Professional Documents

Culture Documents

Jsa No 18 New Barriction

Uploaded by

Sushil Kumar Yadav0 ratings0% found this document useful (0 votes)

32 views4 pagesall jsa do

Original Title

JSA NO 18 NEW BARRICTION

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentall jsa do

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views4 pagesJsa No 18 New Barriction

Uploaded by

Sushil Kumar Yadavall jsa do

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

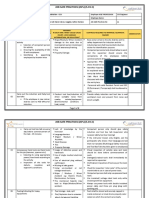

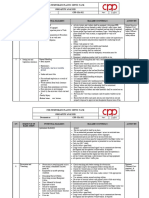

Job Safety Analysis

Job Description : Hard Barricades/ Manual Excavation Revision No .01

Company/Vender Name :Shweta Enterprise JSA No. P & G /JSA/SE-18

Job Participants: Sushil Kumar Yadav Date of issue: 10/10/2022

Analysis By:

Sequence of Steps Potential Hazards Recommended Safe Procedure

1. General Requirement Unauthorized work Permit- Ensure all work permits

may be cause like, STA, and various

accident and Checklist has Work been

property damage verified and authorized before

performing the Task.

Unawareness of the JSA Sharing- JSA should be

safety practices May shared with all the staffs and

cause accident. workers who are involved in the

same task.

Absence of The Supervisor/Engineer and

Supervisor/Engineer safety person should be always

and Safety person present at the site and instruct

may cause accident. the workers.

The Safety person along with

Improper training of the Engineer should give proper

work may cause Induction training about work

personal injury and and work related things before

Property Damage. starting the task..

The Safety person should daily

instruct the team member in the

tool box meeting regarding the

risk Involved in the task

Barricade the Work Area.

Wear Required PPE(Helmet,

Shoes, Goggles, Hand Gloves

etc.

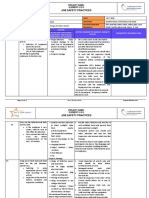

Sequence of Steps Potential Hazards Recommended Safe Procedure

2. Area Hard Barricades Sharp edge Wear hand gloves and use

proper ppe

eye injury All crew person must wear clear

view safety goggle for eyes

protection.

Dust/ fumes Use nose mask

inhalation

non inspected tools use proper inspected tools

injury during proper Hammering

hammering Trained workmen

wearing hand Gloves

trained worker shall be deputed

fall of material at workplace

Use proper PPE safety shoes,

helmet

3. Manual Digging Work

by Excavation Keep soil material at 1 meter

Fall of material / fall away from the edge

of Person Do Not store excessive material

in the Area.

Use Proper body Position

Ergonomics Hazard

Do not carry Heavy material in

the area manually

Use hand trolly for heavy

Material per parson 17 kg

weight

Eyes injury All Crew Person must wear

Clear View Safety Goggles for

Eyes Protection

Dust Hazard Use Nose Mask if Dust Produce

During Manual Digging Work

Hand Injury Wear Cut Resistance Cut Hand

Gloves For General Work

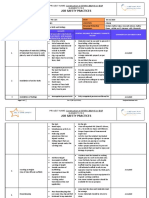

4. painting work ,by painting

Roller or painting brush

Slip/trip & fall Hazard

Use a sign bord who has

properly indicate at painting

surface, to prevent trip and fall

hazard.

Do not store excessive painting

bucket at work site & follow

proper housekeeping at

worksite.

Remove unwanted material

from the workplace.

Fire hazard should be ensure that no any

hot work likes grinding, welding,

cutting, is progress from 30 feet

to the job site

if any hot work required in side

the task area ,should be must

keep a fire watcher cylinder at

the job site.

Remove

combustible/Flammable

material from workplace before

start hot work

Dust/ smoke hazard

Use nose mask at the time of

painting work.

Eye /face injuries

Use face shield and goggle for

face and eye protection.

Slip/trip & fall Hazard

Do not store excessive paint

bucket at work site & follow

proper housekeeping at

worksite.

Remove unwanted material

from the workplace.

Version Issue Date Reason Of Change

Note:-

Barricade the work Area before start the work.

Housekeeping should be always before & after the work.

Take All Work Permit before starting the work.

Use always recommended PPE’s like Helmet, Goggle & safety shoes and according to work

should be use.

Organize scheduled training for die workers.

Safety Supervisor should be present always while work is going on.

All tools and tackles should be certified.

Safety in Charge______________ Initiator (CMO/P&G)______________

(Contractor)

Engineer (Contractor) ______________ Approved by: _____________________

(CMO/P&G Safety Owner)

You might also like

- CIFOR-ICRAF Procedure 1 - RecruitmentDocument34 pagesCIFOR-ICRAF Procedure 1 - RecruitmentJimmy HalimNo ratings yet

- Jsa For Scaffolding ErectionDocument7 pagesJsa For Scaffolding Erectionnoorul IslamNo ratings yet

- JSP For AsphaltDocument8 pagesJSP For Asphaltmohammed tofiqNo ratings yet

- Jsa For Scaffolding Erection & DismentlingDocument7 pagesJsa For Scaffolding Erection & Dismentlingsanath adhikary100% (5)

- JSA For HDPE SLEEVING DEL 89Document3 pagesJSA For HDPE SLEEVING DEL 89Mohammed Minhaj100% (1)

- Cement Plaster JSADocument4 pagesCement Plaster JSAMohammed Minhaj50% (2)

- JSA For Scaffolding Erection and Dismentling at Process AreaDocument5 pagesJSA For Scaffolding Erection and Dismentling at Process Areanoahlungu96No ratings yet

- JOB SAFETY ANALYSIS FOR HT & LT PANEL INSTALLATIONDocument1 pageJOB SAFETY ANALYSIS FOR HT & LT PANEL INSTALLATIONpushpanath reddy100% (1)

- Jsa For Gypsum Fixing & DismentlingDocument5 pagesJsa For Gypsum Fixing & DismentlingSushil Kumar YadavNo ratings yet

- JSA For Welding of HVACDocument4 pagesJSA For Welding of HVACMohammed Minhaj100% (1)

- Jsa For Camera & Fire Alarm InstallationDocument5 pagesJsa For Camera & Fire Alarm InstallationSushil Kumar YadavNo ratings yet

- Job Safety Practices FirefightingDocument16 pagesJob Safety Practices Firefightingmohammed tofiqNo ratings yet

- Erection JsaDocument52 pagesErection JsaMd Danish Raza100% (2)

- Cathodic Protection JSADocument6 pagesCathodic Protection JSAMohammed Minhaj80% (5)

- Jsa For Tile FixingDocument4 pagesJsa For Tile FixingMohammed Minhaj100% (1)

- Job Hazard Analysis PermitDocument1 pageJob Hazard Analysis PermitKhorchnoi Abaja CalimlimNo ratings yet

- Handbook of Multiple Choice Questions For MBA, Volume 1Document272 pagesHandbook of Multiple Choice Questions For MBA, Volume 1autos osman100% (1)

- Exit PolicyDocument10 pagesExit PolicyshrikantrockzNo ratings yet

- Safe Work Method Statement: (See Below)Document6 pagesSafe Work Method Statement: (See Below)Siddharth P100% (1)

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNo ratings yet

- Job Safety Analysis for Brick Work, Tile and Glass RemovalDocument4 pagesJob Safety Analysis for Brick Work, Tile and Glass RemovalSushil Kumar YadavNo ratings yet

- JSA Hand ToolsDocument1 pageJSA Hand ToolsInoy dy hesusNo ratings yet

- Case Study Psda 3 ManagementDocument7 pagesCase Study Psda 3 ManagementMayank pal100% (1)

- Jsa For Intallation of Sub Pipe RackDocument7 pagesJsa For Intallation of Sub Pipe RackMohammed Minhaj100% (2)

- JSA Teflon - U BoltDocument3 pagesJSA Teflon - U BoltHow Chin Engineering Sdn BhdNo ratings yet

- Job Safety Analysis for Poly Pipe InstallationDocument2 pagesJob Safety Analysis for Poly Pipe InstallationHow Chin Engineering Sdn BhdNo ratings yet

- SAP Wage Types ExplainedDocument30 pagesSAP Wage Types Explainedananth-jNo ratings yet

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- 7 Pillars of Organisational WellbeingDocument43 pages7 Pillars of Organisational Wellbeingizdiharyasik100% (1)

- Job Safety Analysis Skim Coating, Sanding, Painting: Preparation of All MaterialsDocument1 pageJob Safety Analysis Skim Coating, Sanding, Painting: Preparation of All MaterialsTheo Vidallon BautistaNo ratings yet

- Job Description - Piping EngineerDocument2 pagesJob Description - Piping EngineerManuel Astros100% (1)

- Communication Flows in An OrganizationDocument2 pagesCommunication Flows in An OrganizationTan JolNo ratings yet

- Jsa No 17 For Gypsum & Painting WorkDocument5 pagesJsa No 17 For Gypsum & Painting WorkSushil Kumar YadavNo ratings yet

- Brick Work JsaDocument1 pageBrick Work JsaAKBAR ALINo ratings yet

- JSA For Scaffolding Erection and Dismentling at Ko DrumDocument5 pagesJSA For Scaffolding Erection and Dismentling at Ko DrumViron BaxhiaNo ratings yet

- Catalyst Filling & SeggregationDocument3 pagesCatalyst Filling & SeggregationMohammed MinhajNo ratings yet

- JSA Elevator MaintenancDocument6 pagesJSA Elevator MaintenancHSE fahadNo ratings yet

- Concreting & Block Bricks Work JSADocument3 pagesConcreting & Block Bricks Work JSAHari NairNo ratings yet

- Plastering Works JSA HSE ProfessionalsDocument1 pagePlastering Works JSA HSE ProfessionalsSamadov 13No ratings yet

- Plastering works JSA HSE ProfessionalsDocument1 pagePlastering works JSA HSE Professionalsm.rehanhseNo ratings yet

- 5.19.3 Job Safety Practices Installation of Anchor Bolts and RailingsDocument3 pages5.19.3 Job Safety Practices Installation of Anchor Bolts and RailingsBarkat UllahNo ratings yet

- Hazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012Document1 pageHazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012somashekhar. ncclNo ratings yet

- R.A FOR Condensate PitDocument5 pagesR.A FOR Condensate PitResearcherNo ratings yet

- Tile Fixing JSA HSE ProfessionalsDocument2 pagesTile Fixing JSA HSE ProfessionalsSamadov 13No ratings yet

- Job Safety Analysis Installation (JSA)Document4 pagesJob Safety Analysis Installation (JSA)Aser Batoy Jr.No ratings yet

- Job Safety Practices Block and Plastering WorksDocument3 pagesJob Safety Practices Block and Plastering WorksBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Installation of Cable TrayDocument3 pages5.19.3 Job Safety Practices Installation of Cable TrayBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionDocument3 pages5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionBarkat UllahNo ratings yet

- Fabrication worksDocument4 pagesFabrication worksmark jayson yabesNo ratings yet

- JSA For Scaffolding Erection and DismentlingDocument5 pagesJSA For Scaffolding Erection and Dismentlingnoahlungu96No ratings yet

- Prudent Saudi Arabia LTD.: Job Safety Analysis - WorksheetDocument4 pagesPrudent Saudi Arabia LTD.: Job Safety Analysis - WorksheetrajavinugmailcomNo ratings yet

- JHA Welding Pipe BenderDocument2 pagesJHA Welding Pipe Bendermohammad arshadNo ratings yet

- Rebar installationDocument4 pagesRebar installationmark jayson yabesNo ratings yet

- JSA for Office Renovation Safety AnalysisDocument5 pagesJSA for Office Renovation Safety Analysismohamed yasinNo ratings yet

- JHSA for Temporary Plastic Septic TankDocument4 pagesJHSA for Temporary Plastic Septic TankAnna JisabaNo ratings yet

- 3. job-safety Sheet piling 钢板桩工作安全分析Document3 pages3. job-safety Sheet piling 钢板桩工作安全分析ADEN LIUNo ratings yet

- Hazard Analysis AutomotiveDocument1 pageHazard Analysis AutomotivejaglansunilNo ratings yet

- Drain Line Work JSA HSE ProfessionalsDocument2 pagesDrain Line Work JSA HSE ProfessionalsSamadov 13No ratings yet

- Risk Assessment - Installation of Back Painted GlassDocument7 pagesRisk Assessment - Installation of Back Painted GlassMuhammad NadeemNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- Omn01ard - Jsa-Installation of Light Sensor at Top of JS and SS SkidsDocument3 pagesOmn01ard - Jsa-Installation of Light Sensor at Top of JS and SS Skidshechame TamerhouletNo ratings yet

