Professional Documents

Culture Documents

OSA-P-SRV-22 Workshop Repair General Procedure

OSA-P-SRV-22 Workshop Repair General Procedure

Uploaded by

deny0 ratings0% found this document useful (0 votes)

19 views8 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views8 pagesOSA-P-SRV-22 Workshop Repair General Procedure

OSA-P-SRV-22 Workshop Repair General Procedure

Uploaded by

denyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

Work Procedure

Rev,

OSA PT. OSA INDUSTRIES INDONESIA No. : OSA-P-Sav-22

Date :30 March 2012 | Page

Indonesia

WORKSHOP REPAIR GENERAL PROCEDURE

Checked & Approved by :

Prepared by:

(Harnf Hutajulu)

operations Manager

. |

QC Engineer

Controlled Co,

ara

| OSA PT. OSA INDUSTRIES INDONESIA _ No.

Indonesia [Date :30 March 2012

| WORKSHOP REPAIR GENERAL PROCEDURE,

Amendment Record Sheet

Date of Revision Item No. Issue No. Description of Change

T | Logo OSA From “OSA |

27March 2012 | Change Logo OSA ou Industries” to “OSA

Industries indonesia” _|

Taare py Hs Smoot Fae

ae Controlled Cop,’

aint

OSA

Work Procedure

| PT OSAINDUSTRIES INDONESIA [No. vosmP-sAva2 Rew 01

Industries }

Indonesia ee Date _:30 March 2012 | Page: 3/8

WORKSHOP REPAIR GENERAL PROCEDURE

Safety Procedures

1.0. Purpose

‘The purpose of this procedure is to establish guidelines and provide a Workshop Repair General

Procedure system at PT. OSA Industries Indonesia and/or the contracts. The procedure shall meets

to any requirement and binding to other procedure continuously.

2.0 Method

2.1 Competency and trained Man Power only authorized for repair and has been trained for

safety training for any execution.

2.2. Safety action taken carefully to bleed off the remaining pressure at valve & actuator, also

remaining energy from mechanism springs hold or stuck.

23. Take normally position between valve and actuator to be sure no more powerful action

required for dissembling any loosen tightens bolt & nut.

24. Devices use by electrical power must be sure for any protection to drop off fuses at MCB, and

‘easy to manage release energy from main panel if emergency required.

2.5. Valve & actuator Stuck must be aware to keep the extra power mechanism action to avoid

back power in order release devices or any tighten component/bolt/nut. Analysis the safety

dissembling unit by prepare additional tools & equipment for safety dissembling unit

accordingly

3.0 Valve & Actuator Receiving

40

Without “Controlled Copy” stomp, documents Uncontralled «

3.1 Identify the valves and actuator from size, ANSI, type, acting system, port size,

3.2 Record the manufacturer's name plate information on the side of the valve in the valve

report.

3.3. Locate and identify the part & components on the valve & actuator

a) Body valve and Actuator

bb) all fittings and adjustable devices

) Flange type

4d) Bolt & nut type

with Allen head screw.

ji. Bolt head type.

3.4. Lifting for loading and unloading unit valve & actuator from truck, must be conducted by

signal Man as receiving process. Lifting shall define rigging tools for robe tightens to the

‘goods, considering balance of weight to avold swing fall from lifting procedure.

During Repair Service

4.1. Personnel must be wearing PPE during in repair service area.

4.2. Prepare proper tools & equipment as required and place in the boxes in free access area.

Solvent chemical uses for easing and rust removal must be awared to point and not face to

person or hot area.

Controlled Coy

tele

r

OSA Saar

Industries eee

Indonesia Date :30March 2012 | Page: 4/8 |

Work Procedure

PT. OSAINDUSTRIES INDONESIA No. : OSA-P-SRV-22 | Rev. :01

WORKSHOP REPAIR GENERAL PROCEDURE |

43. Equipment force by pressure must be indicated the following connection tighted and safe

socket to avoid release from pressure arising

44 Lifting equipment should be managed for loading & unloading dissembling parts/component

‘more than 15 kgsin the right position and free moving access area from person and stuffs.

4.5 Competency Man Power only authorized to conduct as supervisory technician the repair

service, method execution as required due to detail SOP for EA valve & actuator type.

