Professional Documents

Culture Documents

SSERC RAPillar Drill 011015

Uploaded by

Maged AliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SSERC RAPillar Drill 011015

Uploaded by

Maged AliCopyright:

Available Formats

This is a generic Risk Assessment that must be modified to suit your place of work .

The Risk Assessment modifications

should take into consideration the activity, age/stage/pupil ability, department/working environment and the experience of the

teacher in charge. If Control Measures Required as described are implemented the risk is reduced to an acceptable level for

mainstream students.

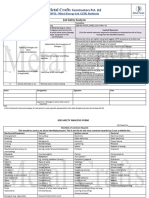

Technology: Risk Assessment Title: Pillar Drill OCTOBER2015

Risk Assessment: Pillar Drill Updated October 2015

Identify the Hazards Who is at What is the Activity Taking Control Measures Required Additional Information

Risk? Harm? Place

Employees and learners should Reference BS 4163:2014

be made aware of the

following hazards. Manufacturer’s instructions and

guidelines must be read through and

retained before using this machine.

1. Hand, Hair or

Clothing Entanglement Technology Long hair, loose Drilling material Long hair and loose clothing should be secured

teachers, clothing etc, can so as to not come into contact with moving

technicians and become parts. Jewellery should be removed.

pupils entangled in

moving parts of Gloves or bandages should not be worn whilst

the drilling operating this machine.

machine.

Chuck keys,

2. Contact From Technology broken drills, PPE including suitable eye protection The Pillar Drill speed should be adjusted

Ejected Pieces teachers, swarf, work conforming to BS EN 166:2002 1B (medium to suit the drill piece diameter and the

Drilling material

technicians and pieces, etc, can energy impact), should be used whilst material to be drilled. A drill

pupils be violently operating the machine. Substantial footwear speed/diameter chart should be placed

ejected. should be worn. next to the machine.

The drilling machine should be fitted with a

suitable guard that extends to the bottom of the

drill bit when it is in the uppermost position.

The table should be adjusted so that, as the

drill bit leaves the guard, it enters the work

piece.

Where appropriate, the work piece should be

Unexpected prevented from spinning around by use of a

spinning of hand machine vice or hand vice, or by clamping it to

Technology the table. A machine vice or hand vice might not

3. Contact From held work pieces

teachers, be required if a small diameter drill is

Spinning Work Pieces could cause

technicians and used. In this case it might be sufficient

injuries to hands. Drilling material The Pillar Drill should have a foot operated

pupils to hold the work piece by hand. School

emergency stop device so that the machine can departments should decide if this

be quickly stopped in an emergency, without practice is allowed as it increases the

requiring the operator to let go of the spindle risk of drill bit contact with the hand.

feed or vice/work piece.

If no rack and pinion rise and fall mechanism

is provided for table adjustment, the safety

collar stop under the table should be used. If

The drill table the head is adjustable, the safety collar

can slip down or Manual handling tasks associated with

underneath it should be secure. changing/moving heavy drill tables and

Technology heavy objects fall

from the table. vices etc, can be beyond the physical

4. Contact From teachers,

Measures must be implemented to minimise capabilities of some persons.

Falling Objects technicians and

risks associated with lifting heavy items (e.g.

pupils Drilling material use of lifting aids, team lifts, and correct lifting

techniques).

The Pillar Drill should be provided with a

means of electrical isolation using a fused

isolating switch on or adjacent to the machine,

Risk Assessment: Pillar Drill and it is controlled by a starter incorporating

Updated October 2015

overload protection and no-volt release.

Drilling

machines present The risk of electric shock is reduced by

an electric shock The machine should be included in a planned good maintenance and the use of double

Technology

hazard. maintenance programme that should include insulated machines.

teachers,

electrical safety inspections and tests.

