Professional Documents

Culture Documents

Abbas Resume

Uploaded by

Shafi UllahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abbas Resume

Uploaded by

Shafi UllahCopyright:

Available Formats

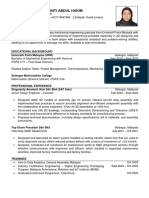

ABBAS KHAN

+92-315-1954681 • abbaskhan923151954681@gmail.com

• linkedin.com/in/abbas-khan-302a98194

Education

UNIVERSITY OF ENGINEERING AND TECHNOLOGY (UET) – CGPA: 3.367/4 Peshawar, Pakistan

Bachelors of Science in Industrial Engineering August 2022 – June 2023

Relevant Coursework: Manufacturing Processes, Production Planning and Control, Quality Control, Operation

Research, Supply chain Management, Lean Manufacturing, Project Management, Human Factor Engineering, etc.

Professional Experience

PAKISTAN TOBACCO COMPANY LIMITED - BAT August 2022 – October 2022

Pakistan's largest cigarette manufacturer and a subsidiary of British American Tobacco located in Akkora Khattak, Pakistan.

Summer Internee

– Assisted in analyzing existing manufacturing processes to identify inefficiencies and bottlenecks, resulting in a 13%

reduction in production time.

– Collaborated with the quality control team to develop and implement inspection procedures, leading to a 20%

decrease in defects and customer complaints.

– Supported the project management team in executing process improvement initiatives, ensuring timely completion

and adherence to project scope.

– Conducted time studies and data analysis to optimize workstations, improving worker efficiency by 10% and

reducing fatigue.

– Assisted in implementing Kanban system, resulting reduction in inventory holding costs & improved material flow.

NEW KAMRAN FLOUR MILLS PVT. LIMITED June 2021 – July 2022

New Kamran Flour Mills Pvt. Limited is a flour mill located in Charsadda, Pakistan.

Industrial & Production Engineer

– Led in analyzing a production line and identifying key areas for improvement using Lean Six Sigma methodologies.

– Implemented process changes, resulting in a 30% reduction in cycle time and a 15% increase in overall productivity.

– Created compelling presentation, conveyed complex info concisely, reduced costs by 30%.

– Ensured line balancing and layout design with agreed-upon production plans, minimizing bottlenecks and

enhancing throughput.

Academic Experience

OPTIMIZATION OF 3D PRINTING PARAMETERS USING DOE TECHNIQUES January 2022 – June 2023

Use of DOE to optimize 3d printing parameters for enhanced performance, aesthetic and reduced resource waste.

Lead Researcher

– Designed and executed a process optimization project that resulted in a reduction in production time while

maintaining product quality and zero-waste.

– Lead successful Final Year Project securing 3rd position in Department for outstanding work in sustainability.

– Published research as a Conference Paper on Springer, highlighting dedication to 3D printing advancements.

– Secured funds from Ignite - National Technology Fund for project support.

SITTING MADE EASY: CRAFTED FOR 95% COMFORT

HEMP HAVEN: REVOLUTIONIZING DIAPERS WITH ECO-FRIENDLY HEMP FIBERS

Extracurricular & Volunteer Experience

UET ASME SOCIETY August 2021 - February 2022

– Graphic Designer Head: Volunteer with JSS (Jalozai Sports Society) and LDS (Literary and Debating Society). Created

posters, logos, and certificates for JC-ARENA_2022 Event held at UET Peshawar Jalozai Campus.

