Group 3.19) Ni-22Cr-14W-2Mo-La Material ASME B16.34 ValvesInaamNo ratings yet

- Caiet de Sarcini Privind Protectia Anticoroziva / Job Specification For Anticorrosive ProtectionDocument7 pagesCaiet de Sarcini Privind Protectia Anticoroziva / Job Specification For Anticorrosive ProtectionRazvan RaduNo ratings yet

- METACOLORDocument1 pageMETACOLORShariq KhanNo ratings yet

- FAL-MTS-01-00 20MnCr5 1730 PDFDocument3 pagesFAL-MTS-01-00 20MnCr5 1730 PDFAndras StegerNo ratings yet

- Hipco Superbuild: First PEB Manufacturer in NepalDocument20 pagesHipco Superbuild: First PEB Manufacturer in NepalRavi KumarNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 4.5 out of 5 stars4.5/5 (2)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionFrom Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- General Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismFrom EverandGeneral Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismNo ratings yet

- Autophagy in Health and DiseaseFrom EverandAutophagy in Health and DiseaseBeverly RothermelNo ratings yet

- Exercise, Sport, and Bioanalytical Chemistry: Principles and PracticeFrom EverandExercise, Sport, and Bioanalytical Chemistry: Principles and PracticeNo ratings yet