Professional Documents

Culture Documents

Long-Term Behavior of Prestressed Composite Beams at Service Loads For One Year

Uploaded by

LauOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Long-Term Behavior of Prestressed Composite Beams at Service Loads For One Year

Uploaded by

LauCopyright:

Available Formats

Long-Term Behavior of Prestressed Composite Beams at

Service Loads for One Year

Weichen Xue1; Min Ding2; Chi He3; and Jie Li4

Abstract: The combined effects of creep and shrinkage of concrete and relaxation of prestressing tendons cause gradual changes in the

internal forces and deflections of composite beams. However, most of the research work conducted on prestressed steel–concrete com-

Downloaded from ascelibrary.org by New York University on 05/15/15. Copyright ASCE. For personal use only; all rights reserved.

posite beams has focused on short-term behavior; research findings on the long-term behavior are scarce in the literature. For the

wide-scale use of prestressed composite beams in civil engineering applications, the long-term behavior must be investigated. This paper

presents an experimental program designed to examine the long-term behavior of prestressed composite beams under sustained load

conditions for one year. The test program consisted of two prestressed composite beams and one nonprestressed composite beam. On the

basis of the age-adjusted effective modulus method and energy principle, the creep stiffness matrix and the creep force matrix of

prestressed composite beams were developed. A time-dependent analytical model is presented to predict the long-term behavior of

prestressed composite beams. Close agreement is observed between the analytical and experimental results. It is proposed that the

Multiplier 3.1 of the instantaneous deflection be used to calculate the deflection of prestressed composite beams for one year.

DOI: 10.1061/共ASCE兲0733-9445共2008兲134:6共930兲

CE Database subject headings: Composite beams; Steel; Concrete; Time dependence; Prestressing; Creep; Shrinkage.

Introduction bridge engineering, large-span building structures, rail transit, and

strengthening existing structures.

Nonprestressed steel–concrete composite beams are a popular and Prestressed composite beams, like all other structural mem-

economical form of construction in both buildings and bridges. In bers, must be designed to satisfy the requirements of both the

a composite beam the steel section is connected to the concrete strength and serviceability limit states. Design for adequate flex-

slab using shear connectors so that they act compositely. This ural strength is relatively straightforward, with plastification in

structural arrangement results in an efficient lightweight beam positive bending and buckling in negative bending generally gov-

with a high load-carrying capacity. But there are also some prob- erning the ultimate strength of individual cross sections. The de-

lems in composite beams, such as there being too large a deflec- sign for serviceability, however, is not as straightforward, since

tion at midspan. In addition, in the negative bending region, the the prediction of behavior under sustained service loads is com-

slab is in tension and may crack at service loads. The slab is, plicated by time-dependent deformations in the composite beams

therefore, far less beneficial, since its contribution to the strength due to creep and shrinkage of concrete and relaxation of pre-

and stiffness of the composite section largely disappears when the stressing tendons. At the present time, a large number of research

concrete cracks. studies on prestressed composite beams have focused on short-

Composite beams prestressed with external tendons can over- term behavior 共Szilard 1959; Hoadley 1963; Reagen and Krahl

come the above and at the same time offer several major advan- 1967; Saadatmanesh et al. 1989a,b; Dezi 1994; Dall’Asta and

tages, such as elastic behavior under heavier loads, increased Dezi 1998; Chen 2005; Lorenc and Kubica 2006兲, whereas there

ultimate capacity, and improved fatigue and fracture behavior. are few researches published on the long-term behavior of exter-

Externally prestressed composite beams are mainly employed in nally prestressed composite beams.

A serviceability analysis of simply supported nonprestressed

1

Professor, Dept. of Building Engineering, Tongji Univ., Shanghai, composite beams that included the effects of creep and shrinkage

China 200092 共corresponding author兲. E-mail: xuewc@mail. in the concrete slab was presented previously 共Gilbert 1988;

tongji.edu.cn

2 Bradford and Gilbert 1989兲. To validate the analytical model, four

Ph.D. Candidate, Dept. of Building Engineering, Tongji Univ.,

Shanghai, China 200092. E-mail: dingmin2005@gmail.com simply supported composite beams were tested 共Bradford and

3

Student, Dept. of Building Engineering, Tongji Univ., Shanghai, Gilbert 1991兲. The analytical and experimental research program

China 200092. E-mail: hechi@163.com at the University of New South Wales 共Sydney, Australia兲 has

4

Professor, Dept. of Building Engineering, Tongji Univ., Shanghai, been extended to study the long-term behavior of statically inde-

China 200092. E-mail: lijie@mail.tongji.edu.cn terminate composite beams. A second series of long-term tests

Note. Associate Editor: Yahya C. Kurama. Discussion open until was undertaken on two-span continuous composite beams sub-

November 1, 2008. Separate discussions must be submitted for individual jected to sustained uniformly distributed load on both spans over

papers. To extend the closing date by one month, a written request must

a period of 340 days 共Gilbert and Bradford 1991; Gilbert and

be filed with the ASCE Managing Editor. The manuscript for this paper

was submitted for review and possible publication on May 21, 2007; Bradford 1995兲. An analysis for simply supported and continuous

approved on October 8, 2007. This paper is part of the Journal of Struc- composite beams was performed by taking into account the

tural Engineering, Vol. 134, No. 6, June 1, 2008. ©ASCE, ISSN 0733- shrinkage only and then the simultaneous creep effects. A generic

9445/2008/6-930–937/$25.00. modeling for the time-dependent analysis of composite beams

930 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008

J. Struct. Eng. 2008.134:930-937.

Downloaded from ascelibrary.org by New York University on 05/15/15. Copyright ASCE. For personal use only; all rights reserved.

