Professional Documents

Culture Documents

Sliding Sleve

Uploaded by

MarceloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sliding Sleve

Uploaded by

MarceloCopyright:

Available Formats

DATE

TECHNICAL MANUAL

MODEL “EXO”

SLIDING SLEEVE 03/09/00

PRODUCT N° 75.152

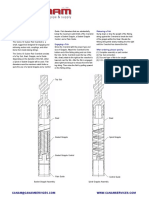

DESCRIPTION / APPLICATION

The type ”EXO” sliding sleeve is designed with a type “EX” nipple profile above and a polished pack-off

area below the inner sliding sleeve. With the inner sleeve in the closed position, sealing off the side ports,

the lower zone can be produced through the essentially full opening tool. The type “EX” nipple in the

sliding sleeve is available for flow control devices when the sleeve ports are closed and it is being used to

flow the lower zone only.

The type “EXO” sliding sleeve is opened by downward jarring utilizing the OTIS standard sliding sleeve

shifting tool.

The type “EXO” sliding sleeve may be located any place in the tubing string where it is necessary or may

be desirable to provide communication to the tubing-casing annulus. The sliding sleeve is a valuable aid

in such completion and production procedures as circulating, washing, alternating zone production or any

selective or multiple completion. It may be run into the hole with the sleeve in either the open or the

closed position. The sleeve is then closed or opened as necessary using standard wireline methods.

Any number of sliding sleeve may be run as part of a tubing string and any or all of these may be opened

or closed with one run of the OTIS wireline tools.

OPERATION

The type “EXO” sliding sleeve is positioned by means of the self releasing positioning tools which are run

with a standard string of wireline tools. Keys on the shifting tool are so arranged that they will easily pass

through the closing sleeve (8) when the positioning tool is traveling in one direction. When the tool is

moved the opposite direction, the keys will engage in the recesses in the closing sleeve and move it.

Since the positioning tool is threaded on each end, a wireline socket or suitable thread protector should

be screwed on the lower threads when the tool is run.

The closing sleeve (8) of the type “EXO” sliding sleeve may be placed in any of three positions: “open”,

“equalizing”, or “closed”. A collet latch at the lower end of the closing sleeve latches into any of three

detents in the bottom sub and holds the closing sleeve in position thus preventing accidental movement.

In the “closed” position the twelve ports through the nipple (2) are blanked off by the solid portion of the

closing sleeve.

TO OPEN ALL SLIDING SLEEVE OR ALL ABOVE A SPECIFIC LEVEL

The positioning tool with a standard set of keys should be run with its retracting sub screwed into the

knuckle joint of the wireline string. Run it to the first sliding sleeve to be opened and proceed down the

tubing string. If a pressure differential exists, allow the closing sleeve to remain in the “equalizing”

position before opening the sleeve and proceeding to the next.

TO CLOSE ALL SLIDING SLEEVE OR ALL ABOVE A SPECIFIC LEVEL

The positioning tool with a standard set of keys is run with its body sub screwed into the knuckle joint

of the wireline string. As each sliding sleeve is reached, it may be closed and the positioning tool will

be released allowing it to come up to the next.

TO OPEN ANY ONE SLIDING SLEEVE OR ANY GROUP OF SLIDING SLEEVES

A key retractor is run on the lower end of the positioning tool to prevent keys engaging the sleeves as

it passes through. The tool is run through the lowermost sleeve to be opened then pulled up to release

Copyright Ó 2000 Weatherford. All rights reserved.

Page 1 of 4

DATE

TECHNICAL MANUAL

MODEL “EXO”

SLIDING SLEEVE 03/09/00

PRODUCT N° 75.152

the keys. Each closing sleeve is opened by driving down until the positioning tool releases, indicanting

full travel. The tools are raised to the next sleeve and the operation repeated. Any sleeve in the series

may be left in the up position by merely pulling the tools up through it driving down.

TO CLOSE ANY ONE SLIDING SLEEVE OR ANY GROUP OF SLIDING SLEEVES

The positioning tool with a set selective keys is run to a point below the uppermost sleeve to be closed.

