Professional Documents

Culture Documents

071 CLU3 Rev-5.0

Uploaded by

Piotr StankiewiczOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

071 CLU3 Rev-5.0

Uploaded by

Piotr StankiewiczCopyright:

Available Formats

RTA and RT-flex TRAINING

Function of the CLU3

(Vogel PC oiler)

Cylinder Lubrication System

1 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Designation of Lubricating Systems

• (CLU1:) Cylinder lubricating pumps driven by hydraulic motor.

Feed rate adjusting by setting screws and lever position.

Load dependence controlled by lever on fuel linkage

• CLU2: Cylinder lubricating units hydraulically operated.

Controlled by pulses from remote control system

• CLU3: Cylinder lubricating pumps driven by electric motor

• CLU4: Pulse feed and pulse jet.

Cylinder lubricating oil injection controlled by electronic / hydraulics

• CLU5: Cylinder lubricating oil injection controlled by electronic / hydraulics for W-X35 and W-X40

engine types

• flexLube: Cylinder lubricating oil injection controlled by electronic / hydraulics applicable for all 2-stroke

engine types

2 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Characteristics of Lubricating System

• Cylinder lubricating pumps driven by electric motor

• Feed rate adjusted by:

• Setting screws/disks on the lubricating pumps

• Parameter "pump speed factor" in the remote control system.

• Load dependence controlled by frequency converter (variable speed of the electric motor)

• Emergency Control at constant electric motor speed

3 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

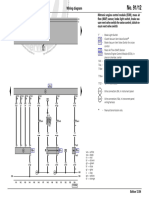

General Layout and Signal Exchange

Remote Control System CLU3 Control Box

Fuel Normal

Command*) Lubr. on

Power Emergency Logic

Engine

Calculation Lubr. on

Speed o

m

rn

m

e

e

E

g

i

lo

rm

lo

p

e

tn

cs

t/d

d

p

y

rin

a

h

scy1

2

o

m

rlC

la

n

n

t

im

se

rxo

2

t1

b

Pre-/ Post-

lubrication Freq./Spd.

Setpoint

Supply 1 Frequency

(Normal) Converter

Cylinder lubr. pumps

Supply 2 M

(Emergency)

*) for RTA engines: Load Indicator

4 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Control Features

• Normal cylinder lubrication on / off control

Automatic start of lubrication when engine starts running / pre-lubrication

• Static load dependence of cylinder lubrication

Automatic adjustment of feed rate acc. to steady engine load

• Dynamic load dependence of cylinder lubrication

Momentary increase of feed rate when load is raising

• Pre- / post lubrication

Pushbutton controlled lubrication for ca. 10 min

• Pump speed factor

Adjustment of feed rate at 100% engine load

5 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Static Load Dependence - Specific Feed Rate

Static Load Dependence Specific Feed Rate

Lubrication g / kWh

100%

Emergency

Lubrication

Normal Lubrication

25% = minimum Feed rate at 100% Power

10%

2% Power 100% 2% Power 100%

6 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Control Modes

• Normal cylinder lubrication:

Load dependent adjustment of electric motor speed

• Emergency lubrication:

Electric motor running at nominal, constant speed

• Consequences for emergency lubrication:

• Increased specific feed rate at part load

• Same feed rate as in normal mode at 100% load only with pump speed factor = 1!

• Pump speed factor > 1: Feed rate at 100% load is lower compared to normal mode

• Pump speed factor < 1: Feed rate at 100% load is higher compared to normal mode

• Emergency lubrication needs careful attention and adjusting of setting screws!

7 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

How to adjust the Cylinder Lubrication

• Adjust the setting screws on the lubricator. Here the upper or lower lubrication level can be adjusted

separately. Also single cylinders can be adjusted separately.

The feed rate will change in big steps

• The feed rate can be adjusted by changing the so called pump speed factor in the RC system.

The parameter should be within 0.85 and 1.15.

By changing the pump speed factor, the feed rate can be adjusted in very small steps.

