Professional Documents

Culture Documents

ST 1

Uploaded by

Grace Candelario ArellanoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ST 1

Uploaded by

Grace Candelario ArellanoCopyright:

Available Formats

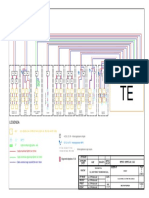

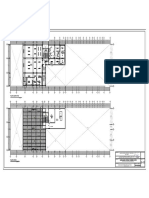

3.20 3.00 3.15 3.00 3.00 3.00 3.15 3.00 3.

20

GB1 GB1 GB1 GB1 GB1 GB1 GB1 GB1 GB1

C1 C1 C1 C1 C1 C1 C1 C1 2.30

F-1 F-1 F-1 F-1 F-1 F-1 F-1 F-1 F-2

C2

2.45

GB1 GB1 GB1 GB1 GB1 GB1 GB1 GB1 GB1

GB1 GB1 GB1 GB1 GB1 GB1 GB1 GB1 GB1

F-SAH

1.65

150 MM thk. CONCRETE SLAB

ON GRADE w/ 12mm RSB

CONSTRUCTION AND SUPPLY

SPACED @ 0.20m O.C.

C1 150 MM thk. CONCRETE SLAB

ON GRADE w/ 12mm RSB C1

3.60

SPACED @ 0.20m O.C.

F-1 F-1

C2

7.30

2.40

GB1 GB1 GB1 GB1 GB1 GB1 GB1 GB1 GB1 F-2

1.65

GB1

GB1 GB1 GB1 GB1 GB1 GB1 GB1 GB1

C1

C1 C1 C1 C1 C1 C1 C1 C1 C2

F-1 F-2

F-1 F-1 F-1 F-1 F-1 F-1 F-1 F-1

GB1 GB1 GB1 GB1 GB1 GB1 GB1 GB1

2.45

2.45

GB1 2.60

GB1 GB1 GB1 GB1 GB1 GB1 GB1 GB1

C1 C1

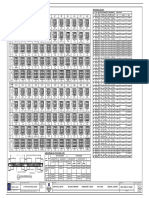

GENERAL CONSTRUCTION NOTES

F-1 F-1

1.0 STANDARDS AND REFERENCES

THE FOLLOWING SHALL GOVERN THE DESIGN FABRICATION AND CONSTRUCTION OF 3.00 3.00 3.15 3.00 3.20

THE PROJECT. 1.1 NATIONAL STRUCTURAL CODE OF THE PHILIPPINES (N.S.C.P 2015) VOL. 1, SEVENTH EDITION. 3.20 3.00 3.15 3.00

2.0 DESIGN CRITERIA

2.1 LOADINGS

A. DEAD LOAD

CONCRETE 23.56kN/m³

STEEL 76.97kN/m³

150mm THK. CHB WALL 2.73 kPa

100mm THK. CHB WALL 2.11 kPa

B. LIVE LOAD

C.

FLOOR AREA

WIND LOAD

BUILDING CATEGORY = 4 ( NON ESSENTIAL FACILITIES )

EXPOSURE = D (FLAT, UNOBSTRUCTED AREAS AND WATER SURFACES)

1.90 KPA

NOTES ON CONCRETE MIXES & PLACING

1. ALL CONCRETE SHALL DEVELOP A MIN. COMPRSSIVE STRENGTH AT THE END OF TWENTY EIGHT (28) DAYS

W/ CORRESPONDING MAXIMUM SIZE AGGREGATE & SLUMP AS FOLLOWS

SWIMMING POOL

MAXIMUM WIND VELOCITY, V = 250 KPH

MAX. SIZE OF

P = qh [(GCpf) - (GCpi)] ( DESIGN WIND PRESSURE) LOCATION 28 DAYS STRENGTH AGGREGATE MAX SLUMP

AMAIA STEPS

D. SEISMIC LOAD

WHERE: qh = VELOCITY PRESSURE (kPa)

V=Cvl

RT W

GCpf = EXTERNAL PRESSURE COEFFICIENT

GCpf = INTERNAL PRESSURE COEFFICIENT

V=2.50Cal

RT W

(DESIGN BASE SHEAR)

V=0.11 CalW

V=0.80ZNVLW (ZONE 4)

ALL OTHERS, INCLUDING

SUSPENDED SLABS

COLUMNS

BEAMS, SLABS

SLAB ON FILL

2. MAINTAIN MINIMUM CONCRETE COVER FOR REINFORCING STEEL AS FOLLOWS.

SUSPENDED SLABS

3000 PSI (21 MPa)

3000 PSI (21 MPa)

3000 PSI (21 MPa)

2500 PSI (17.5 MPa)

20mm

20mm

20mm

20mm

100mm

100mm

100mm

100mm

20mm

1 FOUNDATION PLAN JUNCTION

S 1

R

SCALE

SLAB ON GRADE 40mm

WHERE: W = TOTAL DEAD LOAD

T = NATURAL PERIOD = Ct (h)