Upward jarring is continued only long enough to get a “solid feel” which indicates the sleeve is closed

(excessive jarring may shear the pin and necessitate another run) . When the lowermost sliding sleeve

is closed continued upward jarring will shear the pin, allowing the positioning tool to be pulled without

disturbing the sliding sleeve through which it passes.

TO CLOSE ONE AND OPEN ONE SLIDING SLEEVE IN ONE RUN

Since sliding sleeves are extensively used in multiple zone installations and, generally, only one zone

at a time is to be produced, one of the most common operations is changing or shifting from one zone

to another. In order to perform this a piece of stem or spacer bar which is longer than the stroke of the

jars is placed between two positioning tools. The two positioning tools are placed so that their keys

face in opposite directions. The upper has its body sub screwed into the knuckle joint and its retractor

sub screwed into the spacer. Due to the drag of the extra set of keys, extra stem may be required in

the wireline set-up.

The lower tool should be equipped with a key retractor to prevent opening sleeves going down (other

than the one to be opened). If sleeve to be closed is below sleeve to be opened, run tools through

lower sleeve then up to close this sleeve. This operation will release downward facing keys on lower

tool. Raise tools to some point above sleeve to be opened then lower and jar down to open being

careful to keep top shifting tool from falling far enough to engage sleeve as the sleeve would then be

reclosed on raising the tools.

If sleeve to be opened is below sleeve to be closed, lower the tools to a point below upper sleeve and

pick up to release key retractor and jar up to close sleeve, being careful not to over travel where lower

tool enters sleeve. Lower tools and jar down to open sleeve; do not allow top tool to enter sleeve.

Retrieving tools will not disturb upper sleeves as they pass through.

DISASSEMBLY

1. Place nipple (2) in a vise so that jaws of the vise gripe the section where the ports are located.

2. Remove the top sub (1) and replace O-ring (3).

3. Remove bottom sub (12) and replace O-ring which is the same as (3) on top sub.

4. The closing sleeve (8) will remain connected to the bottom sub and may be removed with the aid of a

positioning tool screwed into a short plece of stem.

5. Remove upper and lower packing sets.

ASSEMBLY

1. Closing sleeve (8) should be inserted into the bottom sub all the way until it shoulders.

2. All packing should be assembled in the nipple (2), both upper and lower set.

3. Measure space remaining for thread make-up in nipple to avoid excess squeeze on packing. Do not

apply more than 1/16 inch longitudinal squeeze on packing.

4. The dummy end sub should be screwed into the top of the nipple.

Copyright Ó 2000 Weatherford. All rights reserved.

Page 2 of 4

DATE

TECHNICAL MANUAL

MODEL “EXO”

SLIDING SLEEVE 03/09/00

PRODUCT N° 75.152

5. The guide plug will be placed in the upper end of the closing sleeve. The closing sleeve will then be

pushed through the nipple and the lower sub made up tight.

6. The guide plug and the dummy end sub will be removed and the upper sub made up tight.

7. After assembly, the sliding sleeve should be pressure tested before it is run in the well.

NOTE: Wrenches should never be placed over the threaded portion of the nipple.

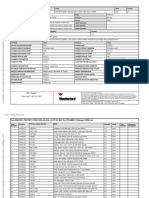

DIMENSIONAL DATA

DIMENSIONS

SIZE ASSEMBLY L B C D E

NUMBER (R) in in in in in

(mm) (mm) (mm) (mm) (mm)

2.3/8”

75.152.12.21 Cs. Hyd

Pin

1.875 33.37 1.875 3.063 1.875 1.937

2.3/8”

(847,60) (47,62) (77,80) (47,62) (49,20)

75.152.12.01 E.U.

Pin

2.7/8”

75.152.23.01 E.U.

Pin

2.313 36.93 2.313 3.750 2.313 2.366

2.7/8

(938,02) (58,75) (95,25) (58,75) (60,10)

75.152.23.11 Cs. Hyd

Pin

3.1/2”

2.866

75.152.29.01 E.U.

(72.80)

Pin

2.750 43.50 2.750 4.279 2.750

3.1/2”

(1104,8) (69,85) (108,70) (69,85)

2.929

75.152.29.11 Cs. Hyd

(74,40)

Pin

Copyright Ó 2000 Weatherford. All rights reserved.

