Professional Documents

Culture Documents

SOFT53

Uploaded by

govind rajCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOFT53

Uploaded by

govind rajCopyright:

Available Formats

SOFT53

Single Orifice Float Trap (with SLR / TV)

Description DN15/20/25

The Forbes Marshall Single Orifice Float Trap SOFT53 is a

condensate drain trap of cast steel body, cover and stainless

steel internals.

Sizes and Pipe Connections 9

5

DN 15, 20, 25, 40 and 50

4

Screwed BSPT / NPT / BSP Socket weldable to ANSI B 16.11 11

1

Flanged ANSI B 16.5 class 150, 300, 600 12 13

BS Table H, J, K, R; PN 10, 16, 25 and 40

Note

1) Available with IBR certificate

2) DN15 Class150 / PN Flanged Versions are available only

with weld on flanges.

3) Flange thickness is common for all Flange ratings as shown 15 14

10

in dimensional details.

8

Available Types

SOFT53 with built in Thermostatic Air Vent (TV) 6 7

SOFT53 with built in Steam Lock Release (SLR) 2 3

Limiting Conditions DN 40 / 50

PMA Maximum allowable pressure 32 bar g @ 425ºC

TMA Maximum allowable temperature 425ºC

PMO Maximum operating pressure 32 bar g

TMO Maximum operating temperature 300ºC @ 32 bar g

Minimum operating temperature 0ºC

DPMX Maximum Differential pressure 1

14

SOFT53-4.5 4.5 bar g 4

13 12 11

SOFT53-10 10 bar g 9

5

SOFT53-14 14 bar g 10

SOFT53-21 21 bar g

SOFT53-32 32 bar g

Cold hydraulic test pressure 48 bar g

Operating range 3

A C

425

400

2

Temperature °C

300

285 8

7

200 A-B

Steam Flanged #150.

100 saturation How to Order

curve C-D

Example DN 25 Single Orifice Float Trap, SOFT53 -

B D Flanged #300.

0 4.5 bar g, TV, screwed BSPT

0 10 20 30 32

Pressure bar g

This product must not be used in this region.

This product should not be used in this region as

damage to the internals may occur.

Process and Energy Efficiency | Environment www.forbesmarshall.com

Capacity Chart

20000

ar g

21b DN50

14/ 32 bar g

10000 50

DN

9000

8000

g

7000

.5 bar DN40

6000 504 40

DN DN bar g 32 bar g

5000 21

4000 ar g

1 0b

50

3000 DN g

.5 bar

4 04

DN

2000

g

0 bar

4 01

DN ar g

1000 21b

25 DN25

900 b ar g DN

4.5 32 bar g

800 25

DN

Condensate (kg/hr)

700

600 g

0 bar

500 2 51

DN g

400 4 bar g

2 51 .5 bar

300 DN 2 04

DN

nd

5a

DN

1 ar g

1 0b

200 20

DN

A ND

15 g

DN 4 bar

2 01

D DN

100 AN

15

90 DN

80

70 g

1 bar

60 2 02

50 D DN

AN ar g

15 2b

40 DN 3

N 20

N DD

30 1 5A

DN

20

0

0.1 0.2 0.3 0.4 0.5 0.7 1 2 3 4 5 7 10 20 32

Differential pressure bar g (x 100 = kPa)

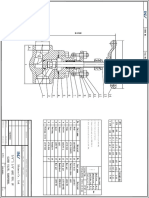

Material (15-25) Dimensions (approx) in mm.

No. Material Standard For Screwed / Socket Weld End and CLASS 600 FLG

Part

Size (DN) A B C D E T* W (kg )

1a. Base flange Cast Steel ASTM A216

DN 20-50 Gr.WCB 15/20 230 84 84 172 120 23 10

1b. Base Screwed/SWE Forged Carbon 25 220 119 88 225 160 24 13

ASTM A105

DN 15-20 Steel 111

40 297 131 250 200 26 20

Base Screwed/SWE ASTM A216 40 (# 600) 350 131 121 250 200 29 25

1c. Cast Steel

DN 25 Gr.WCB 50 320 134 123 250 200 26 27

ASTM 50 (# 600) 335 134 127 250 200 32 31

2. Bolts Alloy Steel

A193 B7

* For screwed/socket weldable ends: T = 0 Gen Tol. ± 3

Nuts ASTM

3. Carbon Steel

15/20NB ONLY A194 2H

SS Reinforced (SOFT53 DN15/20) (SOFT53 DN25)

4. Cover Gasket Exfoliated graphite

ASTM A216

5. Cover Cast Steel

Gr. WCB

6. Valve Seat Stainless Steel ASTM A276

SS 410

7. Valve Seat Stainless Steel ASTM A240

Gasket SS 410

(SOFT53 DN40) (SOFT53 DN50)

Pivot Frame IS-1364

8. Assly. Stainless Steel SS304

Set Screws

9. Ball Float & ASTM A240

Stainless Steel

Lever SS304

10. ASTM A276

SLR Stem Stainless Steel SS316

11. Gland Packing Graphite Dimensions - (approx) in mm.

ASTM A743 All Flanged – (Except CLASS 600)

12. SLR Seat Stainless Steel

CA40

Size (DN) A B C D E T* W (kg)

SLR Seat Stainless Steel ASTM A240

13. 15/20 230 84 84 172 120 23 11

Gasket SS410

25 240 119 88 225 160 24 14

14. Support Frame Stainless Steel ASTM A240

SS304 40 297 131 111 250 200 26 26

15. Pivot Frame Stainless Steel ASTM A240 50 320 134 123 250 200 26 32

SS304

Gen.Tol. 3

* DN15 Class150 / PN Flanged Versions are available only

Installation with weld on flanges.

The arrow on the nameplate must point downwards. The arrow

on casting indicates the flow direction. (SOFT53 DN 15/20) (SOFT53 DN 25)

Servicing

I) For DN 15, 20 and 25 main valve assembly : Unscrew cover

bolts and lift off the cover. Remove complete float assembly

by undoing the two screws on the pivot frame, main valve

seat and gasket and if damaged replace with a new one. Fit

support frame and pivot frame by using two set screws but

do not fully tighten. Place the float arm and complete the (SOFT53 DN 25)

assembly by placing the pin. Now tighten the set screws.

Refit the cover.

II) For DN 40 and 50 main valve assembly : Unscrew cover

bolts and lift off the cover. Unscrew the assembly set

screws. Remove the main assembly, if damaged replace

with a new one. Refit the cover by using the cover bolts and

nuts.

Available Spares

Material (DN 40-50)

Main Valve Assembly with Float (DN15, 20 & 25) A

No. Part Material Standard Main Valve Assembly (DN 40, 50) A+D

1. Cover Cast Steel ASTM A216 Air Vent Assembly B

Gr.WCB Steam Lock Release Unit C

2. Base Cast Steel ASTM A216 Sets of Gaskets (Pkt of 3) E

Gr.WCB Float D

3. Gasket for Base SS Reinforced

and Cover Graphite How to Order Spares

Always order spares using the description given in the column

4. Float Unit Stainless Steel ASTM A240 above, headed “Available Spares”, and stating the size and type

Assembly SS304 and differential pressure of the trap. For codes refer the user

manual.

5. Gland Packing Graphite

6. Valve Housing Stainless Steel BS 3146 Recommended Tightening Torques

Assembly ANC2

Sr.No. Part Torque (Nm)

7. Gasket for Valve SS Reinforced 1. TV seat 45 - 55

Housing Graphite 2. SLR seat 45 - 55

3. SLR body 60 - 70

8. Erosion Deflector Stainless Steel ASTM A276

4. Valve housing (studs) 15 - 20

SS 410

5. Cover bolts 70-80

9. Gland Nut Stainless Steel ASTM A743

GR. CA40

Spare Parts

10. SLR Stem Stainless Steel ASTM A276 The available spare parts are shown in heavy outline in the figure

SS316 below. Parts drawn in broken line are not available as spares.

11. SLR Seat Stainless Steel ASTM A743

GR. CA40

12. Gasket for SLR Stainless Steel ASTM A240

Seat SS 410

ASTM A193

13. Hex Bolt Alloy Steel B7

Gasket Set E

14. Hex Nut Carbon Steel ASTM A194

2H

Air

Ven

t Ass

em

bly

}

D

D

Main valve assembly

with float (DN 15,20, 25)

A

Forbes Marshall Pvt. Ltd. Forbes Marshall International Pte. Ltd.

Opp 106th Milestone, CTS No. 2220, 16A, Tuas Avenue 1,

www.forbesmarshall.com Mumbai-Pune Road, Kasarwadi, Pune- 411034 INDIA #05-21, JTC Space @Tuas

Tel: +91(0)20-68138555 Singapore - 639533

Fax: +91(0)20-68138402 Tel: +65 6219 3890

Forbes Marshall

Krohne Marshall Email : enquiries@forbesmarshall.com

Forbes Marshall Arca

© All rights reserved. Any reproduction or distribution in part or as a whole without written permission of Forbes Marshall Pvt Ltd, its associate companies

Codel International or its subsidiaries (“FM Group”) is prohibited.