WHERE: C = NUMERICAL COEFFICIENT

WALLS ABOVE THE GRADE

BEAM STIRRUPS AND COLUMN TIES

25mm 1:80 MTS

h = BUILDING HEIGHT WHERE CONCRETE IS EXPOSED TO 40mm

I = IMPORTANCE FACTOR = 1.00 EARTH BUT POURED AGAINST FORMS

R = NUMERICAL FCACTOR = 8.50 WHERE CONCRETE IS DEPOSITED 50mm

SEISMIC COEFFICIENT Cv = 0.42 Nv DIRECTLY AGAINST EARTH 75mm

Ca = 0.64 Nv

NEAR SOURCE FACTOR (15km) Nv = 1.0 3. CONCRETE SHALL BE DEPOSITED IN ITS FINAL POSITION WITHOUT SEGREGATION. RE-HANDLING

Na = 1.0

OR PLACING SHALL BE DONE PREFERABLY WITH BUGGIES, BUCKETS OR WHEELBARROWS.

Z = SEISMIC ZONE = 0.40 (ZONE 4)

S = SOIL TYPE = D NO CHUTES WILL BE ALLOWED EXCEPT TO TRANSFER CONCRETE FROM HOPPERS TO BUGGIES,

WHEELBARROWS OR BUCKETS IN WHICH CASE THEY SHALL NOT EXCEED SIX (6) METERS

2.2 DESIGN STRESSES IN AGGREGATE LENGTH.

A. CONCRETE COMPRESSIVE STRENGTH @ 28 DAYS:

a. FOOTINGS, COLUMNS, BEAMS AND SLABS fc = 21MPa (3,000 psi) 4. NO DEPOSITING OF CONCRETE SHALL BE ALLOWED WITHOUT THE USE OF VIBRATORS UNLESS

AUTHORIZED IN WRITING BY THE DESIGNER AND ONLY FOR UNUSUAL CONDITIONS WHERE VIBRATIONS

b. SLAB ON FILL

B. REINFORCING STEEL BARS

fc = 17.5MPa (2,500 psi)

ARE EXTREMELY DIFFICULT TO ACCOMPLISH.

5. ALL ANCHOR BOLTS, DOWELS, AND OTHER INSERTS SHALL BE PROPERLY POSITIONED & SECURED

NOVALICHES QUEZON CITY

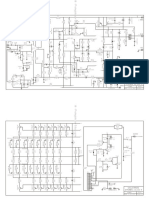

COLUMN SCHEDULE

a. FOR BARS 16mm AND GREATER (STRUCTURAL GRADE DEFORMED BAR) fy = 275 MPa (40,000 psi) IN PLACE PRIOR TO PLACING OF CONCRETE.

b. FOR BARS LESS THAN 16mm (STRUCTURAL GRADE DEFORMED BAR) fy = 275 MPa (40,000 psi)

6. ALL CONCRETE SHALL BE KEPT MOST FOR A MINIMUM OF SEVEN CONSECUTIVE DAYS IMMEDIATELY

C. STRUCTURAL STEEL ASTM-A36 AFTER POURING BY THE USE

FOR TRUSSES, BRACINGS & STRUTS fy = 248 MPa (36,000 psi) 7. STRIPPING OF FORMS AND SHORES:

FOUNDATION 24 HOURS

D. PURLINS

COLD FORMED LIGHT fy = 248 MPa (36,000 psi)

SUSPENDED SLAB EXCEPT WHEN

ADDITIONAL LOADS ARE IMPOSED

8 DAYS

TIE BAR 2 LEGS

E. MASONRY UNIT (CHB) WALLS 21 DAYS

BEAMS 14 DAYS

F.

NON-LOADING BEARING CHB WALLS

WELDS

fm' = 2.07MPa (300 psi)

E - 60XX ELECTRODE

COLUMNS 21 DAYS

8. THE CONTRACTOR OR PROJECT IN-CHARGE SHALL SUBMIT THE SCHEDULE OF POURING OF CONCRETE JOINTS

NAME SECTION NAME SECTION NAME

G. STRUCTURAL BOLTS ASTM A-307 a. Ft = 96.60 mPa (14,000 psi) TO THE STRUCTURAL ENGINEER AT LEAST (4) DAYS PRIOR TO THE POURING FOR APPROVAL.

b. Fv = 69.00 mPa (10,000 psi) 9. THE CONTRACTOR SHALL FURNISH AND MAINTAIN ADEQUATE FORMS AND SHORINGS UNTIL THE C-1 C-2 C-2

BEAM SCHEDULE

CONCRETE MEMBERS HAVE ATTAINED THEIR WORKING CONDITION AND STRENGTH.

3.0 IN THE INTERPRETATION OF THE DRAWING, INDICATED DIMENSIONS SHALL

10. THE CONTRACTOR OR PROJECT IN-CHARGE SHALL MAINTAIN CONCRETE POUR CARD

FOUNDATION FOUNDATION FFL

AMAIA LAND CORP.

