Professional Documents

Culture Documents

Fabrication works

Uploaded by

mark jayson yabesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication works

Uploaded by

mark jayson yabesCopyright:

Available Formats

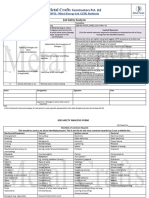

WORK ACTIVITY JOB HAZARD ANALYSIS

PROJECT: WP5-2300 Clubhouse Structural SERIAL NO: JHA-T3G-000____

works, Hann Reserve Project

ACTIVITY/PROCESS

FABRICATION WORKS

IDENTIFIED HAZARDS KEY RISKS EXISTING CONTROL

MEASURES/PRECAUTIONS

1. Preparation of tools and Getting caught Conduct of PATOS prior to the activity.

materials in between Basic (Safety shoes / boots, work

materials; trousers, long sleeves / safety jacket,

Sharp edges hard hat,

reflectorized vest, eye protection)

+ Rubber Gloves

Poor working Observe proper working posture; Take

posture; work breaks if necessary

Overexertion of Employees shall be given a briefing on

force what to expect on the worksite; Cliff

Slipping on areas shall be clearly identified and

descending/mu marked; Self hydration is encouraged.

ddy terrain; Hot Basic (Safety shoes / boots, work

outdoor trousers, long sleeves / safety jacket,

temperature hard hat, reflectorized vest, eye

hand protection).

laceration, back Use of proper appropriate ppe (safety

pain, dust gloves, observe proper posture of the

inhalation body, observe proper manual handling

and lifting, use of dust mask.)

2. Hauling of prepared materials Slipping on Employees shall be given a briefing on

descending/mu what to expect on the worksite; Cliff

ddy terrain; Hot areas shall be clearly identified and

outdoor marked; Self hydration is encouraged.

temperature Basic (Safety shoes / boots, work

hand trousers, long sleeves / safety jacket,

laceration, back hard hat, reflectorized vest, eye

pain, dust protection).

inhalation Use of proper appropriate ppe (safety

Muscle strains, gloves, observe proper posture of the

pulls and body, observe proper manual handling

repetitive and lifting, use of dust mask.)

motion injuries. Each employee should be provided

Injuries training on the safe and proper use of

resulting from the most important, primary tool their

lack of bodies (Strong, Alert, Focused,

communication, Energetic, or SAFE training). Proper

or techniques of stretching, lifting, bending,

miscommunicat moving, rolling rocks, securing good

ion. footing, the importance of good nutrition

and hydration,

Employees will be encouraged to switch

hands often and vary the types of

activities performed to limit exposure to

repetitive motion injuries.

The appropriate number of workers

should be used to move materials. This

Form No.: TCD-WP-JHA-2024

Rev. 1, 01 April 2024

decision may vary between individuals.

Crew leaders will conduct, whenever

appropriate, tailgate safety talks to

provide orientation, discuss project,

safety concerns, assign work.

Good communication between

crewmembers should reinforce

individual awareness of real and

potential hazards.

Communication methods or jargon

should be discussed and agreed upon

prior to moving materials

Communication methods or jargon

should be discussed and agreed upon

prior to moving materials

Instructions should come from one

person when working in teams of two or

more.

Form No.: TCD-WP-JHA-2024

Rev. 1, 01 April 2024

3. Fabrication works (Cutting of Sharp Edges, Workers should be well-trained in power

steel materials (flat or angle bars, Hot surfaces tools handling and operation.

round steel bars, etc.) to be Moving power PPE: Basic (Safety shoes / boots,

welded using cut-off wheel or tool parts; work trousers, long sleeves / safety

grinder.) Defective jacket, hard hat, reflectorized vest, eye

power tools. protection) + rubber (cotton) gloves

: Poor working Ensure that the power tools are working

posture; and safe to use. Machine guards should

Dust and be in place

Fumes Workers should not be allowed to wear

any dangling items like ID lace and

necklace. Tuck in loose shirt and/or

trousers if necessary. A fire watcher

equipped with a portable fire

extinguisher should be present while

doing cutting works.

Proper working posture shall be

encouraged. Breaktime rest shall be

observed.

Provide air moving equipment especially

on confined spaces. Basic + Dust Mask

4. Welding of steel members. Hot metal

surfaces; Competency

radiation from certificates shall be validated for each

welding welder to be deployed

equipment Basic (Safety shoes / boots, work

Muscle pains trousers, long sleeves / safety jacket,

due to awkward hard hat, reflectorized vest, eye

working protection) + welding gloves, welding

positions. apron and welding mask

Dust and Always check the welding machine

Fumes before working. All flammable materials

must be removed near the work area.

Use fire blankets if necessary. A

portable fire extinguisher and a fire

watcher should be present.

Breaktime rest shall be observed to

allow stretching time.

Provide air moving equipment especially

on confined spaces.

Welding / fabrication works shall be

done on open spaces if possible.

5. Grinding of excess welds / flux Hot metal surfaces; Workers should be well-trained in power tools

flying grinded handling and operation.

particles. Basic (Safety shoes / boots, work trousers, long

Moving power tool sleeves / safety jacket, hard hat, reflectorized vest,

parts; Defective eye protection) + rubber (cotton) gloves

power tools. Proper working posture shall be encouraged.

Poor working Breaktime rest shall be observed.

posture; Engineering: Provide air moving equipment

Dust and Fumes especially on confined spaces.

Basic + Dust Mask

6. Housekeeping Repetitive motion or ● Perform a last-minute risk assessment before

other ergonomic performing any material handling task.

concerns

Heavy manual ● Make sure to check the path of travel for any obstacles

lifting/moving before moving any materials.

Form No.: TCD-WP-JHA-2024

Rev. 1, 01 April 2024

● Perform a proper warm up and stretch before performing

any material handling task.

● The PPE required for any material handling tasks are:

Safety glasses, appropriate gloves and appropriate non-

slip footwear. Additional PPE may be required

depending upon environment conditions.

OPS. Area In-Charge: RICHARD SIBUG EHS. Area In-Charge:

Position: SR. ENGINEER INCHARGE Position:

Date: April 2024 Date: April 2024

Project Manager: LEONILO MUNSAYAC Safety Manager: MARK O.YABES

Date: April 2024 Date: April 2024

Form No.: TCD-WP-JHA-2024

Rev. 1, 01 April 2024

You might also like

- Job Safety Tips for Backfilling & CompactionDocument2 pagesJob Safety Tips for Backfilling & Compactionrashid zaman84% (25)

- Concreting Job Safety Analysis (JSA)Document2 pagesConcreting Job Safety Analysis (JSA)sudam kumar raut95% (19)

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Job HazardDocument2 pagesJob HazardBre WirabumiNo ratings yet

- Job Safety Analysis: What Am I About To Do? Who Is Going To Put The Precautions in Place?Document3 pagesJob Safety Analysis: What Am I About To Do? Who Is Going To Put The Precautions in Place?kalai selvan0% (1)

- Flushing Pipe SafelyDocument5 pagesFlushing Pipe SafelyYosua SitumorangNo ratings yet

- Job Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9Document4 pagesJob Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9OGBONNAYA MARTINSNo ratings yet

- Rebar installationDocument4 pagesRebar installationmark jayson yabesNo ratings yet

- 03. JHA - Clearing, grubbing, excavation, backfilling and compaction- Copy - CopyDocument11 pages03. JHA - Clearing, grubbing, excavation, backfilling and compaction- Copy - Copymark jayson yabesNo ratings yet

- 02. JHA - Soil erosion control - CopyDocument9 pages02. JHA - Soil erosion control - Copymark jayson yabesNo ratings yet

- Safty TrainingDocument49 pagesSafty TrainingMannu MoideenNo ratings yet

- Joinery Carpentry Risk AssessmenmtDocument4 pagesJoinery Carpentry Risk Assessmenmtadeniyi abiolaNo ratings yet