Forbes Vyncke Information, designs or specifications in this document are subject to change without notice. Responsibility for suitability, selection, installation, use,

operation or maintenance of the product(s) rests solely with the purchaser and/or user. The contents of this document are presented for informational

Forbes Marshall Steam Systems purposes only. FM Group disclaims liabilities or losses that may be incurred as a consequence of the use of this information.

DOC# FMSS/0423/TIS-SOFT53/R4

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Asco Keystone CompatibilityDocument2 pagesAsco Keystone CompatibilityalexmontellNo ratings yet

- FR-1 Series CatalogueDocument8 pagesFR-1 Series CatalogueNoelNo ratings yet

- VB14 and 21 Vac BreakerDocument2 pagesVB14 and 21 Vac BreakercharlesanNo ratings yet

- 104 13479 Mob02918 DSH 420 J 0018 - 1Document3 pages104 13479 Mob02918 DSH 420 J 0018 - 1Roberto Capcha SernaNo ratings yet

- VV Reductora Pilotada Forbes FMPRV41Document4 pagesVV Reductora Pilotada Forbes FMPRV41cristian villegasNo ratings yet

- BSK1 Bellows Sealed Globe ValvesDocument4 pagesBSK1 Bellows Sealed Globe ValvesAhmed RamadanNo ratings yet

- Data SheetDocument1 pageData Sheetjozef shamsNo ratings yet

- Hd115 - Pressur GaugeDocument2 pagesHd115 - Pressur GaugeKumararaja KonikkiNo ratings yet

- NAF-Knife Knife Gate Valves FK 24.31 (5) GB: Primary CharacteristicsDocument6 pagesNAF-Knife Knife Gate Valves FK 24.31 (5) GB: Primary CharacteristicsNguyen KhaNo ratings yet

- 01 - Single Phase - Bil 200 KV - Polyamide Cap - l63,5 - enDocument1 page01 - Single Phase - Bil 200 KV - Polyamide Cap - l63,5 - enoreinoso2009No ratings yet

- 3 81 e pv15 Pneumatic On Off Globe Valves dn15 100 enDocument6 pages3 81 e pv15 Pneumatic On Off Globe Valves dn15 100 enQuyết Bạch ĐìnhNo ratings yet

- DS - DRG - 300 PSI - 8320Document2 pagesDS - DRG - 300 PSI - 8320Shasin SolankiNo ratings yet

- FT 20 Ball Float Steam TrapDocument2 pagesFT 20 Ball Float Steam Trapravindrasuryavanshi6No ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- Ds-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Document5 pagesDs-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Panisa BanimaNo ratings yet

- Prince Hydraulics - RD-2500 Monoblock Directional Control Valves Offered by PRC Industrial SupplyDocument4 pagesPrince Hydraulics - RD-2500 Monoblock Directional Control Valves Offered by PRC Industrial SupplyPRC Industrial SupplyNo ratings yet

- Prince Valve rd2575 t3 Esa 1Document4 pagesPrince Valve rd2575 t3 Esa 1Rousdi AndraosNo ratings yet

- FT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Document7 pagesFT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Liêm HàNo ratings yet

- RS-13 5-8-5m Annular BOP Operaion ManualDocument6 pagesRS-13 5-8-5m Annular BOP Operaion ManualAlexsandro Cordeiro100% (2)

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- Blagdon: Air Operated Double Diaphragm PumpDocument2 pagesBlagdon: Air Operated Double Diaphragm PumpGagan Deep AgarwalNo ratings yet

- Api 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim MccabeDocument11 pagesApi 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim Mccabesaeed65No ratings yet

- Two Orifice Float Trap: DescriptionDocument4 pagesTwo Orifice Float Trap: DescriptionHiranthaNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- Bellows Sealed DN20Document3 pagesBellows Sealed DN20Turbo Snail RNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- VALVES MACH 11 - CatalogueDocument4 pagesVALVES MACH 11 - CatalogueMohab AhmedNo ratings yet

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiNo ratings yet

- 5/2 Pilot Operated, Single/ Double Solenoid, Subbase Mounted ValveDocument4 pages5/2 Pilot Operated, Single/ Double Solenoid, Subbase Mounted ValveGaurav TripathiNo ratings yet

- Finetek Cable Float Level Switch 2016Document12 pagesFinetek Cable Float Level Switch 2016Oscar Del AngelNo ratings yet

