Professional Documents

Culture Documents

ABE43 Reviewer

Uploaded by

Francine Ann AgapayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABE43 Reviewer

Uploaded by

Francine Ann AgapayCopyright:

Available Formats

Module 1: Introduction to Unit Operations the form or characteristics of agricultural, fishery, forestry

and biological products/materials and includes, but is not

OVERVIEW OF AGRICULTURAL PROCESS

hmited to, cleaning, sorting, grading, treating, drying,

ENGINEERING

dehydrating, grinding, mixing, milling, canning, dressing,

Agricultural and Biosystems Engineering refers to the slaughtering, freezing, pasteurizing, conditioning,

appUcation of engineering science and designs to the packaging, repacking, transporting of agricultural, fishery,

processes and systems involved in the sustainable forestry and other biological products/materials; ( RA

production, post production and processing of safe food, 10915, Section 1 (e) )

feed, fiber, timber and other agricultural and biological

materials and the efficient utilization, conservation, and

management of natural and renewable resources in order to Scope of Practice of Agricultural and Biosystems

enhance human health in harmony with the environment. Engineering. - The practice of agricultural and biosystems

Agricultural and biosystems consist of crops, forestry and engineering within the meaning and intent of this Act shall

other plants, poultry, livestock, fisheries and aquaculture embrace, but not be Umited to, the following. ( RA 10915,

resources and other animals, wildlife and other hving Section 5 )

things; From( RA 10915, Section 1 (a) )

Preparation of engineering designs, plans, specifications,

Agricultural and Biosystems Power and Machinery refers to project studies, feasibility studies and estimates of irrigation

farm power and machinery for the production, harvesting, and drainage, soil and water conservation and management

processing, storage, manufacture, preserving, transporting systems and facilities, agrometeorological systems,

and distribution of agricultural and biological agricultural and biosystems power, and machinery,

products/materials and includes, but is not Umited to, agricultural and biosystems buildings and structures,

tractors and their attachments, power tillers, seeders, renewable/bio-energy systems and farm electrification,

transplanters, windmills, harvesting machines, crop agricultural and bio- processing and post harvest facUities

protection and maintenance equipment, irrigation and system, agricultural and biological waste utilization and

equipment and accessories, greenhouses and other thermal management, agricultural and bio-information system,

conditioning equipment, hvestock, poultry, fishery and agricultural and biosystems resource conservation and

forest equipment, slaughtering equipment, meat/fishery and management, and agricultural and bio-automation and

crop processing equipment, post harvest machines such as instrumentation system; ( RA 10915, Section 5 (a)

milling machines, dryers, threshers, grain and other

)

strippers, agricultural transport machinery and storage;

From( RA 10915, Section 1 (b) ) Supervision or management on the construction, operation,

and maintenance of irrigation and drainage, soil and water

Agricultural and Biosystems Buildings and Structures refer

conservation and management systems and facilities,

to buildings and structures for the production, harvesting,

agrometeorological systems, agricultural and biosystems

processing, storage, manufacture, preserving, transporting

power and machinery, agricultural and biosystems buildings

and

and structures, renewable/bio-energy systems and farm

distribution of agricultural and biological products/materials electrification, agricultural and bio-processing and post

and includes, but is not limited to, silos and its components, harvest facilities and system, agricultural and biological

agricultural and biosystems machinery and equipment waste utilization and management, agricultural and bio-

sheds, farm houses, green/screen houses, poultry houses, information system, agricultural and biosystems resource

piggery houses, slaughterhouses, farm-to-market roads, conservation and management, and agricultural and bio-

farm bridges, agricultural and biological products automation and instrumentation system; ( RA 10915,

storage/warehouse, buildings and structures for poultry, Section 5 (b) )

livestock, fishery, and forestry production and processing,

Preparation and evaluation of farm development plans, farm

kiln drying and lumber treatment structure, farm equipment,

suitability maps and land use maps/reports for agricultural,

farm supphes, and other structures such as self-feeders, and

livestock and poultry, fishery, aquaculture and forest

soil and water conservation structures: ( RA 10915, Section

production and processing; ( RA 10915, Section 5 (i) )

1 (d) )

(1) Agro-processing establishments such as rice mills, feed

Agricultural and Bio-Processing refers to local activity or

mills, sugar mihs, coconut oh mills, fiber extraction

series of activities to maintain or raise the quality or change

processing plants, meat processing plants, fish processing

plants, poultry and meat processing plants, food processing Diagram 1. Social conditions of production, distribution and

plants and agricultural and fishery products storage consumption (Source: Sigaut, 1979)

facihties; (2) Agro-industrial firms or estabhshments,

Main elements of the post-harvest system

corporations and cooperatives and government entities

engaged in agricultural, hvestock, poultry and fishery • Harvesting. The time of harvesting is determined by the

production and processing, the operation and maintenance degree of maturity. With cereals and pulses, a distinction

of plant/forest nurseries and parks, and other agricultural should be made between maturity of stalks (straw), ears or

and biosystems engineering endeavors; seedpods and seeds, for all that affects successive

operations, particularly storage and preservation.

