Professional Documents

Culture Documents

Cement Production EN

Uploaded by

adil alsaadiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement Production EN

Uploaded by

adil alsaadiCopyright:

Available Formats

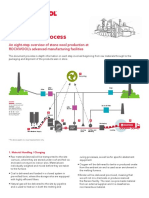

CEMENT MANUFACTURING PROCESS

Obtaining and preparing raw materials

The quarries are exploited by controlled blasting, in the

case of hard materials such as limestone and slate, while

in the case of soft materials (clay and marl) excavators

are used for their extraction.

Crushing

Once the material has been extracted and classified, it is crushed to obtain a granulometry

suitable for the grinding product and transferred to the factory by means of conveyor belts

or trucks for storage in the pre-homogenization park.

Pre-homogeneization

The crushed material is stored in

uniform layers to be subsequently

selected in a controlled manner. The pre-homogenization allows to

prepare the adequate dosage of the

different components, reducing their

variability.

Grinding

These materials are milled to reduce their size and thus favor

their process in the oven.

In the vertical mill the material is crushed by the pressure

performed by its rollers on a rotating table.

From there, the raw material is stored in a silo to increase the

uniformity of the mixture.

Cyclone preheater

The kiln is fed through the cyclone preheater,

which heats the raw material.

The raw material is introduced through the upper

part of the tower and descends through it.

Meanwhile, the gases coming from the kiln rise

upstream, thus preheating the material, which

reaches 1,000ºC before entering the kiln.

Clinker process: kiln ProTIR | Burning zone

Infrared thermal imaging system

As the material progresses inside the kiln, the for continuous temperature monitoring

temperature increases until it reaches 1,500ºC,

producing the complex chemical reactions that Monitoring the temperatures within the burning

produce the clinker. zone is important for quality and efficiency. Our

ProTIR system will provide accurate temperature

To reach the necessary temperatures for processing monitoring at the burning zone to driving off

the raw materials and for the production of clinker, unwanted elements as gases and creating clinker

the kiln has a main flame that burns at 2,000ºC. of the required composition.

RKS300 | Kiln shell

Rotary Kiln Monitoring System

Continuous monitoring along the entire rotary kiln length is important to ensure proper kiln-hell safety and

durability and optimize kiln efficiency. RKS300 System will provide real-time inspection of the entire kiln

length, allowing the detection and measurement of all hotspots on the kiln shell, even at an early stage.

Clinker process: cooler

At the exit of the kiln, the clinker is introduced into the cooler, which

injects cold air from the outside to reduce its temperature from 1,400ºC

to 100ºC.

The hot air generated in this device is reintroduced into the furnace to

promote combustion, thus improving the energy efficiency of the

process.

ProTIR | Clinker cooler

Infrared thermal imaging system for continuous temperature monitoring

It is essential to monitor and measure temperature inside coolers to improve operational efficiency and

combustion control. ProTIR System will detect snowmen, redrivers and other anomalies that take place in

coolers. Also, our system will help you to make routine plant maintenance and shutdowns more

predictable and less disruptive to the process.

Clinker grinding and cement

manufacturing

The clinker is mixed with gypsum and other

additions within a cement mill.

The mills can be made of rollers and balls. The latter consists of a large

tube that rotates on itself and that contains steel balls inside. Thanks to

the rotation of the mill, the balls collide with each other, crushing the

clinker and the additions until a fine and homogeneous powder is

obtained: the cement.

Cement storage

The cement is stored in silos, separated according to

its classes.

FireTIR | Cement storage

Thermography system for early fire detection

In the silos where the cement is stored, the FireTIR system is a flexible solution based on radiometric infrared

cameras that allow the early detection of fire and hot spots, before a deflagration occurs.

Packaging or bulk shipment.

The cement is bagged or unloaded in a tanker truck

for transport by road or rail.

Do you need more information

or more specific advice for your case?

CONTACT OUR EXPERTS IN VISION

+34 951 769 884 info@visiontir.com

More information in WWW.VISIONTIR.COM

Cement manufacturing process information source: IECA (Instituto Español del Cemento y sus Aplicaciones).

The systems for the monitoring and control of the cement manufacturing process are provided by VisionTIR.