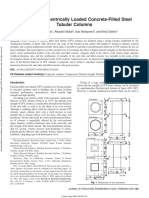

Fig. 1. Overall geometry and reinforcement layout of composite beams

with partial shear interaction that occurs due to the deformation of stressed composite beams, designated PC-1 and PC-2, and the

the shear connection was presented 共Ranzi and Bradford 2006兲. other was a nonprestressed composite beam, designated RC. All

A simplified time-dependent analysis for continuous compos- specimens had the same cross sections, as shown in Fig. 1. Shear

ite beams with flexible shear connection, subjected to static ac- studs were welded to the top flange of the steel beam, spacing

tions, settlements of the supports, shrinkage, and prestressing of 100 mm for PC-1 and 150 mm for PC-2 along the center line of

the concrete slab, was proposed 共Dezi et al. 1995, 1996兲. A time- the beam. Fig. 1 shows the overall geometry and cross section of

dependent analysis program was developed to investigate long- the beams. Here, the units are mm.

term behavior of composite bridges with prestressed composite

slabs 共Wang et al. 1998兲. The program presented the effect of

Material Properties

concrete creep and shrinkage using layered subdivision of each

element, prestressing tendons, structure transformation, effects of The concrete mix proportions are shown in Table 1. Steel wires of

construction loading, and concrete age of each part. high tensile strength with low relaxation 共the relaxation rate is not

This paper focuses on the long-term behavior of externally larger than 2.5%兲 were used as the prestressing tendons. The me-

prestressed composite beams at service loads, as affected by time chanical properties of the concrete, bars, steel beams, and studs

effects, such as creep and shrinkage of concrete slabs and relax- are listed in Tables 2 and 3.

ation of prestressing tendons. This paper describes an experimen-

tal program with three composite beams subjected to sustained Test Loading

uniformly distributed loads. Deflections and prestressing tendon

strains at midspan were monitored for one year. A time-dependent The initial jacking stress was 70% of the ultimate tensile strength

analytical method is proposed to investigate the long-term behav- of the prestressing tendons. The composite beams were only sub-

ior of composite beams, referred to as the general method of time

analysis, where the time-dependent behavior of the concrete is

modeled using algebraic methods, such as the age-adjusted effec- Table 1. Mix Proportions of Bonding Agents

tive modulus method 共AEMM兲. The calculated and measured re-

sponses of these beams were in close agreement, with final long- Fine Coarse

term deflections being several times the short-term values. Water Cement aggregate aggregate

共kg/ m3兲 共kg/ m3兲 共kg/ m3兲 共kg/ m3兲

190.8 477 612 1,135

Experimental Program

Table 2. Mechanical Properties of Concrete

Specimens Elastic Prism compressive Cube compressive

modulus Ec strength f c strength f cu

Three simply supported steel–concrete composite beams were 共GPa兲 共MPa兲 共MPa兲

tested in a scale of 1:5 to simulate the composite beams in a

30.6 27.1 35.5

practical building structure. Two of them were externally pre-

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008 / 931

J. Struct. Eng. 2008.134:930-937.

Table 3. Mechanical Properties of Steel

Prestressing Steel

Batch Bar tendon beam Stud

Normal diameter 共mm兲 6 5 — 16

Yield strength 共MPa兲 371 — 301 400

Ultimate tensile strength 共MPa兲 498 1824 444 444

Elastic modulus 共GPa兲 211 189 190 —

Ultimate elongation 共%兲 22 13 28 17

jected to their own weight before prestressing to simulate the

stresses in the applications. The prestressed composite beams Fig. 3. Comparison of long-term vertical midspan deflection of

Downloaded from ascelibrary.org by New York University on 05/15/15. Copyright ASCE. For personal use only; all rights reserved.

were then subjected to sustained uniformly distributed loads at beams

room temperature for about one year. The loads were applied by

plain concrete blocks mounted on the composite beams 共as illus-

trated in Fig. 2兲. The externally prestressed composite beams had a higher ratio

of long-term-to-instantaneous deflection of 3.1, whereas the non-

prestressed composite beam had a lower ratio of 2.0. In general,

Instrumentation the ratio of long-term-to-instantaneous deflection of prestressed

composite beams depended on the spacing of studs, with the ratio

During the loads testing, the vertical deflections of the beams at

increasing as the spacing increased.

midspan were measured with mechanical dial gauges 共with an

accuracy of 0.01 mm兲 mounted on immobilized stands. The strain

gauges on the prestressing tendons, steel beams, and concrete

slabs were monitored to measure the prestressing tendon strains, Long-Term Prestressing Tendon Strain

strains of steel beams, and concrete slabs. In addition, slips be- Fig. 4 presents the long-term change in the prestressing tendon

tween steel beams and concrete slabs were measured with me- strain of prestressed composite beams. As shown in Fig. 4, the

chanical dial gauges 共with an accuracy of 0.001 mm兲. prestressing tendon strains progressively decreased with time. The

two prestressed composite beams exhibited a similar change in

prestressing tendon strains. After anchorage, the instantaneous

Experimental Results prestressing tendon strains were 5106 for PC-1 and 5255

for PC-2. After 360 days, strains of prestressing tendons for PC-1

Long-Term Deflection Behavior were 763 lower than those of the instantaneous values and

that for PC-2 were 722 . The reduction was about 15%. The

Fig. 3 presents the long-term vertical midspan deflection of the reduction of prestressing tendon strains at 24 h after prestressing

composite beams. The general trend is a high rate of increase of occupied about 20% of the total strain reduction; that on 90 days

deflection for the early period after loading followed by a more accounted for about 34%, 65% on 180 days, and 88% on

gradual rate of increase of deflection. This behavior was exhibited 270 days.

by all beams, irrespective of prestressing tendons or distance of In conclusion, after prestressing the decrease ratio of prestress-

studs. ing tendon strains was higher for the early period, and it became

lower with time.

Long-Term Steel Beam Strain

Fig. 5 presents the long-term change in the bottom flange strain at

midspan of the three composite beams. As shown in Fig. 5, after

Fig. 2. Test loading Fig. 4. Comparison of long-term prestressing tendon strain

932 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008

J. Struct. Eng. 2008.134:930-937.

Fig. 5. Comparison of long-term steel beam strain

Downloaded from ascelibrary.org by New York University on 05/15/15. Copyright ASCE. For personal use only; all rights reserved.

anchorage and loading, the instantaneous bottom flange strains of Fig. 7. Discretization of composite beams used in layered finite-

PC-1, PC-2, and RC, were 344, 297, and 318 , respectively. element analysis

After 180 days, the strains were 393, 427, and 366 , which

were about 15% higher than the instantaneous values. Then, the

strain reached its maximum value after 200 days, and following more or less, unchanged, which is in accordance with the experi-

that it reduced. 360 days after, it became 345, 295, and 252 . mental results monitored by Bradford and Gilbert 共Bradford and

This was probably caused by the surrounding temperature. Gilbert 1991兲.

In general, trends of bottom flange strains of the prestressed In the nonprestressed composite beam, there was no slip at

composite beams were close to that of the nonprestressed com- slab–steel interface during the period of one year’s sustained

posite beam. loading.

Long-Term Concrete Slab Strain Time-Dependent Analysis

Fig. 6 presents the long-term change in the concrete slab strain at

midspan of the three composite beams. As shown in Fig. 6, after Programming Scheme

anchorage and loading, the instantaneous concrete slab stains of

PC-1, PC-2, and RC were −260, −260, and −156 , respec- The program was developed on the basis of a finite-element step-

tively. After 180 days, the strains got to −92, 64, and 88 , by-step method to predict the long-term behavior of prestressed

which increased to 168, 324, and 305 , respectively. Then, the composite beams. The long-term factors, such as concrete creep,

strains reduced. After 360 days, the strains got to −294, −104, and shrinkage, and relaxation of prestressing tendons are considered

−94 , which were 202, 168, and 243 lower than that after in the program.

180 days. On one hand, the composite beam was discretized into several

elements, and the midcross section was selected out for analysis.

The cross section was subdivided into about 20 layers according

Long-Term Slip at the Slab–Steel Interface to concrete, steel beam, rebar, and prestressing tendon 共see Fig.

7兲. The number of elements and layers depends on the calculation

As jacking stress got to 45% of the ultimate tensile strength, slips accuracy required. On the other hand, the method also required

occurred at the slab–steel interface. The maximum value could discretization in time, with subdivision of the creep process into

reach to 0.05 mm. Comparatively, the slips depended on the stud several intervals. Within each time interval, the increments of

distance, with lower slip values as the stud distance decreased. nodal displacements and forces due to creep were calculated and

During the monitoring period of 360 days, the slips remained, added to the initial values to get the nodal displacements and

forces at the end of the interval or the start of the next one. The

integrals of internal forces and displacements at each service

stage were approximated by means of the trapezoidal rule.

The discretization of composite beams used in the layered

finite-element analysis is shown in Fig. 7. The composite cross

section was divided into five concrete layers, 14 steel beam lay-

ers, one prestressing tendon layer, and two rebar layers.

Assumptions

The calculation here is based on the following assumptions:

1. Concrete stress is not larger than 50% of the limited strength.

And within this range, the creep strain–stress relationship

remains linear. It is allowable to superpose strains.

2. Slip at the slab–beam interface, between the concrete and

Fig. 6. Comparison of long-term concrete slab strain any embedded reinforcement, is negligible at service loads.

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008 / 933

J. Struct. Eng. 2008.134:930-937.

Downloaded from ascelibrary.org by New York University on 05/15/15. Copyright ASCE. For personal use only; all rights reserved.

Fig. 8. Equivalent linear strain

3. Plane sections remain plane; i.e., the strain distribution on

any section at any time is linear. 冕 N *

⌬ dA =

A0 0

冕 冉 冊 冕 冉 冊

N

A0

y

c − dA +

N Es

A0 Ec

y

c − dA

冋冕 冕 册

A1 A1 A2

Equivalent Creep Load N

= c dA + n0dA

A0

冋冕 冕 册

A1 A2

Creep is calculated on the basis of the AAEM method. Here, the

elastic modular ratio of a steel beam to concrete n is N1

− ydA + n0ydA 共2兲

A0 A1 A2

Es Es where n0 = 共Es / Ec兲; c = strain at the gravity center of the cross

n= = 关1 + 共t,兲兴 = n0关1 + 共t,兲兴 共1兲

E Ec section; and 共1 / 兲 = curvature. If C represents the gravity center

of the transformed section, then

Due to the time-dependent n, Geometrical properties of the trans-

formed section are time dependent. Ec, E, and 共t , 兲

冕A1

ydA + 冕A2

n0ydA = 0 共3兲

= functions of layer locations in the composite cross section and

冕 冕

are substituted by E*, E*, and *共t , 兲, respectively. The asterisk

means being related to the position of layer in the cross section dA + n0dA = A0 共4兲

and has properties as shown in the following: A1 A2

• In the concrete slab: E* = Ec; with Eqs. 共3兲 and 共4兲, Eq. 共2兲 becomes

• In the steel beam: E* = Es;

• In the concrete slab: E* = Ec; 兰A1⌬*0 dA

c = 共5兲

• In the steel beam: E* = Es; A0

• In the concrete slab: *共t , 兲 = 共t , 兲; and

• In the steel beam: *共t , 兲 = 0. In a similar way, according to the equivalent principle of vir-

tual work of bending stress, work done by stress, as shown in Fig.

Equivalent nodal loads refer to the node loads induced by

8共e兲, with strain in Fig. 8共b兲 is equal to the stress with strain in

initial strain ⌬*0 . As shown in Fig. 8共b兲, ⌬*0 is nonlinear on the

Fig. 8共c兲, and it can be expressed as

cross section and it is inconvenient to get the displacement 兵␦0其

directly, because it only exists at the section of the concrete por-

tion and does not exist at the section of the steel portion. Gener-

ally, the nonlinear ⌬*0 is converted into a linear one 关see Fig.

冕 My *

I0

⌬0 dA = 冕 冉 冊 冕 My

I0

y

c − dA +

n0

My

I0

冉 冊

y

c − dA

冋冕 冕 册

A1 A1 A2

8共c兲兴 on the basis of the equivalent principle of virtual work to M

calculate 兵␦0其 and 兵F0其. = c ydA + n0ydA

I0

冋冕 冕 册

Equivalent linear strain is calculated first. Fig. 8共a兲 presents A1 A2

the composite cross section at time 0; Fig. 8共b兲 presents the M1

initial strain of concrete; Fig. 8共c兲 presents the equivalent linear − y 2dA + n0y 2dA 共6兲

strain; Fig. 8共d兲 shows stress distribution on the cross section I0 A1 A2

induced by axial force N; and Fig. 8共e兲 shows stress distribution If C represents the gravity center of the transformed section, then

induced by moment M.