Honors and Awards

EHSAS SCHOLARSHIP March 2020 – March 2023

LEAN SIX SIGMA GREEN BELT - ALISON August 2023

PROJECT MANAGEMENT CERTIFICATION – COURSERA June 2022

Skills

– Proficient in AutoCAD & Excel

– Production Planning and Scheduling

– Process Optimization and Efficiency Enhancement

– Resource Allocation and Capacity Planning

– Cross-Functional Collaboration

– Root Cause Analysis

– Standard Allowed Minutes (SAM) Calculation

– Continuous Improvement Strategies

– Cost saving and waste elimination, Data Analysis, Lean Manufacturing, 6S Implementation, Kaizen

Methodology, Time Line Balancing, Layout and work method designing, Flexible and Adaptive, Analytical

Skills, Decision Making Skills

Languages

– English (Expert)

You might also like

- Resume-M. AsadDocument1 pageResume-M. AsadAsad QureshiNo ratings yet

- Haxan Resume 2Document2 pagesHaxan Resume 2Asad UllahNo ratings yet

- Contoh CV ATSDocument5 pagesContoh CV ATSZakka Junior Part INo ratings yet

- Abdul Wahab - ResumeDocument2 pagesAbdul Wahab - ResumeAbdul WahabNo ratings yet

- Resume Mohit PatelDocument1 pageResume Mohit PatelJas RandheyNo ratings yet

- Kevin Patel's Resume 2MBDocument2 pagesKevin Patel's Resume 2MBAryan GuptaNo ratings yet

- Project Coordinator AUG 2023Document3 pagesProject Coordinator AUG 2023ezechukwu tochukwu brightNo ratings yet

- MD Emtiaj ResumeDocument1 pageMD Emtiaj ResumeEmtiaj MahmudNo ratings yet

- BgoGA2kB8S ShubhamWakalkar 2023MBA155 OpsDocument1 pageBgoGA2kB8S ShubhamWakalkar 2023MBA155 OpsShubham WakalkarNo ratings yet

- RT67UHBNJIJNDocument2 pagesRT67UHBNJIJNSPECTRUM DRIILING TOOLS INTERNATIONALNo ratings yet

- Abdul Mateen - Resume PDFDocument1 pageAbdul Mateen - Resume PDFPuyish KumarNo ratings yet

- Sample ResumeDocument1 pageSample ResumetasnimNo ratings yet

- Praveen KumarDocument1 pagePraveen KumarpraveenkumarnitkkrNo ratings yet

- Abdul Wahab - Resume (Velosi)Document2 pagesAbdul Wahab - Resume (Velosi)Abdul WahabNo ratings yet

- Umasudhan Updated 1Document1 pageUmasudhan Updated 1Prashant PandeyNo ratings yet

- Devansh Bhardwaj BITSG23+Document1 pageDevansh Bhardwaj BITSG23+Devansh BhardwajNo ratings yet

- Ali Hasan: Areas of Strengths and SkillsDocument3 pagesAli Hasan: Areas of Strengths and SkillsAdnan Ahmed KidwaiNo ratings yet

- Harsh Gupta - Resume-4Document1 pageHarsh Gupta - Resume-4abhinavNo ratings yet

- Bineet Seal Resume For InternshipDocument1 pageBineet Seal Resume For InternshipAbhijeet PatilNo ratings yet

- Ahmed Hassan - : Chemical Engineer (PEC Registered)Document3 pagesAhmed Hassan - : Chemical Engineer (PEC Registered)Engr AhmedNo ratings yet

- Chirag ChengappaDocument2 pagesChirag ChengappaHARISH YESHODANo ratings yet

- Geral Midyen: Work ExperiencesDocument1 pageGeral Midyen: Work Experiencesgeral midyenNo ratings yet

- Mohd Azmeer Bin Mohamad Asri: QualificationsDocument6 pagesMohd Azmeer Bin Mohamad Asri: QualificationsMaisarah AsriNo ratings yet

- Mohammad Iqbal Ismawan - CVDocument4 pagesMohammad Iqbal Ismawan - CVIqbal IsmawanNo ratings yet

- Resume Muhammad AmmadDocument3 pagesResume Muhammad AmmadrizyasNo ratings yet

- Mustaqeem Sajid 18-01-2023 Creative AssociateDocument2 pagesMustaqeem Sajid 18-01-2023 Creative AssociateMustaqeem SajidNo ratings yet

- Muhammad Ashir: Work ExperienceDocument4 pagesMuhammad Ashir: Work ExperienceMuhammad AshirNo ratings yet

