Professional Documents

Culture Documents

Turnbuckle Eye To Eye

Uploaded by

Ned VasicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turnbuckle Eye To Eye

Uploaded by

Ned VasicCopyright:

Available Formats

Rigging_Metric.

fm Page 163 Tuesday, November 25, 2008 5:42 PM

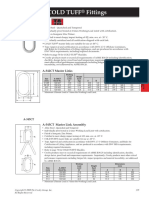

Eye & Eye Turnbuckles

HG-226 • End fittings are Quenched and Tempered, bodies heat treated by normalizing.

• Hot Dip galvanized steel.

• Turnbuckle eyes are forged elongated, by design, to maximize easy attachment in system

and minimize stress in the eye. For turnbuckle sizes 6 mm through 64 mm, a shackle one

size smaller can be reeved through eye.

• Modified UNJ thread on end fittings for improved fatigue properties. Body has UNC

threads.

• Crosby products meet or exceed all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements. Importantly, Crosby

products meet other critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

• TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

• Lock Nuts available for all sizes (see page 170).

• Comprehensive end fitting data provided on page 167.

• Fatigue Rated.

s e l k c u b n r u T e y E & e y E

Accessories

Meets the performance requirements of Federal

Rigging

Specifications FF-T-791b, Type 1, Form 1 - CLASS

4,and ASTM F-1145, except for those provisions

required of the contractor. For additional infor-

mation, see page 391.

HG-226

Eye & Eye

Thread Working Dimensions

Diameter HG2 6 Load Weight (mm)

& Take Up HG-226 Limit Each J K M N X

(mm) Stock No. (t)* (kg) A Open Closed Open Closed R S Closed BB

† 6.35 x 102 1031252 .23 .13 6.35 303 202 314 213 20.6 8.64 44.6 103

† 7.94 x 114 1031270 .36 .22 7.94 354 239 368 253 24.1 11.2 55.8 116

† 9.53 x 152 1031298 .54 .34 9.53 446 294 463 311 28.7 13.5 62.9 155

12.7 x 152 1031314 1.00 .78 12.7 506 354 529 376 35.8 18.0 90.4 153

12.7 x 305 1031350 1.00 1.19 12.7 819 514 841 536 35.8 18.0 89.9 314

15.9 x 152 1031378 1.59 1.25 15.9 552 399 577 425 45.7 22.4 110 153

15.9 x 305 1031412 1.59 1.87 15.9 865 560 891 586 45.7 22.4 110 315

19.1 x 152 1031430 2.36 1.91 19.1 590 438 622 470 53.1 25.4 130 156

19.1 x 305 1031476 2.36 2.78 19.1 905 600 937 632 53.1 25.4 129 320

19.1 x 457 1031494 2.36 3.55 19.1 1210 753 1242 785 53.1 25.4 130 471

22.2 x 305 1031519 3.27 4.01 22.2 932 627 970 665 60.5 31.8 147 309

22.2 x 457 1031537 3.27 5.22 22.2 1249 792 1287 830 60.5 31.8 147 473

25.4 x 152 1031555 4.54 4.36 25.4 666 514 711 559 76.2 36.3 165 157

25.4 x 305 1031573 4.54 5.88 25.4 971 666 1016 711 76.2 36.3 165 309

25.4 x 457 1031591 4.54 7.40 25.4 1276 819 1321 864 76.2 36.3 165 462

25.4 x 610 1031617 4.54 9.14 25.4 1596 987 1641 1031 76.2 36.3 164 631

31.8 x 305 1031635 6.89 9.01 31.8 1070 766 1127 822 91.2 46.2 216 306

31.8 x 457 1031653 6.89 10.8 31.8 1375 918 1432 975 91.2 46.2 216 459

31.8 x 610 1031671 6.89 12.6 31.8 1694 1085 1751 1141 91.2 46.2 216 625

38.1 x 305 1031699 9.71 13.0 38.1 1124 819 1187 882 104 53.8 240 313

38.1 x 457 1031715 9.71 15.4 38.1 1428 971 1492 1035 104 53.8 240 465

38.1 x 610 1031733 9.71 17.9 38.1 1749 1139 1813 1203 104 53.8 240 633

44.5 x 457 1031779 12.7 23.0 44.5 1457 1000 1534 1076 118 60.5 253 467

44.5 x 610 1031797 12.7 26.4 44.5 1762 1153 1838 1229 118 60.5 253 619

51.0 x 610 1031813 16.8 37.9 50.8 1922 1313 2011 1402 148 68.3 331 622

63.5 x 610 1031831 27.2 67.4 63.5 2011 1402 2113 1503 165 79.2 350 625

70.0 x 610 1031859 34.0 79.1 69.9 2066 1456 2180 1571 178 82.6 383 626

* Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit.

†Mechanical Galvanized

Copyright © 2008 The Crosby Group, Inc. 163

All Rights Reserved

You might also like

- FMC 120plus ValveDocument2 pagesFMC 120plus Valvefranz_aditya100% (3)

- Put An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamDocument8 pagesPut An ACE in The Hole: Vam Top Vam Top HC Vam Top HT Vam Top Fe New VamjoseNo ratings yet

- National Standard for Eyelet Bolts GB 799-88Document6 pagesNational Standard for Eyelet Bolts GB 799-88zalabiNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- ME2135 Formula SheetDocument4 pagesME2135 Formula SheetYong Hong100% (2)

- Rural - Materials & ConstructionDocument12 pagesRural - Materials & ConstructionHaresh Babu PitchaimaniNo ratings yet

- HG 225Document1 pageHG 225Claudio Alvarado ArayaNo ratings yet

- Turnbuckle Jaw + JawDocument1 pageTurnbuckle Jaw + JawjoosuasinagaNo ratings yet

- Jaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyDocument1 pageJaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyGustavo ArancibiaNo ratings yet

- HG 226Document1 pageHG 226Konstantinos SynodinosNo ratings yet

- Crosby G-257 PDFDocument1 pageCrosby G-257 PDFKonstantinos SynodinosNo ratings yet

- GemLock-Submital-Binder-1_2024-03-06-143033_ntgyDocument21 pagesGemLock-Submital-Binder-1_2024-03-06-143033_ntgyjeferjoan.11No ratings yet

- Crosby Bolt Type Shackles: Testing The LimitsDocument1 pageCrosby Bolt Type Shackles: Testing The LimitsStephen KokoNo ratings yet

- G-277 Cancamo CrosbyDocument1 pageG-277 Cancamo CrosbyDavid Borja HuarachiNo ratings yet

- Marine Tie Rod Ground Anchoring SolutionsDocument6 pagesMarine Tie Rod Ground Anchoring Solutionspangalengan zaxNo ratings yet

- Angular Contact Bearing SwivelsDocument1 pageAngular Contact Bearing SwivelsmeromikhaNo ratings yet

- M11 MarineDocument12 pagesM11 MarineDiogo CidadeNo ratings yet

- Rulman Kodlama NTN 106 119Document14 pagesRulman Kodlama NTN 106 119mustafa bulatNo ratings yet

- Alloy Screw Pin Shackle G209ADocument1 pageAlloy Screw Pin Shackle G209ARony Prayitno SimeonNo ratings yet

- Jaw & Jaw TurnbucklesDocument1 pageJaw & Jaw TurnbucklesSavin TimofteNo ratings yet

- List - TBC SoftDocument1 pageList - TBC SoftadityadhNo ratings yet

- Master Link A345Document1 pageMaster Link A345Hunnymijie NorNo ratings yet

- PT Bar Systems Brochure 17.05.29Document8 pagesPT Bar Systems Brochure 17.05.29SACHINNo ratings yet

- AbsolyteGP PDFDocument12 pagesAbsolyteGP PDFedin PopNo ratings yet

- Concrete Fiberglass Rebar GuideDocument5 pagesConcrete Fiberglass Rebar GuideSubash Bastola100% (1)

- Absolyte GP SpecsDocument20 pagesAbsolyte GP Specsarya permanaNo ratings yet

- Absolyte Energy PDFDocument12 pagesAbsolyte Energy PDFIsrarul Haque AnsariNo ratings yet

- Absolyte GP PV Alt EnergyDocument12 pagesAbsolyte GP PV Alt EnergysasaNo ratings yet

- CANAN Steel Deck Catalogue - 2023Document48 pagesCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- SSAB - Water Mains - Pipes and Fittings - ENDocument22 pagesSSAB - Water Mains - Pipes and Fittings - ENservice techniqueNo ratings yet

- Bearings and wear rings technical detailsDocument2 pagesBearings and wear rings technical detailsArquimedes PerezNo ratings yet

- Product: CatalogueDocument38 pagesProduct: CataloguekazdanoNo ratings yet

- Turnbuckle CrosbyDocument6 pagesTurnbuckle CrosbyBudi SantonyNo ratings yet

- Correction To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsDocument2 pagesCorrection To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsTimNo ratings yet

- Jc-557 Type 5610 TDS-FNL - LowresDocument7 pagesJc-557 Type 5610 TDS-FNL - LowresDaygoro RuizNo ratings yet

