Professional Documents

Culture Documents

FR-1 Series Catalogue

Uploaded by

NoelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FR-1 Series Catalogue

Uploaded by

NoelCopyright:

Available Formats

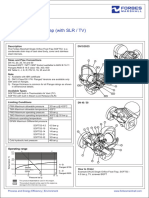

HYDRAULIC DIVISION FR1 SERIES

FR1 SERIES

Tank top return filters

Return filter for mounting on the tank lid. Filter element with inbuilt bypass

valve. Flow rates up to 600 l/min.

TECHNICAL INFORMATION

HOUSING tested according to NFPA T3.10.5.1* , ISO3968

HYDRAULIC SYMBOL: A

PRESSURE: Max working 8 bar

Burst 16 bar

CONNECTION PORTS: G 3/8”÷ G 2”

MATERIALS: Cover: aluminium alloy

Head: aluminium alloy

Bowl: PA6 reinforced (size 10 to 43) - zinc plated steel (size 50 to 64)

Seal: NBR (FKM on request)

BYPASS: Inbuilt in the filter element

B version 1,7 bar

C version 3 bar

ELEMENT tested according to ISO 2941, 2942, 2943, 3968, 16889, 23181

FILTER MEDIA: Microglass fiber G06-G10-G15-G25-G40

Cellulose C10-C25

Wire mesh T60

Synthetic M05-M10-M15

DIFFERENTIAL COLLAPSE PRESSURE: 10 bar

OPERATING TEMPERATURE RANGE: -25°C +100°C

FLUID COMPATIBILITY: Full with HH-HL-HM-HV (acc. To ISO 2943).

For use with other fluid please contact Filtrec Customer Service

(info@filtrec.it).

* as reference method only for verifying the pressure fatigue resistance and establishing the burst pressure ratings.

FR1 SERIES 1/8

HYDRAULIC DIVISION FR1 SERIES

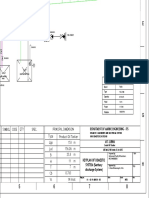

OVERALL DIMENSIONS

FR - 1 - 10 / 11 / 20 / 22 / 30 / 31 TANK MOUNTING PATTERN

INDICATOR

PORT

90

°

D1

B1

FILLING PLUG 3/8”

M

2 HOLES Ø

FR - 1 - 40 / 43 TANK MOUNTING PATTERN

B3 INDICATOR 0°

PORT 12

element removal

45°

R

H2

D1

H3

B1

A

B2

FILLING PLUG 1”

M

3 HOLES Ø

FR - 1 - 50 / 51 / 60 / 64 TANK MOUNTING PATTERN

INDICATOR 90°

H1

PORT

30°

D1

B1

H4

D2 FILLING PLUG 1”

M

4 HOLES Ø

D3

NOMINAL SIZE

WEIGHT

MODEL A Ø B1 B2 B3 Ø D1 Ø D2 Ø D3 H1 H2 H3 H4 M R

Kg

FR1 10 G 3/8" 82 150 0,45

89 25 51 67,5 24 67 60 8 22 M6

FR1 11 G 3/4” - G 1/2" 155 220 0,60

FR1 20 G 1/2" 106 190 0,80

28 24

FR1 22 G 3/4" 28,5 151 230 0,90

115 67 88,5 87 73 M8

FR1 30 G 1" 232 310 1,10

G 1 1/4" 24

FR1 31 32 336 420 1,30

40

FR1 40 G 1” - G 1 1/4" 241 320 2,10

175 35 95 130 129 90 11 30

FR1 43 G 1 1/2" 287 360 2,40

FR1 50 181 270 3,20

G 1 1/4" 50 M10

FR1 51 3,60

G 1 1/2" 220 42 115 175 174 240 105 50 340

FR1 60 G 2" 3,60

63

FR1 64 289 380 4,20

FR1 SERIES 2/8

HYDRAULIC DIVISION FR1 SERIES

ORDERING INFORMATION

1. 2. 3. 4. 5. 6. 7. 8. 9.