- Safety Officer Project SODocument2 pagesSafety Officer Project SODarwin De ChavezNo ratings yet

- Working at Shuttering Yard JSA HSE ProfessionalsDocument2 pagesWorking at Shuttering Yard JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Risk Assessment B.ingDocument1 pageRisk Assessment B.ingkristina panjaitanNo ratings yet

- Jsa For Modification of HoppersDocument5 pagesJsa For Modification of HoppersEdmy RiveraNo ratings yet

- Step Activity Potential Hazards Hazard Controls NoDocument2 pagesStep Activity Potential Hazards Hazard Controls NoKazeneza BMNo ratings yet

- Deshuttering of Plinth JSA HSE ProfessionalsDocument1 pageDeshuttering of Plinth JSA HSE ProfessionalsSamadov 13No ratings yet

- Change-Path Model Drives Organizational TransformationDocument25 pagesChange-Path Model Drives Organizational TransformationYash MittalNo ratings yet

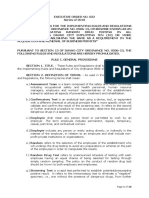

- Executive Order 032 Series of 2018Document10 pagesExecutive Order 032 Series of 2018elayNo ratings yet

- Ethical Issues in Business ValuationDocument111 pagesEthical Issues in Business ValuationMeeta Murarka100% (1)

- Employment Contract: Public Employment Service Office Iligan CityDocument2 pagesEmployment Contract: Public Employment Service Office Iligan CityBarangay SarayNo ratings yet

- Book Summary - Assignment - Wycliffe - Okelo (200447259)Document33 pagesBook Summary - Assignment - Wycliffe - Okelo (200447259)Wycliffe OkeloNo ratings yet

- Payroll Processing ProcedureDocument5 pagesPayroll Processing ProcedureVenkatesan EthirajNo ratings yet

- Payment of Bonus Act-1965Document26 pagesPayment of Bonus Act-1965csJyothirmai100% (1)

- Mngt. 202 ExamDocument4 pagesMngt. 202 ExamMatsouka KouNo ratings yet

- Chapter 1 Recruitment ProcessDocument20 pagesChapter 1 Recruitment ProcessMohd AslamNo ratings yet

- 15 Types of Business Letter Used by BusinessDocument9 pages15 Types of Business Letter Used by BusinessForeva JamaicanNo ratings yet

- Hamza Masoud C.V - "I&C" Instrument and Control SpecialistDocument3 pagesHamza Masoud C.V - "I&C" Instrument and Control SpecialistHamza MasoudNo ratings yet

- Cover Letter For Bank Job in BangladeshDocument6 pagesCover Letter For Bank Job in Bangladeshc2s1qk03100% (1)

- Midterm LaborDocument8 pagesMidterm LaborMark Gerard NebriaNo ratings yet

- Green HRM Approach to Environmental SustainabilityDocument9 pagesGreen HRM Approach to Environmental SustainabilityFaruque Abdullah RumonNo ratings yet

- Promoting Safety and Health in the WorkplaceDocument52 pagesPromoting Safety and Health in the WorkplaceJema Santillan100% (1)

- Planificación Inglés Cuarto Medio 2016Document8 pagesPlanificación Inglés Cuarto Medio 2016Nancy San Martin HenriquezNo ratings yet

- A Complete Case Study Upon Issues Related To Human Resource Management at Apple IncDocument3 pagesA Complete Case Study Upon Issues Related To Human Resource Management at Apple IncGlobal TherapyNo ratings yet

- Clinical Reasoning: The Basis of Practice: Barbara A. Boyt SchellDocument9 pagesClinical Reasoning: The Basis of Practice: Barbara A. Boyt SchellMaria AiramNo ratings yet

- HR Group Training ProposalDocument11 pagesHR Group Training ProposalNurul Syarmilah . AbdullahNo ratings yet

- SAM Questions - 1Document4 pagesSAM Questions - 1Jagadish PatraNo ratings yet

- Job Design and Work Measurement Part I Enova Reynan R.Document19 pagesJob Design and Work Measurement Part I Enova Reynan R.Ruth Ann DimalaluanNo ratings yet