- TurnbucklesallnewDocument6 pagesTurnbucklesallnewrigsme032No ratings yet

- GRC Kwik Couple Elbows GRC Conduit Elbows Nipples CouplingsDocument8 pagesGRC Kwik Couple Elbows GRC Conduit Elbows Nipples CouplingsJuanelo CruzNo ratings yet

- 2019 Crosby Catalog Metric-Rigging-Accessories-Master Link A-342Document1 page2019 Crosby Catalog Metric-Rigging-Accessories-Master Link A-342I-SignNo ratings yet

- Mechanical Seals - Compressor Seals - Separation Seals: Rely On ExcellenceDocument2 pagesMechanical Seals - Compressor Seals - Separation Seals: Rely On ExcellenceAchraf BoudayaNo ratings yet

- CAT Buckets Technical SpecificationsDocument6 pagesCAT Buckets Technical SpecificationsEhab Attia SelimNo ratings yet

- TD-4615 HRDocument8 pagesTD-4615 HRjosfwangNo ratings yet

- BJ Model SV-5 Cement Retainer PDFDocument2 pagesBJ Model SV-5 Cement Retainer PDFmohammad teimuriNo ratings yet

- FAG BearingDocument4 pagesFAG BearingBasem100% (2)

- Marine Tie Bar SystemsDocument7 pagesMarine Tie Bar SystemsSanjoy SanyalNo ratings yet

- Tunneling and Geotechnical SystemsDocument12 pagesTunneling and Geotechnical SystemsHakan_KURUNo ratings yet

- Bolt Capacities: Non-Preloaded Ordinary BoltsDocument1 pageBolt Capacities: Non-Preloaded Ordinary BoltsSelvasathaNo ratings yet

- Marine Tie Bar SystemsDocument7 pagesMarine Tie Bar SystemsGaneshalingam Ramprasanna1No ratings yet

- Mini Ratchet Set Accessory: 2335M 5, 5.5, 6, 7, 8 1025P PH1, PH2 1025T T10, T15, T20 1025H H3, H4, H5, H6Document1 pageMini Ratchet Set Accessory: 2335M 5, 5.5, 6, 7, 8 1025P PH1, PH2 1025T T10, T15, T20 1025H H3, H4, H5, H6hudsonNo ratings yet

- Crosby Wide Body ShacklesDocument1 pageCrosby Wide Body ShacklesPeter BarabasNo ratings yet

- Dextra Marine Tie Bars Interactive Brochure 2020Document7 pagesDextra Marine Tie Bars Interactive Brochure 2020Mohamed abou elnasrNo ratings yet

- Mckissick Overhaul Balls Mckissick Overhaul BallsDocument1 pageMckissick Overhaul Balls Mckissick Overhaul BallsKonstantinos SynodinosNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- Crosby - HG-228 Jaw Jaw Turnbuckles SpecsDocument1 pageCrosby - HG-228 Jaw Jaw Turnbuckles SpecsSalmanNo ratings yet

- BL Spherical Plain BearingsDocument16 pagesBL Spherical Plain BearingsAgus YulfizarNo ratings yet

- Crosby 2130 2150Document1 pageCrosby 2130 2150Sumner TingNo ratings yet

- Bearing Lock Nuts Brochure 20200515Document8 pagesBearing Lock Nuts Brochure 20200515Bayu SutiaraNo ratings yet

- Mckissick RJ Style Drilling BlocksDocument1 pageMckissick RJ Style Drilling BlocksRichard EVNo ratings yet

- Brochure PDFDocument4 pagesBrochure PDFSUJITH KRISHNANNo ratings yet

- Evaluation of External Loads On Welding Neck Flanges As Per Code Case 2901Document6 pagesEvaluation of External Loads On Welding Neck Flanges As Per Code Case 2901NirmalNo ratings yet

- FD Grip Joint Design SpecificationDocument18 pagesFD Grip Joint Design SpecificationMangisi Haryanto ParapatNo ratings yet

- Cold Tuff Master LinkDocument1 pageCold Tuff Master LinkSelamet MirantoNo ratings yet

- Aluminum Structures: A Guide to Their Specifications and DesignFrom EverandAluminum Structures: A Guide to Their Specifications and DesignRating: 5 out of 5 stars5/5 (2)

- Wire Rope Slings - Certex PDFDocument27 pagesWire Rope Slings - Certex PDFPernando SagaNo ratings yet

- Rigging NotesDocument84 pagesRigging Notesrobythoppil88% (24)

- Slings EN 12385-4 - CLASS 6X19Document1 pageSlings EN 12385-4 - CLASS 6X19Ned VasicNo ratings yet

- Wire Ropes and DrillingDocument32 pagesWire Ropes and DrillingNed VasicNo ratings yet

- Lifting Design ConsiderationsDocument3 pagesLifting Design ConsiderationsNed VasicNo ratings yet

- New Assembly Instruction of SMG 1Document49 pagesNew Assembly Instruction of SMG 1akhilesh120No ratings yet

- Especificaciones de Construcción de Trabajo para La Gestión de Las Actividades de SoldaduraDocument14 pagesEspecificaciones de Construcción de Trabajo para La Gestión de Las Actividades de SoldaduraMartin Morales RodriguezNo ratings yet

- General Specifications: Model FU20 Widebody Type pH/ORP SensorDocument21 pagesGeneral Specifications: Model FU20 Widebody Type pH/ORP SensoringNo ratings yet

- Temtron LinecardDocument2 pagesTemtron LinecardAthosSchiavoneNo ratings yet

- Prep Application & Troubleshooting Guide: Commercial and Industrial Flooring SystemsDocument7 pagesPrep Application & Troubleshooting Guide: Commercial and Industrial Flooring Systemsben100% (1)

- MSA Ball Valves PDFDocument24 pagesMSA Ball Valves PDFLuka Borna100% (1)

- HT5Document19 pagesHT5VuiKuanNo ratings yet

- NRG Spinning ProfileDocument10 pagesNRG Spinning Profilesadman sakibNo ratings yet

- Pelletizing Process PDFDocument8 pagesPelletizing Process PDFAbdulhakeemSolimanNo ratings yet

- Product Testing PET Preform BottleDocument9 pagesProduct Testing PET Preform BottleShikha SinghNo ratings yet

- CMS 2000 Bro - ENDocument4 pagesCMS 2000 Bro - ENAndrés Galindo TNo ratings yet

- Mauri Ora Mental Health Sanitary Schedule Te Whatu Ora Lakes REV 9Document14 pagesMauri Ora Mental Health Sanitary Schedule Te Whatu Ora Lakes REV 9cesarNo ratings yet

- Electronics: A New Opportunity For Waste Prevention, Reuse, and RecyclingDocument4 pagesElectronics: A New Opportunity For Waste Prevention, Reuse, and RecyclingOmoloye SulaymanNo ratings yet

- CBDD Standard Paint Spec (With SW Data)Document5 pagesCBDD Standard Paint Spec (With SW Data)lightsonsNo ratings yet

- Seat Tracks and Anchor Plates CatalogDocument7 pagesSeat Tracks and Anchor Plates CatalogSergey FedorinovNo ratings yet

- Building Technology ReviewerDocument117 pagesBuilding Technology ReviewerJess AndanNo ratings yet

- Secondary Injection Testing Vs PrimaryDocument2 pagesSecondary Injection Testing Vs Primaryeddie2166No ratings yet

- Excel-Arc 71 Welding Wire GuideDocument2 pagesExcel-Arc 71 Welding Wire GuidegizaloNo ratings yet

- Chemrite - 520Document2 pagesChemrite - 520ICPL-RWPNo ratings yet

- T4 DNA Ligase Buffer For Ion TorrentDocument3 pagesT4 DNA Ligase Buffer For Ion TorrentNabilahNo ratings yet

- Roller Mill Grinders - Advantages, Limitations and How Roller Mill Grinders Are Changing For The BetterDocument4 pagesRoller Mill Grinders - Advantages, Limitations and How Roller Mill Grinders Are Changing For The BetterMilling and Grain magazineNo ratings yet

- Schema Sigurante A Class A 170Document4 pagesSchema Sigurante A Class A 170ginutaNo ratings yet

- EjqjjqeDocument13 pagesEjqjjqeAyu NurizzaNo ratings yet

- Ammonia Cracker PDFDocument8 pagesAmmonia Cracker PDFpinky_y2kNo ratings yet

- Hand Panning for Copper Ore ConcentrationDocument4 pagesHand Panning for Copper Ore ConcentrationVincent Tayanes CuiNo ratings yet

- Gruner D 238 ENDocument12 pagesGruner D 238 ENErdinç Eşref UsluNo ratings yet

- Local, Distortional, and Euler Buckling of Thin-Walled ColumnsDocument17 pagesLocal, Distortional, and Euler Buckling of Thin-Walled ColumnsReaditReaditNo ratings yet

- Ansys Capabilities 14.5Document8 pagesAnsys Capabilities 14.5viswanathyakkalaNo ratings yet