GOVERN.DISTANCES AND SIZES SHALL NOT BE SCALED FOR CONSTRUCTIONS PURPOSES.

INSPECTION CHECKLIST, CONCRETE POUR MAP FOR EACH SCHEDULED POURING.

4.0 IN REFERENCES TO THE OTHER DRAWINGS, SEE ARCHITECTURAL DRAWINGS FOR

DEPRESSIONS IN FLOOR SLABS, OPENINGS IN THE WALLS AND SLABS, INTERIOR

PARTITIONS, LOCATIONS OF DRAINS ETC.

NOTES ON FOOTINGS: TO TO TO

1. FOOTINGS ARE DESIGNED FOR AN ALLOWANCE SOIL BEARING PRESSURE OF 150 KPa.

5.0 IN CASE OF DISCREPANCIES AS TO THE LAYOUT, DIMENSIONS, AND ELEVATIONS

BETWEEN THE STRUCTURAL PLANS AND ARCHITECTURAL DRAWINGS, THE CONTRACTOR

CONTRACTOR SHALL REPORT TO THE ENGINEER, IN WRITING, THE ACTUAL SOIL CONDITIONS

UNCOVERED AND CONFIRM ACTUAL BEARING CAPACITY OF SOIL BEFORE DEPOSITING CONCRETE.

FFL FFL ROOF BEAM

SHALL NOTIFY BOTH THE STRUCTURAL ENGINEER AND ARCHITECTS. 2. FOOTING SHALL REST AT LEAST 2000mm BELOW NATURAL GRADE LINE UNLESS OTHERWISE

INDICATED IN PLANS. NO FOOTING SHALL REST ON FILL.

6.0 ALL CONCRETE WORKS AND CONCRETE REINFORCEMENTS SHALL BE DONE IN 3. MINIMUM CONCRETE PROTECTION FOR REINFORCEMENT SHALL BE 75mm CLEAR FOR CONCRETE

ACCORDANCE WITH THE ACI.318 95 BUILDING CODE REQUIREMENT AND ALL

STRUCTURAL STEEL WORKS ACCORDING WITH THE AISC SPECIFICATION (9TH EDITION)

DEPOSITED THE GROUND AND 50mm FOR CONCRETE DEPOSITED AGAINST A FRAMEWORK.

4. IN CASES WHERE THE SOIL CONDITION IS SUCH THAT THE MINIMUM ALLOWABLE SOIL PRESSURE NAME AT SUPPORTS AT MIDSPAN

IN SO FAR AS THEY DO NOT CONFLICT WITH THE LOCAL BUILDING CODE OF 96KPa (2000 psi) CAN NOT BE ATTAINED AT A PRACTICAL DEPTHS THE USE OF MICROPILES,

REQUIREMENT. BORED PILES, OR DRIVEN PILES MAY BE ADOPTED IN LIEU OF STANDARD ISOLATED FOOTINGS.

7.0 ACI REFERS TO AMERICAN CONCRETE INSTITUTE, AISC REFERS TO AMERICAN

NOTES ON REINFORCEMENT:

GB1

INSTITUTE OF STEEL CONSTRUCTION AND ASTM REFERS TO AMERICAN SOCIETY FOR

TESTING MATERIALS.

(200 x 300 ) (150 x 250 ) (150 x 250 )

1. UNLESS OTHERWISE NOTED IN PLANS, THE YIELD STRENGTH OF REINFORCING BARS SHALL BE:

A. FOOTINGS, FOOTING BEAMS AND GIRDERS

8.0 CONSTRUCTION NOTES AND TYPICAL DETAILS APPLY TO ALL DRAWINGS UNLESS

OTHERWISE SHOWN OR NOTED. MODIFY TYPICAL DETAILS AS DIRECTED TO MEET

B. COLUMNS AND SHEAR WALLS

C. BEAMS AND GIRDER

MAIN BAR-1 4-D16 MAIN BAR-1 4-D16 MAIN BAR-1

SPECIAL CONDITIONS. D. NON-LOAD BEARING WALL PARTITIONS, BEDDED SLABS, FLOOR & ROOF SLABS,

9.0 SHOP DRAWING WITH ERECTION AND PLACING DIAGRAMS OF ALL STRUCTURAL

STEELS, MISCELLANEOUS IRON, PRE-CAST CONCRETE, ETC. SHALL BE SUBMITTED FOR

PARAPETS, CATCH BASIN, SIDE WALK MAIN BAR-2 2-D12 MAIN BAR-2 2-D12 MAIN BAR-2

2. ALL REINFORCING BARS SIZE 10mm OR LARGER SHALL BE DEFORMED IN ACCORDANCE WITH THE ASTM

ENGINEERS APPROVAL BEFORE FABRICATION.

10. CONTRACTOR SHALL NOTE AND PROVIDE ALL MISCELLANEOUS CURBS, SILLS,

A-706 BARS SMALLER THAN 10mm MAY BE PLAIN.

