Professional Documents

Culture Documents

Hints On Boring in The Lathe

Uploaded by

w4rh4ck3r-scribdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hints On Boring in The Lathe

Uploaded by

w4rh4ck3r-scribdCopyright:

Available Formats

edge for the purpose of forming

BORING IN THE LATHE a recess.

Regarding rate of feed, many

breakages are due to the eagerness of

the worker, in his zest for the job

By “ Scotia ”

in hand, to overwork the tool.

One should always give the tool

time to cut; if it is decided to use

the lathe feed, a good plan is to

select a feed Just a little less than

of hesitancy is almost sure to dive

IcanNlathebethejob,

selection of tools for a

it is true to say that this

done by the experienced

point first into the side of the

material. Any tendency of the tool

one would be inclined to use when

hand-feeding the work. In this

way, a reasonable margin of safety

turner with the absolute minimum to evade cutting in the usual way is allowed for all contingencies, such

of trouble. This is a natural outcome will at one and the same time form a as tool breakage, work shifting in the

of knowing what type of tool to barrier opposing the leading edge chuck, etc.

look for, what it is capable of doing, of the tool, forcing the tool into In conclusion, it may be of interest

and a fair idea of how it will perform. disaster. The same conditions will to remark on the behaviour of a

However, it is only fair to say that arise when surfacing or sliding work boring tool which has become

such a tool as the writer has in mind in the lathe, when tools of similar (through old age or otherwise) rather

isn’t likely to be found in a turner’s faults are used. too small in the head, generally.

tool-chest. Let us say, rather, that The risk of using such tools is This type of tool, which quite often

it is more than probable that such a much increased when back-lash is may still have a strong “ neck ”

tool is “ born ” at the grindstone, present, as the shape of the tool to support it, has an unpleasant

being the result of inexperience. lends itself to taking the least line habit, when cutting hard materials,

It will be seen from the sketch, of resistance, and there is every of throwing metal cuttings up

Fig. 1, that the leading edge of the probability that it will charge the into the operator’s face without

boring tool, for such it is, has been work, with disastrous results. warning.

ground away at much too acute an All this may appear to be of a very In observations made during its

angle. Let it be said at this stage, elementary nature, especially to performance, this phenomenon may

Fig. lA. An incorrectly ground Fig. 1B. Showing the insecurity of its

boring tool performance

that we are concerned only with the those of us who are experienced in be explained by the fact that the

profile of the tool as seen in the lathe-work, but one must never lose tool, being small in the head,

plan view sketch, and it may be sight of the fact, that there is a appears to dip in a series of tiny

assumed that the necessary rake and first time for everything in lathe- movements, while at the same time

clearances are correct, otherwise. work, and indeed a first time for removing chips from the bore. The

To use such a tool on anything everyone. " neck " or body of the tool is

other than the lightest of cuts is The sketch, Fig. 2, shows a boring constantly reverting to its original

asking for trouble. Let us assume tool of correct shape in use. It position. and the net result is that

that a cut of say 1/16in. a side is being will be noted that the trailing edge the chips are catapulted upwards in a

made with this tool in use. The fact of the tool has a distinct clearance most disconcerting manner.

that there may be no back-lash from the work. There is a tendency This is much in evidence when a

present in the lathe-saddle is no among those of little experience, fairly large hole is in course of

guarantee that the tool will perform to have little or no clearance on the being tooled out, and consideration

correctly. There is every chance that trailing edge of a boring tool, result- should be given to replacing such a

during the course of the cut, the ing in much squealing and oscilla- tool at the earliest moment, either

leading edge of the tool may become tion. by the use of a boring bar and

dull, and in the increased resistance In this connection, the tool used tool-bit, or another boring tool

set up towards the cutting of the for boring should be distinct from of heavier duty, if only for the pur-

material, it will almost certainly the recessing type of tool, as the pose of workmg in safety and com-

hesitate, and following that moment latter has a straight or square fort.

, 1

I

2

N O T E T H E TRAILING E D G E

WELL CLEAR OF THE BORE

Fig. 3. Recessing tool-To use this for

Fig. 2. Correctly ground boring tool boring, it should be set slightly askew

503

You might also like

- HintsonboringDocument1 pageHintsonboringFrenchwolf420No ratings yet

- Novices'Corner: Using The D-BitDocument3 pagesNovices'Corner: Using The D-BitBob RossNo ratings yet

- Anvil Cutter Length Gauge: Tool Tip..Document2 pagesAnvil Cutter Length Gauge: Tool Tip..NidhiNo ratings yet

- 44-Shoulder Planes-3-BDocument7 pages44-Shoulder Planes-3-BleeroyhaspoonNo ratings yet

- RaptorDocument3 pagesRaptorNino González-HabaNo ratings yet

- Final G9 WEEK 3Document14 pagesFinal G9 WEEK 3jose ariel barroa jrNo ratings yet

- Technology and Livelihood Education Quarter 1, Wk.2 - Module 2 Afa-Agri Crop Production-Sharpening ToolsDocument12 pagesTechnology and Livelihood Education Quarter 1, Wk.2 - Module 2 Afa-Agri Crop Production-Sharpening Toolsjose ariel barroa jrNo ratings yet

- 10 Best Table Saw AccessoriesDocument6 pages10 Best Table Saw AccessoriesAntônio Castro100% (2)

- HOHNER en C05 OffsettingDocument6 pagesHOHNER en C05 OffsettingRobertNo ratings yet

- 10 Best Saw JigsDocument6 pages10 Best Saw JigsSusan Taylor BarryNo ratings yet

- Chapter 3 - Chipping & PaintingDocument22 pagesChapter 3 - Chipping & PaintingAngel AbesNo ratings yet

- Table Saw Safety Tips and Techniques - Avoid Critical Hazards PDFDocument1 pageTable Saw Safety Tips and Techniques - Avoid Critical Hazards PDFPredrag AndjelkovicNo ratings yet

- Ripping and Crosscutting: A Tablesaw PrimerDocument6 pagesRipping and Crosscutting: A Tablesaw Primerpaul_fredric3173No ratings yet

- Primer SystemsDocument6 pagesPrimer SystemsJesus RicherNo ratings yet

- Overhaul-A Lathe PDFDocument6 pagesOverhaul-A Lathe PDFHaitham MohammadNo ratings yet

- MKT PDFDocument29 pagesMKT PDFelgauchoandresNo ratings yet

- SSERC RAPillar Drill 011015Document3 pagesSSERC RAPillar Drill 011015Maged AliNo ratings yet

- Miter Saw TipsDocument4 pagesMiter Saw TipsJuan Martín Navarro DueñasNo ratings yet

- Cricket Bat Knocking MachineDocument8 pagesCricket Bat Knocking MachineMohammad HuzaifahNo ratings yet

- Ose Oc: It ItDocument7 pagesOse Oc: It Its rNo ratings yet

- New Home:New National Hand Crank Machine Sewing Machine Instruction ManualDocument10 pagesNew Home:New National Hand Crank Machine Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Alatan TanganDocument12 pagesAlatan TanganMaruan MuhammadNo ratings yet

- How To Make A Jack Plane: Overcoming PrejudiceDocument10 pagesHow To Make A Jack Plane: Overcoming Prejudicebollería PebeNo ratings yet

- 12 Scaffolding WorkDocument5 pages12 Scaffolding WorkKoneti JanardhanaraoNo ratings yet

- Woodworking Plans - RabbetingDocument3 pagesWoodworking Plans - RabbetingBob Kowalski100% (2)

- (Cliqueapostilas - Com.br) Apostila de Bateria 57Document76 pages(Cliqueapostilas - Com.br) Apostila de Bateria 57FRANCISCO ANTONIO OSORIONo ratings yet

- TÀI LIỆU WHIRLPOWER PDFDocument178 pagesTÀI LIỆU WHIRLPOWER PDFThái Mai ĐìnhNo ratings yet

- The Planer: MOF Plunge RouterDocument5 pagesThe Planer: MOF Plunge Routerjorge lopezNo ratings yet

- (1911) Singer Instructions For Art EmbroideryDocument120 pages(1911) Singer Instructions For Art EmbroideryHerbert Hillary Booker 2nd100% (25)

- Hand Tools 1944Document79 pagesHand Tools 1944Marivic VillanuevaNo ratings yet

- Foundry Sop PDFDocument112 pagesFoundry Sop PDFBorislav VulićNo ratings yet

- Pfaff 16Document15 pagesPfaff 16José Figueroa MartínezNo ratings yet

- Fine Home Circular Saw Basics PDFDocument6 pagesFine Home Circular Saw Basics PDFtkmrmrNo ratings yet

- UNIT 2 "Instruction and Manual"Document5 pagesUNIT 2 "Instruction and Manual"Muhamad Aufa Fakhry SNo ratings yet

- CRKT Homefront With Field Strip TechnologyDocument5 pagesCRKT Homefront With Field Strip TechnologyTwobirds Flying PublicationsNo ratings yet