- Safety Engineering JHA GuideDocument29 pagesSafety Engineering JHA GuideDarren Dela CruzNo ratings yet

- JOB SAFETY ANALYSIS FOR HOT SPLICING BELT REPLACEMENTDocument8 pagesJOB SAFETY ANALYSIS FOR HOT SPLICING BELT REPLACEMENTPed KapedNo ratings yet

- Brick Work JsaDocument1 pageBrick Work JsaAKBAR ALINo ratings yet

- Apds-Ra-011 Filtration Operation of Apds Filtration System Rev BDocument4 pagesApds-Ra-011 Filtration Operation of Apds Filtration System Rev BHua Tien DungNo ratings yet

- JSA Elevator MaintenancDocument6 pagesJSA Elevator MaintenancHSE fahadNo ratings yet

- Jsa No 18 New BarrictionDocument4 pagesJsa No 18 New BarrictionSushil Kumar YadavNo ratings yet

- Backfilling ENDocument5 pagesBackfilling ENTilalNo ratings yet

- JSA #32 Manual HandlingDocument1 pageJSA #32 Manual HandlingSubham Sohal100% (2)

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Document2 pagesJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNo ratings yet

- Job Hazard AnalysisDocument5 pagesJob Hazard AnalysisMJ D studioNo ratings yet

- Lecture 6 Job Hazard AnalysisDocument28 pagesLecture 6 Job Hazard AnalysisgatdulalanzNo ratings yet

- Excavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Document11 pagesExcavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)PABITRA PANDANo ratings yet

- Job Safety Analysis: Kalco Alu System (P) LTDDocument2 pagesJob Safety Analysis: Kalco Alu System (P) LTDShekh BabulNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.017Document5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.017Yosua SitumorangNo ratings yet

- JSA Gulf Construction Est: Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Document12 pagesJSA Gulf Construction Est: Safe Work Plan (SWP) /phase Hazard Analysis (Pha)mehtab uddinNo ratings yet

- Job Hazard Analysis for Fire Protection System RehabilitationDocument1 pageJob Hazard Analysis for Fire Protection System RehabilitationJane RoNo ratings yet

- TA-Replacing Floor TilesDocument8 pagesTA-Replacing Floor TilesShannon MooreNo ratings yet

- 15 ConstructionDocument2 pages15 ConstructionBob StevenNo ratings yet

- Job Safety Analysis Installation (JSA)Document4 pagesJob Safety Analysis Installation (JSA)Aser Batoy Jr.No ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Document5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Yosua SitumorangNo ratings yet

- Workplace Hazards in ConstructionDocument2 pagesWorkplace Hazards in ConstructionDWi Uwee DejHeNo ratings yet

- PT-03 JSA Dismantling of Slip Form (22-05-09)Document10 pagesPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibNo ratings yet

- JHA- FORM WORKS STRIPPING AND CURRINGDocument7 pagesJHA- FORM WORKS STRIPPING AND CURRINGmark jayson yabesNo ratings yet

- Ewrc SHP Gen Hse Jsa 00040Document12 pagesEwrc SHP Gen Hse Jsa 00040Rickz CabaloNo ratings yet

- TA-Replacing Floor TilesDocument8 pagesTA-Replacing Floor TilesShannon MooreNo ratings yet

- HIRA-WaterproofingDocument16 pagesHIRA-WaterproofingPRIYESH . K. PRIYANNo ratings yet

- Cleaning Site (Hirac)Document4 pagesCleaning Site (Hirac)jovyNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Accident Prevention: Health & Safety Management For QuarriesDocument19 pagesAccident Prevention: Health & Safety Management For QuarriesSanjana Ganesh100% (1)

- JSA - Sheet FixingDocument5 pagesJSA - Sheet FixingSwaroop CherryNo ratings yet

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Safety Officer Project SODocument2 pagesSafety Officer Project SODarwin De ChavezNo ratings yet

- JSA - Repair-Coating and Finition Work THDocument3 pagesJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNo ratings yet

- JHA General Maintenance Activity PDFDocument5 pagesJHA General Maintenance Activity PDFdede SinbadNo ratings yet