According to the equivalent principle of virtual work of axial

stress, work done by stress, as shown in Fig. 8共d兲, with strain in 冕 A1

y 2dA + 冕 A2

n0y 2dA = I0 共7兲

Fig. 8共b兲 is equal to the stress with strain in Fig. 8共c兲, and it can

be expressed as with Eq. 共7兲, Eq. 共6兲 becomes

934 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008

J. Struct. Eng. 2008.134:930-937.

1 兰A1y⌬*0 dA

=− 共8兲

I0

The stress and strain relationship of concrete is given by

⌬

⌬ = ⌬*0 + 共9兲

E*

n−1

⌬*0 = 兺 j

j=0 Ec

关*共tn,t j兲 − *共tn−1,t j兲兴

n−2

⌬t共t j+1,t j兲

兺

Downloaded from ascelibrary.org by New York University on 05/15/15. Copyright ASCE. For personal use only; all rights reserved.

+ 关1*共tn,t j兲 − 2*共tn−1,t j兲兴 共10兲 Fig. 9. Equivalent secondary creep internal force of composite cross

j=0 Ec

section

where ⌬ and ⌬ = strain and stress increments of concrete,

respectively.

By substituting the formula of ⌬*0 into Eqs. 共5兲 and 共8兲, the

Nbt M bt

following expressions are obtained: ⌬bt = − y⬘ 共13兲

冕 再兺

A1 I1

n−1

1 bj And that in steel beams is given by

c = 关*共tn,t j兲 − *共tn−1,t j兲兴

A0 Ec

冎

A1 j=0

n−2 Nst M st

⌬bt共t j+1,t j兲 ⌬st = − y⬙ 共14兲

+ 兺

j=0 Ec

关1*共tn,t j兲 − 2*共tn−1,t j兲兴 dA 共11兲 A2 I2

where y ⬘, y ⬙ = distance from their own axis, respectively.

1

=−

1

I0

冕 y 再 n−1

兺

bj

j=0 Ec

关*共tn,t j兲 − *共tn−1,t j兲兴

The stress redistribution on the composite cross section can be

calculated from Eqs. 共13兲 and 共14兲 and added to the elastic stress

to get the stress after creep.

冎

A1

n−2

⌬bt共t j+1,t j兲

+ 兺

j=0 Ec

关1*共tn,t j兲 − 2*共tn−1,t j兲兴 dA 共12兲 Time-Dependent Analysis Procedure

A time-dependent analytical program was proposed to predict the

where bj = elastic stress increment on the concrete cross section long-term behavior of prestressed composite beams. And the pro-

induced by a new load at the start of time interval 关ti , t j+1兴; cedure is shown in Fig. 10.

⌬bt共t j+1 , t j兲 = stress increment on the concrete cross section in-

duced by creep at time interval 关ti , t j+1兴. Comparisons between Computed and Measured

After the calculation of c and 共1 / 兲, 兵␦0其, nodal displace- Values

ments at the two ends of the element, can be obtained using the

principle of virtual work. At last, the creep equivalent nodal The three composite beams were computed by the time-

forces, fixed end forces induced by initial creep strain, can be dependent analysis procedure and the creep coefficients in the

calculated from the equation 兵F0其 = 兵Kt其兵␦0其. ACI 共CEB-FIP 1978 and CEB-FIP 1990兲 were used. The com-

parisons of computed values and measured results of deflections

for the three composite beams are shown in Fig. 11.

Redistribution of Internal Force on the Composite

As shown in Fig. 11, computed values and measured results

Cross Section Induced by Creep

are in reasonable agreement for the two prestressed composite

After the calculation of total secondary creep internal forces for beams and nonprestressed composite beam. The computed values

the composite cross-section members, the stress redistribution in according to CEB-FIP 1990 are larger than the measured values

them induced by secondary creep internal forces must be calcu- for the three composite beams. For RC, the computed values ac-

lated. cording to ACI are best match with the measured values.

Nt, M t, the secondary creep internal forces at time interval

n 关tn−1, tn兴 on the composite cross section, have been worked out.

Design Proposals on Long-Term Deflection

Fig. 9共a兲 represents secondary creep internal forces of the com-

posite cross section at interval n, applying on the gravity center of According to ANSI/AISC 360-05 共AISC 2005兲, there is no direct

the transformed cross section; the equivalent secondary creep in- guidance in the computation of the long-term deflections of com-

ternal forces of the concrete slab and steel beam at interval n are posite beams due to creep and shrinkage.

applied on the gravity center, respectively, as shown in Fig. 9共b兲. In EC.4 共CEN 1994兲, it reduces the bending stiffness to calcu-

Then Nbt, M bt, Nst, are M st are calculated satisfying the require- late the long-term vertical deflections of composite beams. The

ments of equilibrium and compatibility. effects of creep may be taken into account by using modular

As a result, the stress increment in concrete slabs induced by ratios nL for the concrete. The modular ratios depending on the

creep during interval n is given by type of loading are given by

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008 / 935

J. Struct. Eng. 2008.134:930-937.

Downloaded from ascelibrary.org by New York University on 05/15/15. Copyright ASCE. For personal use only; all rights reserved.

Fig. 11. Comparison of analytical and experimental results

Conclusion

The experimental results of a test program designed to investigate

the long-term behavior of prestressed composite beams have been

Fig. 10. Flow chart of time-dependent analysis presented and compared with the results from an analytical time-

dependent computer model.

Based on the results of this investigation, the following con-

clusions can be drawn:

nL = n0共1 + Lt兲 共15兲 1. The prestressed composite beams show a high rate of in-

where n0 = Es / Ecm; Es = value of elastic modulus of the steel beam; crease of deflection for the early period after loading fol-

Ecm = value of the secant modulus of elasticity of the concrete lowed by a more gradual rate of increase of deflection.

共short-term兲; t = creep coefficient at time t; and L = creep multi- 2. The ratio of long-term-to-instantaneous deflections of pre-

plier depending on the type of loading, which is taken as 1.1 for stressed composite beams was found to increase with the

permanent loads, 0.55 for primary and secondary effects of stud distance increasing.

shrinkage, and 1.5 for prestressing by imposed deformations. 3. The strains in the prestressing tendons decreased with time

As provided in the Chinese Code for design of steel structures progressively with similar trends for the two prestressed

共GB50017-2003兲, the long-term vertical deflections of composite composite beams with different stud distances.

beams are obtained by using 2n0 as the elastic modular ratio of 4. No slip occurred at the slab–steel interface during the sus-

steel beam to concrete slab. tained loading period on the composite beams.

