Professional Documents

Culture Documents

OruDAY100 - 110 - 125 - 130B ENG

Uploaded by

harrykgs7Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OruDAY100 - 110 - 125 - 130B ENG

Uploaded by

harrykgs7Copyright:

Available Formats

HPS 2100-V MANAGEMENT AND CONTROL SYSTEMS

HPS 2100-V

Is a customised and automated software solution for the most advanced The basic hardware configuration includes a personal computer with an

concrete pre-packaging processes. Thanks to its user-friendly interface, LCD monitor as well as the peripheral devices needed to store and enter

the system is extremely simple to use. HPS 2100-V is the result of data. Microsoft Windows operating system is used, available in different

synergies between experience, technology and flexibility, all offered at languages. Real-time operation is ensured by the PLC.

the customer’s disposition.

MOBILE WET

ORU DAY MD 3000/2000_3750/2500_4500/3000_5000/3350

+ ORU LOGIK B4-B5

100

110

ORUDAY

125

130

MAXIMUM TRANSPORTABILITY

HIGH COMPACT

MAXIMUM RELIABILITY

QATAR

ORUDAY 100 110 125 130B ORU DAY 125B with LOGIK WB4 storage unit equipped with

ORU MD 4500/3000 horizontal twin shaft mixer.

Ideal for ready-mixed concrete production for construction

and structural works in sites that must guarantee

ORU DAY MD 3000/2000_3750/2500_4500/3000_5000/3350 + ORU LOGIK B4-B5 high performance.

Le Officine Riunite - Udine S.p.A. | Concrete Division

Via Santa Caterina, 35 Le Officine Riunite_Udine S.p.A. reserve the right to change the information

33030 Basaldella di Campoformido (Udine) - Italy containrd herein without prior notice when they consider it justified. The data

and dimensions are therefore not to be considered as binding. The illustrations

Tel. +39 0432 563911 - Fax +39 0432 562131 may include accessories and therefore they could be slightly different from the

oru@oru.it | imergroup.com standard versions of the equipment.

MOBILE WET ORUDAY 100_110_125_130B

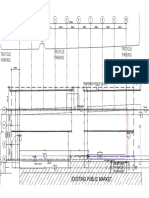

DISTINCTIVE FEATURES LAYOUT HORIZONTAL TWIN SHAFT MIXER

ORU MD 3000/2000_3750/2500_4500/3000_5000/3350

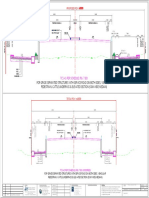

• MIXING UNIT WITH HORIZONTAL TWIN SHAFT

MIXER: POWER AND EFFICIENCY

ORUDAY 100_110_125_130B BELTUP

• PRE-ASSEMBLED AND PRE-WIRED MONOBLOCK

ORUDAY 100B ORUDAY 110B ORUDAY 125B ORUDAY 130B

THAT SIGNIFICANTLY REDUCES INSTALLATION AND

START UP TIME A 10700 10700 11700 11700

B 10200 10200 12100 12100

• MAXIMUM MOBILITY AND TRANSPORTABILITY C 36000 36000 37800 37800

• EXTREMELY VERSATILE FOR MEDIUM AND HIGH High capacity mixing bin

PRODUCTION CAPACITY PLANTS

• SIMPLE TO USE

ORUDAY 100_110_125_130 mixing unit B B 14200

14200 35503550 40004000

with built-in skip and cabin even during transport phases

LOGIK WL4 BELTUP storage unit

EASY TO TRANSPORT AND ASSEMBLE

4400

4400

ORUDAY 100/110 - LOGIK WB4 ORUDAY 125/130 - LOGIK WB4

Synchronised and alternating mixing axis rotation

BY ROAD

1 LOW BED TRUCK

BY ROAD

1 LOW BED TRUCK

A A 22002200 35503550 35503550 22002200 BELTUP WEIGHING BELT

+ 2 STANDARD TRUCKS (13,60M) + 2 STANDARD TRUCKS (13,60M)