3. SPLICES SHALL BE SECURELY WIRED TOGETHER & SHALL LAP OR EXTEND IN ACCORDANCE w/ TABLE B

MAIN BAR-3 - MAIN BAR-3 - MAIN BAR-3

(TABLE OF LAP SPLICE & ANCHORAGE LENGTH) UNLESS OTHERWISE SHOWN ON DRAWINGS, SPLICES SHALL

STOOLS EQUIPMENT AND MECHANICAL BASES THAT ARE REQUIRED BY THE

ARCHITECTURAL, ELECTRICAL AND MECHANICAL DRAWNGS. BE STAGGERED WHENEVER POSSIBLE.

4. FABRICATOR SHALL SUBMIT BAR BENDING & CUTTING SCHEDULE FOR APPROVAL BY THE ENGINEER AND

TIE (MID) D10@150 TIE (MID) D10@150 TIE (MID)

OWNER PRIOR TO BENDING & CUTTING.

11. ALL RESULTS OF THE MATERIAL TESTING FOR CONCRETE, REINFORCING BARS &

TIE (END) TIE (END) TIE (END)

STRUCTURAL STEEL MUST BE NOTED & APPROVED BY THE MATERIALS ENGINEER/

1@50, 10@75 1@50, 10@75

STRUCTURAL DESIGNER.

(200x400)

TIE BAR 2 LEGS TIE BAR TOP BAR 2-d12 2-d16

NOTES ON CONCRETE SLABS:

1. ALL SLAB REINFORCEMENTS SHALL BE 20mm CLEAR MINIMUM FROM BOTTOM AND FROM THE TOP OF SLAB.

BOT BAR 4-d12 2-d16

CONF. REINF.

2. UNLESS OTHERWISE SHOWN, REINFORCEMENT IN OCNTINUOUS ELEVATED SLAB SHALL BE CUT AS FOLLOWS:

JOINT HOOP SPACE @ "2Sh" WHEN

BENT BAR THERE ARE BEAMS HAVING WIDTH OF

STIRRUP D10 1@ 50, 10@75 D10@150

CONF. REINF. D

L1 L2 AT LEAST ONE-HALF THE COLUMN

WIDTH & DEPTHS NOT LESS THAN

THREE QUARTERS OF THE DEEPEST

L 1/4 L 1/4 L 2/4

TOP BAR BEAM THAT FRAME INTO FOUR

SKIN BAR

SIDES OF THE COLUMN. ALL OTHER

FOOTING SCHEDULE SCHEDULE OF SLAB

D

CONDITIONS USE HOOPS @ "Sh" CENTERS.

CONF. REINF.

COMMENT

D

Sh

BOTTOM BAR

COLUMN TIES AS

PER SCHEDULE

3. IF SLABS ARE REINFORCED BOTHWAYS BARS ALONG THE SHORTER SPAN SHALL BE PLACED

BELOW THOSE ALONG THE LONG SPAN AT THE CENTER AND ABOVE THE LONGER SPAN FOR

FOR COL. BAR SPACES SEE TABLE

NAME AT SUPPORTS AT MIDSPAN

REINFORCING BARS NEAR THE SUPPORTS. THE SPACING OF THE BARS AT THE COLUMN STRIPS

TYPE "A"

OF MIN. LAP SPACE LENGTH OF

TYPE "A"

CONF. REINF.

SHALL NOT BE MORE THAN ONE (1) SLAB THICKNESS. COLUMN REINFORCEMENT

4. TEMPERATURE BARS FOR SLAB SHALL BE GENERALLY PLACED NEAR THE FACE IN TENSION AND

Ly GB2

CONF. REINF. D

SHALL NOT BE LESS THAN 0.0025 X GROSS-SECTIONAL AREA (Ag) OF THE SLAB.

Sh

(SEE SCHEDULE BELOW)

E.Q E.Q Ly

D

SCHEDULE OF MINIMUM SLAB REINFORCEMENT NOTE:

CONF. REINF.

ALL CONCRETE REINF. DETAIL SHOULD

MINIMUM TEMPERATURE BARS BE DONE IN ACCORDANCE WITH ACI

Lx/4 Ly-Lx/2 Lx/4

D

DETAILING MANUAL (LATEST EDITION)

AS SHOWN

100 mm 10 mm Ø @ 250mm EACH WAY

125 mm 10 mm Ø @ 250mm EACH WAY

150 mm

175 mm

10 mm Ø @ 250mm EACH WAY

10 mm Ø @ 250mm EACH WAY

X1

D

TYPICAL COLUMN ELEV. SHOWING

200 mm 10 mm Ø @ 250mm EACH WAY

DOWELS AND TIES SPACING Cy Y1

E.Q

5. UNLESS OTHERWISE NOTED IN THE PLANS ALL BEDDED SLABS SHALL BE REINFORCED WITH 10mm Ø

LAP SPLICE LENGTH:

AT 25mm O.C EACH WAY TO CENTER OF SLAB AND CONSTRUCTION JOINTS FOR SAME SHALL

Lx/4

AT ANY LEVEL NO MORE THAN

NOT BE LESS THAN 3.65 METER APART. ALTERNATE BARS SHOULD BE

6. PROVIDE EXTRA REINFORCEMENTS FOR CORNER SLAB ( TWO ADJACENT DISCONTINUOUS EDGES)

AS SHOWN BELOW.

