Professional Documents

Culture Documents

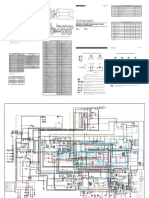

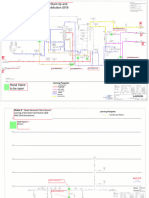

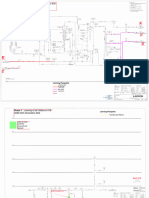

GA 26-30 FS Service Diagram EN Pune 9097554751-01

Uploaded by

Mantenimiento Argen Peanuts SAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GA 26-30 FS Service Diagram EN Pune 9097554751-01

Uploaded by

Mantenimiento Argen Peanuts SACopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10

COMPRESSOR

A1 : dryer (full feature) NOTES

M1 : compressor motor

M2 : fan motor

[a] Maximum fuses with regard to short circuit

PT20 : press. transducer delivery air

protection of starter. Cable section might

TT01 : temp. sensor ambient

impose fuses of smaller value.

TT11 : temp. sensor element outlet

TT90 : temp. sensor LAT Dryer (full feature) [b] Power supply to be connected for:

Y1 : solenoid valve 1. CLOCKwise rotation of fanmotor

B

B1 : Electronikon Drain Cooler

2. COUNTER CLOCKwise rotation of compr. motor

STARTER CUBICLE Rotation to be observed while facing the

drive end shaft of the motors.

F1-5, F10-11 : fuses

Q15 : MPCB for fan motor [c] Dryer connection depending on main power supply

F21 : overload relay compressor motor

K21 : line contactor [d] To connect correct trafo-voltage see on trafo

K22 : star contactor

K23 : delta contactor [f] For field wiring : use 75°C copper wire only.

C

K15 : fan motor contactor

K25 : phase sequence protection

K5 : Auxiliary Contactor motor protection [g] Y1: F.P.E. field provided equipment 115V 17VA

S' : remote pressure sensing B1: F.P.E. field provided equipment 115V 7VA

S1' : remote START/Pr.STOP

[h] Dryer connection:

S3 : emergency stop

refer 9827 6997 00 diagram for dryer connection

S3' : emergency stop remote

S4' : remote load/unload [i] Optional remote emergency stop :

S6' : remote pressure set selection Replace bridge by NC contacts

T1,T2 : Main transformer of remote emergency stop. D

M5 : Cubicle fan motor

[z] Bridges to be removed if CVT is installed.

1X0 : supply connection Customer to connect CVT across terminal

1X2 : earth connection

1X5 : 52,53 and 1X5: 50,51 to be left open.

1X3 : earth connection

CVT rating 230V output,minimum 20VA.

1X4 : control terminal strip

CVT input supply to be arranged by

1X5 : Transformer connections

customer separately.

1X6 : Controller terminal strip

1X7 : Auxiliary contact terminal strip

E

1X9 : Auxiliary contact terminal strip

X110 : Connector for dryer connection(full feature) [k] For fan connection see motor terminal box

COMPRESSOR CONTROL MODULE (E1)

K01 : blocking relay

K02 : aux. relay star contactor

K03 : aux. relay delta contactor

K04 : aux. relay load/unload

K05 : aux. relay fan motor contactor

K06 : aux. relay dryer

K07 : aux. relay manual/automatic operation

K08 : aux. relay general warning

K09 : aux. relay general shutdown

This document is property of Atlas Copco AB and shall not without our permission be altered,

copied, used for manufacturing or communicated to any other person or company.

Confidentiality Class

Name Service Diagram GA22-26FS 1102 K/

G

Not Applicable

CONFIDENTIAL:

Material internal

Treatment Not Applicable ACDE

Scale 1:1 Family Not Applicable A1 Compare Drawing owner

Drawn by Blank nr.

ATLASCOPCO\PNEnip Not Applicable Replaces PNE

Version Drwg Designation Sheet 02 (02)

00 Not Applicable Not Applicable Blank wt. N/A Kg Fini wt. 0 Kg

STATUS 00

Note

Posi-

tion

Modified from Date Intr./Appd. Parent 3D Model Ed.Version 3D Approved Internal

Des checked. Prod checked. Approved. Date

9097554751

28-08-2020 02:08:40

1 2 3 4 5 6 7 8 9 10

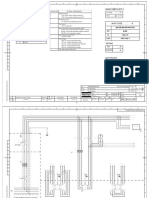

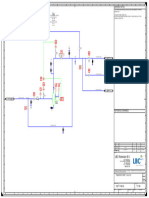

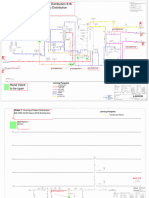

Customer's Installation 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44

Power Supply

400V +/-10%,50Hz 1X4

MAX. FUSE [a] 1

IEC : Class gL/gG S3 11 21

L1

- 28

pre re s tion

L2

)

12 22

et 2

re s )

3

g

P

ssu et 1

[b] L3

sin

d = ssu elec

TO

N A TSHH11 A

ote sen

r.S

1X4

d) d

see pre et s

a

PE

tac ons

T/P

3

nlo

rem ure

)

top

(clo n = ss. s

1X4

con tecti

u

AR

[i]

k = ess

ys

.1

.2

ose ad/

loa

t)

4

e

K23

ST

42

enc

( lin ote pr

(op ote pr

(NO pro

( cl ote lo

Range Model Back up fuse Amp Rating

d=

1X4

ote

erg

5

tor

GA22-30FS GA22 3NA78247 80A F10

e

rem

Remote emergency

rem

1

rem

rem

.3

.4

1

mo

2

em

GA22-30FS GA26 3NA78247 80A

K21

K5 1X5 [d] 1X6 1X6 1X6 1X6 1X6

stop [i]

2 4 6 2

[a]F0' 52 30 30 30 300 300

1X4 1X6

1X4

1 3 5 3 31

230V

18

31

24V

3

30

1

18

18

18

18

11 21

S3'

30

2X30:2 2X30:11 2X30:7 2X30:9 1X5 12 22

32

[f]

5

53 21

1X0 S3 S1' S4' S' S6' 1X4 1X6

F11 3

L1 L2 L3 N

T2 5 32

2

18 .3 22 K5 B

K01 K06 K04 K21 K05 4

K25 15 28 28 .4 28 (min 250VAC 4A AC15)

28

1X3

PE

31

17

K25 2X30:1 2X30:12 2X30:8 2X30:10

13 -

6

1 5 3 1X6

31

[i]

2X30:4 2X30:6

26

27

28

1X6 1X6 1X6 1X6 1X6

[d] 1X4 1X4 1X4 32 33 34 35 36

300

F4 X110

27

44

32

38

33

34

30

35

36

43

K02 K03 13 14 19

2

X110 28 28 3 2X28

N

2 2X27

95

F21

115V

L3

F3 15 16 12 11 14 13 9 10 9 12 11 14 13 7

2X30:3 2X30:5

1

DISupply

DI01

DI02

DI03

DI04

DI06

DI07

DI08

DI09

DI10

DI05

96

DISupply

24 Vac

X110

L2

1 F2 2X30

12

13

19

1

16

6

C

12 11 10 9 8 7 6 5 4 3 2 1

K01

L1

8X50

F1 F5 1X5 15 NO BLOCKING E1 ANTENNA

2

1

50

.1 .1 15 K02 2X31

11 .3 .3 NO

6 5 4 3 2 1

230V

STAR

Q15 K23 K22 K22 K21 MK5S TOUCH AUTO

K07 NO 40

14 .2 .2 .4 .4

16 NO K03 OPERATION

DELTA

K08 NO

L1

L2

L3

41

26

L2 N 1X5 GENERAL

20 NO K04 WARNING

51 A1 LOAD/UNLOAD

K09 NO 42

8

15

10

11

Dryer GENERAL

23

SETTING'S T1

Control

[c] NO K05

FAN CONTROL SHUTDOWN

B1 0.0

2

K5 A1 K22 A1 K23 A1 K21 A1 Y1 A1 K15 A1

9

PE M 18 NO K06 2X21

4

400

1 ...

DRYER

1 3 5 1 3 5 1 3 5 V A2 A2 A2 A2 X110 [g]

1

A2 2X20

CONTROL

K21 K23 K22 0.1 0.2

M5

2 4 6 2 4 6 2 4 6

Model F21 Q15

1 ...

9

2X26 2X22

1 ...

GA22 29A 1.8A RS485

MEMORY

GA26 34A 1.8A 2X39 CARD

L3 L2 L1

PHASE D

RJ45

PT20

Gnd

Gnd

TT90

TT01

TT11

Gnd

P02

T04

T05

SEQUENCE

Gnd

Gnd

Gnd

Gnd

2

1X4 1X4 1X4 1X4

V+

V+

Ethernet

2 2 2 2

2X28 2X25

1 3 5 2X27 1 2 3 4 5 6 7 8 10 1 2 3 4 5 6 8 2X24

Q15

F21 IN

1 3 5 14 17 16 14 17

- 13 13

202

201

BN

WH

31

10A

7A

29 29

1A

2A

8A

2 4 6

21 GY

10

(To 1X3) 10

1X3 2 4 6

(To 1X3)

61

62

63

X110

1 3 5 5

K15

2 4 6

12 27

[z]

W

U

V

300

300

300

100

101

102

103

104

105

W1

W2

E

1X5

1X4

1X6

201

202

U1

U2

V1

V2

1X7

1X9

1X2

1X3

L1

L2

L3

50

51

52

53

19

18

18

18

13

14

30

30

30

31

32

33

34

35

36

A1 OPTIONAL

N

1

2

2

2

2

3

5

4

1

M M Dryer

[i] [i]

}

M1 3

PE

M2 3

PE CVT AUXILIARY CONTACTS

[c] IN 230V/ 250VAC 10A AC11

[b] [b][k] MIN.20VA

Fan Motor DRYER

Automatic Opration

Compressor Motor

General Shutdown

(For FF Only)

General Warning

M1 M2

kW HP SF kW HP

1X7 1X7 1X7

100 102 104

100

102

104

1X9:201,202

1 3 5 F

2X31 2X31 2X31

K07 K08 K09

41 41 41

13

E

2

1A

2A

7A

10A

8A

2X31 2X31 2X31

WH

BN

WH

BN

2 4 6

101

103

105

1 2 2 1 3 1 2 1 2

1X7 1X7 1X7

-

O -

O -

O

A1 101 103 105

P

A2 Pt..1000 Pt..1000 Pt..1000

Pressure transducer

Y1 TT 11 PT 20 TT 01 TT 90

pin configuration

This document is property of Atlas Copco AB and shall not without our permission be altered,

Solenoid valve Temp.sensor Press. transd. Temp.sensor Temp.sensor

copied, used for manufacturing or communicated to any other person or company.

Solenoid valve element outlet delivery air ambient LAT dryer ID

[g] FF only

1: Supply voltage

2: Ground Name Service Diagram GA22-26FS

Confidentiality Class

G

1102 K/

3: Output Not Applicable

CONFIDENTIAL:

Material internal

4: Sealed with dummy

Treatment Not Applicable ACDE

Scale 1:1 Family Not Applicable A1 Compare

Drawing owner

Drawn by Blank nr.

ATLASCOPCO\PNEnip Not Applicable Replaces PNE

Version Drwg Designation Sheet 01 (02)

00 Not Applicable Not Applicable Blank wt. N/A Kg Fini wt. 0 Kg

STATUS 00

Note

Posi-

tion

Modified from Date Intr./Appd. Parent 3D Model Ed.Version 3D Approved Internal

Des checked. Prod checked. Approved. Date

28-08-2020 02:07:52 9097554751

You might also like

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationFrom EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationRating: 4 out of 5 stars4/5 (1)

- GA37 SchematicsDocument18 pagesGA37 Schematicstechbiomed100% (1)

- Max Fuse: ...... A: Main Power Supply ........... V ...... HZ 3Document13 pagesMax Fuse: ...... A: Main Power Supply ........... V ...... HZ 3jlcegarra100% (1)

- Sensor Nivel cls40 BediaDocument1 pageSensor Nivel cls40 BedianovincontrolNo ratings yet

- Detail "B": 90 DEG 180 DEGDocument3 pagesDetail "B": 90 DEG 180 DEGcarlos ramos100% (1)

- LT Cable Sizing Calculation With TECTON Comments - NTPL-TEC-TA5-E-222-B - R1Document19 pagesLT Cable Sizing Calculation With TECTON Comments - NTPL-TEC-TA5-E-222-B - R1Purushothaman SeenuNo ratings yet

- McQuay Mini-Chiller M4AC-M5AC Technical Manual EngDocument180 pagesMcQuay Mini-Chiller M4AC-M5AC Technical Manual EngFernando SilvaNo ratings yet

- Concrete cable trench and direct buried cable trench detailsDocument1 pageConcrete cable trench and direct buried cable trench detailsAbid AyubNo ratings yet

- Dh3 Generation Lototo Plan Phase 2 RGC 08sep2023Document8 pagesDh3 Generation Lototo Plan Phase 2 RGC 08sep2023Borislav VulicNo ratings yet

- LBC Rotterdam B.V.: General NotesDocument1 pageLBC Rotterdam B.V.: General NotesAndi SandraNo ratings yet

- Switch Yard Single Line DiagramDocument2 pagesSwitch Yard Single Line DiagramOktarico PradanaNo ratings yet

- Šeme Kompresora GA90Document21 pagesŠeme Kompresora GA90terhaf89No ratings yet

- Dh3 Generation Lototo Plan Phase 1 RGC 08sep2023Document8 pagesDh3 Generation Lototo Plan Phase 1 RGC 08sep2023Borislav VulicNo ratings yet

- Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoDocument4 pagesHazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoVijaya Seharan NairNo ratings yet

- SCHEMATIC All Models00192Document1 pageSCHEMATIC All Models00192Du TrầnNo ratings yet

- Solid State Magnetic Controller For Material Handlers Electrical System, 283-1452-00 (RENR3125-08)Document2 pagesSolid State Magnetic Controller For Material Handlers Electrical System, 283-1452-00 (RENR3125-08)sughieanto100% (1)

- Diagrama Elétrico CPVS 100-150Document16 pagesDiagrama Elétrico CPVS 100-150Emerson Rodrigues100% (2)

- 330 CaterpillarDocument6 pages330 CaterpillarpopNo ratings yet

- A600-1106 Rev0 PDFDocument2 pagesA600-1106 Rev0 PDFLuis Alejandro Piñeros PardoNo ratings yet

- WSM 0004516 01Document1 pageWSM 0004516 01La servici La serviciNo ratings yet

- Plano Electrico MinicargadorDocument1 pagePlano Electrico MinicargadorAlex Consuegra MedinaNo ratings yet

- Plano Electrico Yyz1607Document4 pagesPlano Electrico Yyz1607Alex Consuegra MedinaNo ratings yet

- Pnid ExamplesDocument1 pagePnid Examplessecret soldierNo ratings yet

- Control TA25DU19 Datasheet PDFDocument16 pagesControl TA25DU19 Datasheet PDFejazNo ratings yet

- UENR2643UENR2643-05 - SIS Electrico Diagrama PDFDocument4 pagesUENR2643UENR2643-05 - SIS Electrico Diagrama PDFJaime LopezNo ratings yet

- Sistema Eletrico 226Document4 pagesSistema Eletrico 226f8ytws84csNo ratings yet

- MC Midea Rashladnik Vode KatalogDocument84 pagesMC Midea Rashladnik Vode KatalogAINo ratings yet

- Block Diagram: 5.1 Main BoardDocument8 pagesBlock Diagram: 5.1 Main BoardFRANCISCO ALVARADO VERGARANo ratings yet

- Wiring Diagram S300WD2H21Document34 pagesWiring Diagram S300WD2H21Albert Briceño100% (3)

- Tank 100KL 12M A3 - 5 Layout1Document1 pageTank 100KL 12M A3 - 5 Layout1Tarun SinghalNo ratings yet

- WMRT Schaltbild R1.00Document1 pageWMRT Schaltbild R1.00ropiNo ratings yet

- Dol 0000 Ppi 00001 - Z19Document1 pageDol 0000 Ppi 00001 - Z19ywahyudiNo ratings yet

- Winone Elevator Connection DiagramDocument40 pagesWinone Elevator Connection DiagramMuhammad Rashid75% (4)

- EHS I Način RadaDocument25 pagesEHS I Način Radasloba68No ratings yet

- 65 93 PR Pid 01090 - 0001 - BDocument1 page65 93 PR Pid 01090 - 0001 - BgeocaustasNo ratings yet

- Dh3 Distribution P&id Lototo Phase 3 PDFDocument8 pagesDh3 Distribution P&id Lototo Phase 3 PDFBorislav VulicNo ratings yet

- Cat.dcs.Sis.controller[1]938gllDocument4 pagesCat.dcs.Sis.controller[1]938gllhernanNo ratings yet

- Ae2 Comp Insta Guide Na enDocument2 pagesAe2 Comp Insta Guide Na enAnonymous rrD8UKYNXNo ratings yet

- D 350 eDocument2 pagesD 350 eMahmoud ElbakryNo ratings yet

- EE002Document1 pageEE002johnkarl.bentingNo ratings yet

- Product Manual - R 3EL 125 - PO 8584Document71 pagesProduct Manual - R 3EL 125 - PO 8584Ravi RamdeoNo ratings yet

- Type 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Document3 pagesType 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Tien Nguyen TatNo ratings yet

- Drive Technology, Automation, and System Integration ServicesDocument1 pageDrive Technology, Automation, and System Integration Servicesmarius_brkt6284No ratings yet

- 9 3 PDFDocument2 pages9 3 PDFАлексейNo ratings yet

- Group 3 Electric SystemDocument2 pagesGroup 3 Electric SystemАлексейNo ratings yet

- 2SB1587 PDFDocument1 page2SB1587 PDFisaiasvaNo ratings yet

- Multi-turn CK actuators dimensions and specificationsDocument1 pageMulti-turn CK actuators dimensions and specificationsSuresh DNo ratings yet

- 09ad2 Fmmi RmacDocument1 page09ad2 Fmmi RmacTeddy AndriantsihoaranaNo ratings yet

- 6050 FS 3Document1 page6050 FS 3medkh0411No ratings yet

- ISO 10628 PFD Legend SheetDocument4 pagesISO 10628 PFD Legend SheetPrathmesh GujaratiNo ratings yet

- ECONOMICAL DIA ANALYSIS AND PUMP HEAD CALCULATIONDocument11 pagesECONOMICAL DIA ANALYSIS AND PUMP HEAD CALCULATIONmehtaabhi99_27916695No ratings yet

- 2019 Therma V Split R32Document2 pages2019 Therma V Split R32Constantin CilibiuNo ratings yet

- 2020 I30 G 1.4 T-GDI-DIAGRAMDocument1 page2020 I30 G 1.4 T-GDI-DIAGRAMcarsexpressNo ratings yet

- Ebz Offer Watco MCC 02Document3 pagesEbz Offer Watco MCC 02Mky YAduNo ratings yet

- I-DE-3010.2G-5425-944-HG4-001 - 0 - IFD Keppel CommentsDocument1 pageI-DE-3010.2G-5425-944-HG4-001 - 0 - IFD Keppel CommentsChoong K WNo ratings yet

- Global Coordinates MEP LayoutDocument49 pagesGlobal Coordinates MEP LayoutFaisal Abdel RahmanNo ratings yet

- C-ADAPTER Items Added: New Product NewsDocument3 pagesC-ADAPTER Items Added: New Product NewsAnonymous HPlNDhM6ejNo ratings yet

- Run-Up Performance Data SheetDocument2 pagesRun-Up Performance Data Sheetdava gladi tataNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Functions and Graphs Technology (Casio)Document2 pagesFunctions and Graphs Technology (Casio)Ava PidgeonNo ratings yet

- Dowty Propeller Service Bulletin IndexDocument2 pagesDowty Propeller Service Bulletin IndexriversgardenNo ratings yet

- Kumulative Dissertation Uni WienDocument8 pagesKumulative Dissertation Uni WienWebsitesThatWritePapersForYouSingapore100% (1)

- 32-BIT VS 64-BIT KEY DIFFERENCESDocument9 pages32-BIT VS 64-BIT KEY DIFFERENCESAnnalyn AgpoonNo ratings yet

- Throttle Linkage CheckDocument4 pagesThrottle Linkage Checkjbert55No ratings yet

- Brochure2-Mobil Greases PDFDocument2 pagesBrochure2-Mobil Greases PDFPedro PerezNo ratings yet

- CFO - IIM CourseDocument13 pagesCFO - IIM CourseRajesh RamakrishnaNo ratings yet

- FortiClient EMS 7.0 Course Description 2Document2 pagesFortiClient EMS 7.0 Course Description 2johntattonNo ratings yet

- Enhancing The Fan Experience at Live Sporting EventsDocument31 pagesEnhancing The Fan Experience at Live Sporting Eventsفاطمة الاغاNo ratings yet

- Monthly Statement: This Month's SummaryDocument4 pagesMonthly Statement: This Month's Summaryit proNo ratings yet

- ER Model What Is An Entity Relationship DiagramDocument10 pagesER Model What Is An Entity Relationship DiagramInfo techNo ratings yet

- EAGLE v5.0+ Board Convert To Gerber Made Easy!Document20 pagesEAGLE v5.0+ Board Convert To Gerber Made Easy!Brian LewisNo ratings yet

- ANALYSIS OF STEAM CYCLESDocument4 pagesANALYSIS OF STEAM CYCLESahmedytxzNo ratings yet

- Use Business TechnologyDocument35 pagesUse Business Technologyabricobm100% (3)

- Huawei Data Center Facility Handbook 20230425-1Document67 pagesHuawei Data Center Facility Handbook 20230425-1SatriaWahyuEkaSaputraNo ratings yet

- Heavy Saddle ClampsDocument1 pageHeavy Saddle ClampsSudarshan KaragudariNo ratings yet

- Reflective Report 3 - ME-T12324PWB-1 - Group 8Document8 pagesReflective Report 3 - ME-T12324PWB-1 - Group 8Xiao FengNo ratings yet

- CHAPTER 6 - 7 PadinDocument4 pagesCHAPTER 6 - 7 Padinpadin.jcNo ratings yet

- CLE-C4ED SMDocument69 pagesCLE-C4ED SMAndrei TraintaNo ratings yet

- Contoh InvoiceDocument2 pagesContoh InvoiceLinda RizkaNo ratings yet

- TS-832PX, TS-832PXU-RP, TS-832PXU Compare Products - QNAPDocument12 pagesTS-832PX, TS-832PXU-RP, TS-832PXU Compare Products - QNAPAkram M. AlmotaaNo ratings yet

- Laop 2018 CFPDocument2 pagesLaop 2018 CFPapi-394315691No ratings yet

- Introduction To Structured Query Language (SQL) - Part 1 PDFDocument14 pagesIntroduction To Structured Query Language (SQL) - Part 1 PDFbazezewNo ratings yet

- Dell Case Study - G02Document3 pagesDell Case Study - G02Miniteca Mega Rumba0% (1)

- Battery Report: Installed BatteriesDocument8 pagesBattery Report: Installed BatteriesSyafiQah MirrahNo ratings yet

- Agilent 7890GC Firmware Bulletin B.02.05.03 and A.01.16Document35 pagesAgilent 7890GC Firmware Bulletin B.02.05.03 and A.01.16infinity1200No ratings yet

- HJC Letter To Daniel EkDocument2 pagesHJC Letter To Daniel EkTHROnlineNo ratings yet

- Updating The QR Factorization and The Least Squares Problem (2008)Document73 pagesUpdating The QR Factorization and The Least Squares Problem (2008)Eran MaromNo ratings yet

- Juan Carlos Rodriguez Jimenez C.C 79.786.948 Industrial Engineer, MBA Spe. Computerize Industry and SimulationDocument3 pagesJuan Carlos Rodriguez Jimenez C.C 79.786.948 Industrial Engineer, MBA Spe. Computerize Industry and SimulationPaula TamayoNo ratings yet

- Gigatron TTL Microcomputer HistoryDocument103 pagesGigatron TTL Microcomputer HistoryOlegOxidNo ratings yet

![Cat.dcs.Sis.controller[1]938gll](https://imgv2-1-f.scribdassets.com/img/document/723231781/149x198/6f1be03413/1713192816?v=1)