Professional Documents

Culture Documents

OSA-P-SRV-25 PSV Diagnostic and Maintenance Repair and Testing Procedure

OSA-P-SRV-25 PSV Diagnostic and Maintenance Repair and Testing Procedure

Uploaded by

deny0 ratings0% found this document useful (0 votes)

22 views4 pagesOriginal Title

OSA-P-SRV-25 PSV Diagnostic and maintenance repair and testing procedure

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views4 pagesOSA-P-SRV-25 PSV Diagnostic and Maintenance Repair and Testing Procedure

OSA-P-SRV-25 PSV Diagnostic and Maintenance Repair and Testing Procedure

Uploaded by

denyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

lie =

| __________

| OSA PT. OSA INDUSTRIES INDONESIA No

Industries eee

Indonesia | [Date _:30 March 2012

PSV DIAGNOSTIC AND MAINTENANCE REPAIR AND TESTING

PROCEDURE

r

Prepared by: Checked & Approved by:

1

t

__.d Harry Hutajuly)

QC Engineer Operations Manager

Controlled Co;

M49

OSA | |

PT. OSA INDUSTRIES INDONESIA | No.

Industries

Indonesia Date

osa-p-sav-25 | Rev.: 01

Work Procedure

30 March 2012 | Page: 2/4

PSV DIAGNOSTIC AND MAINTENANCE REPAIR AND TESTING PROCEDURE

Amendment Record Sheet

Date of (eamiN. Issue No, | Description of change

i | Loge OSA From “OSA

| 30March 2012 Change Logo OSA. o1 Industries” to “OSA.

Industries Indonesia”

Without “Contvlled Copy” stamp, documents Uncontrolled>

Controlled Cc;

2049 (>

(OSA | oe

Work Procedure

PT. OSA INDUSTRIES INDONESIA | No. os

SRV-25 | Rev. :01 |

Industries se

Indonesia Date :30March 2012 | Page: 3/4

10

2.0

3.0

4.0

os |

PSV DIAGNOSTIC AND MAINTENANCE REPAIR AND TESTING PROCEDURE

PURPOSE

‘The purpose of this procedure is to guidelines and provide a system for Pressure Safety

Valve Diagnostic, Maintenance and Test Pressure safety Valve. And give direction the

repair sequence of Pressure Safety Valve from preparation and after inspect, repair and

testing.

SCOPE

This procedure applies at Technical and Quality Dept. to ensure that inspection are

according to Quality Standard

DEFINITION

None

PROCEDURE

4.1 PSV DIAGNOSTIC

Refer to TESON/METRUS Procedure, this tool will give the introduction as well as

the position of online testing within the maintenance strategy.

4.2 PSV MAINTENANCE

4.2.1 Check Name Plate and fill the data into Safety Valve Inspection Sheet,

including :

~ Tag Number

- Manufacture

- Model and size

- Set Pressure

= Cold Set Pressure

- Last Test

Service Medium

Back Pressure

4.2.2 Receive and assign traceable control number by stamping/etching to the

valve.

4.2.3. Check whether valve's component are complete

4.2.4 Pre-Test Valve as per condition before repair

4.2.5. Strip, Clean and Inspect all parts

4.2.6 Shot Blast / Steam Clean Valve Body

4.2.7 Checkall critical dimension and tolerances

4.2.8 Document Inspection Result

Without “Controlied Copy” stamp, document is Uncontlledy

Controlled Ce

BO-19-\F

(OSA

cedure

PT. OSA INDUSTRIES INDONESIA, No. Rev. :01

Date :30 March 2012 | Page: 4/4

PSV DIAGNOSTIC AND MAINTENANCE REPAIR AND TESTING PROCEDURE

4.3. TESTING PROCEDURE

4.3.1 Before Valve Repair Project commences, ensure that all dials and gauge

are properly calibrated and certified

43.2 If the Computer assisted facility is to be used, ensure that is already

calibrate and set in conjunction with the analog gauges. A test calibration

sheet should be made available in the container for inspection,

4.3.3 Proper range gauges should be utilized as far as is possible to allow for

greater accuracy and readability.