4.6. Sparkle from grinding or drilling devices shall be sure take action at the safe area from fire

Inspection

Purpose

‘The purpose of this procedure is to establish guidelines and provide an inspection procedures for VALVE

WORKSHOP REPAIR system at PT. OSA Industries Indonesia and/or the contracts. The inspection shall be

conducting by Engineering to find out instruction repair service respectively, and shall binding to

Inventory Check List procedure.

ut

12

13

14

1s

16

17

Check list to Inventory if the repair service unit must be replaced before dismantle from f/s,

colleting from ex-stock Marunda warehouse both from new reconditioned or defective unit

available to repair.

Leak and function test valve to find out defective valve & actuator, record parameter issued and

due to standard requirement test API, ANSL

Dissembling valve and actuator to find defective and fallure damages parts/component, mounting

and body condition. Take a notes and picture for EA damaged goods for any comparison before

and after recondition.

Clean up body & actuator, parts, component, devices to have the clear current condition and

always tag any releasing devices to re-install on the original position.

Separate the good and damages parts, component to prepare the execution of recondition and

repair service.

Engineering Review

a). Decide as the actual condition to repair for minor or major repair

'b) Action plan to execute repair service

) Failure analysis if any critical badly damaged caused of fluid process changing contained

Data base recordable shall tag ID and all information for track and trace repair status monitoring,

up-dating data base to manage F/s, service area, Tag no required for repair memo and remarks

both for field and inventory.

Woot "Coed Copy same, duane stneoncleds erated COL x

ara

Work Procedure

OSA PT.OSA INDUSTRIES INDONESIA | No. :O5A-SRV-22 [Rev :01 |

_ Indonesia [Date :30March 2012 | Page: 5/8 |

= 3 ; 1

WORKSHOP REPAIR GENERAL PROCEDURE

Procurement

Purpose

The purpose of this procedure is to establish guidelines and provide Procurement procedures for VALVE

WORKSHOP REPAIR system at PT. OSA Industries indonesia and/or the contracts. This procedure shall

refer to any procurement pracess and binding to General Procurement Procedure as the master

procedure therefore.

1.1 Record the requirement spare parts, components to procure and must be related standard from

‘original manufacture manual [API, ANSI, NACE, ASTM].

1.2 Fabricate parts/component must be issued the laborary standard shall define and meet to the

current requirement process, meet the temperature, pressure, flow capacity and typical of fluids

characteristic.

4.3 Record all parts/component for actual dimensional parameter if no S/N, and must be adjusted to

existing mounting and bracket as required

1.4 Differential material must be recognized and shall meet to the current requirement at safety

factor standard, Soft goods must be stored for spare units net limited to requirement if any lack of

reconcition need to secondary replacement or reworks

15 Action to Procure

4a) Uist of parts/component inquiry c/w spec, size, material comp

b) Request for proposal to vendor or direct purchase

)_ Prices must be leveling to normal price, and shall define the competitive price

4). Special price allowable accepted only for urgent/emergency requirement

@) Propose for non-rate material contract for approval

£). Delivery material shall meet to the repair service schedule due date completion

1.6 Up-date data to Inventory recordable for buffer stock and running stock always

Fabrication

Purpose

‘The purpose of this procedure is to establish guidelines and provide Fabrication procedures for VALVE

WORKSHOP REPAIR, system at PT. OSA Industries Indonesia and/or the contracts.

1.1 Meterial/eomponent fabrication must be related to standard not limited the composition

materia, original dimensional and meet to current process fluids media.

1.2 Fabrication by welding filler, must be meet to test to ensure from crack material and leaking

following PWHT and WPS as required welding procedure standard.

1.3. Record all parts/component for actual dimensional parameter if no S/N, and must be adjusted to

existing mounting and bracket as required.

Differential material must be recognized and shall meet to the current requirement at minimum.

Scrap material must be stored back to warehouse for junk material record.

Without “Coniled Copy stomp, document is Uncontvaled

Controlled Copy oe

arte 2

Os inl Work Procedure

le | PT.OSA INDUSTRIES INDONESIA No -oSap-sav.22 | Rev. 01

Industries jie. seer seve eee

Indonesia [Date :30March 2012 | Page: 6/8

r es /

WORKSHOP REPAIR GENERAL PROCEDURE |

1.5. Action to Fabricate

a) List of parts/component inquiry c/w spec, size, material comp,

b) Request for proposal to vendor or direct fabrication

©) Prices must be leveling to normal price, and shall define the competitive price

4d). Special price allowable accepted only for urgent/emergency requirement

€) Propose for non-rate material contract for approval

f) Delivery material shall meet to the repair service schedule due date completion

1.6 Up-date dats to Inventory recordable for buffer stock and running stock always

1.7 Sub-contract to vendor for fabrication shall meet the standard and comply with requirements

Recondition, repair sei

Purpose

The purpose of this procedure is to establish guidelines and provide Recondition, repair service

procedures for VALVE WORKSHOP REPAIR system at PT. OSA Industries Indonesia and/or the contracts.