FR1 30 G15 B B B6 0 C 000

R1 30 G15 B SPARE ELEMENT

1. FILTER SERIES FR1

2. FILTER SIZE 10-11

20-22-30-31

40-43

50-51-60-64

3. FILTER MEDIA G06 glassfiber ß7µm(c) > 1.000

G10 glassfiber ß12µm(c) > 1.000

G15 glassfiber ß17µm(c) > 1.000

G25 glassfiber ß22µm(c) > 1.000

G40 glassfiber ß35µm(c) > 1.000

C10 paper ß10µm(c) > 2

C25 paper ß25µm(c) > 2

T60 wire mesh 60 µm

M05 synthetic ß10µm(c) > 1.000

M10 synthetic ß15µm(c) > 1.000

M15 synthetic ß20µm(c) > 1.000

4. BYPASS VALVE B 1,7 bar

C 3 bar (for glassfiber elements only)

5. SEALS B NBR

6. CONNECTION PORT B2 G 3/8” size 10 to 11

B3 G 1/2” size 10 to 31

B4 G 3/4” size 10 to 31

B5 G 1” size 20 to 43

B6 G 1 1/4” size 20 to 64

B7 G 1 1/2” size 40 to 64

B8 G 2” size 50 to 64

7. FILLING PLUG 0 no filling plug

T with filling plug

8. INDICATOR PORT C 1/8" plugged

9. CLOGGING INDICATORS 000 no indicator

MPB (ex R9) press. gauge rear connection

MRB (ex R10) press. gauge radial connection for "B" bypass

PDB (ex R13) pressure switch

MPC press. gauge rear connection

MRC press. gauge radial connection for "C" bypass

PDC (ex R14) pressure switch

FR1 SERIES 3/8

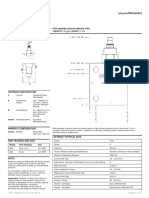

HYDRAULIC DIVISION FR1 SERIES

PRESSURE DROP (∆p) INFORMATION FOR FILTER SIZING

The total Delta P through a filter assembly is given from Housing ∆p + Element ∆p.

The max recommended total ∆p for return filters is 0,4 – 0,6 bar with clean element.

N.B. All the reported data have been obtained at our laboratory, according to specification ISO3968 with

mineral oil having 32 cSt viscosity at 40°C and density 0,875 kg/dm 3.

HOUSING PRESSURE DROP

The housing ∆p is given by the curve of the considered model and port, in correspondence of the flow rate value.

FR110-11 FR120-22

FR130-31 FR140-43

FR150-51 FR160-64

FR1 SERIES 4/8

HYDRAULIC DIVISION FR1 SERIES

ELEMENT PRESSURE DROP

The element ∆p (bar) is given by the flow rate (l/min) multiplied by the factor in the table here below

corresponding to the selected media and divided by 1000.

If the oil has a viscosity V1different than 32 cSt a corrective factor V1/32 must be applied.

Example: 80 l/min with R130G10B and oil viscosity 46 cSt > 80 x 3,19/1000 x 46/32 = 0,36 bar