Only the total amount can be adjusted. It is not possible to adjust the upper / lower level or single units

with the pump speed factor

8 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Vogel PC Type Oiler

Components

01 E-motor 01

02 Quick disconnection motor plug 04 05 02

03 Gear box

04 Pump element upper level

05 Non return valves

06 Non flow alarm sensor

07 Pump element lower level

06 03

07

9 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Vogel PC Type Oiler

Components

01

01 Non return valves

02

02 Overpressure protection

03

03 Shut off valve 04

04 Venting screw 05

05 Level alarm switch

10 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Vogel PC Type Oiler

11 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Pump Element

12 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

How to Adjust Pump Element

• Remove fixing screw (16) at the adjustment disc (8) of the pump element

• Loosen hex nut (9) half turn

• Move adjustment disc (8, SW24) to the desired setting

• Turn the fixing screw (16) back again

• Retighten hex nut (9)

Setting Delivery volume

position per lubrication

level

[ml/stroke]

1 0.27

2 0.36

3 0.47

4 0.63

5 0.83

6 1.10

13 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Control Box

• The normal power supply, as well as the emergency power

supply for the lubricator are connected to the CLU3 control

box

• The frequency converter converts the 4-20mA (0-160%

Lubrication Signal) signal from the Remote Control system to

a speed signal (0-2880rpm ) for the E-Motor on the lubricator

• All parameters in the frequency converter are already set

during shop test

• In case of a replacement of the converter later in service, the

parameters have to be set again as per parameter list

• On the Frequency converter the output frequency as well as

speed of the electric motor is indicated. The speed of the Frequency

electric motor can be seen by changing to parameter 0102 Converter

14 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Lubricators

Accumulator type quill CLU3

è SB 76

15 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Running-in Feed Rate

For the running in and cylinder lubrication feed rates please refer to Service Bulletin 161

è SB 161

16 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

CLU3

Adjusting of Feed-rate

For detailed instruction consult your “Operation” manual, chapter 7218

17 © Wärtsilä PUBLIC Sep-18 Clue3_Chapter_71 / Turku Training Centre

You might also like

- Railway CatalogDocument20 pagesRailway CatalogCounter RoverNo ratings yet

- TC Logic 4469-4467Document3 pagesTC Logic 4469-4467Dev KumarNo ratings yet

- SM 39Document1,385 pagesSM 39rpizanaNo ratings yet

- TPM & MaintenanceDocument17 pagesTPM & MaintenanceGopalakrishnan100% (5)

- L-IG41M3: Revision History Rev Data Description 2 0 0 9 / 0 3 / 1 4Document37 pagesL-IG41M3: Revision History Rev Data Description 2 0 0 9 / 0 3 / 1 4William Rangel GarciaNo ratings yet

- F&B Controls-BAsic PoliciesDocument7 pagesF&B Controls-BAsic Policiesdafni fernandesNo ratings yet

- New Karting Generation: A Z (E) : S P A C (K V), G C (T K V) N D V (Z P)Document1 pageNew Karting Generation: A Z (E) : S P A C (K V), G C (T K V) N D V (Z P)api-25888683No ratings yet

- Biopure Max Sticker TemplateDocument1 pageBiopure Max Sticker TemplateChaNo ratings yet

- E Li O LDTB Ahitt Exploring Oracle Database ArchitectureDocument54 pagesE Li O LDTB Ahitt Exploring Oracle Database Architecturejay karandikarNo ratings yet

- Trabajo de Cementacion ExitosaDocument15 pagesTrabajo de Cementacion Exitosajoel linneoNo ratings yet

- Strand Century Lighting CCR 600 Series Dimmer Modules Spec Sheet 6-77Document2 pagesStrand Century Lighting CCR 600 Series Dimmer Modules Spec Sheet 6-77Alan MastersNo ratings yet

- Recognizing Expenses When Incurred Rather Than When PaidDocument2 pagesRecognizing Expenses When Incurred Rather Than When PaidNath BongalonNo ratings yet