- SOP 15 - Hopper Cleaning ActivityDocument6 pagesSOP 15 - Hopper Cleaning Activityfaraz ahmed100% (2)

- Conditions To Prevent AccidentDocument21 pagesConditions To Prevent Accidentczds6594No ratings yet

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- JSA 17-Rev.01 - Flange tightening jobDocument2 pagesJSA 17-Rev.01 - Flange tightening jobgolusinghdataNo ratings yet

- JSA 03-Rev.02 - BlindingDebliding under Nitrogen purgingDocument2 pagesJSA 03-Rev.02 - BlindingDebliding under Nitrogen purginggolusinghdataNo ratings yet

- Cutting ActivitiesDocument3 pagesCutting ActivitiesWalid KhelfaNo ratings yet

- 8 Runs Primary Ductline Jha FormDocument2 pages8 Runs Primary Ductline Jha FormNova CastyNo ratings yet

- Job Hazard Analysis: Installation of Fm200 Fire Suppression SystemDocument6 pagesJob Hazard Analysis: Installation of Fm200 Fire Suppression SystemJohn Mark MacoyNo ratings yet

- HIRAC PLAN for Hazard Control ProcedureDocument5 pagesHIRAC PLAN for Hazard Control ProcedureJulzNo ratings yet

- Cleaning: Risk Assessment For: Establishment: Assessment By: DateDocument4 pagesCleaning: Risk Assessment For: Establishment: Assessment By: DateEzzati AzizNo ratings yet

- Positif Jsa HMCFDDocument4 pagesPositif Jsa HMCFDBryant TorresNo ratings yet

- JHA Power Hand Tool Use - ROMODocument3 pagesJHA Power Hand Tool Use - ROMOMohd AleemNo ratings yet

- water proofingDocument2 pageswater proofingmark jayson yabesNo ratings yet

- JHA Tower Crane ErectionDocument4 pagesJHA Tower Crane Erectionmark jayson yabesNo ratings yet

- JHA- FORM WORKS STRIPPING AND CURRINGDocument7 pagesJHA- FORM WORKS STRIPPING AND CURRINGmark jayson yabesNo ratings yet

- 04. MS - Clearing and Grubbing, Excavation, Backfilling and CompactionDocument16 pages04. MS - Clearing and Grubbing, Excavation, Backfilling and Compactionmark jayson yabesNo ratings yet

- LIFTING PLANDocument2 pagesLIFTING PLANmark jayson yabesNo ratings yet

- Construction ID Color Tag per zoneDocument1 pageConstruction ID Color Tag per zonemark jayson yabesNo ratings yet

- Material Request Form: Project Name: Hann Reserve Project Address: Bamban (New Clark City) TarlacDocument2 pagesMaterial Request Form: Project Name: Hann Reserve Project Address: Bamban (New Clark City) Tarlacmark jayson yabesNo ratings yet

- SDS Petro Canada Gasoline UnleadedDocument15 pagesSDS Petro Canada Gasoline Unleadedmark jayson yabesNo ratings yet

- MOTORCYCLEDocument1 pageMOTORCYCLEmark jayson yabesNo ratings yet

- Pms ChecklistDocument1 pagePms Checklistmark jayson yabesNo ratings yet

- Leptospirosis National Guidelines - Sri LankaDocument56 pagesLeptospirosis National Guidelines - Sri LankaBrainy-Paykiesaurus LuminirexNo ratings yet

- Acoustic Design For Call CenterDocument16 pagesAcoustic Design For Call CenteraliNo ratings yet

- Toaz - Info Super Coolant Af Nac PRDocument6 pagesToaz - Info Super Coolant Af Nac PRsugi yantoNo ratings yet

- Development of Automatic Mini Fan with PIR SensorDocument8 pagesDevelopment of Automatic Mini Fan with PIR SensorToheebdareNo ratings yet

- ANALYSIS OF TRANSFORMER OIL TESTING USING GAS CHROMATOGRAPHY METHODDocument9 pagesANALYSIS OF TRANSFORMER OIL TESTING USING GAS CHROMATOGRAPHY METHODmuhammad yaminNo ratings yet

- Decline of Controversy and the Catholic ChurchDocument3 pagesDecline of Controversy and the Catholic ChurchEugenio PalandriNo ratings yet

- NCERT Solutions For Class 8 Science Chapter 6Document4 pagesNCERT Solutions For Class 8 Science Chapter 6D Rong saNo ratings yet

- Cja YDocument18 pagesCja YC-jay PizarraNo ratings yet

- Service Manual CT 50Document284 pagesService Manual CT 50Alvaro Restrepo GarciaNo ratings yet

- Aeroacoustic and Aerodynamic Optimization of Propeller BladesDocument14 pagesAeroacoustic and Aerodynamic Optimization of Propeller BladesWouterr GNo ratings yet

- A 1000 Calorie Diet Plan For Weight Loss - DMooseDocument15 pagesA 1000 Calorie Diet Plan For Weight Loss - DMoosekwasnyciakristinaNo ratings yet

- Jazz Band LiteratureDocument4 pagesJazz Band LiteratureJohnny LaounNo ratings yet

- Chapter2 AligningSelectionProjectsDocument36 pagesChapter2 AligningSelectionProjectsZeynep SenerNo ratings yet

- Group 3 Safety Issues in ICTDocument15 pagesGroup 3 Safety Issues in ICTRoseAnnNo ratings yet

- Max Out On Squats Every Day PDFDocument7 pagesMax Out On Squats Every Day PDFsamsung684No ratings yet

- (Paul M. S. Monk) Physical Chemistry UnderstandinDocument3 pages(Paul M. S. Monk) Physical Chemistry UnderstandinAshwani kumar SinghNo ratings yet

- 2) Inequality GraphsDocument14 pages2) Inequality Graphsmanobilli30No ratings yet

- F 25 Sensor Family Miniature Sensors for Precision DetectionDocument34 pagesF 25 Sensor Family Miniature Sensors for Precision DetectionAlex GarduñoNo ratings yet

- Company & Project Information for Electrical, Instrumentation ServicesDocument28 pagesCompany & Project Information for Electrical, Instrumentation ServicesMrudul PatilNo ratings yet

- Provisional RestorationsDocument9 pagesProvisional RestorationsshivaprasadmNo ratings yet

- Budget-of-Work-General Biology 1Document2 pagesBudget-of-Work-General Biology 1joei ArqueroNo ratings yet

- Evaluation of Plant Extracts Against Two Spotted Spider MiteDocument7 pagesEvaluation of Plant Extracts Against Two Spotted Spider MiteAnkaranaRenvaNo ratings yet

- Remote Controlled Home Appliances Project ReportDocument5 pagesRemote Controlled Home Appliances Project ReportASHU KNo ratings yet

- HYBRIFLEX® RRH Hybrid Cable Solution 12 X 24, 6AWG, Low-Inductance, Single-Mode Fiber, DLC Connectors Top and Bottom, 240 FTDocument3 pagesHYBRIFLEX® RRH Hybrid Cable Solution 12 X 24, 6AWG, Low-Inductance, Single-Mode Fiber, DLC Connectors Top and Bottom, 240 FTNoame Pauline SimbajonNo ratings yet

- Guidelines For Dengue Surveillance Edition2.PDF WHODocument115 pagesGuidelines For Dengue Surveillance Edition2.PDF WHOFebyan Kuan Lu Hap100% (1)

- Mater BiDocument10 pagesMater BihanjunyieeNo ratings yet

- 00 - Orientation LessonDocument32 pages00 - Orientation LessonRekha ShahNo ratings yet

- Modern Chicken Types & BreedsDocument14 pagesModern Chicken Types & BreedsMelody DacanayNo ratings yet

- SP HousekeepingDocument4 pagesSP HousekeepingLomunyak SaruniNo ratings yet

- Water Cycle Cer 002Document2 pagesWater Cycle Cer 002api-434008934No ratings yet