G06 G10 G15 G25 G40 C10 C25 T60 M05 M10 M15

R110 33,84 15,68 12,50 8,81 4,54 4,83 4,13 2,56 10,46 8,94 5,58

R111 12,28 7,32 4,48 4,28 2,27 2,74 2,06 0,81 4,79 4,09 2,00

R120 13,85 8,65 6,44 6,32 2,77 4,09 2,52 0,86 5,65 4,83 3,19

R122 7,80 5,27 3,92 3,60 1,55 2,70 1,41 0,76 3,83 3,27 1,79

R130 5,09 3,19 2,25 2,06 0,90 1,64 0,82 0,49 2,31 1,98 1,02

R131 3,34 1,94 1,37 1,26 0,46 1,06 0,42 0,24 1,41 1,20 0,63

R140 2,43 1,31 1,25 1,10 0,43 0,85 0,39 0,22 0,95 0,82 0,62

R143 2,25 1,21 1,15 1,00 0,39 0,83 0,35 0,20 0,88 0,75 0,57

R150 2,16 1,12 1,08 0,96 0,37 0,82 0,34 0,19 0,81 0,69 0,54

R151 1,80 0,88 0,77 0,71 0,29 0,64 0,26 0,15 0,64 0,55 0,38

R160 1,49 0,74 0,71 0,51 0,25 0,45 0,23 0,10 0,54 0,46 0,35

R164 1,32 0,52 0,45 0,42 0,13 0,36 0,12 0,10 0,38 0,32 0,21

EXAMPLE OF TOTAL ∆p CALCULATION

FR130G10BBB60C000 with 80 l/min and oil 46 cSt:

Housing ∆p 0,01 bar + element ∆p 0,36 bar (80 x 3,19/1000 x 46/32) = total assembly ∆p 0,37 bar

BYPASS VALVE PRESSURE DROP

The bypass valve ∆p is given by the curve of the considered model and setting, in correspondence of the flow rate

value.

FR110-31 FR140-64

FR1 SERIES 5/8

HYDRAULIC DIVISION FR1 SERIES

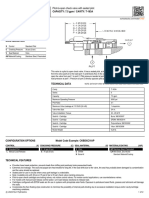

USER TIPS INSTALLATION

5 6

1 FILTER HEAD 1. the filter head (1) must be properly positioned

1 and well secured on the tank lid through the

2 FILTER BOWL fixing holes

4 IN 2. the hose must be properly connected to the IN

3 FILTER ELEMENT port

3. the OUT port must be clear (an extension tube

4 SPRING could be fitted, if needed for having the outlet

2

3 below the oil level)

5 INDICATOR PORT 4. verify that no tension is present on the filter after

mounting

6 FILLING PLUG

5. enough space must be available for filter

element replacement

6. the visual clogging indicator must be in a easily

viewable position

7. when a electrical indicator is used, make sure

OUT that it is properly wired

8. keep in stock a spare FILTREC filter element for

timely replacement when required

SPARE SEALS KIT

NBR FKM

FR-1-10/11 06.021.00170 06.021.00174 OPERATION

FR-1-20/22/30/31 06.021.00171 06.021.00175

1. the filter must work within the operating

FR-1-40/43 06.021.00172 06.021.00176 conditions of pressure, temperature and compatibility

FR-1-50/51/60/64 06.021.00173 06.021.00177 given in the first page of this data sheet

2. the filter element must be replaced as soon as

FIXING BOLTS TIGHTENING TORQUE the clogging indicator signals at working

temperature

M6 10 Nm 3. If no clogging indicator is mounted, replace the

M8 25 Nm element according to the system manufacturer’s

recommendations

M10 50 Nm

INDICATOR TIGHTENING TORQUE

10 Nm MAINTENANCE

1. before removing the top cover from the head,

SPARE SPRING ensure that the system is switched off and there

is no residual pressure in the filter

When a spare spring (4) is needed please ask for,

2. unscrew the fixing bolts of the top cover and

specifying model and production batch (data given in the

remove it

identification label on the top cover)

3. remove the spring (4) first, then the dirty element

(3) and the bowl (2)

4. clean the bowl (2) and fit a new FILTREC

element (3), verifying the part number,

WARNING particularly concerning the micron rating

5. when fitting the new element (3), open its plastic

Make sure that Personal Protective Equipment (PPE) is protection on the open end side and insert it

worn during installation and maintenance operation. onto the spigot in the filter bowl, then remove

completely the plastic protection

6. check the top cover O-ring conditions and

replace if necessary

DISPOSAL OF FILTER ELEMENT 7. put the spring (4) in its position on the filter

element (3)