• NO CONCRETE PILLARS

BY SEA BY SEA AND/OR SKIP PIT

1X40’ FR H=3250 + 1X40’ OT 1X40’ FR H=3250 + 2X40’ OT

+ 1X40’ OT H=2450 + 1X20’ OT H=2500 • LOW AGGREGATE LOADING POINT

Transport valid for the standard configuration

WITHOUT REDUCING CAPACITY

Automatic lubrication system equipped with 4 programmable

and independent pumps

• HORIZONTAL AGGREGATE WEIGHING

TECHNICAL CHARACTERISTICS - (Standard configuration) SYSTEM AND MAXIMUM CAPACITY

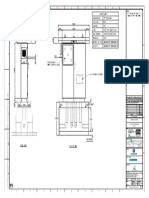

MIXER TECHNICAL DATA MAIN OPTIONAL ACCESSORIES

ORUDAY 100B ORUDAY 110B ORUDAY 125B ORUDAY 130B

3000/2000 3750/2500 4500/3000 5000/3350

Hourly production m 3/h 100 110 125 130 Load capacity l 3000 3750 4500 5000 • 600 HB WEAR-PROOF CAST IRON

ALLOY INTERNAL LINING

ORU LOGIK B

Batch capacity (vibrated concrete) m 3

2 2,5 3 3,35

Load capacity Kg 4740 5930 7100 7900

Power required kW 120 132 174 190 BELTUP WEIGHING BELTS

AGGREGATE STORAGE UNITS

Vibrated yield l 2000 2500 3000 3350

Twin shaft mixer mod ORUMD 3000/2000 ORUMD 3750/2500 ORUMD 4500/3000 ORUMD 5000/3350 • THICKER BLADES AND VERTICAL

Skip (speed) m/s 0,58 0,58 0,61 0,61

Cycle time sec. 55 60 65 70 PANELS Beltup

Max inert size mm 0-150 0-150 0-150 0-150 • MODULAR AND HIGH PERFORMANCE B4

Cement weighing hopper l 1600 1600 2000 2000

Mixing power kW 2x37 2x45 2x55 2x65 • AUTOMATIC HIGH PRESSURE • HEAT GALVANISED BINS AND FRAME WITH LARGE WIDTH AT Width (m) 1.00

Water weighing hopper l 800 800 1000 1000 C 3550

Mixing blades n. 12 16 20 20

CLEANING SYSTEM LOADING POINT Flow (m /h)

3

350

Weighing system (approved-Type) mod by load cells by load cells by load cells by load cells

Length (m) 16.60

Oil hydraulic unit kW 1.5 1.5 2.2 2.2 • MAXIMUM STORAGE CAPACITY AND LOW LOADING POINT

Aggregates storage (capacity) m3 96÷120 96÷120 96÷120 96÷120 • CONFIGURATIONS FOR EXTREME B5

Aggregates hygrometer probe (microwave) (recommended optional) mod PK-3 PK-3 PK-3 PK-3 Skip load capacity l 3000 3750 4500 5000 WEATHER CONDITIONS • LONGITUDINAL PANELS WITH HIGH INCLINATION AND VERTICAL

DIVIDERS Width (m) 1.00

Additives system (recommended optional) l/min 3x24 3x24 3x45 3x45 Standard skip speed m/min 35 35 37 37

Flow (m 3/h) 350

Electric compressor (recommended optional) mod B7000 B7000 B7000 B7000 Skip power kW 30 37 45 55 • DISCHARGE CONES AND AGGREGATE WEIGHING BINS LINED

Length (m) 20.10

Management unit mod HPS 2100V HPS 2100V HPS 2100V HPS 2100V

WITH INTERCHANGEABLE WEARING ELEMENTS

Weight Kg 7100 8200 9300 9500

You might also like

- OruDNK - 80 - 100 - 120 - 130 ENGDocument2 pagesOruDNK - 80 - 100 - 120 - 130 ENGharrykgs7No ratings yet

- ECIA - LEAD - TIME - BREAKDOWN - August 2020 PDFDocument2 pagesECIA - LEAD - TIME - BREAKDOWN - August 2020 PDFSHIVAM TOMAR MBA 2019-21 (Delhi)No ratings yet

- Elevation at A: Ramp Tire GuideDocument1 pageElevation at A: Ramp Tire GuideReynaldo CaingcoyNo ratings yet

- ZG AppDocument4 pagesZG AppAuyuNo ratings yet

- Plan Splice Detail of Rafter I-Beam Wall Footing DetailDocument1 pagePlan Splice Detail of Rafter I-Beam Wall Footing Detailzab04148114No ratings yet

- 2022 Highway Traffic Volume MapsDocument2 pages2022 Highway Traffic Volume MapsGyan KafleNo ratings yet

