Professional Documents

Culture Documents

Safety Officer Project SO

Uploaded by

Darwin De ChavezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Officer Project SO

Uploaded by

Darwin De ChavezCopyright:

Available Formats

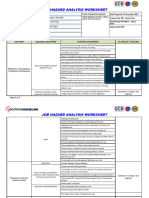

Step Job Steps Hazards Identified Control Measures

No.

1 Area preparation for the Physical handling of materials (pinch points, Pre-Job Safety Briefing for all workers.

scheduled activity sharp objects). Potential for personnel injury Require appropriate hand gloves for handling of materials.

Uneven ground surface, slips and trips Workers must be aware for the area.

Stay focus on the given task and maintain good eye sight on the access way.

Post warning sign

Defective tools and equipment Ensure the equipment / tool to be used for chipping are free from defect

Equipment inspection

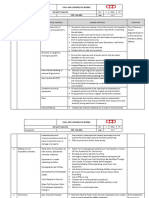

2 Rock / concrete Breaking Fire or explosion Gas test first the area before commencing to any hot work activity

using chipping hammer LEL must be 0, Oxygen level must be 20.8%, CO=0ppm, and H2S=0ppm

Ensure fire extinguisher is present and functioning

Standby fire watcher & water

Isolate the area / enclose the work area

Struck by/ Against Heavy Equipment Isolate equipment swing areas

Flying Debris, Protruding Objects Communication / Make eye contact with operator before approaching equipment

Barricade or enclose the work area

Restrict work area entry to authorized personnel only during construction

Shoulder, lower back, body injury. activities

Physical handling/manual handling Wear hard hats, safety glasses, face shield, reflectorized jacket, and steel-toe

Heavy load and repetitive movement safety boots

Vibration Rotation tasks to minimize workers exposure to equipment vibration

Warm up exercises, correct posture, and correct technique

Take regular breaks/rotate work

High Noise Levels Use hearing protection when exposed to excessive noise levels (greater than 85

dBA over an 8-hour work period) use ear plug.

Extreme physical conditions (humidity). Establish rest areas in the vicinity of the work area

Potential for workforce injury from heat related Establish rest break and hydration frequency

disorders. Provide fluids / water to prevent worker dehydration

Poor relationship between operator and in- Avoid horse playing; establish house rules, defined roles and responsibilities,

Prepared by: Reviewed by:

Darwin De Chavez German S. Bagsic / Guian Carlo Soriano

Safety Officer Project SO

charge for workforce injury, property damage. discuss any potential conflicts during tool box meetings.

Proper coordination communication between operator and in-charge

Wear N5 respirator or dust mask

Inhalation of dust particles

Electrocution

Do not use frayed cables, and ensure that it was connected with ELCB

Cables, especially the connection must not be lied on water

Ensure that the chipping gun is in good condition

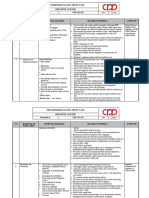

Housekeeping Manual Material handling. Physical injuries Asses sharp, pointed edges/tip & pinch points of tools & materials.

due to caught in between. Sharp & pointed Assess hole, protruding objects on walkways. Remove obstruction

edges/tip of tools Practice and follow 5S

Uneven ground surface

Prepared by: Reviewed by:

Darwin De Chavez German S. Bagsic / Guian Carlo Soriano

Safety Officer Project SO

You might also like

- JSA Machinal PipingDocument7 pagesJSA Machinal PipingNaitik Desai48100% (1)

- Pornography Addiction (Compulsive Pornography Use) : Identification, Treatment and Couples RecoveryDocument74 pagesPornography Addiction (Compulsive Pornography Use) : Identification, Treatment and Couples RecoveryLuizInácioNo ratings yet

- JSA For Welding of HVACDocument4 pagesJSA For Welding of HVACMohammed Minhaj100% (1)

- Job Safety Tips for Backfilling & CompactionDocument2 pagesJob Safety Tips for Backfilling & Compactionrashid zaman84% (25)

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- Exavation Works PipercksDocument4 pagesExavation Works PipercksHRTYR100% (1)

- JSA Maintenance Fire Alarm PDFDocument2 pagesJSA Maintenance Fire Alarm PDFBernath100% (3)

- Portable Power Tools - Risk Assessment2Document3 pagesPortable Power Tools - Risk Assessment2Basit Nawaz100% (1)

- JSa For Operation of Jack HammeringDocument3 pagesJSa For Operation of Jack Hammeringyc safety0% (1)

- JSA Installation-Fire-Alarm-SystemDocument12 pagesJSA Installation-Fire-Alarm-Systemuz9143895No ratings yet

- JSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentDocument4 pagesJSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentMohammed Minhaj100% (1)

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- SITE CLEARING SAFETYDocument7 pagesSITE CLEARING SAFETYElvyn Fabellore HerreraNo ratings yet

- Excavation SafetyDocument11 pagesExcavation SafetyDenease CrummieNo ratings yet

- Job HazardDocument2 pagesJob HazardBre WirabumiNo ratings yet

- JSA Install Automatic Parking GateDocument6 pagesJSA Install Automatic Parking GateMarhendraNo ratings yet

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pages0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- Introductory Lecture by DR Prafull VijayakarDocument139 pagesIntroductory Lecture by DR Prafull Vijayakarpredictive amar100% (1)

- JHA HondaDocument2 pagesJHA HondaJaycee QuinNo ratings yet

- Jsa Dismantling The Wooden Framework-NewDocument3 pagesJsa Dismantling The Wooden Framework-NewHow Chin Engineering Sdn BhdNo ratings yet

- JSA For DPTDocument3 pagesJSA For DPTMohammed Minhaj100% (1)

- Job Steps Potential Hazards Recommended Safe Job ProceduresDocument3 pagesJob Steps Potential Hazards Recommended Safe Job ProceduresDJadee Anuppur AmlaiNo ratings yet

- Brick Work BSM Jha - 1Document3 pagesBrick Work BSM Jha - 1Dwitikrushna RoutNo ratings yet

- JSA For MPIDocument3 pagesJSA For MPIMohammed MinhajNo ratings yet

- Referred PainDocument9 pagesReferred PainElsa Tamara SaragihNo ratings yet

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pages0017 JS A Hot Job (Welding, Grinding & Cutting)midozotyNo ratings yet

- Cataract Case GuideDocument3 pagesCataract Case GuideVetrivel Tamizh100% (1)

- RASA BooksDocument57 pagesRASA BooksArathy Krishna100% (1)

- How to Don and Doff Sterile Gloves SafelyDocument32 pagesHow to Don and Doff Sterile Gloves SafelyCoreen Mangaoang83% (6)

- Excavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Document11 pagesExcavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)PABITRA PANDANo ratings yet

- Job Hazard Analysis for Fire Protection System RehabilitationDocument1 pageJob Hazard Analysis for Fire Protection System RehabilitationJane RoNo ratings yet

- CS Sub Station JsaDocument4 pagesCS Sub Station JsaEHS Unit IINo ratings yet

- JSA Gulf Construction Est: Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Document12 pagesJSA Gulf Construction Est: Safe Work Plan (SWP) /phase Hazard Analysis (Pha)mehtab uddinNo ratings yet

- JSA Elevator MaintenancDocument6 pagesJSA Elevator MaintenancHSE fahadNo ratings yet

- Hard BarricationDocument3 pagesHard BarricationViron BaxhiaNo ratings yet

- JSA Template for FRP Piping InstallationDocument6 pagesJSA Template for FRP Piping InstallationDanial AfandiNo ratings yet

- Job Hazard AnalysisDocument5 pagesJob Hazard AnalysisMJ D studioNo ratings yet

- RCC Safety Supervisor: CivilDocument7 pagesRCC Safety Supervisor: CivilDwitikrushna RoutNo ratings yet

- 1 SurveyDocument5 pages1 Survey王志伟0% (1)

- Job Hazard Assessment: Sequence of Job Potential Hazards Recommended Action, Procedure, And/or EquipmentDocument2 pagesJob Hazard Assessment: Sequence of Job Potential Hazards Recommended Action, Procedure, And/or EquipmentAsra AsraNo ratings yet