- Luni - Vineri (Monday - Friday) Sâmbătă (Saturday) Si Duminică (Sunday)Document1 pageLuni - Vineri (Monday - Friday) Sâmbătă (Saturday) Si Duminică (Sunday)Doru AtyNo ratings yet

- C Fi I Tho LNT Ke I T Configuring The Oracle Network EnvironmentDocument38 pagesC Fi I Tho LNT Ke I T Configuring The Oracle Network Environmentjay karandikarNo ratings yet

- PDF Pioneer b2 Tests CompressDocument65 pagesPDF Pioneer b2 Tests Compressalejandra.cuasquerNo ratings yet

- Benigno Morales CruzD80190GC11 Sg2Document242 pagesBenigno Morales CruzD80190GC11 Sg2Miguel Alberto Jiménez GutiérrezNo ratings yet

- Optimal Transformer Condition MonitoringDocument1 pageOptimal Transformer Condition MonitoringDavid_Allen_007No ratings yet

- Systair Cirec: Notice TechniqueDocument25 pagesSystair Cirec: Notice TechniqueNabil HOUHOUNo ratings yet

- DownloadDocument1 pageDownloadpilopoNo ratings yet

- Det-Tronics Flame DetectionDocument2 pagesDet-Tronics Flame DetectionGabriel MendezNo ratings yet

- ZM Series Vacuum EjectorsDocument18 pagesZM Series Vacuum EjectorsAlbert BriceñoNo ratings yet

- Scope Sequence of Architectural ServicesDocument1 pageScope Sequence of Architectural Servicesezhil2arasanNo ratings yet

- DTB Mit Database MaintenanceDocument30 pagesDTB Mit Database Maintenancejay karandikarNo ratings yet

- Online Hotel Management SystemDocument49 pagesOnline Hotel Management SystemShibly100% (2)

- DreamsDocument8 pagesDreamssara sanchezNo ratings yet

- Poster Summer Program 2022Document1 pagePoster Summer Program 2022kenedysilvabjNo ratings yet

- Time Log Sheet - AmazingExcel AcademyDocument1 pageTime Log Sheet - AmazingExcel AcademyLeny HrNo ratings yet

- Training 2021 - APACDocument204 pagesTraining 2021 - APACAlbert Nguyen100% (2)

- Grafix DFPM LightdiffuserDocument4 pagesGrafix DFPM LightdiffuserfiskitNo ratings yet

- LZDZ Issue 3 2017 PDFDocument32 pagesLZDZ Issue 3 2017 PDFLEDOMNo ratings yet

- Solution Manual For Engineering Mechanics Statics 9th Edition by MeriamDocument2 pagesSolution Manual For Engineering Mechanics Statics 9th Edition by MeriamAdamJoneskdija97% (38)

- Camera Turbo HD Exterior 1MP IR 40m - HikVision DS-2CE16C0T-IT3F-wDocument3 pagesCamera Turbo HD Exterior 1MP IR 40m - HikVision DS-2CE16C0T-IT3F-wchitic.florin22No ratings yet

- EF3e Uppint Filetest 02aDocument19 pagesEF3e Uppint Filetest 02aViviana IanNo ratings yet

- BK DR C Fi Ti Backup and Recovery: ConfigurationDocument18 pagesBK DR C Fi Ti Backup and Recovery: Configurationjay karandikarNo ratings yet

- Edoc - Pub - Transformer Foundation DesignDocument26 pagesEdoc - Pub - Transformer Foundation DesigndineshNo ratings yet

- D84838GC10 Les04Document46 pagesD84838GC10 Les04saberNo ratings yet

- SPWLA Curve Mnemonics - SPWLA WorldDocument1 pageSPWLA Curve Mnemonics - SPWLA WorldStewart DavidNo ratings yet

- Thecnical Guitar RSLDocument132 pagesThecnical Guitar RSLgabouru100% (1)

- etaSMART APFCDocument8 pagesetaSMART APFCMIB100% (1)

- O LDTB M TT L Oracle Database Management ToolsDocument24 pagesO LDTB M TT L Oracle Database Management Toolsjay karandikarNo ratings yet

- Change Impact Analysis TemplateDocument5 pagesChange Impact Analysis TemplatesreekantthNo ratings yet

- Eswitch ProductMatrixDocument36 pagesEswitch ProductMatrixwqeNo ratings yet

- Predective Modelling Business Report SetDocument10 pagesPredective Modelling Business Report Setpriyada16No ratings yet

- Tech Tips: September 11 2009: REVISION To WordingDocument4 pagesTech Tips: September 11 2009: REVISION To WordingDamian ZawadzkiNo ratings yet

- MATH2080 4057EONL Asignment 1.2 Draft FinalDocument8 pagesMATH2080 4057EONL Asignment 1.2 Draft FinalKimchhorng HokNo ratings yet

- Instructor'S Solutions Manual: ,!7IA3C1-ccgfab!:t K K K KDocument1 pageInstructor'S Solutions Manual: ,!7IA3C1-ccgfab!:t K K K KYeison JairNo ratings yet

- M I Uddt Managing Undo DataDocument22 pagesM I Uddt Managing Undo Datajay karandikarNo ratings yet

- Comparison of Percentage Weightage of Top Ten Topics in JEE MainDocument1 pageComparison of Percentage Weightage of Top Ten Topics in JEE Mainrineeth22745No ratings yet

- Vdocuments - MX - 12d 2c1 Basic Civil DesignDocument87 pagesVdocuments - MX - 12d 2c1 Basic Civil DesignMarcus RodolfoNo ratings yet

- Types of Loads: Structural Design I P. 1 / 2Document2 pagesTypes of Loads: Structural Design I P. 1 / 2malganissNo ratings yet

- Jettaa4 11Document1 pageJettaa4 11Juan GonzalezNo ratings yet

- Unit 1 CHP 3Document3 pagesUnit 1 CHP 3kala1975No ratings yet

- D3E802FEE69-TT 24-08-01 All Models With 1 8T Engine - Pressure Loss Fault Code P1297Document4 pagesD3E802FEE69-TT 24-08-01 All Models With 1 8T Engine - Pressure Loss Fault Code P1297Ondřej PolákNo ratings yet

- DiagramaEurovan2 8LDocument18 pagesDiagramaEurovan2 8LJonathan De Jesus Astudillo CanoNo ratings yet

- The Politics of National Capitalism: Peronism and the Argentine Bourgeoisie, 1946–1976From EverandThe Politics of National Capitalism: Peronism and the Argentine Bourgeoisie, 1946–1976No ratings yet

- It's So Easy Going Green: An Interactive, Scientific Look at Protecting Our EnvironmentFrom EverandIt's So Easy Going Green: An Interactive, Scientific Look at Protecting Our EnvironmentNo ratings yet

- Engine RT-flex Operation Practical AdvancedDocument3 pagesEngine RT-flex Operation Practical AdvancedPiotr StankiewiczNo ratings yet

- Linki YT ADocument1 pageLinki YT APiotr StankiewiczNo ratings yet

- Linki YTDocument1 pageLinki YTPiotr StankiewiczNo ratings yet

- Technicalupdate-HotWorkPermitandSafety Precautions in Connection With Welding and Cutting Work OnboardDocument39 pagesTechnicalupdate-HotWorkPermitandSafety Precautions in Connection With Welding and Cutting Work OnboardPiotr StankiewiczNo ratings yet

- 2.03 Moduł PDFDocument25 pages2.03 Moduł PDFPiotr StankiewiczNo ratings yet

- 2.03 Moduł PDFDocument25 pages2.03 Moduł PDFPiotr StankiewiczNo ratings yet

- Technical Data: EEG-1250 ElectroencephalographDocument12 pagesTechnical Data: EEG-1250 ElectroencephalographAnonymous HUY0yRexYfNo ratings yet

- Experiment 402 Plane and Spherical Mirrors (Analysis and Conclusion)Document2 pagesExperiment 402 Plane and Spherical Mirrors (Analysis and Conclusion)zidrick benjaminNo ratings yet

- Week 12 Myp 4 HWDocument2 pagesWeek 12 Myp 4 HWAnchal ChadhaNo ratings yet

- Huawei DC1 - TP48300A-DX15A1 & Extension User ManualDocument87 pagesHuawei DC1 - TP48300A-DX15A1 & Extension User ManualF. B. I.No ratings yet

- Gas Dynamics MCQsDocument6 pagesGas Dynamics MCQsprawinlNo ratings yet

- Presentation - Company Products - Eng (June 2012)Document11 pagesPresentation - Company Products - Eng (June 2012)Ricky Ocktavi RizkyNo ratings yet

- MatterDocument1 pageMatterKunle Asekunola AbiodunNo ratings yet

- Co - Ordinate GeometryDocument27 pagesCo - Ordinate GeometrySabbir MasumNo ratings yet

- Pset 2Document13 pagesPset 2rishiko aquinoNo ratings yet

- In Process Quality Control Tests (IPQC) For Solid Dosage FromDocument28 pagesIn Process Quality Control Tests (IPQC) For Solid Dosage FromSagar kishor savale75% (8)

- Laminar Flow ManualDocument16 pagesLaminar Flow ManualJOSHUA KETERNo ratings yet

- Shell and Tube Heat Exchanger Sample Problem and SolutionDocument9 pagesShell and Tube Heat Exchanger Sample Problem and Solutionlouisealfonzo.chanNo ratings yet

- Thumb Rules - Xls For Chemical EngineerDocument46 pagesThumb Rules - Xls For Chemical EngineerAnuj KaliyerNo ratings yet

- VGGHB FFVVVVN KRG 2Document26 pagesVGGHB FFVVVVN KRG 2adielev2No ratings yet

- Huygens' Principle, Maxwell's Displacement CurrentDocument7 pagesHuygens' Principle, Maxwell's Displacement CurrentGalleta Galleta MetralletaNo ratings yet

- 6 - Mass, Weight and C.GDocument17 pages6 - Mass, Weight and C.GRafayNo ratings yet

- Cardinal Points and Types of NorthDocument18 pagesCardinal Points and Types of NorthKrishnanshu MishraNo ratings yet

- Strength of Materials - Task 1. Chapter 1.Document3 pagesStrength of Materials - Task 1. Chapter 1.Eduard Avila Meriño100% (1)

- Lks 1900 AnDocument91 pagesLks 1900 AnLuis Enrique Bermudez HernandezNo ratings yet

- DanielJacobs QuestionsDocument79 pagesDanielJacobs QuestionsJimena MedinaNo ratings yet

- Ross 2015Document11 pagesRoss 2015mohanpusNo ratings yet

- Class 12 Physics Derivations Shobhit NirwanDocument6 pagesClass 12 Physics Derivations Shobhit Nirwanaastha.sawlaniNo ratings yet

- CU-2022 B.sc. (Honours) Mathematics Semester-1 Paper-CC-1 QPDocument4 pagesCU-2022 B.sc. (Honours) Mathematics Semester-1 Paper-CC-1 QPMy MathNo ratings yet

- 05 Stress DistributionDocument29 pages05 Stress DistributionJoshua OrcalesNo ratings yet

- Bolting and Welding PDFDocument25 pagesBolting and Welding PDFDennis RangwetsiNo ratings yet

- Observational AstronomyDocument427 pagesObservational AstronomyKorhan KaraNo ratings yet

- 0234 - Chimney Structural - R0Document7 pages0234 - Chimney Structural - R0Rufus D SNo ratings yet

- Factsheet Slinky Installation V5Document4 pagesFactsheet Slinky Installation V5pusicantonijeNo ratings yet

- Sliding SleveDocument4 pagesSliding SleveMarceloNo ratings yet

- Final Exam Calculus 2021 Second BatchDocument2 pagesFinal Exam Calculus 2021 Second BatchOliric NabcihNo ratings yet