- Vibrating Grizzly Drawing P1566Document1 pageVibrating Grizzly Drawing P15663568No ratings yet

- Heavy duty lifting lug designDocument1 pageHeavy duty lifting lug design3568No ratings yet

- Typical Arrangement: Shaft Section B-BDocument1 pageTypical Arrangement: Shaft Section B-Bsumant giriNo ratings yet

- 2021 04 14 - Layout Plan - 230904 - 154256Document2 pages2021 04 14 - Layout Plan - 230904 - 154256nisha justofficeNo ratings yet

- TEMP FENCE - v1Document1 pageTEMP FENCE - v1Yosemite TecsonNo ratings yet

- Ick Work - Partition Layout (Third Floor)Document1 pageIck Work - Partition Layout (Third Floor)Shubham PokhriyalNo ratings yet

- Akrapovic Ducati Multistrada 1200-1200S-1200S Touring 10-12Document3 pagesAkrapovic Ducati Multistrada 1200-1200S-1200S Touring 10-12mcbuinNo ratings yet

- Gandhi Chouk to Manbharan Tiraha Road Survey MapDocument1 pageGandhi Chouk to Manbharan Tiraha Road Survey Mapshivshankar kushwahaNo ratings yet

- Client: Mr. Digvijay Vaidya Project Name: Vaidya's Shakuntal Heights Lift Details: G+5, Auto Door, Geared With Machine RoomDocument1 pageClient: Mr. Digvijay Vaidya Project Name: Vaidya's Shakuntal Heights Lift Details: G+5, Auto Door, Geared With Machine RoomRV OfficialNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHarish Kumar MahavarNo ratings yet

- School restroom floor planDocument1 pageSchool restroom floor planPorshia DimarucutNo ratings yet

- Precast Panel DetailsDocument1 pagePrecast Panel DetailsSimeon James Defeo VillacrusisNo ratings yet

- Adobe Scan 25 Dec 202Document1 pageAdobe Scan 25 Dec 202Jimit ShahNo ratings yet

- Elevation of Control RoomDocument1 pageElevation of Control RoomgohilnarendraNo ratings yet

- A12-01a - Level 01 - Part A (Reflected Ceiling Plan)Document1 pageA12-01a - Level 01 - Part A (Reflected Ceiling Plan)consultnadeem70No ratings yet

- 2 Plan Layout 240 KLD STP Based On SBR For NIA-ModelDocument1 page2 Plan Layout 240 KLD STP Based On SBR For NIA-ModelJaved HasanNo ratings yet

- A1 Production Building Laying HouseDocument1 pageA1 Production Building Laying HouseTeamagri Industrial CorporationNo ratings yet

- Left Side View Rear View Right Side View: SFL Soffit LVLDocument2 pagesLeft Side View Rear View Right Side View: SFL Soffit LVLHomer TiongcoNo ratings yet

- Service Cabinet Type A Basic General Arrangement DrawingDocument1 pageService Cabinet Type A Basic General Arrangement DrawingJericFuentesNo ratings yet

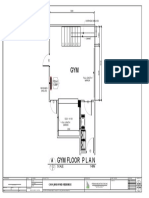

- Gymfloor Plan: Scale: 1:40M 1 2Document1 pageGymfloor Plan: Scale: 1:40M 1 2Joane ColipanoNo ratings yet

- Bridge No. XXXXXX: Plan and Elevation (Sheet 1 of 5)Document5 pagesBridge No. XXXXXX: Plan and Elevation (Sheet 1 of 5)Ana Maria Nina EstrellaNo ratings yet

- Ick Work - Partition Layout (First Floor)Document1 pageIck Work - Partition Layout (First Floor)Shubham PokhriyalNo ratings yet

- STANDARD_ULTRAPOLYLOK_GRAVITY_MSUG200_Rev.DDocument1 pageSTANDARD_ULTRAPOLYLOK_GRAVITY_MSUG200_Rev.DJohn Mark De Vera DiazNo ratings yet

- 2000 300 (For U/s)Document1 page2000 300 (For U/s)Mrinal kayalNo ratings yet

- GAD-1013Document1 pageGAD-1013RAJESHWARNo ratings yet

- Ax001 PDFDocument1 pageAx001 PDFAl Fakhamah LiftsNo ratings yet

- Status: Confidentiality Class Acc. To 1102 KDocument1 pageStatus: Confidentiality Class Acc. To 1102 KAbdellah IbrahimNo ratings yet