26

• Pre-harvest drying, mainly for cereals and pulses.

(3) Financing and banking institutions engaged in providing

Extended pre-harvest field drying ensures good preservation

credit and financial assistance on agribusinesses which are

but also heightens the risk of loss due to attack (birds,

commercial in nature such as irrigation, post-harvest

rodents, insects) and moulds encouraged by weather

facilities, agro-processing and storage, forest products,

conditions, not to mention theft. On the other hand,

aquaculture, food and fiber production facilities and

harvesting before maturity entails the risk of loss through

machineries; and (4) Consultancy firms, foundations,

moulds and the decay of some of the seeds.

nongovernment organizations and other organized groups

engaged in providing agricultural and biosystems • Transport. Much care is needed in transporting a really

engineering services relative to management and mature harvest, in order to prevent detached grain from

consultancy, training and extension, research and falling on the road before reaching the storage or threshing

development and/or the provision of irrigation, post-harvest place. Collection and initial transport of the harvest thus

facilities, agro- processing and storage, forest products, depend on the place and conditions where it is to be stored,

aquaculture, food and fiber production facilities and especially with a view to threshing.

machineries and soil and water conservation. (RA 10915).

• Post-harvest drying. The length of time needed for full

Postharvest Losses for Grains drying of ears and grains depends considerably on weather

and atmospheric conditions. In structures for lengthy drying

• The post-harvest system should be thought of as

such as cribs, or even unroofed threshing floors or terraces,

encompassing the delivery of a crop from the time and

the harvest is exposed to wandering livestock and the

place of harvest to the time and place of consumption, with

depredations of birds, rodents or small ruminants. Apart

minimum loss, maximum efficiency and maximum return

from the actual wastage, the droppings left by these

for all involved.

marauders often result in higher losses than what they

actually eat. On the other hand, if grain is not dry enough, it

is vulnerable to mould and can rot during storage.

• Moreover, if grain is too dry it becomes brittle and can

crack after threshing, during hulling or milling. This applies

especially to rice if milling takes place a long time (two to

three months) after the grain has matured, when it can cause

heavy losses. During winnowing, broken grain can be

removed with the husks and is also more susceptible to

certain insects (e.g. flour beetles and weevils). Lastly, if

grain is too dry, this means a loss of weight and hence a loss

of money at the time of sale.

• Threshing. If a harvest is threshed before it is dry enough,

this operation will most probably be incomplete.

Furthermore, if grain is threshed when it is too damp and

then immediately heaped up or stored (in a granary or bags),

it will be much more susceptible to attack from micro-

organisms, thus limiting its preservation.

• Storage. Facilities, hygiene and monitoring must all be grain preservation. In agriculture, moisture content or

adequate for effective, long-term storage. In closed humidity rate is usually indicated as a proportion of the

structures (granaries, warehouses, hermetic bins), control of moist product; i.e. the moisture content is the proportion of

cleanliness, temperature and humidity is particularly the weight of moisture to the total weight of dry matter and

important. Damage caused by pests (insects, rodents) and moisture.

moulds can lead to deterioration of facilities (e.g. mites in

• Damage. Damage is a clear deterioration in the product,

wooden posts) and result in losses in quality and food value

e.g. broken or pitted grain, which affects more its quality

as well as quantity.

than its quantity and can in the long-term result in a definite

• Processing. Excessive hulling or threshing can also result loss. Both damage and loss should be quantified in terms of

in grain losses, particularly in the case of rice (hulling) weight and cost.

which can suffer cracks and lesions. The grain is then not

• Direct and indirect losses. Direct losses occur when the

only worth less, but also becomes vulnerable to insects such

disappearance of a foodstuff is caused by leakage (for

as the rice moth (Corcyra cephalonica).

example, spillage from bags) or consumption by pests

• Marketing. Marketing is the final and decisive element in (insects, rodents, birds), whereas indirect losses occur when

the post-harvest system, although it can occur at various a reduction in quality leads to the consumer's refusal to

points in the agro-food chain, particularly at some stage in purchase.

processing. Moreover, it cannot be separated from transport,

• Weight loss. While weight loss is easy to observe and

which is an essential link in the system.

measure, it does not necessarily mean food loss, since it can

result simply from a reduction in moisture content. Moisture

loss during drying is therefore not a food loss. On the other

Some basic definitions are needed before moving on to the

hand, an abnormal increase in weight through moisture

various types of loss.

absorption following rainfall on stocks left in the open can

• Grains and seeds. Cereals, pulses and oilseeds grown in cause serious damage resulting in loss.

most climates and latitudes for human consumption. The

• Weight loss can be caused by leakage, during transport for

main cereals are wheat, maize, rice, barley, sorghum, millet,

example, if sacks have holes or are insecurely attached. It is

oats and rye; pulses cover the various species of pea, bean,

often the result of prolonged infestation and consumption

broad bean and lentil; and oilseeds cover soya, groundnut,

by insects, rodents and birds or poor packaging. Weight loss

sesame, rapeseed and sunflower.