From the analysis for the three specimens, two points can be 5. It is proposed that the ratios of deflections for one year to

obtained as follows: instantaneous deflections for nonprestressed composite

1. In terms of EC 4, prestressed composite beams and nonpre- beams and prestressed composite beams are 2.0 and 3.1, re-

stressed composite beams have ratios of long-term-to- spectively.

instantaneous deflections of 1.5 and 1.4 for one year. 6. The time-dependent analytical method proposed to predict

2. According to the Chinese Code GB50017-2003, prestressed the long-term behavior of prestressed composite beams, sat-

composite beams and nonprestressed composite beams have isfying the requirement equilibrium and compatibility, gave

ratios of long-term-to-instantaneous deflection of 1.3 and 1.2 calculated results that have a good match with the test

for one year. results.

3. According to the experimental results, prestressed composite

beams and nonprestressed composite beams have ratios of

long-term to instantaneous deflections of 3.1 and 2.0 for one Acknowledgments

year. Obviously, the calculated results in terms of EC 4 and

Chinese code GB50017-2003 are less safe. Here, it is pro- Support for this research by the Shanghai Development Founda-

posed to obtain the long-term vertical deflections for one tion of Science and Technology under Grant No. 992012044 and

year of nonprestressed composite beams by using 2.0 as the the “Shu Guang” project supported by the Shanghai Municipal

multiplier of instantaneous deflection, and 3.1 for prestressed Education Commission and Shanghai Education Development

composite beams. Foundation No. 04SG24.

936 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008

J. Struct. Eng. 2008.134:930-937.

Notation ⌬st ⫽ stress increments in steel beams induced by

creep during the interval n 共MPa兲;

The following symbols are used in this paper: 兵␦0其 ⫽ creep displacements of nodes;

A1 ⫽ area of concrete slab 共mm2兲; 1 / ⫽ curvature;

A2 ⫽ area of steel beam 共mm2兲; ⫽ relaxation coefficient;

A0 ⫽ area of transformed composite cross-section 1 ⫽ relaxation coefficient at time tn; and

at time 0 共mm2兲; 2 ⫽ relaxation coefficient tn−1;

AcL ⫽ transformed area of concrete slab 共mm2兲;

Ec ⫽ elastic modulus of concrete 共GPa兲;

Es ⫽ elastic modulus of steel beam 共MPa兲; References

Ec ⫽ elastic modulus of concrete 共MPa兲;

Ecm ⫽ value of the secant modulus of concrete American Institute of Steel Constructors 共AISC兲. 共2005兲. “Specification

共MPa兲; for structural steel buildings.” ANSI/AISC 360-05, AISC, Chicago.

E ⫽ age-adjusted elastic modulus of concrete Bradford, M. A., and Gilbert, R. I. 共1989兲. “Nonlinear behavior of simply

Downloaded from ascelibrary.org by New York University on 05/15/15. Copyright ASCE. For personal use only; all rights reserved.

共MPa兲; supported composite beams.” Struct. Eng., 67共14兲, 263–268.

f cu ⫽ concrete cubic compressive strength, Bradford, M. A., and Gilbert, R. I. 共1991兲. “Experiments on composite

100 mm⫻ 100 mm⫻ 100 mm 共MPa兲; beams at service loads.” Trans. Inst. Eng. Austr. Civil Eng., 33共4兲,

285–291.

f c ⫽ prismy compressive strength,

Chen, S. 共2005兲. “Experimental study of prestressed steel—Concrete

100 mm⫻ 100 mm⫻ 300 mm 共MPa兲; composite beams with external tendons for negative moments.” J.

兵F0其 ⫽ equivalent creep forces of node; Constr. Steel Res., 61, 1613–1630.

I0 ⫽ inertia moment of transformed composite Dall’Asta, A., and Dezi, L. 共1998兲. “Nonlinear behavior of externally

cross section at time 0 共mm4兲; prestressed composite beams: Analytical model.” J. Struct. Eng.,

I1 ⫽ inertia moment of concrete slab 共mm4兲; 124共5兲, 588–597.

I2 ⫽ inertia moment of steel beam 共mm4兲; Dezi, L. 共1994兲. “Shrinkage effects in composite beams with flexible

IcL ⫽ transformed inertia moment of concrete slab connection.” J. Constr. Steel Res., 28, 295–320.

共mm4兲; Dezi, L., Leoni, G., and Tarantino, A. M. 共1995兲. “Time-dependent analy-

兵Kt其 ⫽ creep stiffness matrix; sis of prestressed composite beams.” J. Struct. Eng., 121共4兲, 621–

M ⫽ bending moment applied on the cross section 633.

Dezi, L., Leoni, G., and Tarantino, A. M. 共1996兲. “Algebraic methods for

共N m兲;

creep analysis of continuous composite beams.” J. Struct. Eng.,

M t ⫽ equivalent bending moment due to creep

122共4兲, 423–430.

共N m兲; European Committee for Standardization 共CEN兲. 共1994兲. “Design of

M bt ⫽ equivalent bending moment on concrete slab composite steel and concrete structures. Part 1.1: General rules and

due to creep 共N m兲; rules for buildings.” Eurocode 4, CEN, Brussels, Belgium.

M st ⫽ equivalent bending moment on steel beam Gilbert, R. I. 共1988兲. Time effects in concrete structures, Elsevier Science,

due to creep 共N m兲; Amsterdam, The Netherlands.

N ⫽ axial force applied on the cross section, 共N兲; Gilbert, R. I., and Bradford, M. A. 共1991兲. “Time-dependent behavior of

Nt ⫽ axial force due to creep 共N兲; continuous composite beams.” UNICIV Rep. R-307, School of Civil

Nbt ⫽ equivalent axial force on concrete slab due to Engineering, Univ. of New South Wales, Sydney, Australia.

creep 共N兲; Gilbert, R. I., and Bradford, M. A. 共1995兲. “Time-dependent behavior of

Nst ⫽ equivalent axial force on steel beam due to continuous composite beams at service loads.” J. Struct. Eng., 121共2兲,

creep 共N兲; 319–327.

n ⫽ age-adjusted elastic modular ratio of steel Hoadley, P. G. 共1963兲. “Behavior of prestressed composite steel beams.”

J. Struct. Div., 89共3兲, 21–34.

beam to concrete;

Lorenc, W., and Kubica, E. 共2006兲. “Behavior of composite beams pre-

n0 ⫽ modular ratio of steel beam to concrete; stressed with external tendons: Experimental study.” J. Constr. Steel

y ⫽ distance from the center axis of transformed Res., 62, 1353–1366.

composite cross section 共mm兲; Ranzi, G., and Bradford, M. A. 共2006兲. “Analytical solutions for the

y ⬘ ⫽ distance from the concrete axis 共mm兲; time-dependent behavior of composite beams with partial interac-

y ⬙ ⫽ distance from the steel beam axis 共mm兲; tion.” Int. J. Solids Struct., 43, 3770–3793.

⫽ creep coefficient; Reagen, R. S., and Krahl, N. W. 共1967兲. “Behavior of prestressed com-

c ⫽ strain at the center axis of the cross section; posite beams.” J. Struct. Div., 93共6兲, 87–105.

⌬*0 ⫽ initial strain on the composite cross section; Saadatmanesh, H., Albrecht, P., and Ayyub, B. M. 共1989a兲. “Experimen-

bj ⫽ elastic stress increment on the concrete tal study of prestressed composite beams.” J. Struct. Eng., 115共9兲,

cross-section induced by new load at the start of 2348–2363.

Saadatmanesh, H., Albrecht, P., and Ayyub, B. M. 共1989b兲. “Analytical

time interval 关ti , t j+1兴 共MPa兲;

study of prestressed composite beams.” J. Struct. Eng., 115共9兲, 2364–

⌬bt共t j+1 , t j兲 ⫽ stress increment on the concrete cross-section 2381.

induced by creep at time interval 关ti , t j+1兴 Szilard, R. 共1959兲. “Design of prestressed composite steel structures.” J.

共MPa兲; Struct. Div., 85共9兲, 97–124.

⌬bt ⫽ stress increments in concrete slabs induced by Wang, J., Li, J., and Liang, Z. 共1998兲. “Time-dependent analysis of pre-

creep during the interval n 共MPa兲; stressed composite bridge.” Eng. Mech., 2, 550–555 共in Chinese兲.

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008 / 937

J. Struct. Eng. 2008.134:930-937.

You might also like

- Oracle Forms Developer 10G Student Guide - 1Document440 pagesOracle Forms Developer 10G Student Guide - 1Jayant Agarwal100% (3)

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)From EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Rating: 4 out of 5 stars4/5 (10)

- Roeder (1999) - Shear Connector Requirements For Embedded Steel Sections PDFDocument10 pagesRoeder (1999) - Shear Connector Requirements For Embedded Steel Sections PDFTeodora BogdanNo ratings yet

- Microsoft Test4prep AI-900 v2020-09-07 by Abdullah 25qDocument19 pagesMicrosoft Test4prep AI-900 v2020-09-07 by Abdullah 25qANIMESH301No ratings yet

- Ch3 Profiles, Password Policies, Privileges, and RolesDocument79 pagesCh3 Profiles, Password Policies, Privileges, and Rolesahlam alzhraniNo ratings yet

- (Asce) 0733-9445 (2005) 131 10 (1593)Document8 pages(Asce) 0733-9445 (2005) 131 10 (1593)abadittadesseNo ratings yet

- Connection Performance in Steel - Concrete Composite Truss Bridge StructuresDocument16 pagesConnection Performance in Steel - Concrete Composite Truss Bridge StructuresmulualemNo ratings yet

- Seismic Performance of Steel-Encased Composite ColumnsDocument21 pagesSeismic Performance of Steel-Encased Composite ColumnsatyanNo ratings yet

- Seismic of Encased BeamDocument21 pagesSeismic of Encased BeamvardhangargNo ratings yet

- Wang 2010Document12 pagesWang 2010Haytham BouzidNo ratings yet

- Behavior of High-Strength Friction-Grip Bolted Shear Connectors in Sustainable Composite BeamsDocument12 pagesBehavior of High-Strength Friction-Grip Bolted Shear Connectors in Sustainable Composite BeamsvardhangargNo ratings yet

- (Asce) ST 1943-541X 0002294Document14 pages(Asce) ST 1943-541X 0002294Sergio Alejandro barreiroNo ratings yet

- Comparative Study of R.C.C & Structural Steel - Concrete Composite Frame For Linear and Non-Linear AnalysisDocument10 pagesComparative Study of R.C.C & Structural Steel - Concrete Composite Frame For Linear and Non-Linear AnalysisAnonymous kw8Yrp0R5r100% (1)

- 2002c-Dhakal Maekawa PDFDocument10 pages2002c-Dhakal Maekawa PDFdmep25No ratings yet

- Tekban Lanjut 4Document7 pagesTekban Lanjut 4Bastian Artanto AmpangalloNo ratings yet

- Progressive Collapse Analysis of Steel Braced FramesDocument9 pagesProgressive Collapse Analysis of Steel Braced FrameswalaywanNo ratings yet

- Perea Et Al. - Slender CFT Experiments - Interaction Behavior - JSE 2014Document12 pagesPerea Et Al. - Slender CFT Experiments - Interaction Behavior - JSE 2014prisciliano1No ratings yet

- Deformation Analysis of Prestressed Continuous Steel-Concrete Composite BeamsDocument13 pagesDeformation Analysis of Prestressed Continuous Steel-Concrete Composite BeamsSaul Max Huayta AguilarNo ratings yet

- Analysis of Flectural Stiffness of Composite BeamsDocument22 pagesAnalysis of Flectural Stiffness of Composite BeamsVictorNo ratings yet

- 2022 Capacity Design of Coupled Composite Plate Shear Wall ConcreteDocument18 pages2022 Capacity Design of Coupled Composite Plate Shear Wall ConcreteHamid GoodarziNo ratings yet