- Aina Nurshahiera Binti Abdul Hakim - ResumeDocument2 pagesAina Nurshahiera Binti Abdul Hakim - ResumeIrfanNo ratings yet

- CV of Masiv Al Hasan, PlanningDocument1 pageCV of Masiv Al Hasan, PlanningMasiv Al HasanNo ratings yet

- MBA22002 AakashDeepDocument1 pageMBA22002 AakashDeepAAKASH DEEPNo ratings yet

- Production Engineer-2Document4 pagesProduction Engineer-2Farhan SaghirNo ratings yet

- Suraj S Nair FinalDocument1 pageSuraj S Nair Finalsuraj nairNo ratings yet

- Abhishek KumarDocument1 pageAbhishek Kumarparitosh kumarNo ratings yet

- 0editedbishalghataneyresume2022 2023pdfDocument1 page0editedbishalghataneyresume2022 2023pdfapi-697327881No ratings yet

- Shah Dhruvil Vipulbhai - NITIEDocument1 pageShah Dhruvil Vipulbhai - NITIEDeep kardaniNo ratings yet

- Manveen Kaur ResumeDocument1 pageManveen Kaur ResumeSaiPraneethNo ratings yet

- Rachit Gupta CV PDFDocument2 pagesRachit Gupta CV PDFVinay KumarNo ratings yet

- Rachit Gupta CV PDFDocument2 pagesRachit Gupta CV PDFVinay KumarNo ratings yet

- SS Auddy - IIFMDocument1 pageSS Auddy - IIFMKunal PurohitNo ratings yet

- CVArshad 98Document3 pagesCVArshad 98Arshad AliNo ratings yet

- Engr - Tayyab ZafarDocument3 pagesEngr - Tayyab ZafarTayyabNo ratings yet

- Syed Azeen Ahmed: Professional ExperienceDocument1 pageSyed Azeen Ahmed: Professional ExperienceIffatNo ratings yet

- Cv-Ryan WarisDocument1 pageCv-Ryan Warisaakh.med.aaliii69No ratings yet

- IIT Ropar CV Template 4Document1 pageIIT Ropar CV Template 4unnati singhNo ratings yet

- Ahmed Hassan CV UPDocument2 pagesAhmed Hassan CV UPenggahmed27No ratings yet

- Md. Rafsunjani: Industrial & Production EngineerDocument2 pagesMd. Rafsunjani: Industrial & Production EngineerShahriar AbirNo ratings yet

- Adil-Mallick MechanicalDocument1 pageAdil-Mallick MechanicalAdil MallickNo ratings yet

- USMAN CV MFG Mech Engr13Document2 pagesUSMAN CV MFG Mech Engr13Digital InfoNo ratings yet

- Joseph Uthiriam: AccomplishmentsDocument3 pagesJoseph Uthiriam: AccomplishmentsJoseph UthiriamNo ratings yet

- Munzir Resume.Document1 pageMunzir Resume.Ali HaiderNo ratings yet

- Final CV Mohiiuddin Munna PDFDocument3 pagesFinal CV Mohiiuddin Munna PDFraiyanduNo ratings yet

- Tumuluri Sarath Chandra Resume V4Document1 pageTumuluri Sarath Chandra Resume V4Sarath ChandraNo ratings yet

- Mohd Azmeer Bin Mohamad Asri: QualificationsDocument5 pagesMohd Azmeer Bin Mohamad Asri: QualificationsMaisarah AsriNo ratings yet

- Paritosh Kumar - DR Reddys - NITIEDocument1 pageParitosh Kumar - DR Reddys - NITIEparitosh kumarNo ratings yet

- Rushikesh YadgirikarDocument1 pageRushikesh YadgirikarGanoba 444No ratings yet

- Kunal WaghchoureDocument2 pagesKunal WaghchouresatyajitlNo ratings yet

- CV BhavaniDocument1 pageCV BhavaniBhavaniShankarNo ratings yet

- Md. Asaad SDocument2 pagesMd. Asaad STimothy King LincolnNo ratings yet

- Education: LinkedinDocument2 pagesEducation: LinkedinTanay MaheshwariNo ratings yet