VisionTIR © 2018

You might also like

- Waste (Used) Oil Burners, Heaters and BoilersDocument6 pagesWaste (Used) Oil Burners, Heaters and BoilersMohd Tanveer AshrafNo ratings yet

- Tyre Life Management SystemDocument30 pagesTyre Life Management Systemash31399941100% (2)

- Glass Plant Process by Sanjeev ShekherDocument12 pagesGlass Plant Process by Sanjeev ShekherSanjeev ShekherNo ratings yet

- Manufacturing of Portland CementDocument13 pagesManufacturing of Portland CementSharon K ThomasNo ratings yet

- Dry ProcessDocument4 pagesDry ProcessFahamidur Rahman ShawonNo ratings yet

- Construction ProcessDocument8 pagesConstruction ProcessLa BeamNo ratings yet

- Kiln Start Up Procedures PDFDocument12 pagesKiln Start Up Procedures PDFfaheemqc100% (2)

- Cement ManufacturingDocument10 pagesCement Manufacturinglawrence catipayNo ratings yet

- A. Indira National Power Training InstituteDocument80 pagesA. Indira National Power Training InstituteAyan MajiNo ratings yet

- Materials Engineer Accreditation Examination ReviewerDocument67 pagesMaterials Engineer Accreditation Examination ReviewerJonathan Del Rosario100% (1)

- SinteringDocument5 pagesSinteringdfhhjjjNo ratings yet

- The Technology of Cement IndustriesDocument42 pagesThe Technology of Cement Industriestesfayregs gebretsadik0% (1)

- Mechanical National Diploma SyllabusDocument106 pagesMechanical National Diploma SyllabusAlexander Mugabe100% (4)

- Overview of Cement Manufacturing 09.06.21Document39 pagesOverview of Cement Manufacturing 09.06.21Abhishek Michael ChandNo ratings yet

- Course 3 - Clinker Production: 3.3 PreheatersDocument26 pagesCourse 3 - Clinker Production: 3.3 PreheatersAndreea Ștefura100% (1)

- Manufacture Cement LafargeDocument3 pagesManufacture Cement LafargepratheeshkannanNo ratings yet

- Gold DeportmentDocument17 pagesGold DeportmentahmedkhidryagoubNo ratings yet

- Cooling TowerDocument3 pagesCooling Toweradearyani4No ratings yet

- Instrumentation in Cement IndustriesDocument9 pagesInstrumentation in Cement Industriesdina safiri100% (2)

- Application of DryingDocument31 pagesApplication of Dryinguzzal ahmedNo ratings yet

- WhertecDocument31 pagesWhertechamzahNo ratings yet

- Bypass SystemDocument9 pagesBypass SystemirfanNo ratings yet

- A Beginner's Guide To Eco Printing Fabric: Bonnie BowmanDocument4 pagesA Beginner's Guide To Eco Printing Fabric: Bonnie BowmanBagio Ranthe100% (2)

- Mugher Cement EnterpriseDocument27 pagesMugher Cement EnterpriseTasisa Kuma100% (7)

- Ceiling BaffleCeiling 20190514Document8 pagesCeiling BaffleCeiling 20190514BeatrizLlamasNo ratings yet

- Production Process of CementDocument2 pagesProduction Process of CementMarwaNo ratings yet

- VDZDocument28 pagesVDZAnonymous iI88Lt100% (2)

- Cement ManufacturingDocument30 pagesCement ManufacturingHARISH RANIWAL100% (7)

- Cement ProcessDocument13 pagesCement ProcessAsrar Uddin100% (1)

- Rotary KilnDocument12 pagesRotary KilnNasjilah Muhayati100% (1)

- Kiln Burning Systems: Raw Mill From Storage Feed RateDocument43 pagesKiln Burning Systems: Raw Mill From Storage Feed RateMuhammad Kureshi100% (1)

- Kiln Burning SystemDocument12 pagesKiln Burning SystemMuhammadShoaib100% (1)

- Obtaining and Preparing Raw Materials: Cement Manufacturing ProcessDocument1 pageObtaining and Preparing Raw Materials: Cement Manufacturing ProcessMuhammad YaseenNo ratings yet

- 9 NCRIET (Automation of Clinker Cooling System Using PLC)Document6 pages9 NCRIET (Automation of Clinker Cooling System Using PLC)Phillip007No ratings yet

- Overall Increase in Efficiency in Raw MeDocument6 pagesOverall Increase in Efficiency in Raw MeMadanKarkiNo ratings yet

