0% found this document useful (0 votes)

258 views35 pagesKap 05

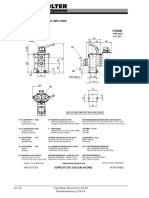

The document discusses piston variations and developments for various MAN B&W engine types. It focuses on piston crown designs that have transitioned from low topland designs to high topland designs for improved combustion and lower temperatures. It also details MAN Diesel's production of pistons according to the latest designs and with increased chrome plating in the ring grooves from 0.3mm to 0.5mm for longer piston life.

Uploaded by

abhinav sinhaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

258 views35 pagesKap 05

The document discusses piston variations and developments for various MAN B&W engine types. It focuses on piston crown designs that have transitioned from low topland designs to high topland designs for improved combustion and lower temperatures. It also details MAN Diesel's production of pistons according to the latest designs and with increased chrome plating in the ring grooves from 0.3mm to 0.5mm for longer piston life.

Uploaded by

abhinav sinhaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd