Professional Documents

Culture Documents

Data Sheet - Aluminum EN AW 5754

Uploaded by

Marko0 ratings0% found this document useful (0 votes)

2 views1 pageOriginal Title

Data-Sheet_-Aluminum-EN-AW-5754 (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pageData Sheet - Aluminum EN AW 5754

Uploaded by

MarkoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Data Sheet

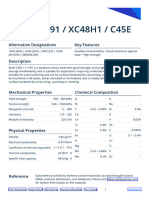

Aluminium 5754 / 3.3535 / Al-

Mg3

Alternative Designations Key Features

EN AW-5754 / AlMg3 | A-G3M (AFNOR) | AA5754 Weldability • Corrosion resistance • Non-heat

(AISI/AA) | A95754 (UNS) | 4130 (SIS) | L-3390 treatable • Suitable for marine applications

(UNE)

Description

This material has very high mechanical properties when compared to other non-heat treatable

aluminum alloys. In addition, it comes with good resistance to atmospheric and seawater corrosion. It

has excellent welding characteristics and can be welded using all standard welding methods. It can also

be cold formed and forged. It is a non-heat treatable alloy. It can be precipitation hardened to high

strength levels by cold working. It has good ductility and formability.

Mechanical Properties Chemical Composition

Yield strength 80 MPa Al Rest is Al N -

Tensile strength 180 – 250 MPa Bi - Nb -

Elongation at break 14 – 16% C - Ni -

Hardness 45 Cd - O -

Module of elasticity 70.5 GPa Co - P -

Cr ≤ 0.30% Pb -

Physical Properties Cu ≤ 0.10% S -

≤ 0.40% Si ≤ 0.40%

Density 2.66 g/cm³ Fe

18.797 m/Ω · mm² H - Sn -

Electrical conductivity

Mg 2.6 – 3.6% Ti ≤ 0.15%

Coefficient of thermal expansion 23.9 K-1 · 10-6

Mn ≤ 0.50% V -

Thermal conductivity 140 – 160 W/m · K

Mo - Zn ≤ 0.20%

Specific heat capacity 900 J/kg · K

Reference Datasheets provided by Xometry contain materials sourced through trusted

OEMs, material distributors, and databases. Please visit Materialdatacenter.com

for further information on this material.

CNC Machining • Sheet Metal • 3D Printing • Injection Moulding • Die Casting | xometry.eu

You might also like

- Product Categories: Fittings, Valves, Clamps & Accessories For Hose, Pipe and TubeDocument35 pagesProduct Categories: Fittings, Valves, Clamps & Accessories For Hose, Pipe and TubeRaj DomadiyaNo ratings yet

- Maintenance and Repair of Centrifugal PumpsDocument4 pagesMaintenance and Repair of Centrifugal Pumpsaserf251No ratings yet

- Conveyor IdlersDocument255 pagesConveyor IdlersEd AceNo ratings yet

- Catalogue Power Transformers 2012Document24 pagesCatalogue Power Transformers 2012SatyaNo ratings yet

- ASTM B580 - Anodic Oxide Coating For AluminumDocument3 pagesASTM B580 - Anodic Oxide Coating For AluminumEduardo Javier Granados Sanchez100% (2)

- Steel PropertiesDocument22 pagesSteel PropertiesMOHD SALMANNo ratings yet

- Soportes de TuberíasDocument8 pagesSoportes de Tuberíasaecf_13No ratings yet

- 5.1 Sumatane HSDocument4 pages5.1 Sumatane HSjnu6mnju6njNo ratings yet

- Stainless Steel 1.4404Document1 pageStainless Steel 1.4404Alexandra PetreNo ratings yet

- Steel-1 0570Document1 pageSteel-1 0570Klemen KavčičNo ratings yet

- Steel 1.1191 XC48H1 C45EDocument1 pageSteel 1.1191 XC48H1 C45EAmirhossein Shahidi NejadNo ratings yet

- Aluminium 2017A 3.1325 Al Cu4MgDocument1 pageAluminium 2017A 3.1325 Al Cu4Mgk.d.oliveira.lucasNo ratings yet

- Steel-1 7131Document1 pageSteel-1 7131H. BeatsNo ratings yet

- Zamak-3 XometryDocument1 pageZamak-3 XometryFrancisco BocanegraNo ratings yet

- Aluminium ADC12Document1 pageAluminium ADC12Gowtham Raj KNo ratings yet

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- Inox 316 L: (Stainless Steel, Austenitic, AISI 316L, Annealed)Document3 pagesInox 316 L: (Stainless Steel, Austenitic, AISI 316L, Annealed)Hamid AZZOUZINo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Aluminium Alloy 6063 NB PDFDocument2 pagesAluminium Alloy 6063 NB PDFBrijendra Mani PandeyNo ratings yet

- Thyssenkrupp Materials (UK) LTD Aluminium Alloy 6063: Material Data SheetDocument2 pagesThyssenkrupp Materials (UK) LTD Aluminium Alloy 6063: Material Data Sheetdinesh choudharyNo ratings yet

- Aluminium Alloy 6063 NBDocument2 pagesAluminium Alloy 6063 NBBrijendra Mani PandeyNo ratings yet

- AmuDocument2 pagesAmuavinashchauhan2695No ratings yet

- CuZn30 PDFDocument2 pagesCuZn30 PDFavinashchauhan2695No ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Physical Properties Metric English: @strain 2.00 % @strain 2.00 %Document1 pagePhysical Properties Metric English: @strain 2.00 % @strain 2.00 %Rahul SanjayanNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- ENSAM - Metz: Report 1Document11 pagesENSAM - Metz: Report 1Metin PehlivanovNo ratings yet

- JIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelDocument1 pageJIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelPuji RiatnoNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFMuhammad Asif IqbalNo ratings yet

- Automig FC 71 T1Document1 pageAutomig FC 71 T1Sushil BhansaliNo ratings yet

- 303-Cruicible SteelDocument2 pages303-Cruicible SteelARUNKANNANNo ratings yet

- Steel 316 LDocument5 pagesSteel 316 LManjunatha VNo ratings yet

- Lecture 10Document24 pagesLecture 10spsu2010No ratings yet

- Metalcor Cual10fe3mn2Document1 pageMetalcor Cual10fe3mn2robertjob34No ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKMuhammad Asif IqbalNo ratings yet

- Bronze c54400 SpecificationsDocument3 pagesBronze c54400 SpecificationsRam Parimalam100% (1)

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- 316L SS CrucibleDocument2 pages316L SS CrucibleARUNKANNANNo ratings yet

- 303-Stainless Steel-Annealed BarDocument2 pages303-Stainless Steel-Annealed BarARUNKANNANNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- Copper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument7 pagesCopper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webboydoc inspectionNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Amandeep SinghNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- Aluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocument2 pagesAluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyLuis BadoffNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- Automig 70S-61Document1 pageAutomig 70S-61tarun kaushalNo ratings yet

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- 2024-O ASM Material Data SheetDocument2 pages2024-O ASM Material Data SheetAnonymous mq0U43UsPNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- 316 Stainless Steel, Annealed SheetDocument2 pages316 Stainless Steel, Annealed SheetZASSNo ratings yet

- Cu-ETP: C11000 Industrial RolledDocument4 pagesCu-ETP: C11000 Industrial Rolledsrsivaraman81No ratings yet

- Cu ZN 15 TombacDocument2 pagesCu ZN 15 TombacPetrus UngureanuNo ratings yet

- GBTDocument1 pageGBTRaviTeja BhamidiNo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- MG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetDocument7 pagesMG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetAbdulrahman AlabdanNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- 09.CARBO - ZIBRO 6 AC eDocument1 page09.CARBO - ZIBRO 6 AC eDAVID SOTONo ratings yet

- Ppte Acier Fiablement AllierDocument3 pagesPpte Acier Fiablement AllierConception & Fabrication MécaniqueNo ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- Heat-Treatable Steels, Alloy Steels and Free-Cutting Steels - Part 3: Case-Hardening Steels (ISO 683-3:2016)Document7 pagesHeat-Treatable Steels, Alloy Steels and Free-Cutting Steels - Part 3: Case-Hardening Steels (ISO 683-3:2016)MarkoNo ratings yet

- Alloy Steels Annealed Quenched TemperedDocument12 pagesAlloy Steels Annealed Quenched TemperedMarkoNo ratings yet

- Heat-Treatable Steels, Alloy Steels and Free-Cutting Steels - Part 3: Case-Hardening Steels (ISO 683-3:2019)Document7 pagesHeat-Treatable Steels, Alloy Steels and Free-Cutting Steels - Part 3: Case-Hardening Steels (ISO 683-3:2019)MarkoNo ratings yet

- V-Block Pairs Special Cast Iron Hardened Steel Surface 120x270x180mm GG-3 With 3 120x270x180mm-1652201Document1 pageV-Block Pairs Special Cast Iron Hardened Steel Surface 120x270x180mm GG-3 With 3 120x270x180mm-1652201MarkoNo ratings yet

- V-Block Pairs Special Cast Iron Hardened Steel Surface 120x270x180mm GG-3 With 3 120x270x180mm-1652201Document1 pageV-Block Pairs Special Cast Iron Hardened Steel Surface 120x270x180mm GG-3 With 3 120x270x180mm-1652201MarkoNo ratings yet

- V-Block Pairs Special Cast Iron Hardened Steel Surface 120x270x180mm GG-3 With 3 120x270x180mm-1652201Document1 pageV-Block Pairs Special Cast Iron Hardened Steel Surface 120x270x180mm GG-3 With 3 120x270x180mm-1652201MarkoNo ratings yet

- Safety AssignmentDocument5 pagesSafety AssignmentWK PangNo ratings yet

- Zinc Chromate PaintDocument2 pagesZinc Chromate PaintBash MatNo ratings yet

- 1800cpb2 Series Regulators American MeterDocument11 pages1800cpb2 Series Regulators American Meterultron2099ultronNo ratings yet

- Manual SwitchgearDocument48 pagesManual SwitchgearVinícius MartinsNo ratings yet

- Fafnir - Separix-EDocument8 pagesFafnir - Separix-Ewarung1bensinNo ratings yet

- 20 Sabiana Carisma Coanda Carte Tehnica 10.10.11 CI enDocument28 pages20 Sabiana Carisma Coanda Carte Tehnica 10.10.11 CI enccercel9898No ratings yet

- Sturbridge Case StudyDocument2 pagesSturbridge Case Studyárokszállási norbertNo ratings yet

- Calefactor TG8HDocument6 pagesCalefactor TG8HIng. José Antonio GuerreroNo ratings yet

- CF CM HE 4206a enDocument60 pagesCF CM HE 4206a enNius Pahala NainggolanNo ratings yet

- Nt20703 Lab Report Dietary FiberDocument2 pagesNt20703 Lab Report Dietary FiberAmne BintangNo ratings yet

- Chemistry Presentation (Viva)Document41 pagesChemistry Presentation (Viva)ZiHong100% (1)

- Brochure SouthpartnersDocument19 pagesBrochure SouthpartnersStanislau Felix Garcia RomeroNo ratings yet

- 20 MN CR 5Document4 pages20 MN CR 5Pulkit GururaniNo ratings yet

- TCS SMB Manufacturing Solution Modules Reports PDFDocument4 pagesTCS SMB Manufacturing Solution Modules Reports PDFManish MishraNo ratings yet

- PB Cables and Wires v2 IntDocument16 pagesPB Cables and Wires v2 IntSaša AleksićNo ratings yet

- ECE 340 Lecture 26: Reverse Bias Breakdown: Class OutlineDocument20 pagesECE 340 Lecture 26: Reverse Bias Breakdown: Class OutlineDao ZhangNo ratings yet

- Bvsde Paho Toilets CompostDocument10 pagesBvsde Paho Toilets CompostSean ColonNo ratings yet

- Cetiol CC (OPP)Document1 pageCetiol CC (OPP)paromanikNo ratings yet

- Testing Charges - Coe Indutech Capabilities (NABL Accredited Laboratory)Document6 pagesTesting Charges - Coe Indutech Capabilities (NABL Accredited Laboratory)tharunkarraNo ratings yet

- Reactive Dye PrintingDocument15 pagesReactive Dye Printingsandipsoni221811No ratings yet

- Dislocations in HCP LatticeDocument10 pagesDislocations in HCP LatticePhysics Mathematics SolutionsNo ratings yet

- ConclusionDocument2 pagesConclusionRohit Kumar75% (4)

- Certificado Brida 3Document1 pageCertificado Brida 3juan aguilarNo ratings yet