- Motorized Screw JackDocument19 pagesMotorized Screw JackPushpendra Kumar33% (3)

- Basic of SoundDocument54 pagesBasic of SoundRoslina Jaafar75% (4)

- Compact NSX Lv432677Document3 pagesCompact NSX Lv432677Dhiki KurniawanNo ratings yet

- Psur-Sscp UnterschiedeDocument14 pagesPsur-Sscp UnterschiedewNo ratings yet

- Platform Size 350x350 MM: Easy System IntegrationDocument4 pagesPlatform Size 350x350 MM: Easy System IntegrationHuy VũNo ratings yet

- Plagarisim Report1Document54 pagesPlagarisim Report1Maulik JainNo ratings yet

- Introduction To ProgrammingDocument20 pagesIntroduction To ProgrammingJohnBenedictRazNo ratings yet

- Weigh Bridge Truck Out Finding ReportDocument6 pagesWeigh Bridge Truck Out Finding Reportbee398No ratings yet

- H1 Bent-Axis Motor: Customer / ApplicationDocument1 pageH1 Bent-Axis Motor: Customer / ApplicationRodrigues de OliveiraNo ratings yet

- LW SeriesDocument8 pagesLW SeriesAbraham AutomationNo ratings yet

- Building Management Systems For Pharma, Healthcare & Life SciencesDocument12 pagesBuilding Management Systems For Pharma, Healthcare & Life Sciencesdubaisrinivasulu100% (1)

- Flygt 2620 EnglishDocument2 pagesFlygt 2620 Englishedwin martinezNo ratings yet

- 2021 Campus Selection Process & EligibilityDocument1 page2021 Campus Selection Process & EligibilityNishant KumarNo ratings yet

- ISAA HoA4 (Unit-5)Document10 pagesISAA HoA4 (Unit-5)052 Deepak NaralaNo ratings yet

- MC Lab Manual PDFDocument48 pagesMC Lab Manual PDFShivamPradhanNo ratings yet

- Katalog MCCB Terasaki S160-SCJ Data SheetDocument3 pagesKatalog MCCB Terasaki S160-SCJ Data SheetanitaNo ratings yet

- Interaction DesignDocument3 pagesInteraction DesignRahatoooNo ratings yet

- Migration ToolkitDocument124 pagesMigration Toolkitdaruwin cristianNo ratings yet

- DS 20230511 ST2236UX Datasheet V16 ENDocument2 pagesDS 20230511 ST2236UX Datasheet V16 ENMazhr HamzaNo ratings yet

- Sample ResumeDocument2 pagesSample ResumeJackkyNo ratings yet

- FTTX Technology ReportDocument48 pagesFTTX Technology ReportanadiguptaNo ratings yet

- Pcan-Usb Userman EngDocument29 pagesPcan-Usb Userman EngantidoteunrealNo ratings yet

- CRM in Russia and U.S. - Case Study From American Financial Service IndustryDocument40 pagesCRM in Russia and U.S. - Case Study From American Financial Service IndustryebabjiNo ratings yet

- 7) Progress PaymentDocument5 pages7) Progress Paymentkerwin jayNo ratings yet

- Electromechanical Test MachinesDocument2 pagesElectromechanical Test Machinesapi-254876696No ratings yet

- Resonance Electrical CircuitsDocument3 pagesResonance Electrical CircuitsdllabarreNo ratings yet

- Agnes CVDocument3 pagesAgnes CVMaziwa ProNo ratings yet

- Hardware Reference Guide: Small Form Factor Models Compaq Evo Desktop FamilyDocument63 pagesHardware Reference Guide: Small Form Factor Models Compaq Evo Desktop FamilySébastien MunozNo ratings yet

- Course Allocation For First Semester 2017/2018 SessionDocument9 pagesCourse Allocation For First Semester 2017/2018 SessionlivityhotNo ratings yet

- GK500 ManualDocument14 pagesGK500 ManualDox BachmidNo ratings yet