- Analysis of Exterior Reinforced Concrete Beam Column Joint: S.Gomathi, K.SelviDocument4 pagesAnalysis of Exterior Reinforced Concrete Beam Column Joint: S.Gomathi, K.SelviMarjorie BlossiersNo ratings yet

- Improving The Failure Mode of Over Reinforced Concrete Beams Using SHCC-Ahmed M Atta-2016Document11 pagesImproving The Failure Mode of Over Reinforced Concrete Beams Using SHCC-Ahmed M Atta-2016sardarumersialNo ratings yet

- Nonlinear Analysis of Beams Reinforced IDocument12 pagesNonlinear Analysis of Beams Reinforced IMike MatshonaNo ratings yet

- (2-6) (ASCE Structure) Experimental and Nonlinear Numerical Analysis of Precast Concrete Column Splices With High-Yield Metal PlatesDocument15 pages(2-6) (ASCE Structure) Experimental and Nonlinear Numerical Analysis of Precast Concrete Column Splices With High-Yield Metal PlatesPhạm Tiến ĐạtNo ratings yet

- Shear Connector BehaviourDocument10 pagesShear Connector BehaviourNONGTHONNo ratings yet

- WuandPantelides2018JCCDocument16 pagesWuandPantelides2018JCCJohn TrasviñaNo ratings yet

- Behavior of Interior Beam-to-Column Connections UnderDocument7 pagesBehavior of Interior Beam-to-Column Connections UnderMarimuthu KaliyamoorthyNo ratings yet

- TEC Compo BeamDocument11 pagesTEC Compo BeamvardhangargNo ratings yet

- Fatigue Behavior of Prestressed Concrete BeamDocument16 pagesFatigue Behavior of Prestressed Concrete BeamFYNo ratings yet

- 1978-T. PAULAY, R. PARK, and M. J. N. PRIESTLEY-Reinforced Concrete Beam-Column Joints Under Seismic ActionsDocument9 pages1978-T. PAULAY, R. PARK, and M. J. N. PRIESTLEY-Reinforced Concrete Beam-Column Joints Under Seismic ActionsRomanbabu OinamNo ratings yet

- 8.behavior of FRP-Steel Confined Concrete TubularDocument12 pages8.behavior of FRP-Steel Confined Concrete TubularPraneeth SaiNo ratings yet

- Determination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsDocument3 pagesDetermination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsklllNo ratings yet

- 1 Artig 1Document9 pages1 Artig 1rpierottNo ratings yet

- Structural Behavior of Reinforced Reactive Powder ConcreteDocument9 pagesStructural Behavior of Reinforced Reactive Powder ConcreteadilNo ratings yet

- New Reinforcement Detailing For Concrete Jacketing of Nonductile Exterior Beam - Column JointsDocument9 pagesNew Reinforcement Detailing For Concrete Jacketing of Nonductile Exterior Beam - Column JointsPaul KohanNo ratings yet

- Engineering Structures: Mahbuba Begum, Robert G. Driver, Alaa E. ElwiDocument10 pagesEngineering Structures: Mahbuba Begum, Robert G. Driver, Alaa E. ElwiGuilhermeFregoneziNo ratings yet

- Finite Element Analysis of R.C Beams Using Steel Scraps Under Cyclic Loading Using ETABSDocument5 pagesFinite Element Analysis of R.C Beams Using Steel Scraps Under Cyclic Loading Using ETABSjuan carlosNo ratings yet

- (Asce) st.1943-541x.0000973 78Document12 pages(Asce) st.1943-541x.0000973 78Marimuthu KaliyamoorthyNo ratings yet

- N Fea S - C C S: Onlinear Nalysis of Teel Oncrete Omposite Tructures by Wendel M. Sebastian and Richard E. McconnelDocument13 pagesN Fea S - C C S: Onlinear Nalysis of Teel Oncrete Omposite Tructures by Wendel M. Sebastian and Richard E. Mcconnelnithya kjNo ratings yet

- Modeling, Analysis, and Behavior of Load-Carrying Precast Concrete Sandwich PanelsDocument13 pagesModeling, Analysis, and Behavior of Load-Carrying Precast Concrete Sandwich PanelsAristotle MedinaNo ratings yet

- Ijser: Beam-Column Connection With Crossed Inclined Reinforcement Bars: An OverviewDocument5 pagesIjser: Beam-Column Connection With Crossed Inclined Reinforcement Bars: An OverviewNishma GuragaiNo ratings yet

- Behaviour of Non-Seismic Detailed RC BC ConnectionDocument17 pagesBehaviour of Non-Seismic Detailed RC BC ConnectionmekidesNo ratings yet

- Deformation-Based Strut-and-Tie Model For Interior Joints of Frames Subject To Load ReversalDocument11 pagesDeformation-Based Strut-and-Tie Model For Interior Joints of Frames Subject To Load ReversalMarimuthu KaliyamoorthyNo ratings yet

- Experiment and Analysis of Flexural Capacity and Behaviors of Pre-Stressed Composite BeamsDocument7 pagesExperiment and Analysis of Flexural Capacity and Behaviors of Pre-Stressed Composite BeamsErivaldo Maia Lourenço FilhoNo ratings yet

- Experiments On Ductile and Non Ductile R PDFDocument13 pagesExperiments On Ductile and Non Ductile R PDFbiniamNo ratings yet

- Effects of Axial Compression Load and Eccentricity On Seismic Behavior of Nonseismically Detailed Interior Beam-Wide Column JointsDocument11 pagesEffects of Axial Compression Load and Eccentricity On Seismic Behavior of Nonseismically Detailed Interior Beam-Wide Column JointsMarimuthu KaliyamoorthyNo ratings yet

- 1 s2.0 S2352012420300862 MainDocument14 pages1 s2.0 S2352012420300862 MainkgapuNo ratings yet

- Carolin Et Al. (2005) BDocument10 pagesCarolin Et Al. (2005) BBenzaamia AliNo ratings yet

- Research 2Document11 pagesResearch 2chaitanya krishnaNo ratings yet

- Analysis and Design of Multistory Building Using Composite StructureDocument15 pagesAnalysis and Design of Multistory Building Using Composite Structuredillibabu rNo ratings yet

- Shear Strength of Normal and High-Strength Fiber Reinforced Concrete Beams Without StirrupsDocument9 pagesShear Strength of Normal and High-Strength Fiber Reinforced Concrete Beams Without StirrupsMsheer Hasan AliNo ratings yet