SPLICED MIN. DISTANCE BET.

TWO ADJACENT BARS SPLICES

SHALL BE 600mm.

(150x400)

7. CONCRETE SLAB REINFORCEMENT BE PROPERLY SUPPORTE4D WITH 10mm. STEEL CHAIR Y2

OR APPROVED EQUIVALENT SPACED AT 1.0 METER ON CENTER BOTHWAYS. C

L Y1 TOP BAR 2-d12 2-d16

Cx

Lx

0.37

X2

Lx/2

IMPORTANT: THESE DRAWINGS AS INSTRUMENTS

DOWN INTO EDGE BEAM. EXTENDED

TYPE "B"

Lx

4-12Ø @ 1800 LONG TOP BARS BEND Ø12 X 1000 LONG AT

BARS MIN. OF 1,200 (4'-0") INTO BARS. L

4-d12 2-d16

MID-DEPTH OF SLAB

BOT BAR

4 - 12Ø BOTT. BARS

AT EACH CORNER

H (CLEAR HEIGHT OF COL.)

1-12Ø TOP & BOTT. BARS

WITHIN CENTER

Y3

OF SERVICE, ARE THE PROPERTY AND

HALF OF "H"

0.

60

SLAB

38mm

0.25L SPLICE

Y1

G.L STIRRUP D10 1@ 50, 10@75 D10@150

60

E.Q

OPENING

Lx/4

TOP BARS @ SUPPORT (CONT.)

0.

CLEAR

REQ'D BOTT. BARS @ SUPPORT

SKIN BAR DOCUMENTS OF THE ARCHITECT. IT SHALL BE

H

JT. REINF.

CONF. REINF. TIES LAT. TIES

IN TWO WAY SLAB EXTEND

BARS UP TO BEAM SUPPORT

0.

OMIT TRIMMER BARS WHERE

COMMENT

60

TYPICAL CORNER SLAB DETAIL

OPENING IS FRAMED BY BEAM

TYPICAL SLAB

X1 X1

UNLAWFUL FOR ANY PERSON WITHOUT THE

D

BOTTOM BARS

0.12

OPENING DET.

Y1

0.165L SPLICE

WRITTEN CONSENT OF THE ARCHITECT OF

AT MID SPAN

0.22L

EXTRA TOP BARS

X1 X3

NOTES ON COLUMNS @ SUPPORT

1. PROVIDE EXTRA SETS OF TIES AT 100 O.C FOR TIED COLUMN REINFORCEMENT ABOVE

AND BELOW BEAM-COLUMN CONNECTIONS FOR A DISTANCE FROM FACE OF CONNECTION TYPICAL DETAIL OF COL. LAP SPLICE

SPLICE = 1:3Ld

TOP BAR AUTHORS OF SAID DOCUMENTS, TO DUPLICATE

EQUAL TO GREATER OF THE OVERALL THICKNESS OF COLUMN, 61 THE CLEAR HEIGHT OF & EXT. GIRDER TO COL. CONNECT.

COLUMN OR 450mm.

2. COLUMN TIES SHALL BE PROTECTED EVERYWHERE BY A COVERING OF CONCRETE CAST

MONOLITHICALLY WITH THE CORE WITH A MINIMUM THICKNESS OF 40mm AND NOT LESS

BOTTOM BAR OR COPY SAID INSTRUMENTS

NOTES ON BEAMS AND GIRDERS

THAN 40 TIMES THE MAXIMUM SIZE OF COARSE AGGREGATE IN MILLIMETERS.

3. WHERE COLUMNS CHANGE IN SIZE, VERTICAL REINFORCEMENT SHALL BE OFFSET AT A 1. UNLESS OTHERWISE NOTED IN PLANS, CAMBER ALL BEAMS AND GIRDER AT FOOTING COLUMN REBAR

SLOPE MONOLITHICALLY WITH THE CORE WITH MINIMUM THICKNESS OF 40mm AND

LEAST 6mm FOR EVERY 4.50M OF SPAN, EXCEPT CANTILEVERS FOR WHICH

SOIL

NOT LESS THAN 40 TIMES THE MAXIMUM SIZE COARSE AGGREGATE IN MILLIMETERS.