- Proposed Row 60000 Road Cross SectionDocument1 pageProposed Row 60000 Road Cross SectionDeepak_pethkar100% (1)

- Pre-cast ISMC 400x100 structural detailsDocument1 pagePre-cast ISMC 400x100 structural detailsses2003_kNo ratings yet

- Drawing1 Model PDFDocument1 pageDrawing1 Model PDFArshad AliNo ratings yet

- Puerta Rellano Central 2 Hojas 2 Panel Centre Parting Landing Door 40/10 DIN 18.091Document1 pagePuerta Rellano Central 2 Hojas 2 Panel Centre Parting Landing Door 40/10 DIN 18.091Osama OdehNo ratings yet

- GNC-Bathrooms-PlansDocument2 pagesGNC-Bathrooms-Plansakankshitha.kakinada045No ratings yet

- P-7 Miscellenaous DetailsDocument1 pageP-7 Miscellenaous DetailsarjayymerleNo ratings yet

- PT Catalog 2018 Pt8907 UsDocument284 pagesPT Catalog 2018 Pt8907 UsTrần Trung DũngNo ratings yet

- Plan A: Department of Public Works and Highways Regional Office 4 S100.0Document1 pagePlan A: Department of Public Works and Highways Regional Office 4 S100.0Adrian PachecoNo ratings yet

- 1028905951-01 - Desenho Dimensional CPM - BMDocument2 pages1028905951-01 - Desenho Dimensional CPM - BMgetdatamachinaNo ratings yet

- Typical Cross Section A-A From E-381 To E-418, E-458 To E-500Document1 pageTypical Cross Section A-A From E-381 To E-418, E-458 To E-500Rohit BandagaleNo ratings yet

- New Fender Anchor Bolt DetailDocument1 pageNew Fender Anchor Bolt Detailabdul chalikNo ratings yet

- Initial Pile Load Test Drawing-37+655-20-10-2023Document1 pageInitial Pile Load Test Drawing-37+655-20-10-2023Tanveer IqbalNo ratings yet

- L E G E N D: Casa Arellano HotelDocument1 pageL E G E N D: Casa Arellano Hotellagan2008No ratings yet

- Typical Layout of Telecobalt InstallationDocument1 pageTypical Layout of Telecobalt InstallationJaskarn SinghNo ratings yet

- DITO PH0600474 Candidate C 3GT-40-280C-Z DDD V5 14Document1 pageDITO PH0600474 Candidate C 3GT-40-280C-Z DDD V5 14rafael nazaretaNo ratings yet

- CPA 10-20 TM Dimension Drawing EN Pune 9097 5110 92-01Document1 pageCPA 10-20 TM Dimension Drawing EN Pune 9097 5110 92-01youcef alimNo ratings yet

- Daf3 CumDocument1 pageDaf3 CumKELVIN TECHNOLOGIESNo ratings yet

- 62-61118-04 Supra - 850 - 850MTDocument98 pages62-61118-04 Supra - 850 - 850MTJuan M Marín100% (1)

- Elevation (E-1) Elevation (E-2) Elevation (E-3) : Roof Plan PlanDocument1 pageElevation (E-1) Elevation (E-2) Elevation (E-3) : Roof Plan PlanRavi Kishore GadariNo ratings yet

- TR 500Document1 pageTR 500gbreelNo ratings yet

- De 725 P16 34002 Exe R0.1Document1 pageDe 725 P16 34002 Exe R0.1Edelson DuarteNo ratings yet

- Details of Septic Tank: Clean Out Details Catch Basin DetailsDocument1 pageDetails of Septic Tank: Clean Out Details Catch Basin DetailsMark Christian EsguerraNo ratings yet

- cross section 5Document1 pagecross section 5pravin awalkondeNo ratings yet

- Banglieng 3 - INTAKE - KM 1 ADocument4 pagesBanglieng 3 - INTAKE - KM 1 AK'm VPsNo ratings yet

- Proposal of Drilled Elements For The FloorDocument1 pageProposal of Drilled Elements For The FloorJulius SamacNo ratings yet

- 2015 PPL Workbook v2Document28 pages2015 PPL Workbook v2NeethNo ratings yet

- Clarke 1973 Loss of InnocenceDocument13 pagesClarke 1973 Loss of InnocencePaula TralmaNo ratings yet