The used filter elements and the filter parts dirty of oil 8. mount the top cover onto the head and fix it

are classified as “Dangerous waste material”: they screwing the fixing bolts

must be disposed according to the local laws by 9. the used filter elements cannot be cleaned and

authorized Companies. re-used

FR1 SERIES 6/8

HYDRAULIC DIVISION FR1 SERIES

CT10-rev.01-03/21

www.filtrec.com

FR1 SERIES 8/8 Technical information may change without notice

You might also like

- Filtrec F100 SeriesDocument8 pagesFiltrec F100 Serieshkhan10No ratings yet

- F280-D1 SERIES IN-LINE MEDIUM PRESSURE FILTER TECHNICAL INFORMATIONDocument8 pagesF280-D1 SERIES IN-LINE MEDIUM PRESSURE FILTER TECHNICAL INFORMATIONHorea CordunianuNo ratings yet

- Asco Keystone CompatibilityDocument2 pagesAsco Keystone CompatibilityalexmontellNo ratings yet

- Pig Launcher Specification SheetDocument19 pagesPig Launcher Specification SheetCarlos Felipe Reyes MartínezNo ratings yet

- Filtrec F160 SeriesDocument8 pagesFiltrec F160 Serieshkhan10No ratings yet

- Wafer type butterfly valve Z 011-A with integrated thermometerDocument4 pagesWafer type butterfly valve Z 011-A with integrated thermometerJOHNNo ratings yet

- LOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterDocument2 pagesLOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterHassan KhattabNo ratings yet

- VALVES MACH 11 - CatalogueDocument4 pagesVALVES MACH 11 - CatalogueMohab AhmedNo ratings yet

- SOFT53Document4 pagesSOFT53govind rajNo ratings yet

- Parker H Series 2-Valve Manifold CatalogDocument6 pagesParker H Series 2-Valve Manifold CatalogAngler's Lab (Angler's Lab)No ratings yet

- Direct Tank Mounted Oil FiltersDocument3 pagesDirect Tank Mounted Oil FiltersVilasNo ratings yet

- Spin-On Filters: FeaturesDocument2 pagesSpin-On Filters: FeaturesRuben NunezNo ratings yet

- 08 - FPS01 Subsea Series (Issue 4 Feb 05)Document4 pages08 - FPS01 Subsea Series (Issue 4 Feb 05)Peter RhoadsNo ratings yet

- Principal Dimension Type Product Oil Tanker: Symbol Code QTY SpecDocument1 pagePrincipal Dimension Type Product Oil Tanker: Symbol Code QTY Specgita suryaNo ratings yet

- Planta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEDocument1 pagePlanta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEAnthony InostrozaNo ratings yet

- Mccoy Lift CylinderDocument1 pageMccoy Lift CylinderShairul KhaizulNo ratings yet

- RDFALWN-CAM S Full en Us LetterDocument5 pagesRDFALWN-CAM S Full en Us LetterJustinNo ratings yet

- Model 5:1 Pilot Ratio, Pilot-To-Open Check Valve With Standard PilotDocument2 pagesModel 5:1 Pilot Ratio, Pilot-To-Open Check Valve With Standard PilotVignesh PandiyanNo ratings yet

- X C N (None) : Important: Carefully Consider The Maximum SystemDocument4 pagesX C N (None) : Important: Carefully Consider The Maximum SystemenovanovaNo ratings yet

- F74G Excelon General Purpose FilterDocument2 pagesF74G Excelon General Purpose Filtermoudar72No ratings yet

- DF1v ParkerDocument8 pagesDF1v ParkerHector Carrera MoralesNo ratings yet

- Underbody Clamp K... UZ T08: With Centering Pin, Self-Locking Type, For Seat Ø20 - 40 MMDocument1 pageUnderbody Clamp K... UZ T08: With Centering Pin, Self-Locking Type, For Seat Ø20 - 40 MMBe HappyNo ratings yet

- Parker Pneumatic LV / EZ Series Lockout Valves: Material Specifications Operating InformationDocument2 pagesParker Pneumatic LV / EZ Series Lockout Valves: Material Specifications Operating InformationSoriSori2008No ratings yet

- PDF Created On 9 Aug 2014 Page 1 of 6Document6 pagesPDF Created On 9 Aug 2014 Page 1 of 6Roget Alvis BatallanosNo ratings yet