THE CAMBER SHALL BE AS NOTED IN PLANS OR AS ORDERED BY THE ENGINEER

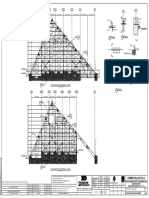

BUT IN NO CASE LESS THAN 20mm FOR EVERY 3.0M OF FREE SPAN. NAME TYP. CAPA. REMARK SHORT DIRECTION ( X ) LONG DIRECTION ( Y )

2. TYPICAL BARS BENDING AND CUTTING DETAILS FOR BEAMS SHALL BE AS

4. UNLESS OTHERWISE INDICATED IN THE PLANS, LAP SPLICES FOR VERTICAL COLUMN

SHOWN IN FIG. B-1 THK. Lx Ly Cx Cy X1 Y1 X2 Y2

REINFORCEMENT SHALL BE MADE WITHIN THE CENTER HALF OF COLUMN HEIGHT, AND

THE SPLICE LENGTH SHALL BE LESS THAN 40 BAR DIAMETERS. NAME TYPE THK.

H

L1 L2 D16 D16 X1 X2 X3 Y1 Y2 Y3

L1 31 L1 31 L2 31 L2 13 F-1 B 300 1200 1200 200 300 @200 @200 150 H=VARIES

350mm. MAX.

D12 D12 d12 d12 d12 d12 d12 d12

S-1 A 150

10

F-2 B 300 900 900 150 250 @150 @150 150 H=900 @200 @200 @200 @200 @200 @200

d

S-01

H

L1 51 L1 51 L2 51 L2 51

m

in

.

2 - 12mmØ SIDE BARS TOP BARS WEB BARS

BOTTOM BARS

FIGURE B-1

You might also like

- Turkey in The StrawDocument2 pagesTurkey in The StraweverestoNo ratings yet

- Diagrama Hidraulico 16-2050MDocument1 pageDiagrama Hidraulico 16-2050MFrancisco Martín Santay CanNo ratings yet

- Band I Tab C PDFDocument3 pagesBand I Tab C PDFMiguel Peirón ArturoNo ratings yet

- 1.2 Modulo A - Cortes ElevacionesDocument2 pages1.2 Modulo A - Cortes ElevacionesJack GomezNo ratings yet

- Circuit 5 - Iluminat de Siguranta CircuitDocument1 pageCircuit 5 - Iluminat de Siguranta CircuitDanut MarianNo ratings yet

- Tangos Diy1 TabDocument3 pagesTangos Diy1 Tabharryjones999No ratings yet

- Rpipl Up2 FP Ce DWG Misc 006Document1 pageRpipl Up2 FP Ce DWG Misc 006aaaaNo ratings yet

- SHD CSCEC 09 C11 ME PL 09 RF 00 0000 0000 01 (RF 屋面给水泵房图纸 R)Document1 pageSHD CSCEC 09 C11 ME PL 09 RF 00 0000 0000 01 (RF 屋面给水泵房图纸 R)Nabil HafazallaNo ratings yet

- Folklore Lucano 23 Brani PDFDocument35 pagesFolklore Lucano 23 Brani PDFPasquale Prencipe100% (1)

- STM32F407VET6 SchematicsDocument3 pagesSTM32F407VET6 SchematicsZafar Iqbal100% (2)

- STM32 F4ve Schematic PDFDocument3 pagesSTM32 F4ve Schematic PDFHau100% (3)

- 4100 0031 PDFDocument10 pages4100 0031 PDFsqamar68No ratings yet

- Dilermando Reis Noite de Lua3Document15 pagesDilermando Reis Noite de Lua3daniel nogaraNo ratings yet

- As Built: Jqs BuildersDocument4 pagesAs Built: Jqs BuildersGarlic FernandezNo ratings yet

- Cruel Tormento-PianoDocument4 pagesCruel Tormento-PianoJose MeloNo ratings yet

- To The Moon! (Score) (Noam Levy)Document14 pagesTo The Moon! (Score) (Noam Levy)qwertytrewNo ratings yet

- Dynamic 12000 H 2 OhmDocument8 pagesDynamic 12000 H 2 OhmMarcos SilvaNo ratings yet

- Dynamic 12000 H 2 OhmDocument8 pagesDynamic 12000 H 2 OhmEspedito Alves SilvaNo ratings yet

- Stormy Monday IIDocument3 pagesStormy Monday IIPhilippeNo ratings yet

- Lets Fall in Love. Vocal+FULL Big Band. Mandel. Frank-Sinatra-31Document1 pageLets Fall in Love. Vocal+FULL Big Band. Mandel. Frank-Sinatra-31Kiko MorenoNo ratings yet

- Dynamic 20000 H 2ohmDocument9 pagesDynamic 20000 H 2ohmEspedito Alves SilvaNo ratings yet

- Guitar Beginner Chord Study IIDocument2 pagesGuitar Beginner Chord Study IItom furdonNo ratings yet

- prancha-PRANCHA 4 - DET - BLOCOS E BALDRAMEDocument1 pageprancha-PRANCHA 4 - DET - BLOCOS E BALDRAMEPhelipe AlmeidaNo ratings yet

- TC 1424 Diagrama EsquematicoDocument1 pageTC 1424 Diagrama Esquematicomasava03No ratings yet