- Finite-Element Model To Evaluate Nonlinear Behavior of Posttensioned Composite Beams With Partial Shear ConnectionDocument15 pagesFinite-Element Model To Evaluate Nonlinear Behavior of Posttensioned Composite Beams With Partial Shear ConnectionvardhangargNo ratings yet

- Bousselham2010Document13 pagesBousselham2010Hekmatullah NoorzaiNo ratings yet

- Load Capacity of Reinforced Concrete Continuous Deep Beams: K. H. Yang and A. F. AshourDocument11 pagesLoad Capacity of Reinforced Concrete Continuous Deep Beams: K. H. Yang and A. F. AshourJoão Paulo MendesNo ratings yet

- Cracking of rc beam column joints Implications for practical structural analysis and designDocument7 pagesCracking of rc beam column joints Implications for practical structural analysis and designMartin CibulkaNo ratings yet

- Rational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsDocument13 pagesRational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsRayan MahgoubNo ratings yet

- 047 P2 (Asce) 1090 0268 (2005) 9 - 6Document10 pages047 P2 (Asce) 1090 0268 (2005) 9 - 6Novia MerisaNo ratings yet

- Behavior of Eccentrically Loaded Concrete-Filled Steel Tubular ColumnsDocument10 pagesBehavior of Eccentrically Loaded Concrete-Filled Steel Tubular ColumnsvardhangargNo ratings yet

- (Asce) 0733 9445 (2010) 136 1Document11 pages(Asce) 0733 9445 (2010) 136 1Satyajit GhateNo ratings yet

- Seismic Strengthening of RC Structures PDFDocument6 pagesSeismic Strengthening of RC Structures PDFGajendra JoshiNo ratings yet

- (Asce) 1084 0702 (2000) 5:1Document9 pages(Asce) 1084 0702 (2000) 5:1MARUFNo ratings yet

- By M. S. K H A L I L / W. H. Dilger, and A. Ghali: J. Struct. Eng. 1983.109:1980-1996Document17 pagesBy M. S. K H A L I L / W. H. Dilger, and A. Ghali: J. Struct. Eng. 1983.109:1980-1996pkrnNo ratings yet

- Palacio VsDocument2 pagesPalacio VsRaymart SalamidaNo ratings yet

- 7e Extra QDocument72 pages7e Extra QNur AimyNo ratings yet

- Office & Branches: Head Office PT Indosat Mega Media (IM2)Document4 pagesOffice & Branches: Head Office PT Indosat Mega Media (IM2)satriamesumNo ratings yet

- Chapter - 1 NetworksDocument61 pagesChapter - 1 NetworksSummiya JangdaNo ratings yet

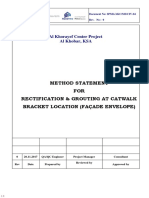

- Catwalk Walk Base Plate Grouting 1Document30 pagesCatwalk Walk Base Plate Grouting 1MdShahbazAhmedNo ratings yet

- Content Analysis Research Paper ExampleDocument5 pagesContent Analysis Research Paper Examplefvfzfa5d100% (1)

- Empowerment Technologies Week 1-2 - Final Term: Prepared By: Mr. Jake Indico Edited By: Ms. Shaira G. RaquilDocument5 pagesEmpowerment Technologies Week 1-2 - Final Term: Prepared By: Mr. Jake Indico Edited By: Ms. Shaira G. RaquilJustine Evasco RubiaNo ratings yet

- Installation and User's Guide InformixDocument52 pagesInstallation and User's Guide Informixissa912721No ratings yet

- 11608-Driving Women Fiction and PDFDocument240 pages11608-Driving Women Fiction and PDFAleksi KnuutilaNo ratings yet

- Bridge Design Manual Part 3 - July14Final MASTERDocument50 pagesBridge Design Manual Part 3 - July14Final MASTERTsegawbezto75% (4)

- CS 702 Lec10Document9 pagesCS 702 Lec10Muhammad TausifNo ratings yet

- AICTE NoticeDocument1 pageAICTE NoticeThe WireNo ratings yet

- Resolution No. 100 - Ease of Doing BusinessDocument2 pagesResolution No. 100 - Ease of Doing BusinessTeamBamAquinoNo ratings yet

- Modern Control Systems Linear Approximation Laplace TransformDocument3 pagesModern Control Systems Linear Approximation Laplace TransformramNo ratings yet

- Extracting Data From GpsDocument7 pagesExtracting Data From GpsRidhima KhajuriaNo ratings yet

- Carbozinc 11Document4 pagesCarbozinc 11DuongthithuydungNo ratings yet

- Passive Fire Protection PDFDocument7 pagesPassive Fire Protection PDFVictor SampaNo ratings yet

- Modified Variable Neighborhood Search Algorithm For Maximum Power Point Tracking in PV Systems Under Partial Shading ConditionsDocument8 pagesModified Variable Neighborhood Search Algorithm For Maximum Power Point Tracking in PV Systems Under Partial Shading ConditionsTELKOMNIKANo ratings yet

- توصية - مستشار زيوت التشحيمDocument4 pagesتوصية - مستشار زيوت التشحيمhasm caadNo ratings yet

- TBelt - 02Document46 pagesTBelt - 02prasanthme34No ratings yet

- Week 05 Simulation Using GPSS (1) NEWDocument59 pagesWeek 05 Simulation Using GPSS (1) NEWPutriska RazaniNo ratings yet

- Sub Engineer Test Model PaperDocument8 pagesSub Engineer Test Model PaperZeeshan AhmadNo ratings yet

- Forms of Hooke's Law: C C C C CDocument2 pagesForms of Hooke's Law: C C C C Cali dimaNo ratings yet

- Nfpa Codes PDFDocument12 pagesNfpa Codes PDFphe zenNo ratings yet

- Calculation of absorption properties of absorbent materialsDocument4 pagesCalculation of absorption properties of absorbent materialsRezaul Karim TutulNo ratings yet

- Boiler Commissioning Procedure1Document62 pagesBoiler Commissioning Procedure1Okeyman100% (1)

- ConclusionDocument1 pageConclusionSAVITHRINo ratings yet