- A Polyhydron Group Company: Pressure Compensated Flow Control Valve Model: 2PF 10Document3 pagesA Polyhydron Group Company: Pressure Compensated Flow Control Valve Model: 2PF 10Rakesh SharmaNo ratings yet

- Filtro para Gas de Italpump - Datos TécnicosDocument6 pagesFiltro para Gas de Italpump - Datos TécnicostiemposmodernosNo ratings yet

- FILTROS Maxiflow - Series PARKERDocument5 pagesFILTROS Maxiflow - Series PARKERDaniel MarNo ratings yet

- Magnetrol TD2-8D00-032 + Tma-A210-007Document1 pageMagnetrol TD2-8D00-032 + Tma-A210-007BRUNONo ratings yet

- 5/2 Internal Pilot Operated, Poppet Type, Namur, Solenoid ValveDocument1 page5/2 Internal Pilot Operated, Poppet Type, Namur, Solenoid Valvemohan babuNo ratings yet

- Filtrec F040 SeriesDocument8 pagesFiltrec F040 Serieshkhan10No ratings yet

- B C N (None) : C-Spool H-SpoolDocument2 pagesB C N (None) : C-Spool H-SpoolPasqualeNo ratings yet

- Optimize Poppet Valve Cartridge Document TitleDocument4 pagesOptimize Poppet Valve Cartridge Document Titledani sanNo ratings yet

- Cartridge Filters: Rugged, Low-Cost Cartridge Design For Flow Rates To 100 GPMDocument2 pagesCartridge Filters: Rugged, Low-Cost Cartridge Design For Flow Rates To 100 GPMJulio Enrique Oliver CuelloNo ratings yet

- Lug Type Butterfly Valve Z 414-A Lug Type Butterfly Valve Z 414-ADocument4 pagesLug Type Butterfly Valve Z 414-A Lug Type Butterfly Valve Z 414-ANguyen Quang NamNo ratings yet

- 25-31-50 SCH 50 P 0046 SHEET 1 - HIGH SPEED OVEN DF1000Document1 page25-31-50 SCH 50 P 0046 SHEET 1 - HIGH SPEED OVEN DF1000atony357No ratings yet

- 200 MM Butterfly Valve CatalogDocument1 page200 MM Butterfly Valve Catalogaccurate pneumaticNo ratings yet

- Pilot-to-open check valve technical detailsDocument2 pagesPilot-to-open check valve technical detailsVEERAMANINo ratings yet

- Pilot-to-close check valve technical detailsDocument2 pagesPilot-to-close check valve technical detailscesar5984No ratings yet

- 31 02 RS160 02 10 13 - WebDocument12 pages31 02 RS160 02 10 13 - WebАнатолий РябухаNo ratings yet

- Dkdr8: Model Normally Closed, Balanced Poppet, Logic Element With Integral T-8A Control Cavity - Vent-To-OpenDocument2 pagesDkdr8: Model Normally Closed, Balanced Poppet, Logic Element With Integral T-8A Control Cavity - Vent-To-OpensnsnagarajanNo ratings yet

- tsf2 h2 Coalescing Filter Data Sheet enDocument4 pagestsf2 h2 Coalescing Filter Data Sheet enCLAUDIA RAMIREZ SAUCEDONo ratings yet

- Model Ninety Degree With Gauge Port: Cavity: T-11ADocument4 pagesModel Ninety Degree With Gauge Port: Cavity: T-11AErasmo LimaNo ratings yet

- Ratio Controller: HD Fire Protect Pvt. Ltd. Technical DataDocument8 pagesRatio Controller: HD Fire Protect Pvt. Ltd. Technical DataDarshAwadNo ratings yet

- Vmy UkDocument8 pagesVmy UkEdwinNo ratings yet

- CPM FMR 22 002Document1 pageCPM FMR 22 002Mark Darrel AranasNo ratings yet

- Dif-Oo15-Int-Ed-0003 PCV Rev 0Document3 pagesDif-Oo15-Int-Ed-0003 PCV Rev 0wado11No ratings yet