4.3.4 Standards to be used in accordance to the user’s specifications should be

Clearly agreed upon so that there is no misunderstanding of what is to be

‘expected of us. Commonly we will use both the API 527 standard as well

as the ASME codes. Any fixtures to be used should have the permission

and approval of customers concern,

4.3.5. Copies of the procedures to be utilized should be kept in the container

for reference.

4.3.6 See the Nozzle Ring and Guide Ring

43.7. Calibrate the valve to the Cold Differential Test Pressure and ensure that

the adjusting screw nut is tight after each adjustment. Also take into

account thr temperature correction factor and the back pressure

tolerance.

4.3.8 Carry Out the Leakage according to API 527, then remove pressure from

the valve iniet.

43.9 Adjust the Nozzle adjusting ring and the guide to manufacture’s

recommended setting and lock with the adjusting ring pin.

4.3.10 Whenever necessary, body test the valve to check integrity of the gasket

and sealing faces. This is done in accordance with ASME Section | or Vill,

diva.

4.4 GENERAL PARAMETER FOR TESTING

44.1 Seat Tightness Testing requirement (Testing with Air)

4.4.2 Seat Tightness Testing Requirement (Testing with Air)

4.43 Pop Test

4.4.4 Bellow integrity Check

Without “Conraled Copy” stomp, decument is Unconroled ae

Controlied Cec iE

90-19,

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- OSA-P-SRV-24 Testing Procedure For DPE Ball Valve (Refer To API 6D Specification)Document12 pagesOSA-P-SRV-24 Testing Procedure For DPE Ball Valve (Refer To API 6D Specification)denyNo ratings yet

- OSA-P-SRV-22 Workshop Repair General ProcedureDocument8 pagesOSA-P-SRV-22 Workshop Repair General ProceduredenyNo ratings yet

- OSA-P-SRV-26 Control Valve Diagnostic and Function Testing ProcedureDocument3 pagesOSA-P-SRV-26 Control Valve Diagnostic and Function Testing ProceduredenyNo ratings yet

- Do. 018 R 36Document1 pageDo. 018 R 36denyNo ratings yet

- TesonDocument1 pageTesondenyNo ratings yet

- AgengDocument2 pagesAgengdenyNo ratings yet

- OSA-P-SRV-13 Testing Procedure For Check Valve (Refer To API 598 Specification)Document18 pagesOSA-P-SRV-13 Testing Procedure For Check Valve (Refer To API 598 Specification)denyNo ratings yet

- Project Execution PlanDocument3 pagesProject Execution PlandenyNo ratings yet

- ADM-10-2011 - PR Office SuppliesDocument2 pagesADM-10-2011 - PR Office SuppliesdenyNo ratings yet

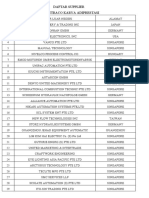

- Daftar SupplierDocument5 pagesDaftar SupplierdenyNo ratings yet

- Omar Syarief - CVDocument2 pagesOmar Syarief - CVdenyNo ratings yet

- TapScanner 18-03-2021-16.22Document1 pageTapScanner 18-03-2021-16.22denyNo ratings yet

- CV Akbar PutraDocument5 pagesCV Akbar PutradenyNo ratings yet

- 000 MARC-GTC Document AuditDocument4 pages000 MARC-GTC Document AuditdenyNo ratings yet

- To Do ListDocument1 pageTo Do ListdenyNo ratings yet

- Supporting Letter To PROMATCON TEPATGUNADocument1 pageSupporting Letter To PROMATCON TEPATGUNAdenyNo ratings yet

- Dokumen Penilaian Kualifikasi: Subject: Major Inspection (MI) of Frame-V GTG G101C Tender No: PS216A1D76Document1 pageDokumen Penilaian Kualifikasi: Subject: Major Inspection (MI) of Frame-V GTG G101C Tender No: PS216A1D76denyNo ratings yet

- NametagDocument4 pagesNametagdenyNo ratings yet

- Dokumen Penawaran: Subject: Blanket Purchase Agreement of Chemical Methanol Tender No: PROC104Document1 pageDokumen Penawaran: Subject: Blanket Purchase Agreement of Chemical Methanol Tender No: PROC104denyNo ratings yet

- Pt. Golden Solution Indonesia: Health and Safety EnvironmentDocument1 pagePt. Golden Solution Indonesia: Health and Safety EnvironmentdenyNo ratings yet