- Third Form Lesson PlanDocument2 pagesThird Form Lesson PlanSheldon MyvettNo ratings yet

- Safety Measures in Using Farm Tools According To Job RequirementDocument2 pagesSafety Measures in Using Farm Tools According To Job RequirementJan IcejimenezNo ratings yet

- JHA Power ToolsDocument3 pagesJHA Power ToolsJulzNo ratings yet

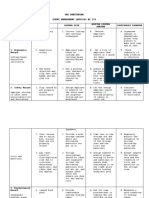

- Job Safety Analysis: Burning UnderwaterDocument2 pagesJob Safety Analysis: Burning UnderwaterEarl alboNo ratings yet

- Hand Cut DovetailsFINALDocument6 pagesHand Cut DovetailsFINALMuhammet OfluoğluNo ratings yet

- Consider in Razor Slitting: Four Factors ToDocument2 pagesConsider in Razor Slitting: Four Factors ToAli AliNo ratings yet

- Handsaw BasicsDocument36 pagesHandsaw BasicsMackila100% (1)

- HOHNER en C04 CenteringDocument3 pagesHOHNER en C04 CenteringRobertNo ratings yet

- Star SP 200 Users Guide ManualDocument54 pagesStar SP 200 Users Guide ManualKroco OlivierNo ratings yet

- Power ToolsDocument9 pagesPower ToolsNatalia Lopez RobredoNo ratings yet

- Riveted Joints TheoryDocument18 pagesRiveted Joints TheoryAvinash PrabhavathyNo ratings yet

- Farsi I CeselliDocument12 pagesFarsi I CesellisdrabaNo ratings yet

- JSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Document2 pagesJSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Koneti JanardhanaraoNo ratings yet

- Chainsaw Mill Build Use Tips N TricksDocument34 pagesChainsaw Mill Build Use Tips N TricksRosangela Rafaele Dos SantosNo ratings yet

- WSS810 5CJTDocument15 pagesWSS810 5CJTroberto martinezNo ratings yet

- Top 10 Workbench Accessories PDFDocument4 pagesTop 10 Workbench Accessories PDFfallenlordNo ratings yet

- Ohs Monitoring Event Management Services NC IiiDocument5 pagesOhs Monitoring Event Management Services NC IiiIrishNo ratings yet

- CH 3 Basic Hand Tools Book Pages 33 - 46Document13 pagesCH 3 Basic Hand Tools Book Pages 33 - 46atul sharmaNo ratings yet

- Chamfer Canned Cycle: Always Prepare For Stopping Cycle in Case Tool Interference!Document1 pageChamfer Canned Cycle: Always Prepare For Stopping Cycle in Case Tool Interference!TuanNo ratings yet

- ST 200015Document12 pagesST 200015Jorge ArbelaezNo ratings yet

- BSS19860 04 MF&C Vis 2Document4 pagesBSS19860 04 MF&C Vis 2Johan TanNo ratings yet

- Elementary Course in Woodwork: Designed for use in high and technical schools, with illustrationsFrom EverandElementary Course in Woodwork: Designed for use in high and technical schools, with illustrationsNo ratings yet

- Popular Mechanics - Hobby Lathe#1Document19 pagesPopular Mechanics - Hobby Lathe#1sonofsilas100% (1)

- Spot Welder PlansDocument4 pagesSpot Welder Planscesargramcko100% (2)

- Popular Mechanics - DIY Fly CutterDocument3 pagesPopular Mechanics - DIY Fly CuttersonofsilasNo ratings yet

- Small Workshop CompressorDocument2 pagesSmall Workshop Compressorw4rh4ck3r-scribdNo ratings yet

- SandblasterDocument3 pagesSandblasterweldeyes100% (3)

- Popular Mechanics - Curing OvenDocument4 pagesPopular Mechanics - Curing OvensonofsilasNo ratings yet

- Center Punch Grinding JigDocument2 pagesCenter Punch Grinding JigmododanNo ratings yet

- Precision Tube Bender PDFDocument9 pagesPrecision Tube Bender PDFrelbuhmNo ratings yet

- Center Punch Grinding JigDocument2 pagesCenter Punch Grinding JigmododanNo ratings yet

- Armas Ninja DIYDocument3 pagesArmas Ninja DIYw4rh4ck3r-scribdNo ratings yet

- Certified Data Centre Professional CDCPDocument1 pageCertified Data Centre Professional CDCPxxxxxxxxxxxxxxxxxxxxNo ratings yet