The green area is an overlap of space

allocated to machines only (250mm

unless otherwise stated.)

from Design and Technology Accommodation in Secondary

Schools – A Design Guide (DfES 2004)

Risk Assessment: Pillar Drill Updated October 2015

You might also like

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- SSERC RAPlastic Trimming 240516Document3 pagesSSERC RAPlastic Trimming 240516Shoaib ManzoorNo ratings yet

- Technology: Risk Assessment Title: Centre Lathe AUGUST2016Document4 pagesTechnology: Risk Assessment Title: Centre Lathe AUGUST2016RadhaKrishnan RNo ratings yet

- Job Hazard Analysis for Erection of Field InstrumentsDocument8 pagesJob Hazard Analysis for Erection of Field Instrumentsசேகர் வேதாரண்யம்No ratings yet

- FTP10EquipoAirless ENDocument2 pagesFTP10EquipoAirless ENGabriel CortésNo ratings yet

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNo ratings yet

- Site Inspection Form for Risk Assessment (Appendix A1Document8 pagesSite Inspection Form for Risk Assessment (Appendix A1Wealth EwomazinoNo ratings yet

- Risk Assessment: Hot Wire Cutters (Updated October 2015Document2 pagesRisk Assessment: Hot Wire Cutters (Updated October 2015Erica LinNo ratings yet

- Jsa For Tile FixingDocument4 pagesJsa For Tile FixingMohammed Minhaj100% (1)

- Job Safety Analysis (JSA) for Pulsation Dampener MaintenanceDocument2 pagesJob Safety Analysis (JSA) for Pulsation Dampener MaintenanceAdel AlKhedawyNo ratings yet

- 17.JSA For Painting of Pole and FencingDocument2 pages17.JSA For Painting of Pole and FencingSumit KumarNo ratings yet

- JOB HAZARD ANALYSIS AND CONTROL Grinding-JHADocument4 pagesJOB HAZARD ANALYSIS AND CONTROL Grinding-JHAlipNo ratings yet

- Copy (2) of JSA For Rebar Sizing Manual & MechanicalDocument4 pagesCopy (2) of JSA For Rebar Sizing Manual & MechanicalMohammed MinhajNo ratings yet

- Gas Cutting JsaDocument4 pagesGas Cutting JsaMohammed Minhaj100% (1)

- 2.7 Working Near Live SwitchyardDocument3 pages2.7 Working Near Live SwitchyardYusuf Afraz100% (1)

- 12 scaffolding workDocument5 pages12 scaffolding workKoneti JanardhanaraoNo ratings yet

- University Lathe Risk AssessmentDocument4 pagesUniversity Lathe Risk AssessmentDhduNo ratings yet

- Lathe Risk Assessment DysonDocument4 pagesLathe Risk Assessment DysonAnkit Mohapatra100% (1)

- Jsa For - SRPDocument3 pagesJsa For - SRPVijay chauhanNo ratings yet

- Safe Working Practices: Wood Turning LathesDocument7 pagesSafe Working Practices: Wood Turning LathesCamilo CubidesNo ratings yet

- Work Smart Work Safe - ENDocument5 pagesWork Smart Work Safe - ENTharaka NuwanNo ratings yet

- Jsa For Intallation of Sub Pipe RackDocument7 pagesJsa For Intallation of Sub Pipe RackMohammed Minhaj100% (2)

- Job Safety Analysis: Date:27-05-2022Document2 pagesJob Safety Analysis: Date:27-05-2022Mohammad HussainNo ratings yet

- Use of 110v Tools B 05Document1 pageUse of 110v Tools B 05cardyNo ratings yet

- Safe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionDocument4 pagesSafe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionArnulfoCruzNo ratings yet

- JSA - Sheet FixingDocument5 pagesJSA - Sheet FixingSwaroop CherryNo ratings yet

- Job Safety Analysis: What Am I About To Do? Who Is Going To Put The Precautions in Place?Document3 pagesJob Safety Analysis: What Am I About To Do? Who Is Going To Put The Precautions in Place?kalai selvan0% (1)

- RA Personal Fall Arrest Fall Restraint Equipment 0007 July 2017Document3 pagesRA Personal Fall Arrest Fall Restraint Equipment 0007 July 2017um erNo ratings yet

- Jsa No 18 New BarrictionDocument4 pagesJsa No 18 New BarrictionSushil Kumar YadavNo ratings yet

- Technology: Risk Assessment Title: Belt Sander/Band Facer SEPTEMBER2015Document3 pagesTechnology: Risk Assessment Title: Belt Sander/Band Facer SEPTEMBER2015aNo ratings yet

- 3-Jaw Chuck Safety ChecklistDocument3 pages3-Jaw Chuck Safety ChecklistMakrem CherifNo ratings yet

- JSA For Construction of E - P WorkshopDocument5 pagesJSA For Construction of E - P Workshopm.rehanhseNo ratings yet

- Jsa Rig Engine Service 750 HRSDocument1 pageJsa Rig Engine Service 750 HRSAdel AlKhedawyNo ratings yet

- JOB SAFETY ANALYSIS FOR 4C CONVEYOR GALLERY STRENGTHEN WORKDocument3 pagesJOB SAFETY ANALYSIS FOR 4C CONVEYOR GALLERY STRENGTHEN WORKMohammad HussainNo ratings yet

- Fall Protection Risk AssessmentDocument3 pagesFall Protection Risk Assessmentsimone0% (1)

- Fall Protection Risk AssessmentDocument3 pagesFall Protection Risk AssessmentsimoneNo ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- JOB SAFETY ANALYSIS FOR HT & LT PANEL INSTALLATIONDocument1 pageJOB SAFETY ANALYSIS FOR HT & LT PANEL INSTALLATIONpushpanath reddy100% (1)

- PT-03 JSA Dismantling of Slip Form (22-05-09)Document10 pagesPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibNo ratings yet

- Mod 4Document2 pagesMod 4pubgmobilekr7722No ratings yet

- Ahu Unit Install JhaDocument3 pagesAhu Unit Install JhafatimahNo ratings yet

- Jsa For Scaffolding Erection & DismentlingDocument7 pagesJsa For Scaffolding Erection & Dismentlingsanath adhikary100% (5)

- Job Safety Analysis: Work Sequence Potential Hazards Recommended Action / Control MeasuresDocument3 pagesJob Safety Analysis: Work Sequence Potential Hazards Recommended Action / Control Measuresmuhammad imtiaz100% (1)

- ER-MO-03 Electrical Work On The Nacelle and TowerDocument13 pagesER-MO-03 Electrical Work On The Nacelle and TowerAlex IgnatNo ratings yet

- Jsa Brick WorkDocument4 pagesJsa Brick WorkRavi thokalNo ratings yet

- Safty TrainingDocument49 pagesSafty TrainingMannu MoideenNo ratings yet

- Sunmow Jha 001Document3 pagesSunmow Jha 001Douglas DellyNo ratings yet

- Jsa For Drilling.Document3 pagesJsa For Drilling.Belsyah Nofriyan75% (4)

- Job HazardDocument2 pagesJob HazardBre WirabumiNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- 1 SurveyDocument5 pages1 Survey王志伟0% (1)

- Electrical Work: Phase Hazard AnalysisDocument10 pagesElectrical Work: Phase Hazard AnalysisBNCHNo ratings yet

- 03-Risk AssessmentDocument4 pages03-Risk AssessmenteldhoNo ratings yet

- Cathodic Protection JSADocument6 pagesCathodic Protection JSAMohammed Minhaj80% (5)

- JSA 03-Rev.02 - BlindingDebliding under Nitrogen purgingDocument2 pagesJSA 03-Rev.02 - BlindingDebliding under Nitrogen purginggolusinghdataNo ratings yet

- Handtool Safety Training Electric Hand Drill 1. Training Safety PrerequisitesDocument3 pagesHandtool Safety Training Electric Hand Drill 1. Training Safety Prerequisitesretheep0% (1)

- Job Safety AnalysisDocument6 pagesJob Safety AnalysisMuhammad TariqNo ratings yet

- Jsa For Modification of HoppersDocument5 pagesJsa For Modification of HoppersEdmy RiveraNo ratings yet

- Jsa For Gypsum Fixing & DismentlingDocument5 pagesJsa For Gypsum Fixing & DismentlingSushil Kumar YadavNo ratings yet

- Installation JSADocument4 pagesInstallation JSAMohammed Minhaj100% (1)

- Gemology PDFDocument65 pagesGemology PDFNamwangala Rashid Natindu50% (2)

- Maintenance Manual HTCM-002: Helicopter Technology CompanyDocument45 pagesMaintenance Manual HTCM-002: Helicopter Technology CompanyrobbertmdNo ratings yet

