0% found this document useful (0 votes)

115 views6 pagesPiston Overhaul

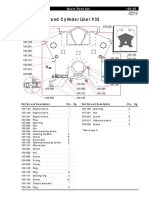

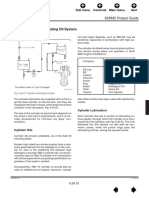

This service letter outlines the necessary inspections and procedures for overhauling VASA 32 engine pistons after 24,000 running hours. It details the inspection criteria for piston crowns and skirts, including visual checks, crack detection tests, and specific measurement guidelines. Additionally, it emphasizes the importance of using proper assembly techniques and replacing components as needed to ensure engine reliability.

Uploaded by

Rajendrasinh PadhiyarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

115 views6 pagesPiston Overhaul

This service letter outlines the necessary inspections and procedures for overhauling VASA 32 engine pistons after 24,000 running hours. It details the inspection criteria for piston crowns and skirts, including visual checks, crack detection tests, and specific measurement guidelines. Additionally, it emphasizes the importance of using proper assembly techniques and replacing components as needed to ensure engine reliability.

Uploaded by

Rajendrasinh PadhiyarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd