Professional Documents

Culture Documents

Method Statement For Flushing & Chemical Cleaning of Chilled Water System

Method Statement For Flushing & Chemical Cleaning of Chilled Water System

Uploaded by

RAJAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Flushing & Chemical Cleaning of Chilled Water System

Method Statement For Flushing & Chemical Cleaning of Chilled Water System

Uploaded by

RAJACopyright:

Available Formats

MS Ref No.

:

PROJECT: ZARA-ENOVA-ALEM-MSS-

ZARA MECH-0003

Rev: 00

STORAGE

Date: 21 October 2023

CREATION

Page 1 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

METHOD STATEMENT

STATEMENT

METHOD

FOR

TITLE

FLUSHING & CHEMICAL CLEANING OF

CHILLED WATER SYSTEM

Rev Date Document Status Prepared By Reviewed by Approved by

Sathiyamoorthy

00 21-10-2023 Issued for Approval Ajeesh Vijayan Henry Ungerer

Meyyappan

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 2 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

CONTENT

1. INTRODUCTION:.......................................................................................................................................3

2. SCOPE OF WORK:.....................................................................................................................................3

3. DEFINITIONS & ABBREVATIONS:........................................................................................................3

4. ROLES AND RESPONSIBILIITIES...........................................................................................................4

5. WORKING ACCESS:..................................................................................................................................9

6. LIGHTING:..................................................................................................................................................9

7. PLANT & EQUIPMENT:............................................................................................................................9

8. MATERIALS:............................................................................................................................................10

9. WORK SEQUENCE:.................................................................................................................................11

10. PROGRAMME...........................................................................................................................................15

11. RISKS & CONTROLS...............................................................................................................................15

12. EMERGENCY ARRANGEMENTS..........................................................................................................16

13. TRAINING.................................................................................................................................................16

14. SUPERVISION..........................................................................................................................................16

15. WORKING HOURS..................................................................................................................................16

16. HOUSEKEEPING......................................................................................................................................17

17. ATTACHMENTS.......................................................................................................................................17

CONTRACTOR AUTHORIZED SIGNATORY

Ajeesh Vijayan Sreesankar Sathiyamoorthy Meyyappan

QAQC ENGINEER Construction Risk Coordinator CONSTRUCTION MANAGER

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 3 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

1. INTRODUCTION:

This Method Statement describes the comprehensive requirements and procedures for the crucial phase of Flushing and

Chemical Cleaning of the Chilled Water System within the newly constructed Zara storage facility at the Mall of the Emirates,

Dubai. This meticulous process is pivotal to ensuring the optimal performance, longevity, and efficiency of the Chilled Water

System, comprising FCUs (Fan Coil Units), FAHUs (Fresh Air Handling Units), and related CHW pipe modifications in and

around the location.

2. SCOPE OF WORK:

The scope of this method statement is to define the procedure for Flushing and chemical cleaning of chilled water piping

system in accordance with the Specification Sections 15120.

3. DEFINITIONS & ABBREVATIONS:

Client Majid Al Futtaim / ENOVA

Tenant Zara

Consultant Mott Macdonald / WSP

Contractor Alemco Electromechanical Contracting L.L.C

PM Alemco Project Manager

CM Alemco Construction Manager

QCM Alemco QA/QC Manager

QCE Alemco Quality Control Engineer

SE Site Engineer

CRM Alemco Construction Risk Manager

ITP Inspection and Test Plan

MSS Method Statement Submittal

MS Material Submittal

SD Shop Drawing

CD Contract Drawing issued for Construction

CL Check List

RA Risk Assessment

MS Material Submittal

MRS Material Reference Schedule

IR Inspection Request

PSSP Project Safety Security Plan

MC Mobile Crane / Man Lift

MIM Manufacturer Instruction Manual

HSE Health, Safety & Environment

HSEMS Health, Safety & Environment Management System

GI Galvanized Iron

CHWP Chilled Water Pipes

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 4 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

PT Pressure Test

VCD Volume Control Damper

4. ROLES AND RESPONSIBILIITIES

Construction Manager

The construction manager will be responsible for following activities:

Ensure high standard of quality workmanship on site.

Ensure total Human Resource Management on site.

Contract improvement actions

Safeguard and promote Alemco interests when dealing with suppliers:

Ensure contract programme deadlines are met and exceeded where possible:

Materials and storage management:

Site Administration

Quality Manager:

The quality manager will be responsible for following activities:

Plan, Organize and Manage the QA QC team for the implementation of project quality management system.

Develop and implement the Project Quality Plan.

Develop and implement Internal and External Audit schedule and conduct /organize audits as per the schedule.

Coordinate with third party laboratories for initial testing activities and material testing. Verify the test reports for the

compliance to specification and submit to consultant.

Develop and establish a comprehensive schedule of all planned material submittals based on the project schedule.

Prepare Review and ensure the detailed material submittal schedule follows project schedule.

