Professional Documents

Culture Documents

2061-Installation Documentation

Uploaded by

jose ruben jimenezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2061-Installation Documentation

Uploaded by

jose ruben jimenezCopyright:

Available Formats

Installation documentation

SingleVario 2061

© KLAUS, Aitrach Art. no. 58532130 Page 1 / 7

Table of contents

Chapter Page

General information 2

Safety instructions 2

Preparing the site of installation 3

Installing the system 4

Power and supply connections 6

Completing the installation 6

Cleaning-up works 6

1 General information

1.1 Validity of the installation instructions

These installation instructions apply to the SingleVario 2061 only.

1.2 Scope of documentation

Installation instructions

These installation instructions have been prepared for trained personnel.

Operating instructions

The operating instructions have been prepared for the users of the SingleVario 2061.

The operating instructions have to be adhered to by the installation personnel when putting the

system into operation.

1.3 Modifications

– Any changes made since the last version of the document are indicated by a vertical line

on the left side.

2 Safety instructions

2.1 Basic information

The same safety regulations apply for the installation and putting into operation as for the

operation of the SingleVario 2061.

Make sure the relevant accident prevention regulations are observed.

Make sure the installation personnel has read and understood and abides by the operating

instructions. The operating personnel must be specially instructed about the system-dependent

features and any possible hazards.

Make sure the maintenance personnel abides by the instructions given by the subsuppliers.

2.2 To avoid accidents

Besides the statutory accident prevention regulations the following safety

regulations must be observed:

© KLAUS, Aitrach Art. no. 58532130 Page 2 / 7

Never work under unsecured lifted platforms.

Danger to life!

Only work under lifted platforms if these were secured on

all four corner so they cannot lower in case of shocks

Wear personal protective equipment

Any installations works must only be carried out if the system has been disconnected from

power supply, i.e., the main switch must have been switched OFF and secured against

unintentional reconnection.

Exempt here are special setup steps and trial runs for which the corresponding safety

measures must be observed.

Danger through live wires in case of defective lines and devices!

Danger through insufficient lighting.

Danger through the laser beam when leveling out the system - do not look into the beam.

Use appropriate binders to bind lost lubricants and fuels, and dispose them correctly –

danger of slipping. Use spray grease well directed.

Avoid contamination due to spray mist – clean, if necessary.

Make sure to abide by the operating instructions when putting the system into operation.

Transport weights for forklift trucks:

-> for slopes up to 9%: max. 2000 kg

-> for slopes up to 14%: max. 1500 kg

-> for slopes up to 18%: max. 1000 kg

Do not carry weights over 55 kg per person over long distances!

3 Preparing the site of installation

Acceptance of structure according to VOB (German Construction Contract Procedures):

3.1 Dimensional check

Check the dimensions and enter them in the installation report

The evenness of the subfloor must be made according to DIN 18202, table 3, line 2. Dimensions in

cm !

– Height

– Length

– Compare width dimensions with installation order

– Concrete quality

Wear personal protective equipment

Danger through insufficient lighting.

Danger through the laser beam when leveling out the system - do not look into the beam.

Watch for openings.

Watch for contamination, unevenness and black ice.

3.2 Dimensional deviations

Compare dimensional undercuts with the installation report (e.g. reduced height, length, etc. with

vehicle limitations.

If dimensions shortcuts were determined beforehand they are indicated here and have already been

discussed with the principal).

Check component widths according to order.

3.3 Dimensional checking of the width-dependent parts

The width-dependent parts (platform profiles, crossheads, etc.) must be measured prior to

installation!

3.4 Checking the craftsmen’s works

The VOB regulates the legal performances for construction works. Here, some aspects on site are

of particular importance:

© KLAUS, Aitrach Art. no. 58532130 Page 3 / 7

If incorrect or false deliveries by builders or craftsmen are accepted without informing the person in

charge of the construction works this may result in immense difficulties for us.

Possible faults: Negative consequences:

– Poor concrete quality – Unstable system

– Insufficient base plate thickness – Unstable system

– No glue anchors for waterproof concrete – Leaky base plate

– Bent walls – System is grazing or gets jammed

– Insufficient lengths, heights – System cannot be installed

– Installed parts (pipes; bearers, etc.) – Vehicle limitations

– Inadequate access routes – No transport possible

– No foundation grounding – Electrostatic charge

If we do not identify or specify these defects this will mean that the preliminary works have been

carried out correctly. Any claims, reworks, etc. resulting from this are then to be borne by us.