from pests is not immediately apparent and may deceive an

• Post-harvest. If harvesting covers the period when the inexperienced purchaser. It can be checked by taking an

various products grown are removed from the field, after equivalent amount of clean, healthy cereal, milling the two

maturity, the post-harvest period runs from exit from the samples and weighing the flour from each. The poorer

field to the time of culinary preparation. For various sample will produce less flour. This method can also be

reasons, but especially to allow the straw and grain to dry used to check whether the weight is really correct, for it is

fully, harvesting may be delayed sometimes for months, as easy to increase it by moistening the grain or adding foreign

happens particularly with maize and rice and in these cases, bodies such as pebbles, earth or waste material.

some people prefer to speak of "post-production" in order to

• Quality loss. Quality criteria cover a wide range and are

indicate the link between harvesting and post-harvest

concerned both with external features, shape and size and

operations.

with odour and taste. The cultural factors that can influence

• Food loss. Food loss refers to total modification or diets and food habits must also be borne in mind.

decrease of food quantity or quality which makes it unfit for

• The cleanliness and healthy condition of a product are

human consumption.

primary concerns for the market and correspond to what is

Types of losses referred to as a "sound, legal and merchantable" product in

commercial law. For example, if a trader takes a handful of

• Moisture content. In bio-chemical terms, organic grain from a sack, he can quickly see if it releases dust and

products are composed of dry matter and water. The work out if this is the result of insect infestation. Similarly,

moisture content is the amount of free water within a given a bad smell can arouse suspicions that rodents have been at

product and is expressed either as a decimal proportion or a the grain, verifiable by the presence of rat or mouse

percentage. For example, with cereals, a 13 percent droppings and hair. Many other objects can be mixed in

moisture content is considered a guarantee of satisfactory

with a foodstuff and reduce its value: bad grain, scraps of unit, we will take up some basic concepts and unit

straw or other plant residue, soil, pebbles, bits of glass, etc. operations that are important in food engineering.

All such objects are hard to remove but some of them

DIMENSIONS

represent a greater risk of contamination than others: the

soluble excreta of pests, oils, pesticides, pathogenic • In food processing, we will talk of several

organisms spread by rodents and toxins from fungi and parameters/quantities that make sense of when their

moulds. dimensions and units are known. A dimension defines a

physical entity, which can be observed and or measured,

• It goes without saying that the presence of foreign bodies,

quantitatively. For example, time, length, area, volume,

which can distort the weight of a batch being sold, also

mass, force, temperature, and energy are all considered

affects the quality and thus the market value of a product.

dimensions. A unit expresses the quantitative value of a

Unit Operation dimension. For example, length may be measured as metres,

centimetres, or millimetres. According to the selected unit,

INTRODUCTION

the magnitude would be different

Most food processing operations are designed to extend the

Primary dimensions

shelf-life of the product by reducing or eliminating

microbial activity. This general objective implies that the • length, time, temperature, mass, and force, express a

processing operation meets the minimum requirement of physical entity.

ensuring any human health safety concerns associated with

microbial activity. It must be acknowledged that most, if not

all, food processing operations will influence the physical

and sensory characteristics of the product. It is now a

common practice within the food industry to utilize Secondary dimensions

processing operations as an approach to enhance the • Area, Volume, Velocity, Pressure, Power, Force, Density,

physical and sensory characteristics of food products for Work.

better consumer acceptance.

AB Engineering units

The aims of the food processing are fourfold:

1. To extend the period during which a food remains

wholesome (the shelf life) by preservation techniques which

inhibit microbiological or biochemical changes and thus

allow greater time for distribution and home storage;

2. To increase variety in the diet by providing a range of

attractive flavours, colours, aromas and textures in food

(collectively known as eating, sensory or organoleptic

quality); a related aim is to change the form of the food to

allow further processing (for example the pulping of fruits);

3. To provide the nutrients required for health (termed as

nutritional quality);

4. To generate income for the entrepreneur or

manufacturing company

All the food processing activities involve a combination of

procedures to achieve the intended changes to the raw

materials. These procedures are conventionally categorized

as unit operations, each of which has a specific, identifiable

and predictable effect on a food item. A number of unit

operations, same or different in nature form a process. The

combination and sequence of operations, same or different

in nature determines the nature of the final product. In this

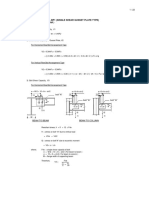

Example

Length

• 132 m to in

3.28 𝑓𝑡 12𝑖𝑛

• 132𝑚 × × =

1𝑚 1𝑓𝑡 Rate of

Area

• 3 ha to 𝑖𝑛2 through

10000𝑚2 (100𝑐𝑚)2 1𝑖𝑛2 = 𝑖𝑛2

• 3ℎ𝑎 × × ×

1ℎ𝑎 1𝑚2 (2.54𝑐𝑚)2

Volume

• 500 L to 𝑚3

1𝑚3

• 500L × 1000𝐿

= 𝑚3 Energy Balance

MODULE 2: Mass and Energy Balances Closed System

Lecture Guide The first law of thermodynamics, often referred to as the

law of energy conservation, is a fundamental principle in

Mass and Energy Balances

the field of thermodynamics. It states that an isolated

Mass can be Neither created nor destroyed, its composition system cannot create or destroy energy. Instead, it can only

can be altered from one form to another. chemical reaction change forms or be transferred from one part of the system

is the process, if there is no chemical reaction, no change in to another.

product composition.

Figure 1. Material balance in

evaporator

Figure 1. Closed, Open and Isolated

System

Figure 2. mass flowrate balance

Energy Balance in a closed System , Work.

Work – Interaction between system and sorroundings.

- Symbol, W

- Unit (J)

Sign Convention

- Work done by the system, Work is (+).

- Work done on the system, Work is (-).

MODULE 3: Application of Fluid Flows in AB

Materials

Introduction

Our experience suggests that most students from

geosciences, natural sciences, and other backgrounds are

not required to take a fluid mechanics class, and most

engineering students who took a fluid mechanics class

earlier may still need to reinforce their physical

understanding of the fluid mechanics concepts. Thereby,

this chapter is intended to provide readers with some basics

of fluid mechanics (particularly, in terms of physics) that

are essential to understand and appreciate flowthrough

geologic media.

Fluid Mechanics is the study of the forces on fluids. These

fluids can be either a gas or a liquid.

Fluid Mechanics includes both fluid statics (the study of

fluids at rest) and fluid dynamics (the study of fluids in

motion). Notice that the fluid mechanics serves as the

fundamental principles in a number of disciplines in science

and engineering. For instance, atmospheric science is built

upon fluid mechanics, as is cardiology – the study of the

blood flow through our veins and arteries. The study of the

infiltration of water and its subsequent movement in

unsaturated subsurface media (vadose zone hydrology) also

relies on fluid mechanics, as do studies of the movement of

groundwater in geologic media (groundwater hydrology). molecules gain enough energy to break away completely,

Other disciplines include surface hydrology (the study of and escape into the adjacent space. Finally, a threshold

movement of water on land surfaces, in canals and rivers, temperature is reached at which molecules throughout the

and in oceans, lakes, estuaries, etc.), and petroleum liquid are becoming energetic enough to escape. Then,

engineering that studies the movement of oil and gas in vapor bubbles form and rise to the surface, and the liquid

geologic reservoirs. becomes a gas. The molecules of a gas are free to move in

every possible way; a gas has neither a definite shape nor a

Examples also include hydraulics which studies fluid

definite volume but expands to fill any container in which it

motions in pipes or man-made conduits (conduit flow

is placed. Both liquids and gases are considered to be fluids.

systems). This chapter first introduces readers to the basic

Strictly speaking, there is no quantitative criteria onto

continuum assumption (i.e., volume averaging concept).

clearly distinguish solids from fluids.

Then, definitions of fluid properties and their units follow.

Nevertheless, a fluid is defined as a substance whose

Forces of static fluids and the relationship between forces

particles can move and change their relative position easily

and energies are discussed subsequently. The chapter then

in contrast to a solid. Specifically, a fluid is a substance that

examines fluid dynamics, in which the fixed and moving

deforms continuously without substantial resistance, when a

coordinate systems are introduced, the time derivatives

shear stress (explained later) is applied to it, no matter how

associated with these two coordinate systems are brought

small the magnitude of the applied shear stress is. A solid

forth, and fluid acceleration is investigated. Using force

can be defined as a material of which the shape or the

balance and acceleration concepts, we derive the Bernoulli

relative position of the constituent elements changes only

equation for flow through pipe; we elucidate its physical

by an insignificantly small amount, when forces acting on it

meaning in term of conservation of energy, which leads to

change, either in magnitude or direction. Thus, the

the concept of total, pressure, velocity, and potential heads.

distinction between solids and fluids is rather relative.

Head loss due to viscous forces ignored by the Bernoulli

While fluids can mean liquids or/and gas, in the context of

equation then explains the limitation of the equation for

understanding the basic processes of subsurface hydrology,

flow through real-world systems. Subsequently, the

we are typically interested in the liquid phase of water when

influence of the relative strength of the viscous force to the

we deal with problems related to water resources. Notice

inertia force of the fluid (i.e., Reynolds Number) is

that in certain cases we may have to deal with liquid and/or

discussed on flow behavior (i.e., laminar or turbulent flow).

gas phases of nonaqueous fluids in the case of groundwater

At the end, this chapter sets the stage for the discussion of

pollution problems.

flow through geologic media in next few chapters, which is

generally considered as laminar flow. Basic Formula Useful for fluids

Fluids and Solids

Discussion of the states of a matter is a way to explain the

definition of fluids and solids. The states of a matter are

also known as phases of the matter or states of an

aggregation, which are: solid, liquid, and gas. Under a solid

state, the molecules of matters are limited to only vibration

about a fixed position. This restriction gives the

Fluid Statics and Dynamics

material both a definite volume and a definite shape. Any

material under this condition is called solid phase. As some

energy is added to a solid, its molecules begin to vibrate

more rapidly until they break out of their fixed positions.

The solid then becomes a liquid. The molecules of a liquid

are free to move throughout the liquid, but are held from

escaping the liquid surface by the intermolecular forces.

This gives a liquid a definite volume, but no definite shape.

As more energy is added to a liquid, a small number of

Q=0.061 kg/ sec

Viscosity

• It is the internal resistance of fluid to shear.

• The coefficient may be considered as the coefficient of

friction of fluid to fluid.

Reynolds Number

•Rate

Reynolds

of Flow is an English investigator who first demonstrate

the •finite existence

The rate of flow of of

fluidthe streamlined

is constant andinturbulent

at any point a system andflow.

there is no

accumulation or depletion of fluid within the system.

• Equation

• Formula

Re = D V d / µ

𝑄 = 𝐴1𝑉1ρ = 𝐴2 𝑉2ρ = ⋯ = 𝐴𝑛 𝑉𝑛ρ

where:

where: Q – mass flow rate, kg/s

A – cross-sectional area of pipe, m2 V –

Re – Reynolds number linear velocity of fluid,

D - inside diameter of pipe, ft of fluid, kg/m3

ρ– Density

V - average velocity of fluid, ft/sec

d– Specific weight, lb/ft3

µ - fluid viscosity, lb-s/ft^2

Example 2.

Example:

If fluid is SAE 30 oil at 20°C and L=7mm, What shear

1. What is the rate of flow of coconut oil in a 2- in. pipe if stress is required to move the upper plate at 3.5 m/s?

the velocity of the fluid is measured at 0.02 m/s? The Compute the Reynolds no. based on L. µ=0.440Pa-s and

specific weight of oil is 1500 kg/m3. ρ=888 kg/m^3.

Given: Inside diameter of pipe - 2 in. Given:

Fluid velocity - 0.02 m/s V = 3.5 m/s

Specific weight of fluid - 1500 kg/m3 Required: Mass flow D = 7 mm

rate

µ = 0.44 Pa-s

Solution: Q = A V d

ρ = 888 kg/m3

Q=¿ ¿¿

Find: NR

Solution:

NR = Dvρ / µ

1m m kg

(7 mm × )(3.5 )( 888 3 )

NR = 1000 mm s m

0.44 Pa−s

NR = 49.4 Examples of Conduction

Why does crushed ice melt faster than ice cubes?

Answer: Because the exposed area is larger

Module 4: Application of Heat Transfer in AB Materials

Why do you save money by turning down the

Principles of Heat Transfer thermostat in cold weather?

Heat transfer is one way of transferring energy to a Answer: Because the temperature difference

body (work is the other) (between inside and outside) is smaller

Occurs only when there is a

temperature difference between the

two bodies (heat flows from hot to Convection

cold)

• Warm air (water) rises and cool air (water) sinks

Occurs through three processes: conduction,

convection, and radiation • Why? Because warm air (water) is less dense and “floats”

on cooler air (water)

From Hot to Cold • The rising of warm air (water) creates circulating

Heat energy is transferred when there is a convection currents

difference in temperature

In an isolated system heat flows from hot to cold • Convection can occur in any gas or fluid

until both bodies are at the same temperature

𝑸𝒄 = 𝒉𝒄𝑨(𝑻𝒔 − 𝑻𝒇)

The Three Types of Heat Transfer Examples of Convection

Conduction: Heat is transferred through a material

• The sea breeze is caused by differences in temperature

(e.g. insulation or glass)

between the ocean and the shore

Convection: Heat is transferred by air or water

currents (e.g. ocean currents) • In fact, all weather and ocean currents are caused by

Radiation: Heat is transferred when a convection

hot body emits radiation (e.g. infrared

radiation given off by a fire) • A draft in a cold room is caused by convection currents

Conduction from air leaking through a window or door

Conduction depends on the following: • A “rolling boil” in a pot is the result of convection

Type of Material: thermal conductivity (e.g. metal

spoons transfer heat better than plastic)

Temperature Difference

Area (e.g. a thin stirring stick transfers less heat Radiation

than a thick spoon) • Radiation results in heat being emitted “at the speed of

Thickness (the distance heat has to travel) light”

• Radiated heat requires no medium (e.g. air) and can

propagate through empty space

• Heat is emitted as electromagnetic radiation (e.g. light)

• Here, radiation does not refer to the emissions of

radioactive substances.

Stefan-Boltzmann Law

𝑸𝒆 = 𝜺𝝈𝑨𝑻𝟒

Qe= Rate which energy emitted

𝜀= Emissivity

𝜎= Stefan-Boltzmann Law Constant A= Area

T= Absolute temperature

Examples of Radiation

• A hot burner on a stove or a fire emits large amounts of

infrared and a smaller amount of visible radiation

•Mammals (~40° C) emit mostly infrared radiation

• Our sun (~6000° C) emits a large amount of visible light

• Incandescent lights (regular light bulbs) have heated

filaments that emit visible light

Example of Heat Transfer

• A radiator works by circulating steam through a series of

pipes, where it condenses and releases heat

• Heat is transferred by conduction, convection, and

radiation

You might also like

- ABElaw For PrintDocument18 pagesABElaw For PrintChristian Dave RoneNo ratings yet

- Implementing Rules and Regulations for Agricultural and Biosystems Engineering ActDocument39 pagesImplementing Rules and Regulations for Agricultural and Biosystems Engineering ActJoselito Tucit80% (5)

- Module 1: Introduction Lessons:: Definition and Importance of Ab Engineering and Republic Act No. 10915Document7 pagesModule 1: Introduction Lessons:: Definition and Importance of Ab Engineering and Republic Act No. 10915Polo Cruz100% (2)

- PNS/BAFPS 20:2008 Philippine standard for corn farmingDocument10 pagesPNS/BAFPS 20:2008 Philippine standard for corn farmingE.t. ChavezNo ratings yet

- Irr of Abe Law As of October 7 2016Document23 pagesIrr of Abe Law As of October 7 2016Mervin AzarconNo ratings yet

- AMM - Chap 02 - Agri MechanizationDocument19 pagesAMM - Chap 02 - Agri MechanizationJohn CennaNo ratings yet

- Agri Waste MgmtDocument24 pagesAgri Waste MgmtTina SorianoNo ratings yet

- CTE Syllabus GuideDocument196 pagesCTE Syllabus GuideAlfredo Ramirez MonaresNo ratings yet

- Waste Management ReviewerDocument11 pagesWaste Management Reviewervalerosm2No ratings yet

- Conservation Agriculture: Training Guide for Extension Agents and Farmers in Eastern Europe and Central AsiaFrom EverandConservation Agriculture: Training Guide for Extension Agents and Farmers in Eastern Europe and Central AsiaNo ratings yet

- Agri-Fishery Mechanization Law SummaryDocument12 pagesAgri-Fishery Mechanization Law SummaryChristian Dave RoneNo ratings yet

- Tor Organic CertificationDocument4 pagesTor Organic CertificationsambhalaNo ratings yet

- 21.01.2021 A&b FarmingDocument12 pages21.01.2021 A&b FarmingSHAHBAZ BALOCHNo ratings yet

- AB EngineeringDocument31 pagesAB EngineeringDeverlyn LamsisNo ratings yet

- Aben21 Final Reviewer MidtermsDocument13 pagesAben21 Final Reviewer MidtermsRosemary MarquezNo ratings yet

- UPSC IFos 2022 SyllabusDocument2 pagesUPSC IFos 2022 SyllabusBhadar SimarNo ratings yet

- Midterm NotesDocument3 pagesMidterm NotesMon AmiNo ratings yet

- Crop ProductionDocument28 pagesCrop ProductionAbdul qadeerNo ratings yet

- Report of FOURTH DEANS COMMITTEE On Agricultural Education in India Supplement (Syllabi) Education DivisionDocument215 pagesReport of FOURTH DEANS COMMITTEE On Agricultural Education in India Supplement (Syllabi) Education DivisionBala Ratnakar KoneruNo ratings yet

- 05Document45 pages05mohites1100% (1)

- Agriculture (302) Syllabus For Class 12Document3 pagesAgriculture (302) Syllabus For Class 12Saksham PathakNo ratings yet

- Introduced: Fourteenth Congress of The Republic The PhilippinesDocument12 pagesIntroduced: Fourteenth Congress of The Republic The PhilippinesSak EnNo ratings yet

- Operational Guidelines of AGROFOREST Y Under RKVYDocument10 pagesOperational Guidelines of AGROFOREST Y Under RKVYAshirwad SinghalNo ratings yet

- RA 10601 Irr OcrDocument44 pagesRA 10601 Irr OcrJerry SerapionNo ratings yet

- Unit 1 Farm Designing Land Preparation and Buffer Zone: StructureDocument20 pagesUnit 1 Farm Designing Land Preparation and Buffer Zone: StructureArsalan GanaiNo ratings yet

- Upsc If S Agricultural Engineering Syl Lab UsDocument3 pagesUpsc If S Agricultural Engineering Syl Lab Usashok mahaleNo ratings yet

- Dessye Belay Melkamu Fetene The Effect oDocument10 pagesDessye Belay Melkamu Fetene The Effect oAlemayehu TeshomeNo ratings yet

- Environmental Guideline on Poultry RearingDocument5 pagesEnvironmental Guideline on Poultry Rearingshekhar sarodeNo ratings yet

- Crop Production GuidelinesDocument23 pagesCrop Production GuidelinesBrhane WeldegebrialNo ratings yet

- Managing production problems in tropical fruitDocument1 pageManaging production problems in tropical fruitwidagdoNo ratings yet

- Agricultural Science PaperDocument13 pagesAgricultural Science PapernilNo ratings yet

- ENV-214 - Lecture-7-8 - Hmk1 - Spring 2023Document49 pagesENV-214 - Lecture-7-8 - Hmk1 - Spring 2023TMTNo ratings yet

- Abe 424 Farm Structures and Environmental ControlDocument42 pagesAbe 424 Farm Structures and Environmental ControlAmabi SilasNo ratings yet

- History: Agricultural Engineering Is The Engineering Discipline That AppliesDocument2 pagesHistory: Agricultural Engineering Is The Engineering Discipline That Applieseipolle16No ratings yet

- Sri Lanka National Agriculture PolicyDocument10 pagesSri Lanka National Agriculture PolicyChanakaNo ratings yet

- The Effect of Cassava Effluent and Empty Oil Palm Fruit Bunch On Remediation of Petroleum Polluted Soil and Crop Production in The Tropics A ReviewDocument13 pagesThe Effect of Cassava Effluent and Empty Oil Palm Fruit Bunch On Remediation of Petroleum Polluted Soil and Crop Production in The Tropics A ReviewIchipi-ifukor Patrick ChukuyenumNo ratings yet

- Factsheet Agri Practices Under Ecoscheme - en - 0Document5 pagesFactsheet Agri Practices Under Ecoscheme - en - 0yu'sheng'chenNo ratings yet

- Virtual Class: Aben 131. Module 3Document53 pagesVirtual Class: Aben 131. Module 3Jesha Marie AbudeNo ratings yet

- Rehabilitating Arjunanadhi Sub Basin IrrigationDocument277 pagesRehabilitating Arjunanadhi Sub Basin IrrigationMinnalrajNo ratings yet

- Climate Smart AgricultureDocument2 pagesClimate Smart AgricultureMichelle MarbellaNo ratings yet

- Cropping SystemsDocument28 pagesCropping Systemsalemneh bayehNo ratings yet

- Syllabus For Combined Technical Examination Dt. 20.04.2015 677079505 PDFDocument196 pagesSyllabus For Combined Technical Examination Dt. 20.04.2015 677079505 PDFMLemeren LcrNo ratings yet

- Agricultural Engineering Processes and ApplicationsDocument9 pagesAgricultural Engineering Processes and Applicationsfaithmark ceriacoNo ratings yet

- Overview of AgricultureDocument31 pagesOverview of AgricultureNicoleQuindaraNo ratings yet

- LEC-8 Adverse Effects of Modern Agriculture - Sustainable Agriculture - Definition - Concept - Goals - ElementsDocument56 pagesLEC-8 Adverse Effects of Modern Agriculture - Sustainable Agriculture - Definition - Concept - Goals - ElementsMandla HimajaNo ratings yet

- New Mini Power TillerDocument29 pagesNew Mini Power TillerArun Kumar R100% (6)

- ENV 107-Sustainable AgricultureDocument28 pagesENV 107-Sustainable AgricultureSyed Faiaz Hossain 1330644030No ratings yet

- Philippine Gap For CornDocument4 pagesPhilippine Gap For Cornvee propagandaNo ratings yet

- Agricultural Engineering: Jump To Navigation Jump To SearchDocument8 pagesAgricultural Engineering: Jump To Navigation Jump To SearchMichaelNo ratings yet

- Module 3 - Other-Specialized-IndustriesDocument28 pagesModule 3 - Other-Specialized-IndustriesKalven Perry AgustinNo ratings yet

- Definition of Agriculture: Agriculture - Any Activity Connected With The Growing of Food, Fibre, Timber and FoliageDocument2 pagesDefinition of Agriculture: Agriculture - Any Activity Connected With The Growing of Food, Fibre, Timber and FoliageFaridullahMomandNo ratings yet

- AgricultureDocument31 pagesAgriculturegraciousmazengera66No ratings yet

- Safety Measures in Farm OperationDocument50 pagesSafety Measures in Farm OperationChristian Paul CasidoNo ratings yet

- Thesis Candela Castillo UpdatedDocument43 pagesThesis Candela Castillo UpdatedGerma CandelaNo ratings yet

- Integrated Farm ManagementDocument4 pagesIntegrated Farm ManagementBerliani FitriNo ratings yet

- Ra 10915 (Phil Agicultural & Biosystems Eng'g Act of 2016Document34 pagesRa 10915 (Phil Agicultural & Biosystems Eng'g Act of 2016almorsNo ratings yet

- Agricultural Waste ManagementDocument20 pagesAgricultural Waste ManagementBatnon Gate FarmsNo ratings yet

- Farm Machinery and Equipment : Improving Productivity in the FieldFrom EverandFarm Machinery and Equipment : Improving Productivity in the FieldNo ratings yet

- Africa Regional Synthesis for the State of the World’s Biodiversity for Food and AgricultureFrom EverandAfrica Regional Synthesis for the State of the World’s Biodiversity for Food and AgricultureNo ratings yet

- Conceptual FrameworkDocument20 pagesConceptual FrameworkFrancine Ann AgapayNo ratings yet

- Parent or Guardian Consent Form 3Document1 pageParent or Guardian Consent Form 3Francine Ann AgapayNo ratings yet

- EA9 - Computer Application in AB Engineering NotesDocument10 pagesEA9 - Computer Application in AB Engineering NotesFrancine Ann AgapayNo ratings yet

- Abe41 NotesDocument10 pagesAbe41 NotesFrancine Ann AgapayNo ratings yet

- Abe11 NotesDocument7 pagesAbe11 NotesFrancine Ann AgapayNo ratings yet

- Fluidsummary 180610171918 PDFDocument190 pagesFluidsummary 180610171918 PDFsing_r100% (1)

- VisiMix LAMINAR User's Guide SimulationDocument83 pagesVisiMix LAMINAR User's Guide Simulationfranz_passariniNo ratings yet

- Fluid Mechanics Chapter PropertiesDocument41 pagesFluid Mechanics Chapter PropertiesYaqein AliNo ratings yet

- Rheocalc ManualDocument65 pagesRheocalc ManualjeremiasNo ratings yet

- CE 315 - HYDRAULICS - Module 1 Lesson 1Document14 pagesCE 315 - HYDRAULICS - Module 1 Lesson 1Rey Angelo Carbilledo Jr.100% (1)

- Wellbore Hydraulics, Pressure Drop CalculationsDocument85 pagesWellbore Hydraulics, Pressure Drop CalculationsNikhil ShahaneNo ratings yet

- Chocolate Yield Stres PDFDocument6 pagesChocolate Yield Stres PDFAleykerPuertasMipNo ratings yet

- Basic Tubing ForcesDocument21 pagesBasic Tubing ForcesOzzie GonzalezNo ratings yet

- The Effect of Bed Roughness On Velocity ProfileDocument7 pagesThe Effect of Bed Roughness On Velocity ProfileFachri JahriNo ratings yet

- Arm301 QBDocument6 pagesArm301 QBKunal KhandelwalNo ratings yet

- Column Design RCDCDocument9 pagesColumn Design RCDCVaishak KrishnanNo ratings yet

- A Rheological Model For Drilling Fluids and Cement SlurriesDocument8 pagesA Rheological Model For Drilling Fluids and Cement Slurriesحسنين عبدالامير دايخ 8No ratings yet

- Exploring The Latest Advancements in SPH Based Virtual Transmission DevelopmentDocument33 pagesExploring The Latest Advancements in SPH Based Virtual Transmission DevelopmentProvocateur SamaraNo ratings yet

- Problem of RehologyDocument4 pagesProblem of RehologyShagufta AfaqueNo ratings yet

- Concrete Shear Wall Design: by Wira Tjong, S.EDocument26 pagesConcrete Shear Wall Design: by Wira Tjong, S.EspinosaNo ratings yet

- FLUID MECHANICS EXPLAINEDDocument29 pagesFLUID MECHANICS EXPLAINEDpwanjotsinghNo ratings yet

- The Stress Tensor: An Internet Book On Fluid DynamicsDocument2 pagesThe Stress Tensor: An Internet Book On Fluid DynamicsABHISEKH JUYALNo ratings yet

- Reinforced Concrete Design FormulasDocument29 pagesReinforced Concrete Design Formulas秦瑋駿No ratings yet

- Midterms Shear Moment 09-23-2020Document9 pagesMidterms Shear Moment 09-23-2020UM RK OrtuosteNo ratings yet

- Clastic Transport and Fluid Flow: Sedimentologi - 5Document25 pagesClastic Transport and Fluid Flow: Sedimentologi - 5Malik FajarNo ratings yet

- Design of laterally unsupported beamDocument3 pagesDesign of laterally unsupported beamLarry XNo ratings yet

- Beam pin connection design calculationsDocument22 pagesBeam pin connection design calculationsballisnothingNo ratings yet

- Lab ManualDocument134 pagesLab Manualmarwananaqi796No ratings yet

- Viscosity Data Modeling of Resin SolutionsDocument12 pagesViscosity Data Modeling of Resin SolutionsHafiz Mudaser AhmadNo ratings yet

- Lviv Polytechnic National UniversityDocument92 pagesLviv Polytechnic National UniversityФедір ЦюпкоNo ratings yet

- Torsion BarDocument2 pagesTorsion BardownloadlagumNo ratings yet

- Rail stress calculation methodology circularDocument13 pagesRail stress calculation methodology circularfiemsabyasachiNo ratings yet

- ASTM D 653-97 Standard Terminology Relating To Soil, Rock, and Contained FluidsDocument35 pagesASTM D 653-97 Standard Terminology Relating To Soil, Rock, and Contained FluidsPablo Antonio Valcárcel VargasNo ratings yet

- Pressure Influences Upon Shear ThickeningDocument11 pagesPressure Influences Upon Shear ThickeningEdgar SharapovaNo ratings yet

- Analysis and Design of Beams For Bending: MEE 320: Strength of MaterialsDocument36 pagesAnalysis and Design of Beams For Bending: MEE 320: Strength of Materialskamalnath100% (1)