- Caja Nacional de Salud: Const. Oficinas Administrativas Camiri SCZDocument1 pageCaja Nacional de Salud: Const. Oficinas Administrativas Camiri SCZJohn STCNo ratings yet

- H.VCC: BSC29-N2420C T402Document1 pageH.VCC: BSC29-N2420C T402Aung HeinNo ratings yet

- El Anfitrion PianoDocument2 pagesEl Anfitrion PianoEmilce KucharukNo ratings yet

- XPROG-m - Schematic DiagramDocument2 pagesXPROG-m - Schematic DiagramAndrei67% (3)

- S3Document1 pageS3Christian Kyle BeltranNo ratings yet

- Ala Est Ep 02 For r00Document1 pageAla Est Ep 02 For r00Thaise OliveiraNo ratings yet

- !boogie Woogie LicksDocument1 page!boogie Woogie LicksAndrei AlNo ratings yet

- Astrid WaltzDocument2 pagesAstrid WaltzDrJuhász FerencNo ratings yet

- Haydn Sonata On Hao Staff (Available at HAOSTAFF - COM in Full)Document1 pageHaydn Sonata On Hao Staff (Available at HAOSTAFF - COM in Full)Jeff HaoNo ratings yet

- Hikix 2012 TableroDocument1 pageHikix 2012 TableroAlejandro carlos VargasNo ratings yet

- Icao Standard (Runway Safety Area)Document1 pageIcao Standard (Runway Safety Area)Pradeep KumaraNo ratings yet

- Planta Quinto Piso: Iglesia Alianza Cristiana Y Misionera Del PeruDocument1 pagePlanta Quinto Piso: Iglesia Alianza Cristiana Y Misionera Del PeruJuan Carlos Quispe HuaytallaNo ratings yet

- Political Map&Zoning 2017Document2 pagesPolitical Map&Zoning 2017Jun InabanganNo ratings yet

- Harmony of The Spheres: Bruno VicenteDocument4 pagesHarmony of The Spheres: Bruno VicenteJuan MendozaNo ratings yet

- 07 522213 4800000612 WSP SLT DRG 110001 - CDocument1 page07 522213 4800000612 WSP SLT DRG 110001 - CMOHD NAZEEF KHANNo ratings yet

- 1 2 A B C E D: H Bo EmtbDocument2 pages1 2 A B C E D: H Bo EmtbHoward RoarkNo ratings yet

- Planta Distribucion de Cielos Semisótano ESC. 1:300: IndicadaDocument1 pagePlanta Distribucion de Cielos Semisótano ESC. 1:300: Indicadasanti RoldánNo ratings yet

- AMAC-DE-TMI-2000-ES-DM - M10 - Rev 2Document1 pageAMAC-DE-TMI-2000-ES-DM - M10 - Rev 2ROGER FRANK VELEZ DE VILLA MEJIANo ratings yet

- CDPS90 Quickstartguide PTDocument2 pagesCDPS90 Quickstartguide PTAnderson BarbosaNo ratings yet

- Continuacion Columnas-ModeloDocument1 pageContinuacion Columnas-ModeloNicollDanielaNo ratings yet

- Pastor López: Trompeta en B 1Document1 pagePastor López: Trompeta en B 1Elkin NavarroNo ratings yet

- Canon (Pachelbel)Document2 pagesCanon (Pachelbel)valeria altamiranoNo ratings yet

- WWW - Vinafix.vn: Usb - RcaDocument1 pageWWW - Vinafix.vn: Usb - RcaNam NhiNo ratings yet

- Truss Details: A B C D E FDocument1 pageTruss Details: A B C D E Fjohn dale ibaleNo ratings yet

- Yes, WantDocument1 pageYes, WantSerafín LozanoNo ratings yet

- Tangos Diy2 TabDocument2 pagesTangos Diy2 Tabharryjones999No ratings yet

- Pci202h - Pci Pre 2 - Mp3000Document1 pagePci202h - Pci Pre 2 - Mp3000AdeniltonNo ratings yet

- Ecs 1GRDocument1 pageEcs 1GRrogerNo ratings yet

- 01 Ubicacion (Hoja A3)Document1 page01 Ubicacion (Hoja A3)Mixo De Los RiosNo ratings yet

- Etude 3 For ViolinDocument1 pageEtude 3 For ViolinGor HovhannisyanNo ratings yet

- Abstract Piece Part 1Document2 pagesAbstract Piece Part 1tomassauterNo ratings yet

- Cooling Fand Corolla 2010Document1 pageCooling Fand Corolla 2010Alfredo jose Medina revattaNo ratings yet

- Social Call Horns Voice-Tenor - SaxophoneDocument2 pagesSocial Call Horns Voice-Tenor - SaxophonewilliamNo ratings yet

- 8 Avanza: Front Fog Light (Before Aug. 2015 Production) Headlight (Before Aug. 2015 Production)Document1 page8 Avanza: Front Fog Light (Before Aug. 2015 Production) Headlight (Before Aug. 2015 Production)aritw541214No ratings yet