3.5 Power supply for the installation works

Danger through live wires in case of defective lines and devices!

Distribution board for construction site:

Use extension cables for power lines < 1.50 m.

Disconnect power supply by pulling the short line.

Make sure to note in the installation report if only construction site supply was available during

installation.

If a submeter is available, read the current consumption there.

Note the count at the beginning and end of the installation works. Note the current consumption in

the installation report.

3.6 GaVo (Garage regulations)

The garage regulations were established by the individual federal states in Germany, and they

regulate the official regulations for garages.

Among other things, the dimensions for parking spaces are specified as 230 cm x 500 cm.

The width of the driveway must be at least 650 cm (for parking space width 230 cm).

3.7 Leaky garage roofs

Danger through malfunctions

Cover the hydraulic unit when installing systems in garages with still to be completed or leaky roofs.

This defect is to be entered in the installation report.

3.8 Incomplete delivery or incorrectly delivered parts

When ordering missing parts, make sure to specify the following:

– Detailed description and article number.

– Order number and address of installation

– Address for freight deliveries

In case of return shipments make sure to specify the order number and address of installation on

the parts.

3.9 Access to aboveground garages

Make sure to enter the following in the installation report:

– Real measurement of access in front of the garage

– Incline (if available) and indication of direction

– Not completed access

3.10 Height of control unit

From floor to lower edge of control unit = 120 cm.

(cable entry from below, if possible - also in underground car parks)

3.11 Tools and machinery

Prepare tools and machinery required for the installation works.

© KLAUS, Aitrach Art. no. 58532130 Page 4 / 7

3.12 Definitions

For defining the garage or the systems, use the following terms:

Front: driveway

Back: Rear wall

Left: Viewed from driveway to rear wall

Right: Viewed from driveway to rear wall

3.13 Interruption of installation works

If the installation works are interrupted due to constructional conditions, a report must be prepared

and signed by the person in charge of the construction works for any waiting and journey times.

3.14 Safeguarding the site of installation

From the start of the installation works the company carrying out the installation works is

responsible for the safety on the site of installation.

Danger spots must be marked at any interruption of the installation works

(e.g. by marker band).

3.15 To be observed for the installation works:

From the start of the installation works the company carrying out the installation works is

responsible for the safety on the site of installation.

Danger spots must be marked at any interruption of the installation works (e.g. by marker band).

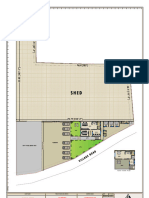

– Layout drawing

– Installation drawings

– Circuit and wiring diagrams

– Safety instructions

– Operating instructions

– Requirements by the dowel manufacturers

Any non-observance of the safety regulations may have labor law consequences!

4 Installing the system

4.1 Assembly

Assembly of the system is made according to the drawings in the spare parts program EtPro.

4.2 Setting instructions

The headroom required is defined above the type description.

Set the headroom using the turnbuckle (see also details in EtPro).

The headrooms from 160 - 210 cm can be adjusted in steps of 10 cm.

Make sure that the mechanic lock is active for the adjusted headroom!

Example: SingleVario 2061-170

Headroom to be adjusted: 170 cm

© KLAUS, Aitrach Art. no. 58532130 Page 5 / 7

Set the headroom using the

turnbuckle

Interlock

active!

5 Power and supply connections

Any electric works must only be carried out by qualified electricians.

Danger through live wires in case of defective lines and devices!

5.1 Connect the control unit.

5.2 Connect hydraulic unit to electric system.

Risk of damaging the internal geared wheel pump:

– Pay attention to correct direction of rotation.

– In case of reverse direction of rotation due to dry running - no pressure build-up.

– Lack of oil.

Each hydraulic unit is provided with a pressure relief valve. Check the preset pressure on the

pressure gauge.

5.3 Sources of defect on the hydraulic unit / system

Motor running, system does not move:

Source of error Remedy

Incorrect direction of rotation change poles

No hydraulic oil Fill up oil; eliminate leakiness

Clogged lines Find clogged parts and eliminate clogging

Pump provides no pressure Check direction of rotation. Air in system?

Only 2 phases available Check fuses

© KLAUS, Aitrach Art. no. 58532130 Page 6 / 7

Motor doesn't run:

Source of error Remedy

No fuses available Insert fuses

Emergency stop button pressed Release emergency stop button

Main switch switched off switch on

No voltage supply available Measure voltage on input and output of main switch

using a voltage tester. The thermal relay may have

tripped - must be set to automatic.

Contactor does not respond Actuate the contactor for a moment and measure

continuity using a voltage tester

– contactor may be defective.

Bridge between coil and thermal relay missing or insert or tighten

loose

Motor defective check if voltage is applied

6 Completing the installation

6.1 Repair any damages to coatings.

6.2 Attach serial plate and CE sign.

6.3 Fill in the installation report and have is signed by the person in charge of the construction works.

7 Cleaning-up works

7.1 Remove any surplus parts and materials.

7.2 Remove and rubbish and debris from the site of installation and dispose of correctly.

© KLAUS, Aitrach Art. no. 58532130 Page 7 / 7

You might also like

- Install Bluetooth Hands-Free System in Volkswagen CrafterDocument18 pagesInstall Bluetooth Hands-Free System in Volkswagen CrafterAndreea MayaNo ratings yet

- New Generation Service ManualDocument12 pagesNew Generation Service ManualMatias YanzonNo ratings yet

- Tir 60-120Document9 pagesTir 60-120GITANOSOFT GARCIANo ratings yet

- Vmax 1VCD600189Document32 pagesVmax 1VCD600189ram_kisna007No ratings yet

- ClickFit EVO Universal Roof HookDocument27 pagesClickFit EVO Universal Roof HookBORBEL ADRIANNo ratings yet

- BBT MethodDocument133 pagesBBT MethodSufiyan KhedekarNo ratings yet

- Moba Matic AnalogDocument44 pagesMoba Matic Analogmartin_powell_15100% (1)

- Legal Solar Unirac Manual Solarmount Flat Roof Calculations Installation - ManualDocument26 pagesLegal Solar Unirac Manual Solarmount Flat Roof Calculations Installation - ManualDouglas Hopkins100% (2)

- MP Tec Assembly Manual SnowflakeDocument12 pagesMP Tec Assembly Manual SnowflakeKarbonKaleNo ratings yet

- 3 - JT262.12 General Instructions For AssemblyDocument10 pages3 - JT262.12 General Instructions For AssemblymliugongNo ratings yet

- KLW Elevator Installation ManualDocument59 pagesKLW Elevator Installation ManualTristan MarcelNo ratings yet

- iSTS A1 User Manual - 19Document18 pagesiSTS A1 User Manual - 19Zaki ArifinNo ratings yet

- Open Terrain System Sigma I: Installation ManualDocument13 pagesOpen Terrain System Sigma I: Installation ManualMurat ToygarNo ratings yet

- Sartorius BASCULADocument112 pagesSartorius BASCULAheberestradaNo ratings yet

- Stream: Operating ManualDocument16 pagesStream: Operating ManualBulent KABADAYINo ratings yet

- Indermediate Shaft Bearing Svenska BearingDocument17 pagesIndermediate Shaft Bearing Svenska BearingImmorthalNo ratings yet

- iNetVu 7000 Controller ManualDocument128 pagesiNetVu 7000 Controller Manualcrispix2000No ratings yet

- 03 Flue Guide June 2016 852183Document40 pages03 Flue Guide June 2016 852183Hassan TangasawiNo ratings yet

- 50TQN240 (E) - Manual de InstalaciónDocument40 pages50TQN240 (E) - Manual de Instalaciónfloro cortes. tNo ratings yet

- 50 TJ 016Document32 pages50 TJ 016hamgasclimatisation100% (1)

- Suspended Platform System Conform UlDocument19 pagesSuspended Platform System Conform Ultejas mirashiNo ratings yet

- Suspended Platform System Conform UlDocument19 pagesSuspended Platform System Conform UlEmerson OliveiraNo ratings yet

- Als-F Iom 510 C - 07-02 e - enDocument48 pagesAls-F Iom 510 C - 07-02 e - enRomeo PunkerNo ratings yet

- TEREX MOBA Matic Big Ski Installation Manual 23562Document15 pagesTEREX MOBA Matic Big Ski Installation Manual 23562Mahmoud ElbakryNo ratings yet

- Falls ChecklistDocument4 pagesFalls ChecklistZainuddin Mohd DaminNo ratings yet

- INetVu 5000 Controller ManualDocument77 pagesINetVu 5000 Controller ManualBranden ButlerNo ratings yet

- Modular Air Handling Unit IOM - (FASI03-2020,21A)Document20 pagesModular Air Handling Unit IOM - (FASI03-2020,21A)Jericho EstrellaNo ratings yet

- I ControlDocument740 pagesI Controloswaldo moraNo ratings yet

- GL0117P-04 NSBP003 - NSBP006 Plastic Bypass Separators GuidelinesDocument12 pagesGL0117P-04 NSBP003 - NSBP006 Plastic Bypass Separators GuidelinesDoug WeirNo ratings yet

- INetVu - Service Manual - 012Document89 pagesINetVu - Service Manual - 012AJ LuisNo ratings yet

- Antenna Installation For Wireless CommunicationsDocument32 pagesAntenna Installation For Wireless Communicationsrishabhnath4844100% (2)

- ATC200-LITE-USB Teletilt Control System Computer Interface SetupDocument2 pagesATC200-LITE-USB Teletilt Control System Computer Interface Setupjason5brooksNo ratings yet

- S418 I0806 Rev3 ENDocument10 pagesS418 I0806 Rev3 ENDaniel NitoiNo ratings yet

- FAAC S418 Swing Gate Motor ManualDocument16 pagesFAAC S418 Swing Gate Motor ManualCao BaoNo ratings yet

- EOS 120 Venere D: I GB F D E PDocument16 pagesEOS 120 Venere D: I GB F D E PJeferson AndradeNo ratings yet

- iNetVu 9000 Controller User Manual - Rev 2.0.2Document85 pagesiNetVu 9000 Controller User Manual - Rev 2.0.2anachromanNo ratings yet

- PM530-I产品说明书 (英文) MANUALDocument34 pagesPM530-I产品说明书 (英文) MANUALINFO TOP SKYNo ratings yet

- Netys RT 1-3 KVA - Manual - 00Document26 pagesNetys RT 1-3 KVA - Manual - 00GGINo ratings yet

- Altistart 22 ATS22C14QDocument26 pagesAltistart 22 ATS22C14QaleksandarlaskovNo ratings yet

- Manual 7.3m AntennaDocument46 pagesManual 7.3m AntennagliceriochipanaNo ratings yet

- Cognex in Sight Micro Installation ManualDocument38 pagesCognex in Sight Micro Installation ManualZoran ColicNo ratings yet

- 80 125mm Horizontal Flue InstructionsDocument12 pages80 125mm Horizontal Flue Instructionssuchit1No ratings yet

- Pm530-C Tower Crane Safety Monitoring System: Product Manual StatementDocument26 pagesPm530-C Tower Crane Safety Monitoring System: Product Manual StatementkabirmkjgfjNo ratings yet

- FM200 Product ManualDocument41 pagesFM200 Product ManualAdel ChiedNo ratings yet

- ABB Vacuum Contactor - InstructionsDocument48 pagesABB Vacuum Contactor - InstructionsVishal KumarNo ratings yet

- TEBS G2 - Load Sensing For Mechanical Suspensions: Service ManualDocument18 pagesTEBS G2 - Load Sensing For Mechanical Suspensions: Service ManualTruck Bus ElectronicaNo ratings yet

- Autopilot V2: Installation GuideDocument28 pagesAutopilot V2: Installation GuideCleberson GomesNo ratings yet

- 005 038Document11 pages005 038shaicoNo ratings yet

- Uni-8_User_Instruction_Manual_ENDocument18 pagesUni-8_User_Instruction_Manual_EN2012sinkersNo ratings yet

- Red Bud - 1-INSTALL 1 M1190Document30 pagesRed Bud - 1-INSTALL 1 M1190Chris CurranNo ratings yet

- Botoneras de Paro - FederalSignal - MPEX - InstruccionesDocument12 pagesBotoneras de Paro - FederalSignal - MPEX - InstruccionesJuan Pablo Herrera PoppeNo ratings yet

- 10-02-00541 Bedienungsanleitung, G176 MS (Eng)Document20 pages10-02-00541 Bedienungsanleitung, G176 MS (Eng)Jehuty88No ratings yet

- 004 Equipment InstallationDocument8 pages004 Equipment InstallationMohamed KasemNo ratings yet

- Manzo - Typical Pipe Support Installation Rev 1Document4 pagesManzo - Typical Pipe Support Installation Rev 1Senzo NkwanyanaNo ratings yet

- Cisco D9865 DVB-S - S2 Directv Receiver 4028650000000Document260 pagesCisco D9865 DVB-S - S2 Directv Receiver 4028650000000ronnycamachoNo ratings yet

- Overspeed GovernorDocument13 pagesOverspeed GovernorAli DiabNo ratings yet

- Lsa 49.3Document28 pagesLsa 49.3Rafki ChandraNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- BOQ - External Development WorksDocument5 pagesBOQ - External Development WorksAmit RuhilNo ratings yet

- Global MessDocument1 pageGlobal MessharshNo ratings yet

- Spiral Cellars Technical Manual Nov 17Document98 pagesSpiral Cellars Technical Manual Nov 17Hung Nguyen100% (1)

- COMPRO Bintang AuroraDocument26 pagesCOMPRO Bintang AurorabintangNo ratings yet

- A B A B A B: Paul Christian L. DomingoDocument1 pageA B A B A B: Paul Christian L. Domingodomingo.paulchristianNo ratings yet

- New EBCS 6 Part 1-2 - SECUREDDocument108 pagesNew EBCS 6 Part 1-2 - SECUREDSitotaw AlemuNo ratings yet

- Owner: Project Location Project TitleDocument4 pagesOwner: Project Location Project TitleErvin ReotutarNo ratings yet

- Construction Drawings - PDF StampedDocument8 pagesConstruction Drawings - PDF StampedAlexander JongNo ratings yet

- NYC Residential Zoning ResolutionDocument208 pagesNYC Residential Zoning ResolutionM Khairul IslamNo ratings yet

- Staff Skills Experience-TMGRTBDocument51 pagesStaff Skills Experience-TMGRTBAlice Margaret HargestNo ratings yet

- P.01 - SC 675 C & H With Cam Lock With Hinge and Cam LockDocument1 pageP.01 - SC 675 C & H With Cam Lock With Hinge and Cam LockJomyJoseNo ratings yet

- Attachments To Section 4.2 - CF E&M PDFDocument15 pagesAttachments To Section 4.2 - CF E&M PDFHo Chee YongNo ratings yet

- Chapter Three PDFDocument11 pagesChapter Three PDFshjahsjanshaNo ratings yet

- Joint Details of Bridge StructureDocument1 pageJoint Details of Bridge StructurePhanindra MajetiNo ratings yet

- Analysis and Design of Flat Slab by Using Etabs Software: 1.1 GeneralDocument8 pagesAnalysis and Design of Flat Slab by Using Etabs Software: 1.1 GeneralPOONAM ABHANGNo ratings yet

- Aircraft Structure ComponentsDocument48 pagesAircraft Structure ComponentsMaheshNo ratings yet

- Foundation PilesDocument123 pagesFoundation PilesPravindNo ratings yet

- Document: Structural CalculationDocument209 pagesDocument: Structural CalculationStephen Mari CanoNo ratings yet

- Electrical Symbols Legend and AbbreviationsDocument5 pagesElectrical Symbols Legend and AbbreviationsjorgeNo ratings yet

- HoA3 (5. Engineer - Architects)Document11 pagesHoA3 (5. Engineer - Architects)003. M.priyankaNo ratings yet

- Checklist For Sleeves & Puddle Flang InstallationDocument1 pageChecklist For Sleeves & Puddle Flang InstallationBelal AlrwadiehNo ratings yet

- Qatar PlasterDocument8 pagesQatar PlasterlingamkumarNo ratings yet

- KUJARIBUDocument1,098 pagesKUJARIBUMike LitoriesNo ratings yet

- DMDave - Dungeons & Lairs 22 - Haunted Castle-2Document20 pagesDMDave - Dungeons & Lairs 22 - Haunted Castle-2Augusto Sant'anna100% (1)

- Poblacion Barangay Locational Characteristics Soil ClassificationDocument15 pagesPoblacion Barangay Locational Characteristics Soil ClassificationChristine Joyce Garay Biala100% (1)

- Davco K11 FlexDocument2 pagesDavco K11 Flexjet toledoNo ratings yet

- AugmentedConstruction GarvinGoepelDocument5 pagesAugmentedConstruction GarvinGoepelkelvinNo ratings yet

- Nordberg 105 S N 34380Document33 pagesNordberg 105 S N 34380Gilberto Garnica MurilloNo ratings yet

- BM-MSF Nozzle Tip ExchangeDocument5 pagesBM-MSF Nozzle Tip Exchangemartin.weisshaarNo ratings yet

- EC (136FC2019-1h) - 190903 - AEC + CS - Expansion Joint Cover SystemsDocument74 pagesEC (136FC2019-1h) - 190903 - AEC + CS - Expansion Joint Cover SystemsAntonio BrasilNo ratings yet