- DS5404 Standard US ENDocument4 pagesDS5404 Standard US ENkicsnerNo ratings yet

- 08 - FPS01 Subsea Series (Issue 4 Feb 05)Document4 pages08 - FPS01 Subsea Series (Issue 4 Feb 05)Peter RhoadsNo ratings yet

- 1.11.E.FLT17-LC Float and Thermostatic Steam Traps DN15-20Document2 pages1.11.E.FLT17-LC Float and Thermostatic Steam Traps DN15-20Son Trinh PhuongNo ratings yet

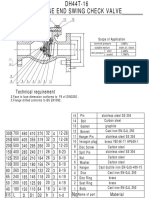

- Flanged End Swing Check Valves DIN3202 F6Document2 pagesFlanged End Swing Check Valves DIN3202 F6AndiniPermanaNo ratings yet

- CA14S Air and Gas Trap DN40 and DN50 (Flanged)Document5 pagesCA14S Air and Gas Trap DN40 and DN50 (Flanged)Daryl DelimanNo ratings yet

- FAB Cable Float Level Switch - NewDocument16 pagesFAB Cable Float Level Switch - NewWidhi ImranovichNo ratings yet

- Dcv1 Disc Check Valve: DescriptionDocument2 pagesDcv1 Disc Check Valve: DescriptionInbarasu SNo ratings yet

- Arcolectric Switches C3972bbaaaDocument2 pagesArcolectric Switches C3972bbaaaManu MathewNo ratings yet

- Wafer Type Butterfly Valve Z 011-A ThermDocument4 pagesWafer Type Butterfly Valve Z 011-A ThermJOHNNo ratings yet

- Parker Subsea Ball Valves CatalogDocument3 pagesParker Subsea Ball Valves Catalogfjb9ms2jgqNo ratings yet

- Thermodynamic DC50 A105 PDFDocument2 pagesThermodynamic DC50 A105 PDFRoo FaNo ratings yet

- Val-Presion de AlivioDocument2 pagesVal-Presion de AlivioCristian CanteroNo ratings yet

- Ins PT003Document1 pageIns PT003faisal hajjNo ratings yet

- Robinet Soupape Avec Soufflet 234Document9 pagesRobinet Soupape Avec Soufflet 234m.plosoussNo ratings yet

- 21-50-007 AVK Resilient Seated Gate Valve DN50-400Document2 pages21-50-007 AVK Resilient Seated Gate Valve DN50-400Ferdi SagalaNo ratings yet

- CTR 004 Yardr 0008 enDocument3 pagesCTR 004 Yardr 0008 enAndy GarciaNo ratings yet

- Classe de Matériel Tuyauterie 20SP11: 6117-XH-SL-STC-2/3Document12 pagesClasse de Matériel Tuyauterie 20SP11: 6117-XH-SL-STC-2/3Guillaume de PluviéNo ratings yet

- (1952) Válv. Ventosa Dav-Ms DorotDocument3 pages(1952) Válv. Ventosa Dav-Ms DorotHOSMANNo ratings yet

- Extended Duty Pressure Switch Ultra Duty Pressure Switch: B C D E F B C D E FDocument1 pageExtended Duty Pressure Switch Ultra Duty Pressure Switch: B C D E F B C D E FmarceloenderleNo ratings yet

- Brosur Valve Hatersley 2Document1 pageBrosur Valve Hatersley 2Muhamad SuryaNo ratings yet

- Uhv Gate Valve, Series 10.8: The Standard Valve For UHV Isolation Applications in Research and IndustryDocument8 pagesUhv Gate Valve, Series 10.8: The Standard Valve For UHV Isolation Applications in Research and IndustryAyesha AmbaniNo ratings yet

- TD62LM & TD62M Thermodynamic Steam Traps With Replaceable Seats ASTM Body (Flanged Connections)Document5 pagesTD62LM & TD62M Thermodynamic Steam Traps With Replaceable Seats ASTM Body (Flanged Connections)Hsalmani1991No ratings yet

- Blagdon: Air Operated Double Diaphragm PumpDocument2 pagesBlagdon: Air Operated Double Diaphragm PumpMurthy NarayananNo ratings yet

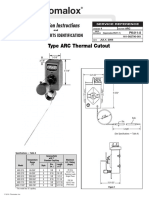

- Chromalox: Installation InstructionsDocument4 pagesChromalox: Installation InstructionsJorgeAlorRodriguezNo ratings yet

- 3521 Gala Gate Valve CatalogDocument1 page3521 Gala Gate Valve CatalogChhomNo ratings yet

- 15mm K115 GW-S CUP STD (SH005 1014 B)Document2 pages15mm K115 GW-S CUP STD (SH005 1014 B)Ionut BucurNo ratings yet