- Nursing Leadership Philosophy PaperDocument6 pagesNursing Leadership Philosophy Paperapi-355764752100% (1)

- Online Advertising BLUE BOOK: The Guide To Ad Networks & ExchangesDocument28 pagesOnline Advertising BLUE BOOK: The Guide To Ad Networks & ExchangesmThink100% (1)

- Different Types of Equity Investors - WikiFinancepediaDocument17 pagesDifferent Types of Equity Investors - WikiFinancepediaFinanceInsuranceBlog.comNo ratings yet

- A Brief Introduction of The OperaDocument3 pagesA Brief Introduction of The OperaYawen DengNo ratings yet

- Sculi EMT enDocument1 pageSculi EMT enAndrei Bleoju100% (1)

- Accounting For Revenue and Other ReceiptsDocument4 pagesAccounting For Revenue and Other ReceiptsNelin BarandinoNo ratings yet

- Ronaldo FilmDocument2 pagesRonaldo Filmapi-317647938No ratings yet

- 1ST Term J3 Business StudiesDocument19 pages1ST Term J3 Business Studiesoluwaseun francisNo ratings yet

- Document 2 - Wet LeasesDocument14 pagesDocument 2 - Wet LeasesDimakatsoNo ratings yet

- Top 7506 SE Applicants For FB PostingDocument158 pagesTop 7506 SE Applicants For FB PostingShi Yuan ZhangNo ratings yet

- Listening Practice9 GGBFDocument10 pagesListening Practice9 GGBFDtn NgaNo ratings yet

- Roselie Ann A. de Guzman Bsihm3A Centro Escolar University - (Makati)Document14 pagesRoselie Ann A. de Guzman Bsihm3A Centro Escolar University - (Makati)Cristopher Rico DelgadoNo ratings yet

- Test Bank For Global 4 4th Edition Mike PengDocument9 pagesTest Bank For Global 4 4th Edition Mike PengPierre Wetzel100% (32)

- Rate Con PO#267800 From Parsippany - NJ To Raeford - NCDocument2 pagesRate Con PO#267800 From Parsippany - NJ To Raeford - NCbiggbioNo ratings yet

- Pre-Paid: Pickup Receipt - Delhivery Challan Awb - 2829212523430 / Delhivery Direct Standard Order ID - O1591795656063Document1 pagePre-Paid: Pickup Receipt - Delhivery Challan Awb - 2829212523430 / Delhivery Direct Standard Order ID - O1591795656063Sravanthi ReddyNo ratings yet

- Rainiere Antonio de La Cruz Brito, A060 135 193 (BIA Nov. 26, 2013)Document6 pagesRainiere Antonio de La Cruz Brito, A060 135 193 (BIA Nov. 26, 2013)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- AI Intelligence (Sam Charrington and Abeba Birhane)Document2 pagesAI Intelligence (Sam Charrington and Abeba Birhane)Ethel Shammah Waoulda Acleta90% (10)

- Data Warga RT 02 PDFDocument255 pagesData Warga RT 02 PDFeddy suhaediNo ratings yet

- Sbi Rural PubDocument6 pagesSbi Rural PubAafrinNo ratings yet

- 1.1 Cce To Proof of Cash Discussion ProblemsDocument3 pages1.1 Cce To Proof of Cash Discussion ProblemsGiyah UsiNo ratings yet

- Vodafone Training Induction PPT UpdatedDocument39 pagesVodafone Training Induction PPT Updatedeyad mohamadNo ratings yet

- Aaron VanneyDocument48 pagesAaron VanneyIvan KelamNo ratings yet

- Historein11 (2011)Document242 pagesHistorein11 (2011)Dimitris Plantzos100% (1)

- Mavel Francis TurbinesDocument2 pagesMavel Francis TurbineszecaroloNo ratings yet

- Corporate Social Responsibility (CSR) in GrameenphoneDocument7 pagesCorporate Social Responsibility (CSR) in GrameenphoneAfrina KarimNo ratings yet

- SWOT Analysis and Competion of Mangola Soft DrinkDocument2 pagesSWOT Analysis and Competion of Mangola Soft DrinkMd. Saiful HoqueNo ratings yet

- Names of PartnerDocument7 pagesNames of PartnerDana-Zaza BajicNo ratings yet

- Unit Iv - Lesson 1Document2 pagesUnit Iv - Lesson 1SHIERA MAE AGUSTINNo ratings yet

- Stalin Guided NotesDocument2 pagesStalin Guided Notesapi-536892868No ratings yet