- Birla Cement and TextilesDocument11 pagesBirla Cement and TextilesyashNo ratings yet

- Process: - : Hathi and Siddhi CementDocument9 pagesProcess: - : Hathi and Siddhi CementJessica RobinsonNo ratings yet

- Cement Manufacturing ProcessDocument2 pagesCement Manufacturing Processkinghari808100% (1)

- Inplant TrainingDocument13 pagesInplant TrainingAnnamalai PalaniappanNo ratings yet

- Cement Manufacturing ProcessesDocument10 pagesCement Manufacturing ProcessesKevin BlotsNo ratings yet

- Assignment On Operation Process of Jaypee Cement Plant: Sumbitted By: Anmol Garg (A1802014082) Mba-IbDocument13 pagesAssignment On Operation Process of Jaypee Cement Plant: Sumbitted By: Anmol Garg (A1802014082) Mba-Ibanmolgarg129No ratings yet

- Rockwool Stone Wool Manufacturing Production Process Fact SheetDocument2 pagesRockwool Stone Wool Manufacturing Production Process Fact Sheetprashant_salima6377No ratings yet

- Pardillo Me468 Assignment-1Document8 pagesPardillo Me468 Assignment-1Kent LabajoNo ratings yet

- Hoyumpa ME468 Assignment-1Document8 pagesHoyumpa ME468 Assignment-1Kent LabajoNo ratings yet

- Industry Sectors - CementDocument16 pagesIndustry Sectors - CementCrestian Nebreja MortaNo ratings yet

- Cement Process: Company Profile Products Cement Process Environmental Latest News Awards Contact Us Career OpportunitiesDocument2 pagesCement Process: Company Profile Products Cement Process Environmental Latest News Awards Contact Us Career OpportunitiesZümra OzdemirNo ratings yet

- Cement Manufacturing ProcessDocument2 pagesCement Manufacturing ProcessVenkata Ramana Murty GandiNo ratings yet

- CEMENTDocument2 pagesCEMENTChannis ExoNo ratings yet

- Cement Mining and ManufacturingDocument3 pagesCement Mining and ManufacturingEmmanuel ChibweNo ratings yet

- Bed Ash Cooler's in Ir-Cfbc Boilers PDFDocument12 pagesBed Ash Cooler's in Ir-Cfbc Boilers PDFpradeep1987coolNo ratings yet

- Internship Presentation: DG Khan Cement Company - Khairpur PlantDocument13 pagesInternship Presentation: DG Khan Cement Company - Khairpur Planthamza abbasNo ratings yet

- CE 2105 - Dry Process - 1801041Document5 pagesCE 2105 - Dry Process - 1801041SAUMIK HASAN TANIMNo ratings yet

- Method, Processes and Equipment in Manufacturing of Cement: Presented byDocument18 pagesMethod, Processes and Equipment in Manufacturing of Cement: Presented byJohn Paul ParoNo ratings yet

- Simulation Model For The Calcination Process of Cement .: Idalia@unam - MXDocument8 pagesSimulation Model For The Calcination Process of Cement .: Idalia@unam - MXKARKAR NABILNo ratings yet

- Inplant Training Undergone in India Cements LTD Sankarnagar-627 357. Tirunelveli - DistDocument10 pagesInplant Training Undergone in India Cements LTD Sankarnagar-627 357. Tirunelveli - DistSunny ThomasNo ratings yet

- Cement Manufacturing ProcessDocument13 pagesCement Manufacturing ProcessDovah KiinNo ratings yet

- CERE 136 Laboratory Report 1Document10 pagesCERE 136 Laboratory Report 1Edison LimbagaNo ratings yet

- Report Proposal (Oven)Document12 pagesReport Proposal (Oven)Victor NudanuNo ratings yet

- Raining Report at Acc CementsDocument52 pagesRaining Report at Acc CementsRahulNo ratings yet

- Modern Iron Making MM321Document49 pagesModern Iron Making MM321Sanjeev SahuNo ratings yet

- Roller Hearth Kiln - IjoeDocument6 pagesRoller Hearth Kiln - IjoeSunit AroraNo ratings yet

- Reverberatory FurnceDocument6 pagesReverberatory Furncerh.rassan.connectNo ratings yet