- 4A Figure 31-41 Bronze SeriesDocument8 pages4A Figure 31-41 Bronze SeriesCarlos Alberto OspinaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Fujitsu Lifebook A530 Notebook: DatasheetDocument6 pagesFujitsu Lifebook A530 Notebook: DatasheetnirwalamitNo ratings yet

- Data Communication NotesDocument5 pagesData Communication NotesitsmelittyNo ratings yet

- Chapter 1Document24 pagesChapter 1AzerbaijanGalacNo ratings yet

- MDGF ModulDocument2 pagesMDGF ModulZoran NesicNo ratings yet

- Six Essential Skills For Managing ConflictDocument4 pagesSix Essential Skills For Managing ConflictErdi Karatepe100% (2)

- Speed Lever - Calibrate: Calibration CalibrationDocument2 pagesSpeed Lever - Calibrate: Calibration Calibrationmohamed aliNo ratings yet

- 3.2.2.4 Packet Tracer - Configuring Trunks Instructions IGDocument7 pages3.2.2.4 Packet Tracer - Configuring Trunks Instructions IGElaa TrujilloNo ratings yet

- 04 - PGP4108 Drilling FluidsDocument16 pages04 - PGP4108 Drilling Fluidsodong anthonyNo ratings yet

- Excel Proficiency TestDocument3 pagesExcel Proficiency Testakoe_2No ratings yet

- Comparative Study On Concentric Steel Braced Frame Structure Due To Effect of Aspect Ratio Using Pushover AnalysisDocument6 pagesComparative Study On Concentric Steel Braced Frame Structure Due To Effect of Aspect Ratio Using Pushover AnalysisijsretNo ratings yet

- Director of Finance/CFODocument3 pagesDirector of Finance/CFOapi-77850220No ratings yet

- Cotton Ginning Machine Plant Quotation Ethopia 23 02 2024Document2 pagesCotton Ginning Machine Plant Quotation Ethopia 23 02 2024sultannesru2030No ratings yet

- Experiencing ArchitectureDocument14 pagesExperiencing ArchitectureTote123456789100% (1)

- 120 2013 Final StudyGuide 1Document5 pages120 2013 Final StudyGuide 1Anonymous zN7CjfgnENo ratings yet

- Notice: Antidumping: Large Newspaper Printing Presses and Components Assembled or Unassembled From— TurkeyDocument1 pageNotice: Antidumping: Large Newspaper Printing Presses and Components Assembled or Unassembled From— TurkeyJustia.comNo ratings yet

- Lptop Toshiba Schematic l100Document27 pagesLptop Toshiba Schematic l100Swati BaslaNo ratings yet

- FIDIC Clause: Delegation of The Engineer'S Authority Revision: ? DateDocument6 pagesFIDIC Clause: Delegation of The Engineer'S Authority Revision: ? DateTomoe GozenNo ratings yet

- SOG F5 PWR Silo Fire FightingDocument9 pagesSOG F5 PWR Silo Fire FightingGothandaraman Muthu ManickamNo ratings yet

- ResumeDocument2 pagesResumee-blitzNo ratings yet

- Bomba Pioner - ManualDocument29 pagesBomba Pioner - ManualRodrigoArayaNo ratings yet

- Pitting Trenching Activty eDocument2 pagesPitting Trenching Activty eFARHA NAAZNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Adarsh Singh KshatriyaNo ratings yet

- Wind Turbine - Control and Monitoring PDFDocument462 pagesWind Turbine - Control and Monitoring PDFElisete Mota Nascimento100% (3)

- XK3101 (HL-2065) IndicatorDocument20 pagesXK3101 (HL-2065) IndicatorEliana Cristina100% (1)

- LAUDA Overall Brochure Constant Temperature Equipment en 2020-2021Document151 pagesLAUDA Overall Brochure Constant Temperature Equipment en 2020-2021FithriyyahningsihNo ratings yet

- HGST Partitioning and Formatting GuideDocument21 pagesHGST Partitioning and Formatting GuidejaylorbenNo ratings yet

- Semple Material TagingDocument4 pagesSemple Material Tagingppg.desyaalfatih82No ratings yet

- Siphon FinalDocument6 pagesSiphon Finalfyodor aswswswsNo ratings yet

- Welcome To OU Training!: Key Event DetailsDocument4 pagesWelcome To OU Training!: Key Event Detailsaercio manuelNo ratings yet

- The Five Stages of Business GrowthDocument2 pagesThe Five Stages of Business GrowthRachel Honey100% (2)