Coordinate with team and Consultants - to ensure the progress of material submittals is as per schedule.

Establish and Implement the Material and work Inspection procedure for the project. Monitor inspection status,

analysis status reports and trend analysis, implement corrective actions for the variations of plan.

Ensure the non-conforming materials are tagged and removed from site and provide the rejected material inspection

report to commercial and procurement for corrective actions.

Organize/Manage offsite inspections in coordination with team, Consultant and /supplier / manufacturer.

Establish and Implement procedures for monitoring and controlling quality of work including site surveillance,

recording the deficiencies and continuous follow up with construction tea for closing the recorded deficiencies.

Close Site Instructions/non-conformance reports from consultant within 14 days of receipt and conduct the review of

the Site instruction/corrective action to verify the scope for a potential claim.

Coordinate with team and consultant for implementing the corrective actions and closing the site instruction /NCR.

Coordinate with team for the timely submission of material submittals, test reports and O & M manual for the project.

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 5 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Prepare the closeout documentation requirements for the project and manage the Preparation / compilation and

submission of project closeout documents to consultant.

Coordinate with consultant for testing and commissioning inspections.

Establish and implement the procedures for snagging /de-snagging at project site. Coordinate with Consultant to

complete the snagging and de-snagging inspections as per project schedule.

Provide accurate progress updates of material submittals to planning department weekly and monthly.

Provide accurate status of material inspections to planning department weekly.

Present weekly material submittal status, weekly look ahead, status of site instructions to management and implement

the actions decided for any variations from plan.

Report to commercial department regarding the poor performance of team in quality or any other concerns, which

needs to be taken contractually.

Organize trainings on special systems/new procedures introduced in the project.

Lead, motivate, Train and develop QA QC team.

Design Manager:

The design manager will be responsible for following activities:

Understand the conditions of the contract with the client.

Liaise with client to determine factors affecting planning of the interior architecture, such as budget, architectural

preferences, purpose and function.

Prepare detailed drawings and design specifications and submit these for approval by relevant planning authorities.

Carry out a thorough site survey to determine site characteristics and to assess likely problems.

Advise client on interior design factors such as space planning, layout and utilization of furnishings or equipment, and

colour coordination.

Ensure all fit out work is carried out to the specific requirements of the client.

Coordinate with other professionals, such as contractors, architects, Engineers, and planners, to ensure that work is

completed to the highest standards and that the highest quality product is delivered to the client.

Oversee all the tasks of the design team and to provide motivation and support for the team.

Review and detail shop drawings for construction plans.

Formulate environmental plan to be practical, aesthetic, and conducive to intended purposes, such as raising

productivity or selling merchandise.

Select or design, and purchase furnishings, art works, and accessories.

Render design ideas in form of paste-ups or drawings.

Use computer-aided drafting (CAD) and related software to produce construction documents.

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 6 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Maintain an awareness of developments in the field of architecture so that up-to-date and accurate advice can be given

to clients.

Ensure all work is completed in compliance with the site HSE plan.

Coordinate with the local authorities where necessary

CRM Advisor / Safety Manager:

The CRM Manager will be responsible for the following activities:

Will train construction personnel in safe work practices on the job site.

Will prepare report as required by the Project Leader.

Will monitor, inspect, and report on unusual and/or serious accidents which may occur on the job sit.

Will submit written evaluation and recommendations direct to the Project Leader.

Will be based on site and manage the SAFETY performance of all project team personnel and operative.

Will assist the managers in overseeing SAFETY related activities that are associated with any of Alemco Sub-

contractor personnel, who are working on the project.

Will coordinate and supervise safety advisors and site clinic.

Will assist to prepare ‘lifting operations’ plan, ‘Fire and emergency’ plan and coordinate for its implementation.

Will ensure that method statement/risk assessment is carried out.

Will ensure that ‘Emergency Evacuation’ training is carried out. Monitor for drill compliance and recommend areas of

improvement.

Will ensure that workplace monitoring is implemented and carried out by the allocated managers.

Site Manager / Section Manager:

The Site Manager will be responsible for following activities:

Will implement engineering systems, documentation, and controls by compliance with Healthy Safety and

Environmental Alemco and industry standards, including Temporary works.

Will go through the project scope of work such as drawings, specification, Quality Plans, project program.

Will check engineering drawings and specification to identify and resolve design conflicts.

Will prepare method statements, ITPs, and risk assessments in accordance with Alemco Quality Systems as and when

required.

Will ensure all technical information is available when required for delivery of design or construction.

Will provide effective supervision and guidance to less experienced engineering staff.

Will actively manage safety and quality on site ensuring side wide compliance and not just their area of operation.

Site Engineer:

The site engineer will be responsible for following activities:

Will go through the project scope of work such as drawings, specification, Quality Plans, project program.

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 7 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Will supervise site mobilization and demobilization for each and every activity under his / her control.