- Kilns and Furnaces Used in Ceramic and Refractory IndustriesDocument4 pagesKilns and Furnaces Used in Ceramic and Refractory IndustriesDwiky SuryaNo ratings yet

- Clinker and FinishedDocument6 pagesClinker and FinishedSuzayui White GremoryNo ratings yet

- Sinter PlantDocument5 pagesSinter PlantJulioCesarLunaIbañezNo ratings yet

- Equipment's Used in Cement Manufacturing Raw MillDocument3 pagesEquipment's Used in Cement Manufacturing Raw MillRenato OrosaNo ratings yet

- Cement Manufacturing ProcessDocument2 pagesCement Manufacturing ProcessMorning Kalal0% (1)

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- F10480476C219Document6 pagesF10480476C219adil alsaadiNo ratings yet

- 2010 3 110 CaDocument8 pages2010 3 110 Caadil alsaadiNo ratings yet

- How To Convert Kaolin To Calcined Kaolin: The IssueDocument5 pagesHow To Convert Kaolin To Calcined Kaolin: The Issueadil alsaadiNo ratings yet

- CEMENTDocument21 pagesCEMENTadil alsaadiNo ratings yet

- Ubc 2019 May Penson CurtisDocument150 pagesUbc 2019 May Penson Curtisadil alsaadiNo ratings yet

- Astm C125 20Document4 pagesAstm C125 20adil alsaadiNo ratings yet

- A Review On The Effect of Metakaolin On The Chloride BindingDocument21 pagesA Review On The Effect of Metakaolin On The Chloride Bindingadil alsaadiNo ratings yet

- (Tec) KeyDocument11 pages(Tec) KeyJose M. Lorente AparicioNo ratings yet

- Mini Interruptores Termomagnéticos e Interruptores DiferencialesDocument52 pagesMini Interruptores Termomagnéticos e Interruptores DiferencialesJay SantanNo ratings yet

- BoilerDocument3 pagesBoilerTerry YongNo ratings yet

- Pub 1080Document6 pagesPub 1080Junaid YNo ratings yet

- Mineral Deposits in India - Chief Mineral Resources - Global Production - Domestic Production - Applications - Contemporary IssuesDocument21 pagesMineral Deposits in India - Chief Mineral Resources - Global Production - Domestic Production - Applications - Contemporary IssuessriharshaNo ratings yet

- A 02 1064Document4 pagesA 02 1064Marliton SalinasNo ratings yet

- System Reference.Document28 pagesSystem Reference.Ronald Bienemi PaezNo ratings yet

- Chapter 4 Heating, Ventilating, and Air-Conditioning (Hvac) Equipment and ControlsDocument16 pagesChapter 4 Heating, Ventilating, and Air-Conditioning (Hvac) Equipment and Controlssanizan80No ratings yet

- Compression and Transfer MoldingDocument12 pagesCompression and Transfer MoldingpandalynaNo ratings yet

- 5871 - 0617-Determination of Mineral Oil Hydrocarbons in Vegetable OilDocument1 page5871 - 0617-Determination of Mineral Oil Hydrocarbons in Vegetable OilBaek Ho KimNo ratings yet

- MAXON PresentationDocument27 pagesMAXON PresentationJaroslav KurucNo ratings yet

- Paramesh CivilDocument25 pagesParamesh CivilSai kumarNo ratings yet

- Behavior of Plastic TilesDocument4 pagesBehavior of Plastic TilesJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- 1110pm24 DR I Sundar PDFDocument8 pages1110pm24 DR I Sundar PDFANUSHA MNo ratings yet

- Prediction of Thrust Force and Torque in Drilling On Aluminium AlloyDocument7 pagesPrediction of Thrust Force and Torque in Drilling On Aluminium Alloyanilsamuel0077418No ratings yet

- Ascon ManualDocument76 pagesAscon ManualZulfiqar AhmedNo ratings yet

- Lead Alloy Calculators 082311Document6 pagesLead Alloy Calculators 082311Rafael Blancas ChaucaNo ratings yet

- Catalogo SMC en InglesDocument20 pagesCatalogo SMC en InglesAnonymous 9NekBnx9VWNo ratings yet

- Homework 1Document3 pagesHomework 1hassaniqbal84No ratings yet

- Nissan Cube Z12 2008-2012 General InformationDocument51 pagesNissan Cube Z12 2008-2012 General InformationNuttapong SukganNo ratings yet