- Hydac Ball ValvesDocument6 pagesHydac Ball ValvesSamad A BakarNo ratings yet

- Asme PCC-1-2000Document32 pagesAsme PCC-1-2000lemuel bacsaNo ratings yet

- H Section 1 Conventional Heat Generation Boiler General Description PDFDocument579 pagesH Section 1 Conventional Heat Generation Boiler General Description PDFNicolas Pallero FernandezNo ratings yet

- Guideline For Grade and Compensation FitmentDocument5 pagesGuideline For Grade and Compensation FitmentVijit MisraNo ratings yet

- DCRP Active Product List July 2017Document47 pagesDCRP Active Product List July 2017WaleedBarwaniNo ratings yet

- Sizing a Flare Stack and Calculating Flame Distortion from Wind VelocityDocument49 pagesSizing a Flare Stack and Calculating Flame Distortion from Wind VelocityBayu AjipNo ratings yet

- Galvanized and Black Malleable Iron Pipe Fittings SpecificationsDocument24 pagesGalvanized and Black Malleable Iron Pipe Fittings Specificationshse vje100% (1)

- Chapter 14-SolutionDocument3 pagesChapter 14-Solutionmp6w9qw7t2No ratings yet

- Assignment 2 - 2023Document3 pagesAssignment 2 - 2023Andrew ChikuselaNo ratings yet

- Hull Survey MethodsDocument21 pagesHull Survey MethodsSanta Clara100% (2)

- Stiffness Modifiers As Per IS 1893 (Part 1) - 2016Document6 pagesStiffness Modifiers As Per IS 1893 (Part 1) - 2016Kamal Rao100% (1)

- Continuous Beam AnalysisDocument42 pagesContinuous Beam AnalysisMuhd MuqhreyNo ratings yet

- Delphi TipsDocument36 pagesDelphi TipsPILBNo ratings yet

- Teac Ad-600 PDFDocument50 pagesTeac Ad-600 PDFAnonymous Pr8IgKeNo ratings yet

- Sistem Narrowband Dan WidebandDocument4 pagesSistem Narrowband Dan Widebandarrizky ayu faradila purnamaNo ratings yet

- Case 580sn Super N Tier IV - ADocument1,734 pagesCase 580sn Super N Tier IV - AMichael Kubler100% (3)

- Hotel Housekeeping Chapter 1 IntroductionDocument20 pagesHotel Housekeeping Chapter 1 IntroductionĐoàn ThiệnNo ratings yet

- Difusión en Una Partícula Esférica Con Reacción HomogéneaDocument6 pagesDifusión en Una Partícula Esférica Con Reacción HomogéneaCleider Ciniva100% (1)

- 2013 Beta 300 RR Carburetor Jetting Chart by Altitude and TemperatureDocument1 page2013 Beta 300 RR Carburetor Jetting Chart by Altitude and TemperaturemarceloNo ratings yet

- Uk - NCF TS 20Document36 pagesUk - NCF TS 20Mohamed Hanafy TahaNo ratings yet

- 97 Things Every Programmer Should KnowDocument17 pages97 Things Every Programmer Should KnowPyotr Wrangel100% (1)

- Consensus Theorem in Boolean AlgebraDocument2 pagesConsensus Theorem in Boolean AlgebraSiva GuruNo ratings yet

- RD Service Integration Doc With Sample CodeDocument17 pagesRD Service Integration Doc With Sample CodePANKAJ SINGHNo ratings yet

- Profil OrientasiDocument138 pagesProfil OrientasiRdy Simangunsong100% (1)

- Krell KPS 25s - ReviewDocument11 pagesKrell KPS 25s - ReviewMike CedersköldNo ratings yet

- Electrode Kinetics and Polarization PhenomenonDocument3 pagesElectrode Kinetics and Polarization PhenomenonbhanuNo ratings yet

- ChappieDocument2 pagesChappieArlyn AlonzoNo ratings yet

- Microsoft Powerpoint 2013 Tutorial Student Technology Assistant CenterDocument12 pagesMicrosoft Powerpoint 2013 Tutorial Student Technology Assistant CenterBosko LjubisavljevicNo ratings yet