Will formulate work breakdown structure and document sub-contractor package including estimates of man hours and

cost.

Will oversee and administer Forman’s daily report to ensure direct labour efficiency.

Will ensure periodic reports are transmitted to Project Leader.

Will track and report material delivery.

Will ensure SAFETY requirements are maintained.

Will co-ordinate with sub-contractor to ensure interface problem are avoided and maximum Quality work achieved.

Will prepare and control inspection requests, ITPs, method statements, risk assessment, check sheets and any other

quality requirements in conjunction with the project quality representative.

Will ensure that the requirements of the Alemco Quality Procedures and followed and adhered to it.

Will raise and process NCR.

Will help create a site culture of best practice regarding safety, housekeeping, workmanship, and waste management.

Will assist supervisors and managers to allocate correct resource to activities and to review and report on the same.

Will create an open site culture where operative and foreman can raise concerns and discuss matters with the mangers

and administer result.

QA/QC Engineer:

The QA/QC Engineer will be responsible for the following activities:

Review the ITPs for each activity along with method statement from, Alemco direct works and sub-contractors works,

to verify the compliance to Project requirements. Ensure the team is adhering to the ITP and inspections are raised

accordingly.

Conduct day to day site surveillance, identify, record, and communicate the deficiencies to team to avoid

reoccurrence.

Conduct work inspections in co-ordination with Alemco team and consultant to verify the compliance to drawings and

specifications, Ensure the records are maintained.

Coordinate and Conduct Material inspections with consultant to verify the compliance to the specifications. Ensure all

rejected materials from internal and consultant inspections are tagged and removed from the site.

Conduct Supplier factory/fabrication yard inspections as per QA QC Manager Instruction to verify the compliance

with project requirements and communicate the observations to project team.

Coordinate with Team and Consultant and ensure all the inspections are conducted as per approved ITP and ensure the

records are maintained.

Coordinate with third-party laboratories and consultants for various field tests as per approved ITP and ensure the test

reports/records are submitted/maintained.

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 8 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Conduct internal verification/inspections for the implementation of corrective and preventive actions for the site NCRs

and deficiencies identified by the QA QC Team. Verify the effectiveness of corrective and preventive actions.

Analyse the status of QA QC activities, prepare the trends including submittals, inspections, tests, deficiencies

identified & NCRs and communicate to QA QC Manager/Project team.

Conduct snagging – De-snagging inspections coordinating with Alemco execution Team and Consultants.

Lead and guide the inspection team to achieve the project Goals.

Site Surveyor:

The Site Surveyor will be responsible for the following activities:

Topographic and as built survey on site.

Compute the area and volume for cut and fill.

To setting out points of foundations, columns, beam lines, etc. before casting.

To setting out the base plates, points for block works and slab edges.

To prepare sketches and written reports following the surveying of an area.

To prepare contour plans and compile data from survey findings.

Solve practical problems and deal with the variables in situations where limited standardisation exists.

To input and prepare coordinates using Auto Cad.

To check the dimensions on drawings and ensure this reflects what is built on site.

Update drawings to ensure any changes during construction are accounted for.

To calculate distances, angles, area, and volume on site using surveying methods.

To manage the surveying equipment, monitoring accuracy and ensuring it is calibrated.

To assist the Alemco related businesses and Sub-Contractors in location of points and updating of drawings.

Cooperate with the façade team in marking the accurate.

Observe the displacement of structure for deflection.

Take the as built for all construction items after casting concrete.

General Foreman:

Will supervise the work to ensure that technical, Quality and SAFETY requirement are met.

Will go through the project scope of work such as drawings, specification, Quality Plans, project program.

Will prepare site daily report.

Will co-ordinate labor and sub-contractor in order to achieve program requirements.

Will ensure compliance with stated Quality requirements.

Will ensure comply with Safety requirements and regulation.

Will attend daily site meeting and communicate his report with the Line Manager.

Will participate in training and development of his subordinates.

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 9 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Will organize with the Site Engineer or Section Engineer to ensure the availability of plant, equipment, and labor to

his designated work activities.

Will closely monitor the usage of consumable and materials by his crew in order to minimize wastage.

Will co-ordinate with Site Engineer regarding material requisition orders.

Will Maintain high standards of housekeeping on site.

Responsible persons for each stage of work are marked against each phase of work in work sequence section

5. WORKING ACCESS:

The access / egress for the construction vehicles for the installation of activities shall be as per the logistic Plan.

Ensure Proper coordination with all interfacing contractors for Logistics, access prior to commencement of all activities.

6. LIGHTING:

i. Safety Lighting:

The minimum safety lighting as per general requirements (Minimum 50 lux) will be provided.

ii. Task Lighting:

Task lighting shall be provided in addition to the safety lighting to undertake the task with the proper level of lighting to meet

acceptable safety and quality of workmanship standards.