1.1 Parts/component/body must ensure could be reconditioned. Resize and over size dimensional is

not allow to recondition if any devices not meet to mounting body.

1.2 Wall thickness reduce by process only allowable to recondition and shall meet the wall thickness

requirement for re-metal, hard facing to the original dimens‘onal size.

1.3 Loosen and Tighten all Bolt & Nut shall allow to ANSI class requirement for torque moment, and

shall re-check the final action before dispatch and packing,

1.4 Record all parts/component for actual dimensional parameter if no S/N, and must be adjusted to

‘existing mounting and bracket as required.

1.5. Modification shall allow not to change any function, specification and system to operate the unit

for reason of re-positioning or swapping parts/component from other scrap unit if any,

Action to recondition

Dissembling

Recondition, repair service

Parts/ component replacement

Re-assembling

Coating & Painting

Testing

Packing

1.6 Up-date data recordable to Master Data Base.

1.7. Sub-contract to. vendor for recondition repair service shall meet the standard and comply with

requirements and acknowledge by the Company.

‘Without *Conroled Copy” stomp, docoment i Uncontroed ,

Controlled Co;

RL

Work Procedure

PT. OSA INDUSTRIES INDONESIA | No. : OSA-P-SRV-22 | Rev. :01

[ate :30March 2012 | Page: 7/8 |

WORKSHOP REPAIR GENERAL PROCEDURE

Pressure & Function Testing

1.0 Purpose

‘The purpose of this procedure is to maintain a system which identifies the leak and function test

for valve & operated device due to standard EA type of API, ANSI, NACE, ASTM, ISO.

2.0 Scope

Every valve is to be hydrostatically tested to ensure the pressure integrity of valve body. The valve

seat is also checked to verify that leakage past the relevant standard and customer requirement

Function test is required for complete operating valve & operated devices ensure to operable &

reliable.

3.0 Definitions

2. Product Result of a set interrelated or interacting activities which transforms

inputs into outputs.

b. Record Document —_: Stating results achieved or providing evidence of activities performed.

Inspection Conformity evaluation by observation and judgment accompanied as

appropriate by measurement, testing or gauging.

4, Bidirectional Valve: Avalve designed for sealing in either direction.

e. Plug Prevents flow or leakage into the down stream conduit when in the

closed position. Valves shall be single or double seated, bidirectional

‘or unidirectional, Unidirectional valves shall be marked with a flow

irection arrow.

f. Closure Member: That part of a valve which is positioned in the flow stream to.permit,

obstruct or regulate flow.

4.0 References Material

4.1 AVIW-TBM-001 ‘Work Instruction of Test Bench Machine AYFC-1

4.2. APIStandard 598: Valve Inspection and Test

4.3, APISpecification Specification for Pipeline Valves (Gate, Plug, Ball and Check Valves)

6D

4.4 APIStandard 608: Metal Ball Valves-Flanged, Threaded and Welding Ends

4.5 ASMEB1.20.1 Pipe Threads, General Purpose (inch)

46 ASMEBI6.11 Forged Steel Fitting, Socket-Welding and Threaded

4.7 ASMEBI6.34 Valves - Flanged, Threaded, and Welding Ends

48 MSSSP-55 Quality Standard for Steel Castings for Valves, Flanges and Fittings

and

other Piping Components - Visual Method

4.9 MS55P-91 : Guidelines for Manual Operation of Valves

With “Controle Copy” stomp, documents Uncontrolled

Controlled Copy

eae

OSA

Work Procedure

PT. OSA INDUSTRIES INDONESIA No. :OSA-P-SRV-22 | Rev. :01

Industries LI

Indonesia Date :30 March 2012 | Page: 8/8

WORKSHOP REPAIR GENERAL PROCEDURE

Packaging

1.0, Purpose

20

3.0

40

‘The purpose for Packaging is to find the best and safe for material transportation both for on and

off shore delivery. The procedure is not limited to recondition valve & operated devices, but for

sure as a guide line to various materials required for packaging.

‘Scope

Every valve and actuator must be bended at packaging for delivery requirement, safe for loading

and unloading, safe while boat transportation fram shaking and hook to avoid damages goods.

Packaging Method

3.1. Sizing and weight material to prepare wooden raw material

3.2. Material take in place on top available Pallet, and shall fit at surface to ensure proper

position at bottom site in balance and fully bended by stect plating

3.3. Wrap all face Pallet with wooden and nailed strongly to form container frame and cover all

Material

3.4. Direction informative to hook up and loading-unloading

Description

4.1 Construction Pallet & Wooden Box with equal dimensional to material size nailed

for any connection and shall pallet at bottom side.

4.2 Locking All boxes must be bended between Materials to the wooden box by

steel plate and have no shaking for load & unload action.

4.3 Packing Uist Destination, Material spec Info and Quantity.

4.4 Delivery Must be safe from hook and maneuver during loading-unloading, easy

for rigging wrap and robe tighten for lifting.

4.5. Final Check : Final Check list before delivery must be approved by authorized

personnel or Supervisor

Without “Contreled Cony” stomp, document is Uncortaled

Controlled Co)

Dewrere

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- OSA-P-SRV-24 Testing Procedure For DPE Ball Valve (Refer To API 6D Specification)Document12 pagesOSA-P-SRV-24 Testing Procedure For DPE Ball Valve (Refer To API 6D Specification)denyNo ratings yet

- OSA-P-SRV-25 PSV Diagnostic and Maintenance Repair and Testing ProcedureDocument4 pagesOSA-P-SRV-25 PSV Diagnostic and Maintenance Repair and Testing ProceduredenyNo ratings yet

- OSA-P-SRV-26 Control Valve Diagnostic and Function Testing ProcedureDocument3 pagesOSA-P-SRV-26 Control Valve Diagnostic and Function Testing ProceduredenyNo ratings yet

- Do. 018 R 36Document1 pageDo. 018 R 36denyNo ratings yet

- TesonDocument1 pageTesondenyNo ratings yet

- AgengDocument2 pagesAgengdenyNo ratings yet

- OSA-P-SRV-13 Testing Procedure For Check Valve (Refer To API 598 Specification)Document18 pagesOSA-P-SRV-13 Testing Procedure For Check Valve (Refer To API 598 Specification)denyNo ratings yet

- Project Execution PlanDocument3 pagesProject Execution PlandenyNo ratings yet

- ADM-10-2011 - PR Office SuppliesDocument2 pagesADM-10-2011 - PR Office SuppliesdenyNo ratings yet

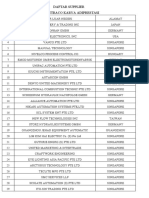

- Daftar SupplierDocument5 pagesDaftar SupplierdenyNo ratings yet

- Omar Syarief - CVDocument2 pagesOmar Syarief - CVdenyNo ratings yet

- TapScanner 18-03-2021-16.22Document1 pageTapScanner 18-03-2021-16.22denyNo ratings yet

- CV Akbar PutraDocument5 pagesCV Akbar PutradenyNo ratings yet

- 000 MARC-GTC Document AuditDocument4 pages000 MARC-GTC Document AuditdenyNo ratings yet

- To Do ListDocument1 pageTo Do ListdenyNo ratings yet

- Supporting Letter To PROMATCON TEPATGUNADocument1 pageSupporting Letter To PROMATCON TEPATGUNAdenyNo ratings yet

- Dokumen Penilaian Kualifikasi: Subject: Major Inspection (MI) of Frame-V GTG G101C Tender No: PS216A1D76Document1 pageDokumen Penilaian Kualifikasi: Subject: Major Inspection (MI) of Frame-V GTG G101C Tender No: PS216A1D76denyNo ratings yet

- NametagDocument4 pagesNametagdenyNo ratings yet

- Dokumen Penawaran: Subject: Blanket Purchase Agreement of Chemical Methanol Tender No: PROC104Document1 pageDokumen Penawaran: Subject: Blanket Purchase Agreement of Chemical Methanol Tender No: PROC104denyNo ratings yet

- Pt. Golden Solution Indonesia: Health and Safety EnvironmentDocument1 pagePt. Golden Solution Indonesia: Health and Safety EnvironmentdenyNo ratings yet