Professional Documents

Culture Documents

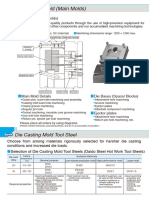

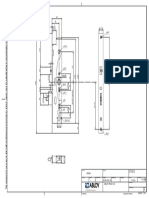

Drdiecast 2011jul

Uploaded by

sobheysaidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drdiecast 2011jul

Uploaded by

sobheysaidCopyright:

Available Formats

Dr.

Die

Cast

Can’t Someone Come Up With Some

New Problems to Solve?

Don’t forget the basics. Educating companies delivering castings at neer to place a specification on a

our customers. PPM levels that would have been print that has little to do with the

Most of my former employ- thought impossible only a few fit and function of the component.

ers became clients after I started years ago. Our customer’s qual- However that same feature may

consulting. One morning as we ity standards constantly increase, add significant cost to the tool-

were going through a daily pro- as they should. After all, we have ing and/or casting. One example

duction review meeting, I stopped yet to make perfect castings, at of overdesigning a casting would

and looked around the table at least in unlimited quantities at an have added approximately $25,000

the usual list of suspects and economical cost. to the cost of the tooling. I asked

said, “Isn’t anyone going to come What I am saying is that many the designer, “Is that feature

up with some new problems or of the castings that are labeled as really worth $25,000?” His initial

defects?” Sometimes it seems we’re defective today would have been answer was that it was absolutely

in “Groundhog Day,” where we deemed acceptable a few years ago. necessary. However, two weeks

re-live the same problems over and The levels of porosity or finish at later the feature had disap-

over again. Certainly they have which we operate today are much peared from the design. Had we

different names, part numbers and higher standards than provided in not brought it to his attention it

have moved to a different machine, previous years, but the definition would have remained on the print

operator or shift, but ultimately, or description remains unchanged, unchanged and pushed him over

the problems are the same. The therefore the comment, “They’re his budget and possibly killed the

common defects of porosity, miss- the same defect.” project for everyone. I find that

fill or distortion or some variation What is our response? As an most people are grateful for the

of the above abound. industry, we need to educate our input and education.

Please don’t misunderstand customers to the benefits but also When is the last time you helped

me. I’m not saying that we as the limitations of our processes. your customer reduce their cost and

an industry are stuck in some We oversell our companies when design better castings? Hopefully it

time warp unable or unwilling to we fail to thoroughly educate our was this week.

improve. We have improved in customers on the benefits but also Until next issue, have a great summer.

response to the demands of our the limitations and costs involved

customers for increasingly higher in meeting their specifications. It !

quality die castings. There are is not unusual for a design engi-

Who’s Dr. Die Cast? Bob McClintic & Associates rmcclintic@ameritech.net

Robert P. McClintic 2544 Almar St www.drdiecast.com

Die Casting Consultant Jenison, MI 49428-9108 (616) 669-2932

www.diecasting.org/dce July 2011 1DIE CASTING ENGINEER/ 11

You might also like

- The Scope Statement: How to Renovate Your Home without Breaking Your BudgetFrom EverandThe Scope Statement: How to Renovate Your Home without Breaking Your BudgetNo ratings yet

- A Complete Guide to Starting a Paintless Dent Repair BusinessFrom EverandA Complete Guide to Starting a Paintless Dent Repair BusinessNo ratings yet

- Mold Maintenance Best PracticesDocument1 pageMold Maintenance Best PracticesJuana ChivoNo ratings yet

- DCM Part Shots August 2002Document1 pageDCM Part Shots August 2002sobheysaidNo ratings yet

- Mcnfeb Issue FinalDocument31 pagesMcnfeb Issue FinalKichu ThomaNo ratings yet

- Drdiecast 2011marDocument1 pageDrdiecast 2011marsobheysaidNo ratings yet

- AMADocument4 pagesAMAAbhranil GuptaNo ratings yet

- Primer Spring 2012Document14 pagesPrimer Spring 2012Jarred AlexandrovNo ratings yet

- Engineering DesignDocument6 pagesEngineering Designhamzah rashidNo ratings yet

- Sales pitchDocument27 pagesSales pitchleomacedonNo ratings yet

- Untitled PresentationDocument28 pagesUntitled PresentationsvanessacardenasNo ratings yet

- Module 2Document2 pagesModule 2Samuel BelisarioNo ratings yet

- Gcse Product Design Coursework GuideDocument6 pagesGcse Product Design Coursework Guidexmufyevcf100% (2)

- Get People and Technology To Work Together.: Roger Pressman & Associates 620 Slope Orange, 06477Document3 pagesGet People and Technology To Work Together.: Roger Pressman & Associates 620 Slope Orange, 06477Ariel AlvarezNo ratings yet

- DT Coursework DevelopmentDocument7 pagesDT Coursework Developmentfzdpofajd100% (2)

- Remodeling Contractor Basic Marketing PlanDocument20 pagesRemodeling Contractor Basic Marketing PlanPalo Alto Software100% (3)

- Gcse Product Design Coursework EvaluationDocument7 pagesGcse Product Design Coursework Evaluationafiwiafoc100% (2)

- PM Life - Becoming A Hardware PM. It's Almost Christmas and As A Self - by Rose Yao - MediumDocument13 pagesPM Life - Becoming A Hardware PM. It's Almost Christmas and As A Self - by Rose Yao - MediumMariam khasawnehNo ratings yet

- Metal Construction NewsDocument84 pagesMetal Construction Newsvkumar_625189100% (1)

- Paint Inspection LTD: WelcomeDocument3 pagesPaint Inspection LTD: WelcomeAndrew PattersonNo ratings yet

- DCM Part Shots December 2002Document1 pageDCM Part Shots December 2002sobheysaidNo ratings yet

- Kojo Year in Review 2022Document14 pagesKojo Year in Review 2022G SNo ratings yet

- 2012 The American Mold Builder Magazine - FallDocument40 pages2012 The American Mold Builder Magazine - FallAMBANo ratings yet

- Value of PCB Manufacturing Quality During Prototype You Get More Than You Pay ForDocument5 pagesValue of PCB Manufacturing Quality During Prototype You Get More Than You Pay ForEduardoNo ratings yet

- TMFLondon 2015Document24 pagesTMFLondon 2015Kumaravel SivaNo ratings yet

- QFD PDFDocument16 pagesQFD PDFravi_entertainfoNo ratings yet

- The Value Proposition: Generating Your Elevator SpeechDocument14 pagesThe Value Proposition: Generating Your Elevator SpeechJayajoannNo ratings yet

- Stefanie Kurnia Dewi & Felicia CarolineDocument11 pagesStefanie Kurnia Dewi & Felicia Carolinestefanie kurnia dewiNo ratings yet

- Aqa A Level Product Design Coursework DeadlineDocument7 pagesAqa A Level Product Design Coursework Deadlineafaybiikh100% (2)

- D.T Resistant Materials Gcse CourseworkDocument5 pagesD.T Resistant Materials Gcse Courseworkiafafzhfg100% (2)

- A Level Product Design Coursework Mark SchemeDocument6 pagesA Level Product Design Coursework Mark Schemegvoimsvcf100% (2)

- Founder Institute - Product Development 2020-07-29Document16 pagesFounder Institute - Product Development 2020-07-29Founder InstituteNo ratings yet

- Project Management:: MS Samreen Malik: Duaa Nadeem 024 Hooriya Naseem 028 Miraj Sikander 047Document10 pagesProject Management:: MS Samreen Malik: Duaa Nadeem 024 Hooriya Naseem 028 Miraj Sikander 047hooriya naseemNo ratings yet

- Alue Proposition: Aligning Your Product and Service Design To Your Customers' NeedsDocument67 pagesAlue Proposition: Aligning Your Product and Service Design To Your Customers' NeedsAviva CantikaNo ratings yet

- The Flow ChartDocument3 pagesThe Flow ChartsrishtiNo ratings yet

- Product Design A Level Coursework Examples OcrDocument6 pagesProduct Design A Level Coursework Examples Ocrafjwfzekzdzrtp100% (1)

- Get Inside The Lives of Your Customers PDFDocument11 pagesGet Inside The Lives of Your Customers PDFJUST LETNo ratings yet

- Landing Page Design That SellsDocument23 pagesLanding Page Design That Sellskartuchosky100% (7)

- Does Injected Damp Course WorkDocument4 pagesDoes Injected Damp Course Workmtywrhajd100% (2)

- Remodeling Contractor 30 Minute Marketing PlanDocument14 pagesRemodeling Contractor 30 Minute Marketing PlanPalo Alto Software100% (1)

- Product Design Coursework EvaluationDocument8 pagesProduct Design Coursework Evaluationzug0badej0n2100% (2)

- Fundamental Premises of The Pitch Deck - A Business Plan in 10 SlidesDocument14 pagesFundamental Premises of The Pitch Deck - A Business Plan in 10 Slidespham ngoc tuanNo ratings yet

- Engineering Thesis Proposal SampleDocument8 pagesEngineering Thesis Proposal Sampleafloziubadtypc100% (2)

- FINAL Test 2020 Autumn Online B2 Intelligent Business Units 5 7 Version ADocument7 pagesFINAL Test 2020 Autumn Online B2 Intelligent Business Units 5 7 Version Ajondi bagaturiaNo ratings yet

- MR DT CourseworkDocument5 pagesMR DT Courseworkuyyjcvvcf100% (2)

- Luke Firth Personal Development Plan 2Document6 pagesLuke Firth Personal Development Plan 2Luke Anthony FirthNo ratings yet

- Gcse Product Design Coursework PowerpointDocument8 pagesGcse Product Design Coursework Powerpointgyv0vipinem3100% (2)

- 10 Templates for Crafting Value PropositionsDocument6 pages10 Templates for Crafting Value PropositionsGeo GlennNo ratings yet

- DT A2 Coursework IdeasDocument7 pagesDT A2 Coursework Ideasafiwiafoc100% (2)

- Presentación Mayo 12Document2 pagesPresentación Mayo 12christopher ramirezNo ratings yet

- Remodeling Contractor Basic Marketing PlanDocument20 pagesRemodeling Contractor Basic Marketing PlanmarkgranNo ratings yet

- Case 5.case Study Bug SlurryDocument4 pagesCase 5.case Study Bug SlurryNananNo ratings yet

- Agile and The BureaucracyDocument16 pagesAgile and The BureaucracyshahvilasNo ratings yet

- SAMPLE Client Satisfaction SurveyDocument5 pagesSAMPLE Client Satisfaction SurveyDevikaNo ratings yet

- Emba SCM FT May20Document16 pagesEmba SCM FT May20Taha AhmedNo ratings yet

- Curled Metal CaseDocument5 pagesCurled Metal CaseGuo YuNo ratings yet

- MR DT Graphics CourseworkDocument5 pagesMR DT Graphics Courseworkafjwrmcuokgtej100% (1)

- CaseStudyQuestions OperationsDocument10 pagesCaseStudyQuestions OperationsImaad Isaacs0% (1)

- P - Inc Nov Dec 2012Document53 pagesP - Inc Nov Dec 2012moizm53No ratings yet

- Drdiecast 2014janDocument1 pageDrdiecast 2014jansobheysaidNo ratings yet

- Drdiecast 2012marDocument1 pageDrdiecast 2012marsobheysaidNo ratings yet

- Drdiecast 2010novDocument1 pageDrdiecast 2010novsobheysaidNo ratings yet

- Die CastingDocument1 pageDie CastingsobheysaidNo ratings yet

- 2017 November DrdiecastDocument1 page2017 November DrdiecastsobheysaidNo ratings yet

- Vier Cylinders 2022Document2 pagesVier Cylinders 2022sobheysaidNo ratings yet

- Semi-Automated Gating System Design With Optimum Gate and Over Flow Positions For Aluminum HPDCDocument15 pagesSemi-Automated Gating System Design With Optimum Gate and Over Flow Positions For Aluminum HPDCsobheysaidNo ratings yet

- Die Casting Design TipsDocument3 pagesDie Casting Design TipssobheysaidNo ratings yet

- Property document restrictionsDocument1 pageProperty document restrictionsdragos_dimitriuNo ratings yet

- 1 Introduction Ams Feb18 17Document41 pages1 Introduction Ams Feb18 17sobheysaidNo ratings yet

- Product Information Flyer: CIMTECH® 285Document2 pagesProduct Information Flyer: CIMTECH® 285sobheysaidNo ratings yet

- 2017 November DrdiecastDocument1 page2017 November DrdiecastsobheysaidNo ratings yet

- DCM Part Shots December 2002Document1 pageDCM Part Shots December 2002sobheysaidNo ratings yet

- GL XX Mobilarma 200Document2 pagesGL XX Mobilarma 200sobheysaidNo ratings yet

- Rust Veto 211 D 1214 GB 0Document1 pageRust Veto 211 D 1214 GB 0sobheysaidNo ratings yet

- BMW MT Training 0305Document68 pagesBMW MT Training 0305Superducks100% (1)

- Product Information Flyer: Cimtech® 285ZDocument2 pagesProduct Information Flyer: Cimtech® 285ZsobheysaidNo ratings yet

- Product Information Flyer: Cimtech® 410CDocument2 pagesProduct Information Flyer: Cimtech® 410CsobheysaidNo ratings yet

- Translean FREE 5S Checklist and Control ChartDocument1 pageTranslean FREE 5S Checklist and Control ChartsobheysaidNo ratings yet

- Product Information Flyer: CIMTECH® 500Document2 pagesProduct Information Flyer: CIMTECH® 500sobheysaidNo ratings yet

- Cimtech 609e - InsolDocument2 pagesCimtech 609e - InsolsobheysaidNo ratings yet

- Product Information Flyer: Producto RI-923Document2 pagesProduct Information Flyer: Producto RI-923sobheysaidNo ratings yet

- Tech Uddeholm-Vancron ENDocument11 pagesTech Uddeholm-Vancron ENsobheysaidNo ratings yet

- Product Information Flyer: CIMTECH® 420Document2 pagesProduct Information Flyer: CIMTECH® 420sobheysaidNo ratings yet

- Cimstar Qualstar XLZDocument2 pagesCimstar Qualstar XLZsobheysaidNo ratings yet

- Product Information Flyer: Cimstar® Qual Star XLDocument2 pagesProduct Information Flyer: Cimstar® Qual Star XLsobheysaidNo ratings yet

- Cimstar Qualstar LFZDocument2 pagesCimstar Qualstar LFZsobheysaidNo ratings yet

- Product Information Flyer: CIMTECH® 495-OIDocument2 pagesProduct Information Flyer: CIMTECH® 495-OIsobheysaidNo ratings yet

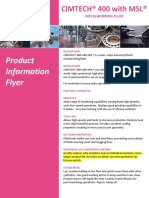

- CIMTECH 400 With MSLDocument2 pagesCIMTECH 400 With MSLsobheysaidNo ratings yet

- Introduction to Globalization ExplainedDocument27 pagesIntroduction to Globalization ExplainedMichael Ron DimaanoNo ratings yet

- Bahasa Inggris Kelas XIIDocument2 pagesBahasa Inggris Kelas XIIMuhammad ImadudinNo ratings yet

- Board Question Paper: March 2018: Geography and EconomicsDocument2 pagesBoard Question Paper: March 2018: Geography and EconomicsVishvajit PatilNo ratings yet

- Wolfgang KohlerDocument16 pagesWolfgang KohlerMaureen JavierNo ratings yet

- Greek Myth WebquestDocument9 pagesGreek Myth Webquesthollyhock27No ratings yet

- Retaining Wall DetailsDocument1 pageRetaining Wall DetailsWilbert ReuyanNo ratings yet

- Christos A. Ioannou & Dimitrios A. Ioannou, Greece: Victim of Excessive Austerity or of Severe "Dutch Disease"? June 2013Document26 pagesChristos A. Ioannou & Dimitrios A. Ioannou, Greece: Victim of Excessive Austerity or of Severe "Dutch Disease"? June 2013Christos A IoannouNo ratings yet

- BSNL TrainingDocument25 pagesBSNL TrainingAditya Dandotia68% (19)

- Atomic Structure QuestionsDocument1 pageAtomic Structure QuestionsJames MungallNo ratings yet

- SecASC - M02 - Azure Security Center Setup and ConfigurationDocument53 pagesSecASC - M02 - Azure Security Center Setup and ConfigurationGustavo WehdekingNo ratings yet

- Manual PDFDocument9 pagesManual PDFRuth ResuelloNo ratings yet

- Unit 7 Noun ClauseDocument101 pagesUnit 7 Noun ClauseMs. Yvonne Campbell0% (1)

- NABARD Dairy Farming Project - PDF - Agriculture - Loans PDFDocument7 pagesNABARD Dairy Farming Project - PDF - Agriculture - Loans PDFshiba prasad panjaNo ratings yet

- Covid 19 PDFDocument117 pagesCovid 19 PDFvicky anandNo ratings yet

- The Beggar's Opera by Gay, John, 1685-1732Document50 pagesThe Beggar's Opera by Gay, John, 1685-1732Gutenberg.orgNo ratings yet

- From Memphis To KingstonDocument19 pagesFrom Memphis To KingstonCarlos QuirogaNo ratings yet

- Mechanism of Heat TransferDocument31 pagesMechanism of Heat Transferedna padreNo ratings yet

- Rose Jean AlvarezDocument15 pagesRose Jean AlvarezMika Ela Pantaleon Doria100% (1)

- Q3 Curriculum Map - Mathematics 10Document3 pagesQ3 Curriculum Map - Mathematics 10Manilyn BaltazarNo ratings yet

- CellphoneBill PDFDocument6 pagesCellphoneBill PDFRaza KhanNo ratings yet

- MCQs on PharmacologyDocument101 pagesMCQs on PharmacologyMohammad Rashid88% (8)

- Nettoplcsim S7online Documentation en v0.9.1Document5 pagesNettoplcsim S7online Documentation en v0.9.1SyariefNo ratings yet

- Is Iso 2692-1992Document24 pagesIs Iso 2692-1992mwasicNo ratings yet

- Plant Chicago 2Document4 pagesPlant Chicago 2api-321978505No ratings yet

- Ventilator Modes - WEANINGDocument3 pagesVentilator Modes - WEANINGAlaa OmarNo ratings yet

- LTG 04 DD Unit 4 WorksheetsDocument2 pagesLTG 04 DD Unit 4 WorksheetsNguyễn Kim Ngọc Lớp 4DNo ratings yet

- FIL M 216 2nd Yer Panitikan NG PilipinasDocument10 pagesFIL M 216 2nd Yer Panitikan NG PilipinasJunas LopezNo ratings yet

- Qcs 2010 Section 13 Part 3 Accessories PDFDocument3 pagesQcs 2010 Section 13 Part 3 Accessories PDFbryanpastor106No ratings yet

- Olt CliDocument2 pagesOlt CliMohammad SaeedNo ratings yet

- Armv8-A Instruction Set ArchitectureDocument39 pagesArmv8-A Instruction Set ArchitectureraygarnerNo ratings yet