Page 3 of 4

DATE

TECHNICAL MANUAL

MODEL “EXO”

SLIDING SLEEVE 03/09/00

PRODUCT N° 75.152

PARTS LIST

ITEM DESCRIPTION QTY. SIZE / PART NUMBER

Nº 1.875 2.313 2.750

E.U. 75.152.12.01.01.00 75.152.23.01.01.00 75.152.29.01.01.00

01 Top Sub 01

C.S. HYD 75.152.12.21.01.00 75.152.23.11.01.00 75.152.29.11.01.00

02 Nipple 01 75.152.12.01.02.00 75.152.23.01.02.00 75.152.29.01.02.00

80.451.33.52.29.46 80.451.33.52.34.46 80.451.33.52.37.46

03 O-Ring 02

(229) (234) (237)

80.451.34.75.23.46 80.451.35.86.52.46 80.451.35.86.53.46

04 O-Ring 02

(331) (12.043)

05 Split Ring 01 75.152.12.01.05.00 75.152.23.01.05.00 75.152.29.01.05.00

06 Female Adapter 04 75.152.12.01.07.00 75.152.23.01.07.00 75.152.29.01.06.00

07 Female Adapter 02 75.152.12.01.07.00 75.152.23.01.07.00 75.152.29.01.07.00

08 Closing Sleeve 01 75.152.12.01.08.00 75.152.23.01.08.00 75.152.29.01.08.00

09 Vee Packing 10 75.152.12.01.09.00 75.152.23.01.09.00 75.152.29.01.09.00

80.451.34.75.23.46 80.451.35.86.52.46 80.451.34.75.30.46

10 O-Ring 01

(331) (12.043) (338)

E.U. 75.152.12.01.12.00 75.152.23.01.12.00 75.152.29.01.12.00

12 Bottom Sub 01

C.S. HYD 75.152.12.11.12.00 75.152.23.11.12.00 75.152.29.11.12.00

Copyright Ó 2000 Weatherford. All rights reserved.

Page 4 of 4

You might also like

- Model A Hydro TripDocument1 pageModel A Hydro TripFernando OlaveoNo ratings yet

- 2023 10.75 TST-2 Service PackerDocument15 pages2023 10.75 TST-2 Service PackerDhenny FarialNo ratings yet

- Bimbar Inflatable PDFDocument36 pagesBimbar Inflatable PDFcarlosdh_03No ratings yet

- Packer HP 6 Technical LiteratureDocument7 pagesPacker HP 6 Technical LiteratureRaul Diaz100% (1)

- GR - WRDSP - Tech LiteratureDocument7 pagesGR - WRDSP - Tech LiteratureDigger Downhole ToolsNo ratings yet

- Sect 08 Plug CatchersDocument14 pagesSect 08 Plug CatcherspaimanNo ratings yet

- Technical Literature - BHF Packer PDFDocument31 pagesTechnical Literature - BHF Packer PDFChinmoyee SharmaNo ratings yet

- New BDMI L 4.5 HE0Document6 pagesNew BDMI L 4.5 HE0Natanael SaputraNo ratings yet

- "Ticfwg" By-Pass Blanking Plug: (Top No Go)Document1 page"Ticfwg" By-Pass Blanking Plug: (Top No Go)Edwin AbelloNo ratings yet

- C2™ Liner Setting Sleeve With Tieback ExtensionDocument5 pagesC2™ Liner Setting Sleeve With Tieback Extensionjosephbenetton100% (1)

- 000 00001 - Trac4 STD P - 01aDocument24 pages000 00001 - Trac4 STD P - 01aAli AliNo ratings yet

- TU-045 - AS-RBP - 9-5.8 inDocument4 pagesTU-045 - AS-RBP - 9-5.8 inAtom InsideNo ratings yet

- 350 Direct Pump Setting tool-DPSTDocument2 pages350 Direct Pump Setting tool-DPSTAdarsh HegdeNo ratings yet