7. PLANT & EQUIPMENT:

i. General:

Appropriate plants and equipment shall be used for the execution of the activity. The plant, tools and equipment shall be

checked visually prior to use.

Only authorized applicator approved and trained by the manufacturer to install manufacturer's products.

All Operators shall be trained and certified by the 3rd party wherever required.

No defective plant and equipment shall be allowed to use on site.

ii. Plant & Equipment Schedule:

Sl No Description of Plant, Equipment & Tools

1 Portable Hand Tools

2 MI/MS Pipe & Fittings for Connections

3 Spirit Level

4 Level Threads

5 Hacksaw Frame with Blades

6 Welding Machine

7 Cutting Equipmens (Oxygen, Acetylene Cylinders, Cutting Torch, etc.)

8 Threading Machine

9 Hole saw Cutter

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 10 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

10 Mechanical Tool Box

11 Step Ladder

12 Scaffolds

iii. Personal Protective Equipment:

(Refer Attachment-1 for Risk Assessment)

All operatives involved in the activity shall be provided with Job specific Personal Protective equipment which are and but not

limited as mentioned below

Polycarbonate Safety Helmet

Safety boots with steel toe

Coverall with high visibility strips

Hand Gloves

Full body Harness

Ear Plugs

Eye protection / Goggles

iv. Power:

The Power supply used on site for power tools shall be 110V only. 230v or higher voltage power supply shall be provided to

site welfare areas and another site establishment.

v. Working Platforms:

The working platforms for the task shall be firm and stable.

The Mobile elevated working platforms- Man Lift / Scissor Lift (Supplied by Client) for the activity shall be used.

Make Sure the tag system is in place and always followed.

The operator shall have IPAF training.

Man lift / Scissor lift shall lift must be inspected by the competent person.

Barriers will be erected beneath the installation area to restrict access to other personnel.

The Mobile working platforms shall be used as only platforms for working and shall not be used for loading heavy

material or equipment on to it.

8. MATERIALS:

SNO PRODUCT PRODUCT

1 ACCEPTA 2877 Cleaning Chemical

2 ACCEPTA 894 Passivator

3 ACCEPTA 2337 Scale Corrosion Inhibitor

4 ACCEPTA 2886 Microbicide

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 11 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

9. WORK SEQUENCE:

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

9.1 Preliminary Activities / Approvals

Submit material submission for all materials related task for Engineer

approval.

As per approved material submittal and IFC drawings / specification prepare

/ submit shop drawings.

Submit MIR for the delivered materials on site.

CM / SM /

MSS / MSRA / RA

Method Statement, Inspection, Test Plan & Risk Assessment shall be SE / QCM

submitted for Engineer approval.

Identify, Quantity & Ensure all risk managed in this method statement &

residual risk are acceptable.

Ensure proper coordination with all interfacing contractors for access/

completion of previous activities before starting all activities at site.

9.2 Pre-Construction Activities CM / SM / MSS / MSRA / RA

SE / QCM /

QC

PRE-CLEANING/FLUSHING START UP CHECKLIST

General

Before startup of any pre-cleaning activity, the following should be

considered:

1. Check all installations & pressure testing must be approved.

2. Check availability of supply of continuous fresh water

(Temporary or permanent as per site conditions).

3. Check availability of power and electricity for permanent system

4. Check availability of labour/manpower.

5. Check availability of chemicals required for flushing/cleaning

operation at site.

6. Identify clearly feed and drain points. Provide locations at site

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 12 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

conditions.

7. Make provision for drain from lowest points. Identify at site &

drawing.

8. Check availability of safety equipment at site and ensure that the

workers are trained in safety requirements.

9. Check operation of permanent system/temporary as per

requirement.

10. Check and identify all air vents present in the circuit. Identify high

level location at site.

11. Install temporary filtration units.

12. Make the complete chilled water piping into a single loop by

making necessary bypass connections to all equipment.

13. All bypass connection should be equal sized. MEP Contractor to

check & provide check list.

14. Check and ensure that all isolating valves enabling circulation in

this circuit are

fully open.

15. To the extent of its applicability on this job, safety precautions in

handling of chemicals should be taken on site. The persons

handling the chemicals while mixing shall wear gloves and

goggles. Clean water will be made available at site by the

contractor. The necessary handling information for the chemicals

as provided in the MSDS shall be put up at the place where

chemicals are being dosed into the system.

16. Samples & Sample Containers: MEP contactor shall submit

samples in clear bottles of a type that is locally available during

various stages of the treatment (as provided in the checklist).

These bottles will be labelled with information of time and

location of sampling point.

17. On site sampling test to be carried out by Water Bird. Final

sample will be collected by independent third party for analysis in

their laboratory.

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 13 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

9.3 Material Receiving & Storage

All When received at site, all chemicals should be checked for

the label and safety instruction and stored properly as per the

product data sheet.

Any item found damaged or not found suitable as per project CM / SM /

requirements shall be quarantined. Non-compliant material shall SE / QCM / MSS / MSRA / RA

be clearly marked and stored separately to prevent any QC

inadvertent use until returned to vendor.

Manufacturer’s instruction shall be strictly followed as

applicable.

.

9.4 Installation Activities

The processes involve the following four states:

A) Static Flushing.

B) Dynamic flushing.

C) Chemical cleaning.

D) Dynamic flushing.

E) Reinstatement of plant items and back flushing.

F) Final inhibition.

Find below the supply water quality parameters to be required for CHW INFO

flushing activity.

Parameter Supply Water

pH 7.0 to 8.5

TDS Max. 250 ppm

Conductivity Max. 350 µs/cm

Total Iron Max. 0.1 ppm

Suspended Solids Max. 5 ppm

Appearance Clear

CM / SM / MSS / MSRA / RA

A) Static Flushing SE / QCM /

QC

The initial static flush should be carried out as detailed below:

MEP Contractor to ensure all pre-requisites as mentioned in the

initial stages have been met.

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 14 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

Fill the system with plain water.

Fully vent the system to ensure no air is trapped within the pipe

work by opening all the system air vents manually.

Gravity flushing will be carried out to remove major debris, loose

particles and suspended solids from the system. Drain from lowest

point to remove all suspended solids and loose debris from the

system.

Circulate the system using the permanent system/temporary

pumps for 6-8 hours.

After circulating open the drain valves at the lowest point in the

system.

Flushed water should be disposed out in the storm water drain or

disposal tanks provided at site.

B) Dynamic Flushing

Add make-up water.

Once water comes from the air vent, close the air vent valve and

start dynamic flushing.

Slowly open the drain valves at the lowest points in the whole

system and adjust it to equate makeup and drainage.

Note: the drainage flow must never be more than the clean make-

up water flow as to avoid system pressure loss and drainage.

Confirm the water is circulating throughout system or adjust the

valve to make sure the circulation.

Return water will be passed through the filter of 25 micron size to

remove any suspended solids and suspended iron.

Systematically remove, examine and clean the entire strainer,

filters and change the same.

Flushing velocities will be measured using calibrated ultra-sonic

flow measurement. Readings will be taken on the largest pipe in

the system. Velocity will be in line with BSRIA Regulations.

C) Chemical Cleaning

Chemical cleaning should be carried out immediately after

dynamic flushing.

The purpose of chemical cleaning is to remove metal oxide

deposits from metal surfaces.

Dose required quantities of cleaning agent using temporary

tank/pump system or manual dosing pot.

Add cleaning chemical Accepta 2877 Neutral pH Cleaner dose at

the rate of 1.0 Kg/m3 as per the system volume.

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 15 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

Circulate the chemical for about 48 hrs, to run either continuously

or intermittently based on the system water temperature not

exceeding 500 C.

Flushed water can be disposed out to the storm water drain at site

subject to compliance with the norms set by municipality for

disposal of water.

Chemical treated water must be taken away by tankers and

disposed of in a suitable location.

C) Dynamic Flushing

Dynamic Flushing is to take out all the left over suspended

particles, mill scale, debris and metal oxides, which are

accumulated in the system during chemical cleaning stage by

continuously flushing with dynamic flushing.

Keep the system in circulation, using all the flushing pumps.

Dynamic flushing through the filter of 10 micron size to remove

any suspended solids and suspended iron.

Open the clean water feed to the system

Slowly open the drain valves at the lowest points in the whole

system and adjust it to equate makeup and drainage.

Note: the drainage flow must never be more than the clean make-

up water flow as to avoid system pressure loss and drainage.

Carry out filling, draining & circulating until the water is visibly

clear and the below parameters are met.

After dynamic flushing is over the system, check the water quality

and clean the strainer.

Water Bird to test and confirm acceptance of water quality, which

shall be as per parameters mentioned below.

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 16 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 17 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 18 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 19 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 20 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

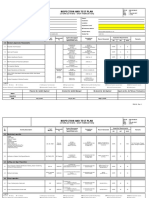

PARAMETERS VALUE (ppm)

pH 7.0-9.0

Conductivity, (µ siemens/cm) Max 800

TDS, (ppm) Max 500

Total Iron, (ppm as Fe) Max 2.0

Suspended Solids (ppm) Max 50

Addition of Passivation Chemical

> Fill the system with make-up water.

Add WB Accepta 894 Passivation Chemical at the rate of 0.1 Kg/ m3.

Circulate the same for about 24 hrs for proper passivation

During circulation the water will be passed through filter of 5 micron size

to remove any leftover suspended solids and suspended iron.

D) Reinstatement of plant items & back flushing

Ensure constant make-up water is supplied

Go to each individual plant item and attach a hose to the return pipe-

work drain off cock, ensure the un-attached end is in a drain or

suitably sized container to take more than the volume of the items coil

and flow & return pipe-work twice.

Close The by-pass

Open the flow isolation valve ensuring the return DRV is still fully

closed.

Slowly open the drain cock and let water flow into the drain or

container until it is visibly clear.

Close the drain cock.

Close the flow isolation valve.

Open the return DRV.

Slowly open the drain cock and let water flow into the drain or

container until it is visibly clear.

Close the drain cock.

Close all valves serving the plant item, Remove the strainer (where

applicable) clean and replace.

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 21 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

Open both the flow and return valves ensuring the flushing by-pass is

fully closed.

Continue these steps with every previously isolated plant item on the

system.

Water Bird to test and confirm acceptance of water quality, which

shall be as per parameters mentioned below.

PARAMETERS VALUE

pH 7.0-9.5

Conductivity, (µ siemens/cm) Max 800

TDS, (ppm) Max 500

Total Iron, (ppm as Fe) Max 1.0

Suspended Solids (ppm) Max 20

E) Final Inhibition

Corrosion Inhibitor & Microbiocide chemicals shall be added at

this point. Accepta 2886 microbiocide at the rate 0.1 Kg/m 3 and

circulate it for 3-4hrs. Then add Accepta 2337 shall be added at

the rate of 3.0 Kg/m3 of Nitrite base Corrosion Inhibitor and

circulate.

Keeps the system in circulation including all the equipment for a

minimum period of 24 hours.

During circulation the water will be passed through filter of 1

micron size to remove any leftover suspended solids and

suspended iron.

Water samples have to be collected from areas selected by

Engineer and Water Bird shall confirm the corrosion inhibitor

level

A final water analysis indicating all the required parameters as

mentioned in below table will be submitted by Water Bird.

Parameter Supply Water After addition of Final Chemical

pH 7.0 to 8.5 8.5 to 11.0

TDS < 250 ppm < 2100 ppm

Conductivity < 350 µs/cm < 3000 µs/cm

Chlorides < 60 ppm <150 ppm

Total Hardness < 60 ppm < 100 ppm as CaCO3

Total Alkalinity < 60 ppm < 250 ppm as CaCO3

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 22 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Responsible Reference/Verifying

DESCRIPTION OF SEQUENCE / METHOD OF WORK

Person Document

Total Iron < 0.1 ppm < 1.0 ppm Fe44

Suspended Solids < 10 ppm < 10 ppm

Nitrite (ppm asNaNO2) NA 600 - 1200

Appearance Clear Clear

Note: After addition of final treatment chemicals, the system must be left full and

completely circulated without any stagnancy.

9.5 Quality Control

Site Management and QAQC personnel should monitor the installation to

CM / SM /

ensure it is done according to the approved drawings. SE / QCM / MSS / MSRA / RA

Ensure phases of inspection and testing are completed as detailed in QC

approved ITP.

10.

PROGRAMME

As per the site construction programme.

11. RISKS & CONTROLS

i. Hazards / Risks

Please refer to the attached Risk Assessment page.

ii. Control Measures / Permits

Please refer to the attached Risk Assessment page.

iii. 3rd party Protection

Please refer to the attached Risk Assessment page.

12. EMERGENCY ARRANGEMENTS

i. General

The Site HSE department shall be responsible to arrange and coordinate with site execution teams in arranging Day &

Night emergency procedures.

In case of any emergency, the CRM will be informed about the emergency.

Emergency assembly point shall be allotted and communicated to all the operatives involved in the job.

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

MS Ref No.:

ZARA-ENOVA-ALEM-MSS-

PROJECT: MECH-0003

ZARA STORAGE Rev: 00

CREATION Date: 21 October 2023

Page 23 of 23

METHOD STATEMENT FOR FLUSHING & CHEMICAL CLEANING OF CHILLED WATER SYSTEM

Ensure clear access to the emergency assembly area with signage’s in place.

No construction activity shall block the access leading to the emergency assembly point. In case of any deviation, the

access has to divert and the same shall be communicated to all the operatives on site.

ii. Fire Precautions

Fire extinguishers shall be put in place in each working zone and a clear access shall be provided to the

location.

All the operatives shall be trained for fire precautions on site.

A fire warden is appointed and trained from each team of operatives.

iii. Communication

The communication on site shall be through mobile provided by the contractor or by two-way wireless radio systems.

13. TRAINING

Necessary safety or operational training shall be provided to the operatives involved in the activities.

14. SUPERVISION

Adequate supervision shall be provided for executing each activity.

Project QA/QC Engineers shall monitor the workmanship and quality of the works.

15. WORKING HOURS

Site working hours as below:

o Day shift - 7:00am to 6:00pm (Break 12:00 pm to 01:00 pm)

Weekly six days will be normal working period and Sunday will be the day off. In emergencies, working will be

extended to Sunday and any public holidays.

16. HOUSEKEEPING

The work areas shall be clean and tidy.

No debris from construction activities are allowed to accumulate in the work area.

Work areas shall be cleaned on daily basis at the end of the shift or on completion of the activity.

Sufficient Waste collection bins shall be provided at each working zone.

Waste segregation area (where recyclable / landfill materials are segregated, usually as Steel, Wood, Plastic, Concrete

and Debris) shall be established to control the waste generated on site due to construction.

17. ATTACHMENTS

1. ITP

2. Risk Assessment

3. Checklists

4. Pressure Test Form

CONTRACTOR: ALEMCO ELECTROMECHANICAL CONTRACTING LLC

You might also like

- MOS-SRWSE-20220405-Mechanical Steel & Gavalnized Steel PipeDocument28 pagesMOS-SRWSE-20220405-Mechanical Steel & Gavalnized Steel PipeKhit MakaraNo ratings yet

- Compliance Statement - PPR CopraxDocument1 pageCompliance Statement - PPR CopraxAhmed HelmyNo ratings yet

- Mels Constuction Limitada: Commercial Management Mechanical Completion CertificateDocument1 pageMels Constuction Limitada: Commercial Management Mechanical Completion CertificateDeonNo ratings yet

- R07-HC3C05-FET-MTS-ME-0012 - C1 Method Statement For Installation of DX UnitsDocument46 pagesR07-HC3C05-FET-MTS-ME-0012 - C1 Method Statement For Installation of DX Unitslike saddamNo ratings yet

- ACMV Inspeciton Check ListDocument22 pagesACMV Inspeciton Check ListNaing Win TunNo ratings yet

- 1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Document1 page1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Eng hassan hussienNo ratings yet

- Method Statement of Hvac Duct System: Class 1Document20 pagesMethod Statement of Hvac Duct System: Class 1EntegharNo ratings yet

- 3.ITP-Above Ground Draiange PipeDocument3 pages3.ITP-Above Ground Draiange Pipesarmad spectrumNo ratings yet

- SBA2021 04 Elevated Water Storage Tower Project COMPLETE REPORTDocument171 pagesSBA2021 04 Elevated Water Storage Tower Project COMPLETE REPORTsamkelo shongweNo ratings yet

- O&m Manual For Landscapeing LightDocument104 pagesO&m Manual For Landscapeing Lightmukilanarul12No ratings yet

- Method Statement - Telecom NetworkDocument44 pagesMethod Statement - Telecom NetworkchethanshivramNo ratings yet

- Samsung VRF Installation Trend For BuildingDocument55 pagesSamsung VRF Installation Trend For BuildingNaseemNo ratings yet

- Sewerage SystemDocument9 pagesSewerage Systemhajjiyare2016No ratings yet

- PPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFDocument14 pagesPPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Karnaphuli Water Supply Project Phase 2: Product Data On Chlorine Booster PumpDocument16 pagesKarnaphuli Water Supply Project Phase 2: Product Data On Chlorine Booster PumpJahangir AlamNo ratings yet

- Checksheet - Installation, Testing of Fuel Oil SystemDocument7 pagesChecksheet - Installation, Testing of Fuel Oil Systemvhin84No ratings yet

- 11a Checklist For Tiling (Floor) AlfredoDocument1 page11a Checklist For Tiling (Floor) AlfredoalfieNo ratings yet

- Subcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoDocument1 pageSubcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoAzwan SunlineNo ratings yet

- Method of Statement PCDocument8 pagesMethod of Statement PCAbada SaadNo ratings yet

- MS For Deep ExcavationDocument8 pagesMS For Deep ExcavationBilalNo ratings yet

- UPVC Drainage Pipes & Fittings - ACDocument101 pagesUPVC Drainage Pipes & Fittings - ACsushant_moreyNo ratings yet

- Mos - Kkt.arch.06 - Window & Door Frame Installation WorkDocument20 pagesMos - Kkt.arch.06 - Window & Door Frame Installation WorkRosnani Ambo sakkaNo ratings yet

- Cable Tray Inst in The Concrete-EnDocument15 pagesCable Tray Inst in The Concrete-EngkutNo ratings yet

- WIR Ew 0452 A TrenchDocument1 pageWIR Ew 0452 A TrenchBONGNo ratings yet

- Method Statement For Installation of PVC PipesDocument23 pagesMethod Statement For Installation of PVC Pipeschathura dharmasenaNo ratings yet

- HN-MECH-31 Progress Report PDFDocument1 pageHN-MECH-31 Progress Report PDFZeshan HaydarNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank Itptuan mai vanNo ratings yet

- ESE-Testing & Commissioning For Fireman Intercom SystemDocument2 pagesESE-Testing & Commissioning For Fireman Intercom SystemalifNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilJagdishNo ratings yet

- Property - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-01 - Water Cooled Chiller Installation Checklist FORM - 2pDocument2 pagesProperty - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-01 - Water Cooled Chiller Installation Checklist FORM - 2pHarum100% (1)

- Msra T&C FM 200 SystemDocument10 pagesMsra T&C FM 200 SystemSharvin NageebNo ratings yet

- Utility Material Table (QCS 2014) PDFDocument1 pageUtility Material Table (QCS 2014) PDFSinan İcikNo ratings yet

- Water Tightness Test Report For Water Retaining StructureDocument2 pagesWater Tightness Test Report For Water Retaining StructureLakshithaGonapinuwalaWithanageNo ratings yet

- ACROPOLIS Method Statement For Domestic Water Piping Installation UG & AGDocument14 pagesACROPOLIS Method Statement For Domestic Water Piping Installation UG & AGVontrex EngrNo ratings yet

- Method Statement For Water Proofing SubstructureDocument6 pagesMethod Statement For Water Proofing SubstructureRaja NasirNo ratings yet

- Water Treatment Plant Design Specifications Checklist: A. Provincial/City/Municipality ProfileDocument2 pagesWater Treatment Plant Design Specifications Checklist: A. Provincial/City/Municipality ProfileNiwled UyNo ratings yet

- MOS For Installation of Drainage Pipes and FittingsDocument14 pagesMOS For Installation of Drainage Pipes and FittingsHubaibNo ratings yet

- Installation, Testing & Flushing of Firefighting Piping System - Method Statement HQDocument20 pagesInstallation, Testing & Flushing of Firefighting Piping System - Method Statement HQvishwas salunkhe100% (1)

- Sikadur®-52 LP: Product Data SheetDocument3 pagesSikadur®-52 LP: Product Data SheetMuamer Jasna ĐulovićNo ratings yet

- CV-0013-005 - Method Statement For Concrete Work (Revised)Document13 pagesCV-0013-005 - Method Statement For Concrete Work (Revised)한상호No ratings yet

- CHECKLIST For Installation of Electrical UPVC DuctsDocument1 pageCHECKLIST For Installation of Electrical UPVC DuctskevinNo ratings yet

- 015-Lifting Plan Method & Risk AssessmentDocument3 pages015-Lifting Plan Method & Risk AssessmentSarabjit Singh SanghaNo ratings yet

- Method Statement Elect Pipe UndergroundDocument67 pagesMethod Statement Elect Pipe Undergroundمقاول تكييف كهرباء وصحيNo ratings yet

- MOS Glass Window WorksDocument5 pagesMOS Glass Window WorksCamlockNo ratings yet

- P1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BDocument16 pagesP1066-CTD-QAC-ITP-004-Rev-A-Inspection & Test Plan For Surface Preparation, Painting & Coating Works-Approved Code-BEILA545 QAQCNo ratings yet

- Inspection and Test Plan: Project NameDocument2 pagesInspection and Test Plan: Project NameehteshamNo ratings yet

- Method Statement For Installation of VAV BoxDocument3 pagesMethod Statement For Installation of VAV BoxRamakrishnanNo ratings yet

- MTS Check ListDocument1 pageMTS Check Listabdlelah.zreikNo ratings yet

- Work Undertaken That Best Illustrates Capability To Handle The Tasks AssignedDocument2 pagesWork Undertaken That Best Illustrates Capability To Handle The Tasks AssignedAkd DeshmukhNo ratings yet

- MethodeDocument24 pagesMethodemuhamadrafie1975No ratings yet

- Lighting and Control Systems CommissioningDocument1 pageLighting and Control Systems CommissioningBruno CelisNo ratings yet

- Method Statement Risk Assessment For Pump Installation 2 - Pipe (Fluid Conveyance) - PumpDocument1 pageMethod Statement Risk Assessment For Pump Installation 2 - Pipe (Fluid Conveyance) - PumptunlinooNo ratings yet

- C0329C-SOW-00-M-0005 - Scope of Work For Scaffolding RentDocument9 pagesC0329C-SOW-00-M-0005 - Scope of Work For Scaffolding RentReza Furqon100% (1)

- SUBMERSIBLE SEWAGE PUMP - (KSB) - Rev.0Document174 pagesSUBMERSIBLE SEWAGE PUMP - (KSB) - Rev.0Firas DabboucyNo ratings yet

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- PAL - Construction GuidelinesDocument28 pagesPAL - Construction GuidelinesCarew Mohammed AbayomiNo ratings yet

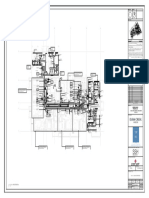

- P-201-SETTING OUT PLAN GVTH114-ModelDocument1 pageP-201-SETTING OUT PLAN GVTH114-ModelRAJANo ratings yet

- Me 4a1 L01 54 1001Document1 pageMe 4a1 L01 54 1001RAJANo ratings yet

- Me 4a1 L08 54 1008Document1 pageMe 4a1 L08 54 1008RAJANo ratings yet

- G F E D C B A: Lobby LoungeDocument1 pageG F E D C B A: Lobby LoungeRAJANo ratings yet