- Dh76 Auto HemaDocument271 pagesDh76 Auto HemaJoshua NarvaezNo ratings yet

- Unit 1Document32 pagesUnit 1Viyat RupaparaNo ratings yet

- Ultra-compact Terrier drilling rig fits through standard doorwaysDocument8 pagesUltra-compact Terrier drilling rig fits through standard doorwaysjpantazis1975No ratings yet

- Parts List of Engine Assy Ofdz-00536Document1 pageParts List of Engine Assy Ofdz-00536CwsNo ratings yet

- 2020 FMGT 1013 - Financial Management RevisedDocument9 pages2020 FMGT 1013 - Financial Management RevisedYANIII12345No ratings yet

- Section 08500 - Windows: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocument7 pagesSection 08500 - Windows: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNo ratings yet

- Empowerment Is A Leadership TrickDocument10 pagesEmpowerment Is A Leadership TrickAura Carla TolentinoNo ratings yet

- Introduction To SQL Programming TechniquesDocument24 pagesIntroduction To SQL Programming Techniquesakashdeepime100% (2)

- Spraying TechniquesDocument12 pagesSpraying TechniquesX800XLNo ratings yet

- Surface Modification of Titanium Orthodontic ImplaDocument30 pagesSurface Modification of Titanium Orthodontic ImplaMary SmileNo ratings yet

- Grammar of The Mondial LanguageDocument63 pagesGrammar of The Mondial LanguageMithridates100% (1)

- Methanol from Syngas Plant DesignDocument13 pagesMethanol from Syngas Plant DesignKhalidMadaniNo ratings yet

- Next Best Action in An Omnichannel EnvironmentDocument40 pagesNext Best Action in An Omnichannel EnvironmentMadhu100% (2)

- BearingsDocument26 pagesBearingstmscorreiaNo ratings yet

- Ratio - Proportion - PercentDocument31 pagesRatio - Proportion - PercentRiyadh HaiderNo ratings yet

- MEL - Math 10C Item Writing - MC & NR ReviewDocument71 pagesMEL - Math 10C Item Writing - MC & NR ReviewMya TseNo ratings yet

- Iron Deficiency Anemia in ChildrenDocument27 pagesIron Deficiency Anemia in ChildrenAde Dinda WulandariNo ratings yet

- Name: K K ID#: Lab Partner: V S Date: Wednesday 22 Course Code: BIOL 2363 - Metabolism Title of Lab: Assay of Tissue GlycogenDocument7 pagesName: K K ID#: Lab Partner: V S Date: Wednesday 22 Course Code: BIOL 2363 - Metabolism Title of Lab: Assay of Tissue GlycogenKarina KhanNo ratings yet

- 1 A Simulation Based Model For The BerthDocument9 pages1 A Simulation Based Model For The Berthmonu_vitsNo ratings yet

- Guided Noteboo Kin GED10 2 (Mathe Matics in The Modern World)Document5 pagesGuided Noteboo Kin GED10 2 (Mathe Matics in The Modern World)Aaronie DeguNo ratings yet

- Detecting Voltage Differences Between Two Points With A Phase ComparatorDocument1 pageDetecting Voltage Differences Between Two Points With A Phase ComparatorContract 42154No ratings yet

- Anatolii PapanovDocument8 pagesAnatolii PapanovKyrademNo ratings yet

- HIST 1010 EXAM 3 TEST PREP (With Answers)Document2 pagesHIST 1010 EXAM 3 TEST PREP (With Answers)Ophelia ThorntonNo ratings yet

- Physics II Eight Chapter Wise TestDocument3 pagesPhysics II Eight Chapter Wise TestSyed Waqas AhmedNo ratings yet

- Final Class 8 Science 20230828084415550Document5 pagesFinal Class 8 Science 20230828084415550aryantomar5112No ratings yet

- Selected Questions Revised 20200305 2HRDocument3 pagesSelected Questions Revised 20200305 2HRTimmy LeeNo ratings yet

- Awfpc 2022Document7 pagesAwfpc 2022Jay-p BayonaNo ratings yet

- ADVANCED ANALOG IC DESIGN Lab ManualDocument27 pagesADVANCED ANALOG IC DESIGN Lab ManualJahnavi Ratnam0% (1)

- The Metacentric Height EX3Document3 pagesThe Metacentric Height EX3Edrees JamalNo ratings yet