- Parveen PRHP Packer: Downhole Completion EquipmentDocument5 pagesParveen PRHP Packer: Downhole Completion EquipmentsambhajiNo ratings yet

- Control Unit Model: WC-CUDocument3 pagesControl Unit Model: WC-CUmahsaNo ratings yet

- 1PackerSystem PackerAccessories&tools PDFDocument21 pages1PackerSystem PackerAccessories&tools PDFAnand aashishNo ratings yet

- Cementing Plugs AND Ancillary EquipmentDocument16 pagesCementing Plugs AND Ancillary EquipmentTeguh Akbar HarahapNo ratings yet

- Plug and Ball CatcherDocument48 pagesPlug and Ball CatcherDoni KurniawanNo ratings yet

- Assy Vol IDocument4 pagesAssy Vol IFernando CastelblancoNo ratings yet

- Series 10 Sucker Rod Overshots: Releasing A FishDocument4 pagesSeries 10 Sucker Rod Overshots: Releasing A Fishfelipe100% (1)

- Completion Components: Oil and Gas Well CompletionsDocument28 pagesCompletion Components: Oil and Gas Well CompletionsJuan SueNo ratings yet

- RTTS Forced Circulation Valve and RTTS Positive Circulating ValveDocument14 pagesRTTS Forced Circulation Valve and RTTS Positive Circulating ValveMohamed ShafieNo ratings yet

- CatalogDocument424 pagesCatalogLuis David Concha CastilloNo ratings yet

- ELDER IX 5 5 X 2 375Document8 pagesELDER IX 5 5 X 2 375crni rokoNo ratings yet

- 4-06 Tandem Side Loading Stripper PackerDocument14 pages4-06 Tandem Side Loading Stripper PackerDEATH ASSASSIN GAMERNo ratings yet

- DHSV TestDocument7 pagesDHSV TestRonald Lucas Silva Lefundes OliveiraNo ratings yet

- OptiSleeve Sliding SleeveDocument3 pagesOptiSleeve Sliding SleeveRichard More LeonNo ratings yet

- Arrow-Pak Retrievingtool: Specification GuideDocument7 pagesArrow-Pak Retrievingtool: Specification GuideTech AlfaNo ratings yet

- 3in BOP Inner & Outer SealsDocument1 page3in BOP Inner & Outer SealsusamakhattakNo ratings yet

- Y-Tool 7 - SLB Thailand 13% Cr-Support ClampDocument3 pagesY-Tool 7 - SLB Thailand 13% Cr-Support ClampNattakorn sangmarkNo ratings yet

- BJ S C, USA: Doug LehrDocument12 pagesBJ S C, USA: Doug LehrBalkis FatihaNo ratings yet

- Packer Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2Document4 pagesPacker Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2eberthson hernandezNo ratings yet

- Sur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitDocument3 pagesSur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitTamer Hesham AhmedNo ratings yet

- Gas Lift Side Pocket Mandrel Gauge SpecsDocument2 pagesGas Lift Side Pocket Mandrel Gauge SpecsGonza PfNo ratings yet

- 2024 - 13.375 TST-2 Service PackerDocument15 pages2024 - 13.375 TST-2 Service PackerDhenny FarialNo ratings yet

- E-Hydro Trip Sub Technical DatasheetDocument4 pagesE-Hydro Trip Sub Technical DatasheetEvolution Oil ToolsNo ratings yet

- T-2 On/Off Tool Technical DatasheetDocument2 pagesT-2 On/Off Tool Technical DatasheetEvolution Oil ToolsNo ratings yet

- Wellstar Tubing-Retrievable Safety ValveDocument2 pagesWellstar Tubing-Retrievable Safety ValveaminoNo ratings yet

- Drill Stem Testing RD Sampler: SmartstarDocument1 pageDrill Stem Testing RD Sampler: SmartstarDenier RubianoNo ratings yet

- 616-35000 Assembly DrawingDocument1 page616-35000 Assembly DrawingAl KautsarNo ratings yet

- GFB-2 Equalizing Check Valve technical specificationsDocument10 pagesGFB-2 Equalizing Check Valve technical specificationsCARLOS MORENONo ratings yet