- JHA - Unloading of Sheet PileDocument3 pagesJHA - Unloading of Sheet PileJensen Sunga100% (1)

- Jsa FormatDocument6 pagesJsa FormatMohdHuzairiRusliNo ratings yet

- Cable Laying Safety MeasuresDocument5 pagesCable Laying Safety MeasuresDwitikrushna RoutNo ratings yet

- JSA FOR CONCREATE AND CIVILWORKSDocument7 pagesJSA FOR CONCREATE AND CIVILWORKSAnna JisabaNo ratings yet

- Siddhivinayak Jsa-004-Work in ShaftDocument5 pagesSiddhivinayak Jsa-004-Work in Shaftyogeshraut1910No ratings yet

- ER-MO-03 Electrical Work On The Nacelle and TowerDocument13 pagesER-MO-03 Electrical Work On The Nacelle and TowerAlex IgnatNo ratings yet

- Job Hazard Analysis: Installation of Fm200 Fire Suppression SystemDocument6 pagesJob Hazard Analysis: Installation of Fm200 Fire Suppression SystemJohn Mark MacoyNo ratings yet

- JHSA for Temporary Plastic Septic TankDocument4 pagesJHSA for Temporary Plastic Septic TankAnna JisabaNo ratings yet

- Job Safety Analysis (Jsa)Document9 pagesJob Safety Analysis (Jsa)MohdHuzairiRusliNo ratings yet

- Jha ExcavationDocument11 pagesJha ExcavationMohd Firdaus OthmanNo ratings yet

- AsasasaDocument2 pagesAsasasahalfy safitriNo ratings yet

- Handtool Safety Training Electric Hand Drill 1. Training Safety PrerequisitesDocument3 pagesHandtool Safety Training Electric Hand Drill 1. Training Safety Prerequisitesretheep0% (1)

- Deshuttering of Plinth JSA HSE ProfessionalsDocument1 pageDeshuttering of Plinth JSA HSE ProfessionalsSamadov 13No ratings yet

- Plastering Works JSA HSE ProfessionalsDocument1 pagePlastering Works JSA HSE ProfessionalsSamadov 13No ratings yet

- Apds-Ra-011 Filtration Operation of Apds Filtration System Rev BDocument4 pagesApds-Ra-011 Filtration Operation of Apds Filtration System Rev BHua Tien DungNo ratings yet

- JSA 02-Rev.01 - Blinding & DeblindingDocument1 pageJSA 02-Rev.01 - Blinding & DeblindinggolusinghdataNo ratings yet

- National Builders and Services: Painting Construction Maria Jessa Mae Diaz Maria China Andallo Project in ChargeDocument2 pagesNational Builders and Services: Painting Construction Maria Jessa Mae Diaz Maria China Andallo Project in ChargeMaria Jessa Mae DiazNo ratings yet

- Plastering works JSA HSE ProfessionalsDocument1 pagePlastering works JSA HSE Professionalsm.rehanhseNo ratings yet

- Jsa for Concreate and CivilworksDocument7 pagesJsa for Concreate and CivilworksAnna JisabaNo ratings yet

- M/S Arun Kumar Mitra: Job Hazard AnalysisDocument5 pagesM/S Arun Kumar Mitra: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Garudadhwaja Structures (P) Ltd. Job Hazard Analysis: JHA No.:05Document3 pagesGarudadhwaja Structures (P) Ltd. Job Hazard Analysis: JHA No.:05Dwitikrushna Rout0% (1)

- 021 Manual Excavation JSA For FLS SiteDocument3 pages021 Manual Excavation JSA For FLS SiteViron BaxhiaNo ratings yet

- JSEA042022001_Aluminium worksDocument6 pagesJSEA042022001_Aluminium worksWeru MorrisNo ratings yet

- Inspection CheclistDocument1 pageInspection CheclistDarwin De ChavezNo ratings yet

- Eei Construction & Marine, Inc.: Toolbox Meeting AttendanceDocument1 pageEei Construction & Marine, Inc.: Toolbox Meeting AttendanceDarwin De ChavezNo ratings yet

- TestingDocument7 pagesTestingDarwin De ChavezNo ratings yet

- ME Private Well Testing BrochureDocument4 pagesME Private Well Testing BrochureDarwin De ChavezNo ratings yet

- Strategies For Minimizing Dispensing ErrorsDocument3 pagesStrategies For Minimizing Dispensing ErrorsAnah MayNo ratings yet

- NutritionDocument4 pagesNutritionAlisahNo ratings yet

- Lembar Jawaban Skill Lab Evidence Based Medicine (Ebm) Nama: Muhammad Fadill Akbar NIM: 04011281621080Document20 pagesLembar Jawaban Skill Lab Evidence Based Medicine (Ebm) Nama: Muhammad Fadill Akbar NIM: 04011281621080Ya'kubNo ratings yet

- Coe, & Vandegrift. 2015 (Youth Politics and Culture in Contemporary LA A Review)Document23 pagesCoe, & Vandegrift. 2015 (Youth Politics and Culture in Contemporary LA A Review)Alejandro MolinaNo ratings yet

- Septoplasty: Information For Patients From Head and NeckDocument4 pagesSeptoplasty: Information For Patients From Head and NeckKris RNo ratings yet

- My Asthma Action Plan: Recognising Symptoms and Taking ActionDocument2 pagesMy Asthma Action Plan: Recognising Symptoms and Taking ActionMallika EssamsettyNo ratings yet

- Physical ExaminationDocument2 pagesPhysical ExaminationPopa Elena0% (1)

- Xerox Wc423 SMDocument600 pagesXerox Wc423 SMkerintNo ratings yet

- National Polio Lab ChecklistDocument12 pagesNational Polio Lab ChecklistSelaina NawadraNo ratings yet

- C11 - Study 1Document6 pagesC11 - Study 1zeeshan78No ratings yet

- Instructions: Answer What Are Being Asked ForDocument23 pagesInstructions: Answer What Are Being Asked ForCatlyn Tagala CalzadoNo ratings yet

- PT&T Policy Against Married WomenDocument12 pagesPT&T Policy Against Married WomenHershey Delos SantosNo ratings yet

- Key To Eye Diagnosis by Tashfeen NasiraDocument8 pagesKey To Eye Diagnosis by Tashfeen Nasiralakshay sharmaNo ratings yet

- TC Electronic M-100 User ManualDocument21 pagesTC Electronic M-100 User Manualzewdaroo9599No ratings yet

- RPH NOTESDocument37 pagesRPH NOTESRaine TaclaNo ratings yet

- Disclosure of Research InformationDocument64 pagesDisclosure of Research InformationThe Hastings CenterNo ratings yet

- DRUG STUDY: Lidocaine, Methocarbamol, MetaxaloneDocument28 pagesDRUG STUDY: Lidocaine, Methocarbamol, MetaxaloneLucas, Darah Angelica A.No ratings yet

- CPSP Dissertation Data SheetDocument8 pagesCPSP Dissertation Data SheetPayToWritePaperSingapore100% (1)

- Review Questions DRUGSDocument7 pagesReview Questions DRUGSjoy LoretoNo ratings yet

- Project SarvodayaDocument21 pagesProject SarvodayaArun Kumar PNo ratings yet

- ISO Datasheet UE-71D10 Preliminary BMSTDocument1 pageISO Datasheet UE-71D10 Preliminary BMSTNamtien UsNo ratings yet

- The University of Melbourne Tuition Fees 2020: Tuition Fee Tables For International StudentsDocument32 pagesThe University of Melbourne Tuition Fees 2020: Tuition Fee Tables For International StudentsRuchi ChinfhaChinthaNo ratings yet

- CBRC Gensan Nle Nov 2015Document3 pagesCBRC Gensan Nle Nov 2015Maria Theresa Badayos-TeeNo ratings yet

- Shean19 VaPID RefthroughGeneBankDocument8 pagesShean19 VaPID RefthroughGeneBankAnh H NguyenNo ratings yet