Professional Documents

Culture Documents

Transocean Flyer Transpoxy Masterbond

Uploaded by

Antonio MendezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transocean Flyer Transpoxy Masterbond

Uploaded by

Antonio MendezCopyright:

Available Formats

Transpoxy Masterbond

The versatile It is common knowledge that a better quality of surface preparation results

in a longer life time expectation of the coating system. Therefore, blast clean-

solution for ing or high pressure waterjetting are usually preferred over mechanical surface

preparation methods. However, reality shows that blasting is not always pos-

maintenance of sible or desired. Access, time and budget are just but a few of the reasons why

ships and steel surface preparation by using power tools such as wire brushes or sanding disks

are the only feasible option. Transpoxy Masterbond was developed as an anti-

structures corrosive system not only on blast cleaned steel but also on powertool cleaned

surfaces. This knowledge gives operators and owners peace of mind as only

one type of paint is needed regardless whether blast cleaning or powertool

cleaning is used as surface preparation method.

Exceptionally suitable for general maintenance of all vessel areas. Upgrades

existing paint systems.

Excellent corrosion protection and good resistance against impact and abrasion.

Tolerates a lower degree of surface preparation. Compatible with firmly adher-

ent old coating systems. Can be recoated with various finishing systems.

Grain carriage certificate available. Low flame spread characteristics according

to the IMO FTP-code.

Approvals by various companies such as Petronas, Shell, YPF, Petrobras, Swire

and many more.

Approved as coating for ballast tanks according to IMO-PSPC standard.

Approved as coating for crude oil tanks according to IMO-PSPC standard.

Approved for Jet Fuel carriage according to MIL-Spec PRF 4556F.

Transpoxy Masterbond

Superior performance in tests and practice The laughing dolphin

The excellent anticorrosion protection of Transpoxy Masterbond was proved in a

guarantees worldwide

benchmark with other surface tolerant epoxy formulations. Panels coated with 1 coat local service. It’s unique!

of paint were measured with Electrochemical Impedance Spectroscopy (EIS) in line with

Since 1959, Transocean Coatings is

ISO 16773.

active in the manufacture and sup-

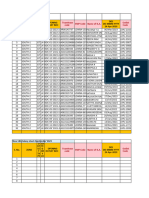

Resistance - Rc (Ω/cmC) after 3 weeks Relative water uptake after 3 weeks ply of antifoulings, anticorrosives and

other coatings for commercial ships,

5,10E+08 0,6

0,5

4,10E+08

3,10E+08

0,4 pleasure crafts and steel structures

onshore as well as offshore.

0,3

2,10E+08

0,2

1,10E+08 0,1

Extensive research and develop-

1,00E+07 0

Transpoxy

Masterbond

Competitor 1 Competitor 2 Competitor 3 Competitor 4 Transpoxy

Masterbond

Competitor 1 Competitor 2 Competitor 3 Competitor 4 ment work has provided Transocean

Coatings with a series of products

Resistance (Rc) in Ω/cmC offered by the coating. Relative water absorption by the coating. Low values

which professionals acknowledge to be

Higher values mean better corrosion resistance. indicate better corrosion protection. Again, Transpoxy

Transpoxy Masterbond offers the highest resistance Masterbond has the lowest values of all tested surface complete and of high quality.

value. tolerant epoxies. Transocean Coatings has a network

of manufacturers, producing its range

These results clearly demonstrate superior properties which is supported by results of coatings in some 40 countries and

from practice too. Below pictures of storage tanks after 6 years of exposure in a subsequently distributing the paints to

marine-industrial climate. The tanks were initially painted with a 2-layer system of all continents.

Transpoxy Masterbond and topcoated with Transurethane Finish Matt. Manufacturing takes place using strin-

After 6 years, the tanks are in excellent condition, even the riveted sections which are gent formulations. Whether a product

known sources of corrosion are very well protected. is supplied in Europe, Asia, North- or

South America, in Africa or Australia,

the quality is guaranteed identical.

At any shore therefore, wherever in

the world, you can rely on Transocean

Coatings. And local service assures

quick delivery of factory-fresh products

at competitive prices.

That’s unique!

Transocean Coatings

Now, Transpoxy Masterbond is well-known for its excellent performance on steel sub-

Prins Hendrikkade 12c

strates. However, the product offers superior adhesion on concrete substrate too. In

Australia for instance, Transpoxy Masterbond has been and is being extensively used as 3071 KB Rotterdam

concrete primer or concrete coating system on itself for factory floorings, distribution The Netherlands

centres, parking lots, garage floors etc.

Phone +31 (0)10 - 413 44 77

Below two project examples where a full Transpoxy Masterbond system was used as a info@transocean-coatings.com

priming and finishing system. www.transocean-coatings.com

8.000 mC aircraft hangar at Melbourne airport. 8.000 mC factory hall in Dan denong industrial area.

WORLDWIDE NETWORK WITH LOCAL SERVICE

You might also like

- Lime Hemp and Rice Husk-Based Concretes for Building EnvelopesFrom EverandLime Hemp and Rice Husk-Based Concretes for Building EnvelopesNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Offshore Eng PDFDocument8 pagesOffshore Eng PDFClintonDestinyNo ratings yet

- Transocean - C5-M Typical Coating SystemDocument2 pagesTransocean - C5-M Typical Coating SystemMuhammad Nu'manNo ratings yet

- Marine Paints GuideDocument8 pagesMarine Paints GuideKakde Krushna LNo ratings yet

- Transocean Marinepaints Engels 2018Document8 pagesTransocean Marinepaints Engels 2018Tom CatNo ratings yet

- Epoxy resin free flow grout for heavy duty applicationsDocument4 pagesEpoxy resin free flow grout for heavy duty applicationsFeri Oktara IrawanNo ratings yet

- Derakane - Tech SupportDocument34 pagesDerakane - Tech SupportJainam ShahNo ratings yet

- Team Repair - NewDocument36 pagesTeam Repair - NewSachin D PatilNo ratings yet

- Technical Data Sheet: Epoguard EnamelDocument3 pagesTechnical Data Sheet: Epoguard Enameltrường phạmNo ratings yet

- SubseaLV DatasheetDocument1 pageSubseaLV DatasheetPablo TorresNo ratings yet

- B-13-03567EN KMT Abrasive Flow Products ROCTECDocument8 pagesB-13-03567EN KMT Abrasive Flow Products ROCTECAtul ScNo ratings yet

- RESOLTECH Chemical Resistance GuideDocument45 pagesRESOLTECH Chemical Resistance GuideAhmed Ben HmidaNo ratings yet

- Pure Epoxies Vs Epoxy Mastics For Maintenance PDFDocument4 pagesPure Epoxies Vs Epoxy Mastics For Maintenance PDF003086100% (1)

- Duraplate 301K - Sherwin WilliamsDocument4 pagesDuraplate 301K - Sherwin WilliamsJardenson CésarNo ratings yet

- Transocean - C5-I Typical Coating System INDUSTRIALDocument1 pageTransocean - C5-I Typical Coating System INDUSTRIALfpiccoli_4No ratings yet

- Intergard 343 - Marine CoatingsDocument9 pagesIntergard 343 - Marine CoatingsSerggie TabanaoNo ratings yet

- Intergard 343 Universal PrimerDocument9 pagesIntergard 343 Universal PrimerAndri AjaNo ratings yet

- E-Bond T526 Technical Data Sheet-1Document5 pagesE-Bond T526 Technical Data Sheet-1fatemeh.ahmadkhaniNo ratings yet

- X-Roc Epoxybond: Epoxy Resin Bonding AgentDocument2 pagesX-Roc Epoxybond: Epoxy Resin Bonding AgentAmr RagabNo ratings yet

- Conbextra EP150 UAEDocument4 pagesConbextra EP150 UAEjasonNo ratings yet

- AF Range BrochureDocument27 pagesAF Range Brochureboom10100% (1)

- FOSROCDocument4 pagesFOSROCAji Setya Riio NurcahyoNo ratings yet

- Epoxy TypesDocument4 pagesEpoxy TypesBechir FoudhailiNo ratings yet

- Understanding The Revised 2011 ANSI AWWA D102 StandardDocument31 pagesUnderstanding The Revised 2011 ANSI AWWA D102 StandardClarkFedele27No ratings yet

- cloverdale-tds-83021a-eDocument4 pagescloverdale-tds-83021a-eErnesto Javier Martín RosabalNo ratings yet

- Reinforcement Rod Coatings GuideDocument3 pagesReinforcement Rod Coatings GuideRishikesh DholeNo ratings yet

- A9RD4BE Hipoclorito Derakane TradcirDocument8 pagesA9RD4BE Hipoclorito Derakane TradcircaveroglassaNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Derakane - Tech SupportDocument32 pagesDerakane - Tech SupportJainam ShahNo ratings yet

- Epoxy CatalogueDocument21 pagesEpoxy CatalogueChinthamani PandiNo ratings yet

- Nelcote E-766B PCB Epoxy Prepreg, 120 E-Glass Reinforced.Document5 pagesNelcote E-766B PCB Epoxy Prepreg, 120 E-Glass Reinforced.jackNo ratings yet

- Interseal 670HS: Surface Tolerant EpoxyDocument2 pagesInterseal 670HS: Surface Tolerant EpoxyAndri AjaNo ratings yet

- DERAKANECRGuideDocument74 pagesDERAKANECRGuideBapu612345No ratings yet

- Journal of Mechanical EngineeringDocument11 pagesJournal of Mechanical EngineeringNawaf SaeidNo ratings yet

- Carbozinc 608 HB-ProductFlyer - 112817Document2 pagesCarbozinc 608 HB-ProductFlyer - 112817Muhammad Prima JayaNo ratings yet

- SWANCOR 901-3: Epoxy Vinyl Ester ResinsDocument2 pagesSWANCOR 901-3: Epoxy Vinyl Ester ResinsSofya Andarina100% (1)

- Technical Data Sheet for X-Roc EpoxyBondDocument2 pagesTechnical Data Sheet for X-Roc EpoxyBondLakmal JayashanthaNo ratings yet

- Selexsorb COS Data SheetDocument2 pagesSelexsorb COS Data SheetAmir RahbariNo ratings yet

- PS 14 Anchor Bolt TolerancesDocument4 pagesPS 14 Anchor Bolt TolerancesjebrijaNo ratings yet

- Fosroc Conbextra EP150: Free Flow Epoxy Resin Grout Uses DescriptionDocument4 pagesFosroc Conbextra EP150: Free Flow Epoxy Resin Grout Uses DescriptionVincent JavateNo ratings yet

- Protective CoatingsDocument8 pagesProtective CoatingsKakde Krushna LNo ratings yet

- cloverdale-tds-83003Document4 pagescloverdale-tds-83003Ernesto Javier Martín RosabalNo ratings yet

- Conbextra EP120 TDS PDFDocument3 pagesConbextra EP120 TDS PDFzulfikarNo ratings yet

- 10 Conbextra EP10Document2 pages10 Conbextra EP10ahmad wildaanNo ratings yet

- Approved Data Sheet & Painting SchemeDocument10 pagesApproved Data Sheet & Painting SchemeParikshit GaurNo ratings yet

- Simacover EP Tar Epoxy 3404-00Document4 pagesSimacover EP Tar Epoxy 3404-00Perseroan MustikaNo ratings yet

- Conbextra Ep40Document3 pagesConbextra Ep40talatzahoorNo ratings yet

- Primal Ac337 Emulsione Acrilica 890029 TdsDocument18 pagesPrimal Ac337 Emulsione Acrilica 890029 TdsForeverNo ratings yet

- Cortec ProductDocument20 pagesCortec ProductLiu YangtzeNo ratings yet

- Specseal LC Endothermic Firestop Sealant: ApplicationsDocument2 pagesSpecseal LC Endothermic Firestop Sealant: ApplicationsKarim TarekNo ratings yet

- tính kháng hóa chất của đóng rắn epoxyDocument15 pagestính kháng hóa chất của đóng rắn epoxyminhhuan0101100% (1)

- Conbextra Ep65Document3 pagesConbextra Ep65Angelo Carlo MalabananNo ratings yet

- CWST Coating For Subsea Fasteners 2pp FINALDocument2 pagesCWST Coating For Subsea Fasteners 2pp FINALRizky PratamaNo ratings yet

- SF 0654Document4 pagesSF 0654QA LAB ISMNo ratings yet

- Fosroc Nitomortar EL: Constructive SolutionsDocument4 pagesFosroc Nitomortar EL: Constructive SolutionsVincent JavateNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Polymer Linings For Restoration Corrosion Protection of Steel SurfacesDocument7 pagesPolymer Linings For Restoration Corrosion Protection of Steel Surfacesfrancisco javier rubioNo ratings yet

- XOMOXPlugvalvesEurope BrochureDocument12 pagesXOMOXPlugvalvesEurope BrochureAnonymous ItzBhUGoiNo ratings yet

- Interline 850+br+eng PDFDocument2 pagesInterline 850+br+eng PDFMohamed NouzerNo ratings yet

- Feasibility Studies Guide for Economic ProjectsDocument60 pagesFeasibility Studies Guide for Economic Projectsice100% (2)

- Viii Class Xi B Studies AssignmentDocument1 pageViii Class Xi B Studies AssignmentAwwCakeNo ratings yet

- Cryomatrix Series Cryo Freezer User & Service ManualDocument30 pagesCryomatrix Series Cryo Freezer User & Service ManualTrung Hiếu CamNo ratings yet

- Ross12e Chapter05 TBDocument19 pagesRoss12e Chapter05 TBHải YếnNo ratings yet

- Formula Sheet: FV (Continuous Compounding) PVDocument5 pagesFormula Sheet: FV (Continuous Compounding) PVTanzim HudaNo ratings yet

- An Economics AssignmentDocument17 pagesAn Economics AssignmentReza RezaNo ratings yet

- Provisional Sum and Prime Cost ItemsDocument4 pagesProvisional Sum and Prime Cost Itemsizyan_zulaikha100% (2)

- Hotel Reservation FormDocument1 pageHotel Reservation FormAdriansyah GokongNo ratings yet

- Globalization TheoryDocument20 pagesGlobalization Theoryyehualashet TadesseNo ratings yet

- Gestão Da Diversidade 6Document2 pagesGestão Da Diversidade 6Adaís LinsNo ratings yet

- GBD1006 5033 ASM2 Presentation UniqueTeamDocument49 pagesGBD1006 5033 ASM2 Presentation UniqueTeamPhương DungNo ratings yet

- Cost Sheet Direct CostgDocument19 pagesCost Sheet Direct CostgLOKESH KUMARNo ratings yet

- Purchase order for chemical lab equipmentDocument2 pagesPurchase order for chemical lab equipmentYadnyesh KarkareNo ratings yet

- Section 9 - Brickwork and BlockworkDocument6 pagesSection 9 - Brickwork and BlockworkShing Faat WongNo ratings yet

- Synchro-Cog HT: Synchronous Drive BeltDocument32 pagesSynchro-Cog HT: Synchronous Drive BeltDavid BaylissNo ratings yet

- LBA Salary Sheet September'2023 SouthDocument28 pagesLBA Salary Sheet September'2023 SouthManojNo ratings yet

- Cost Acc. & Control QuizzesDocument18 pagesCost Acc. & Control Quizzesjessamae gundanNo ratings yet

- CICPA Contract Report SampleDocument1 pageCICPA Contract Report SampleRhea RamirezNo ratings yet

- Engineering Economy For Video 1Document12 pagesEngineering Economy For Video 1Domingo, Jake VincentNo ratings yet

- New Classicals, New Keynesian and Neo New Classical ModelDocument33 pagesNew Classicals, New Keynesian and Neo New Classical ModelmahamNo ratings yet

- Chapter 5 Discrete Probalitity Dsitributions - Jaggia4e - PPTDocument66 pagesChapter 5 Discrete Probalitity Dsitributions - Jaggia4e - PPTpeter shlomoNo ratings yet

- SAE Flat Washer Dimensions & Specifications - AFT FastenersDocument1 pageSAE Flat Washer Dimensions & Specifications - AFT FastenersKai LinNo ratings yet

- Brochure 3F Linda LED enDocument30 pagesBrochure 3F Linda LED enHarris SouglerisNo ratings yet

- Week 6 Homework Chi-Square TestsDocument58 pagesWeek 6 Homework Chi-Square TestsJasonNo ratings yet

- CatrionaDocument4 pagesCatrionaShyrine EjemNo ratings yet

- Process For Materials and ConversionDocument4 pagesProcess For Materials and ConversionShahzaib NaseerNo ratings yet

- Eco Test 1 Prep NotesDocument3 pagesEco Test 1 Prep NotesadzwinjNo ratings yet

- ZambiaDocument402 pagesZambiaPaula-Raluca Socaciu100% (1)

- Futures' Bhavcopy Analyser - Setup 1Document6 pagesFutures' Bhavcopy Analyser - Setup 1Sreenivas GuduruNo ratings yet

- Voskoboynikov2021 TheRussianEconomy AVeryShortIntroductionDocument4 pagesVoskoboynikov2021 TheRussianEconomy AVeryShortIntroductionnizar.22139No ratings yet