- Type 680 Hydraulic Stage CollarDocument6 pagesType 680 Hydraulic Stage Collar唐辉No ratings yet

- Packer 7in Crest-II Sapex SpecDocument3 pagesPacker 7in Crest-II Sapex SpecbayuNo ratings yet

- 2021 16.0 TST-2 Service PackerDocument15 pages2021 16.0 TST-2 Service PackerDhenny FarialNo ratings yet

- Arrow-Pak RT 266-45Document3 pagesArrow-Pak RT 266-45Tech AlfaNo ratings yet

- National Oilwell W600S OMEGA OPERATION MAINTENANCE MANUALDocument37 pagesNational Oilwell W600S OMEGA OPERATION MAINTENANCE MANUALariel feNo ratings yet

- Venturetech XK 90 Power Swivel Spec SheetDocument1 pageVenturetech XK 90 Power Swivel Spec Sheetwilliam pinzonNo ratings yet

- CS® Tubing Torque ChartDocument2 pagesCS® Tubing Torque Chartjesus infanteNo ratings yet

- BJ Services 9.6 TST-3 Service Packer ManualDocument26 pagesBJ Services 9.6 TST-3 Service Packer ManualBalkis FatihaNo ratings yet

- 3-06 Side Loading StripperDocument28 pages3-06 Side Loading StripperDEATH ASSASSIN GAMERNo ratings yet

- 9.625'' Inspection SheetDocument3 pages9.625'' Inspection SheetMohamed Mahmoud Rezk DimoNo ratings yet

- Design Overview: Basic Design and Maintenance InstructionsDocument5 pagesDesign Overview: Basic Design and Maintenance Instructionsazze bouzNo ratings yet

- Rupture Disk FUL-FLO Sampler: HalliburtonDocument2 pagesRupture Disk FUL-FLO Sampler: Halliburtonsaeed65No ratings yet

- BTU Retreivable PlugDocument1 pageBTU Retreivable Plugbrunolb1No ratings yet

- BakerDocument4 pagesBakerWilliam EvansNo ratings yet

- Wireline Pressure Control EquipmentDocument6 pagesWireline Pressure Control EquipmentArielNo ratings yet

- Oil States Swab Cups PDFDocument2 pagesOil States Swab Cups PDFramudo ZNo ratings yet

- Kline General CatalogDocument30 pagesKline General CatalogservicemenruNo ratings yet

- NEXO Sliding SleeveDocument3 pagesNEXO Sliding SleevetongsabaiNo ratings yet

- Model NEXO-2 Non-Elastomeric Sliding Sleeve: DescriptioDocument5 pagesModel NEXO-2 Non-Elastomeric Sliding Sleeve: DescriptiofelipeNo ratings yet

- Gages Calibrados PDFDocument182 pagesGages Calibrados PDFSIMON S. FLORES G.No ratings yet

- SKF RemeniceDocument91 pagesSKF RemeniceSeherzada Kadric-RibicNo ratings yet

- EatonDocument1 pageEatonMarceloNo ratings yet

- Weatherford Ind. e Com. Ltda: Listagem ConfiguraçõesDocument7 pagesWeatherford Ind. e Com. Ltda: Listagem ConfiguraçõesMarceloNo ratings yet

- Catalogo BCP WHTDocument5 pagesCatalogo BCP WHTMarceloNo ratings yet

- TDS - Rheofinish 288 FDDocument2 pagesTDS - Rheofinish 288 FDVenkata RaoNo ratings yet

- G8 - Element - Metal ReactionDocument29 pagesG8 - Element - Metal ReactionListya RahmawatiNo ratings yet

- EKS 17 Miniature Piston Pump SpecificationsDocument1 pageEKS 17 Miniature Piston Pump SpecificationsdujobozinovicNo ratings yet

- Human Papillomavirus (HPV) Test and PAP Smear As Predictors of Outcome in Conservatively Treated Adenocarcinoma in Situ (AIS) of The Uterine CervixDocument7 pagesHuman Papillomavirus (HPV) Test and PAP Smear As Predictors of Outcome in Conservatively Treated Adenocarcinoma in Situ (AIS) of The Uterine CervixodivarNo ratings yet

- Afterlife: The Strange Science of DecayDocument4 pagesAfterlife: The Strange Science of DecayPhoenix Che-LaiNo ratings yet

- 17EEX01-FUNDAMENTALS OF FIBRE OPTICS AND LASER INSTRUMENTATION SyllabusDocument2 pages17EEX01-FUNDAMENTALS OF FIBRE OPTICS AND LASER INSTRUMENTATION SyllabusJayakumar ThangavelNo ratings yet

- PDDDocument88 pagesPDDapi-336689769No ratings yet

- Cessna 208 (B) Caravan I T.T.R.Document7 pagesCessna 208 (B) Caravan I T.T.R.Junior Mebude SimbaNo ratings yet

- VolvoTD70 Service Manual EngineDocument110 pagesVolvoTD70 Service Manual EngineHeikki Alakontiola87% (47)

- CIE IGCSE BiologyDocument25 pagesCIE IGCSE Biologytgdzbspikio.comNo ratings yet

- Cranes & Hoists ProgramDocument28 pagesCranes & Hoists ProgramImtiyaz AkhtarNo ratings yet

- SPE 35687 Environmentally Safe Burner For Offshore Well Testing OperationsDocument12 pagesSPE 35687 Environmentally Safe Burner For Offshore Well Testing OperationsTheNourEldenNo ratings yet

- The Declaration of Alma-Ata at 40Document19 pagesThe Declaration of Alma-Ata at 40Nicole MedinaNo ratings yet

- Example Hospital Development PlanDocument6 pagesExample Hospital Development PlanMary Jean Gelito0% (1)

- General Catalogue 2019: UNIOR D.DDocument401 pagesGeneral Catalogue 2019: UNIOR D.DjinpoeNo ratings yet

- Enppi EI BrochureDocument51 pagesEnppi EI Brochurenithin spNo ratings yet

- Econ Double Regulating ValvesDocument18 pagesEcon Double Regulating ValvesElimKaAdda100% (1)

- Medical Equipment List for District HospitalDocument60 pagesMedical Equipment List for District Hospitalramesh100% (1)

- 2 Second Grade English Diagnostic Test (Autoguardado)Document5 pages2 Second Grade English Diagnostic Test (Autoguardado)MELISSA KARENTH MONTES PINTONo ratings yet

- Common Admission Test (CAT) 2020 Admit Card: BarcodeDocument2 pagesCommon Admission Test (CAT) 2020 Admit Card: BarcodeViraaj ThakurNo ratings yet

- Smoke & Ventilation CalculationsDocument7 pagesSmoke & Ventilation CalculationsZine ModelsNo ratings yet

- AcetophenoneDocument3 pagesAcetophenonepriteshpatNo ratings yet

- BG 370 Operation & Maintenance ManualDocument32 pagesBG 370 Operation & Maintenance ManualRamasubramanian SankaranarayananNo ratings yet

- 10 DNA Testing Myths Busted, and Other Favorite Posts: by Blaine T. BettingerDocument11 pages10 DNA Testing Myths Busted, and Other Favorite Posts: by Blaine T. BettingerSexy888No ratings yet

- بﻮﺤﻟا ﻦﺤﻃ ﺔﻧﺎﻘﺗ - Cereal Milling Technology: · January 2013Document202 pagesبﻮﺤﻟا ﻦﺤﻃ ﺔﻧﺎﻘﺗ - Cereal Milling Technology: · January 2013Moh Al Basher BabikerNo ratings yet

- User list of chemistry analyzerDocument1 pageUser list of chemistry analyzerHussain Amir AliNo ratings yet

- Statin RisksDocument2 pagesStatin RisksYazen JoudehNo ratings yet

- English Hand Out for Class 3Document19 pagesEnglish Hand Out for Class 3Pat WibawaNo ratings yet

- UntitledDocument10 pagesUntitledVeneta GizdakovaNo ratings yet

- Bonding in Organic Compounds - Organic Synthesis Marks SchemeDocument96 pagesBonding in Organic Compounds - Organic Synthesis Marks SchemeRaiyan RahmanNo ratings yet