- Vivaldi - SummerDocument1 pageVivaldi - SummerAleJandro Fernández Rueda50% (2)

- Classics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoFrom EverandClassics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoRating: 3.5 out of 5 stars3.5/5 (14)

- Architecture, Science and Technology:: History Lecture CourseDocument10 pagesArchitecture, Science and Technology:: History Lecture Coursebisba66No ratings yet

- 8th Feb IG2 ReportDocument17 pages8th Feb IG2 ReportRashid Jamil100% (2)

- Sofonias Apartment BuildingDocument12 pagesSofonias Apartment BuildingGizachew BegnaNo ratings yet

- NSCPDocument53 pagesNSCPZaela EfronNo ratings yet

- Revised BAR Process Report - City of Charleston/DPZDocument49 pagesRevised BAR Process Report - City of Charleston/DPZCharlestonCityPaperNo ratings yet

- DSI ALWAG-Systems Pantex Lattice Girders EDocument8 pagesDSI ALWAG-Systems Pantex Lattice Girders Epramods_8No ratings yet

- Bridge BearingsDocument6 pagesBridge BearingsABHISHEK NAVGIRENo ratings yet

- AAC Blocks Vs Red BricksDocument34 pagesAAC Blocks Vs Red BricksRi SovannaphumiNo ratings yet

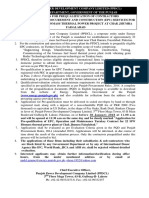

- PPDCL PQN Biomass FSD Ad 22122017Document1 pagePPDCL PQN Biomass FSD Ad 22122017WaleedNo ratings yet

- DeflectionDocument9 pagesDeflectionXet FatNo ratings yet

- Programme ExamplesDocument1 pageProgramme ExamplesJesús Rodríguez RodríguezNo ratings yet

- Costing Steelwork #1: Offices FocusDocument7 pagesCosting Steelwork #1: Offices FocusMathias OnosemuodeNo ratings yet

- Catalogo Dyl DualDocument2 pagesCatalogo Dyl DualadrianitoalaNo ratings yet

- D6R Series III Track-Type Tractor Hydraulic System: Pressure ManifoldDocument2 pagesD6R Series III Track-Type Tractor Hydraulic System: Pressure ManifoldchakrouneNo ratings yet

- Key Performance Indicators Drive Best Practices For General ContractorsDocument9 pagesKey Performance Indicators Drive Best Practices For General ContractorsMarcus Skookumchuck VanniniNo ratings yet

- Attachment-4 Bill of QuantityDocument1 pageAttachment-4 Bill of QuantitysparkCENo ratings yet

- WCTE2016 Special RothoblaasDocument72 pagesWCTE2016 Special RothoblaasnaresworoNo ratings yet

- Frond Flexiform PDFDocument3 pagesFrond Flexiform PDFzenislerNo ratings yet

- 2019 - 3.3 Projektovanje Zav. I Zalemljenog SpojaDocument21 pages2019 - 3.3 Projektovanje Zav. I Zalemljenog SpojaticmaNo ratings yet

- Soil NailingDocument306 pagesSoil NailingSanath Gamage100% (1)

- Operating Instructions: Sempell Series Vse/Vsr Full Lift and Normal Safety Relief ValveDocument16 pagesOperating Instructions: Sempell Series Vse/Vsr Full Lift and Normal Safety Relief Valveayman akrabNo ratings yet

- Kelani Cable - ArmouredDocument1 pageKelani Cable - Armouredsukiraj Rasalingam50% (2)

- 26 Type of Electrical Cables LT, HT, ST, EHT, PVC, XLPE, Oil, FlatDocument7 pages26 Type of Electrical Cables LT, HT, ST, EHT, PVC, XLPE, Oil, FlatSubbuNo ratings yet

- GPCDOC GTDS Shell Gadus S2 A320 2 (En) TDS PDFDocument2 pagesGPCDOC GTDS Shell Gadus S2 A320 2 (En) TDS PDFJako MishyNo ratings yet

- A1085 Pocket Reference Guide From Atlast TubeDocument17 pagesA1085 Pocket Reference Guide From Atlast TubeJoe RipaNo ratings yet

- Connection Design Standard Document PDFDocument47 pagesConnection Design Standard Document PDFclam2014No ratings yet

- Preboard Exam 1: Structural Engineering and ConstructionDocument6 pagesPreboard Exam 1: Structural Engineering and ConstructionEllen Bumal-oNo ratings yet

- PFC Newsletter July 2018Document34 pagesPFC Newsletter July 2018Sachin RaoNo ratings yet

- U07754QOSM - Project O & M Manual TemplateDocument12 pagesU07754QOSM - Project O & M Manual TemplateRithesh ShettyNo ratings yet

- FacadeSymposium Andrew Kiel PDFDocument127 pagesFacadeSymposium Andrew Kiel PDFMargarita KianidouNo ratings yet