- CKBDXCV_APDocument2 pagesCKBDXCV_APŁukasz OlszewskiNo ratings yet

- Piping Class Specification for Gas Pipeline ProjectDocument17 pagesPiping Class Specification for Gas Pipeline ProjectGuillaume de PluviéNo ratings yet

- Model All Gasket Ports: Cavity: T-22ADocument4 pagesModel All Gasket Ports: Cavity: T-22ALennyn Mamani VenturaNo ratings yet

- CVCV Full en Metric A4Document2 pagesCVCV Full en Metric A4Ηρακλης ΤσαπραζηςNo ratings yet

- Sofima TM178 Air Breather PlugDocument8 pagesSofima TM178 Air Breather PlugJoe DiscourtNo ratings yet

- HD263Document8 pagesHD263Ahamed IbrahimNo ratings yet

- p06060Document3 pagesp06060Daniel Sandoval FernándezNo ratings yet

- Technical Information Series D3A General Description: Directional Control ValvesDocument3 pagesTechnical Information Series D3A General Description: Directional Control Valvess bNo ratings yet

- Model All Ports Blocked Cavity Plug: Series 2 / Cavity: T-3ADocument1 pageModel All Ports Blocked Cavity Plug: Series 2 / Cavity: T-3AMarcelo Partes de OliveiraNo ratings yet

- 4-Port, Spool Type, Directional Control Valves With Hand Lever Actuation and Wide Variety of Spool Types With Spring-Centered, Spring-Offset and De-Tent ArrangementsDocument4 pages4-Port, Spool Type, Directional Control Valves With Hand Lever Actuation and Wide Variety of Spool Types With Spring-Centered, Spring-Offset and De-Tent ArrangementsSiddharth GajjarNo ratings yet

- Pilot-to-close check valve technical detailsDocument2 pagesPilot-to-close check valve technical detailsErasmo LimaNo ratings yet

- Sda s17893 Adic1 Ms 2105 00005 Data Sheet Instrument Air Compressor Filter A03Document3 pagesSda s17893 Adic1 Ms 2105 00005 Data Sheet Instrument Air Compressor Filter A03Oladiran AgbaraoluwaNo ratings yet

- CXDA-80 L/min check valveDocument2 pagesCXDA-80 L/min check valveSara SaritaNo ratings yet

- Colloidal and Rheological Properties of Natural Rubber Latex ConcentrateDocument11 pagesColloidal and Rheological Properties of Natural Rubber Latex ConcentrateEason HuangNo ratings yet

- Lecture 6Document73 pagesLecture 6yeshi janexoNo ratings yet

- Aspen Exchanger Design and Rating Fired Heater V11Document1 pageAspen Exchanger Design and Rating Fired Heater V11MarcoNo ratings yet

- Al2O3 ZrO2 FoamsDocument7 pagesAl2O3 ZrO2 Foamspranaya_beheraNo ratings yet

- Pre Medical Nurture Test Series Detailed SyllabusDocument8 pagesPre Medical Nurture Test Series Detailed SyllabusLishaNo ratings yet

- Nanoparticles Technology For Drug DeliveryDocument418 pagesNanoparticles Technology For Drug DeliveryJosé CatalánNo ratings yet

- MECHANICAL (AUTOMOBILE) ENGINEERING - 2019-Scheme-S3-Syllabus - Ktustudents - inDocument44 pagesMECHANICAL (AUTOMOBILE) ENGINEERING - 2019-Scheme-S3-Syllabus - Ktustudents - injishnu unniNo ratings yet

- Hydraulic Fluid - PropertiesDocument7 pagesHydraulic Fluid - Propertiesprajapati1436No ratings yet

- Two Phase Flow Experiment COMSOL MultiphysicsDocument30 pagesTwo Phase Flow Experiment COMSOL Multiphysicsgf-antaresNo ratings yet

- 1989 Book ViscousFlowApplicationsDocument195 pages1989 Book ViscousFlowApplicationsLalón Gitud De OndaNo ratings yet

- Jurnal 2001 - Textural Analysis of FatReduced Vanilla-AIMEDocument10 pagesJurnal 2001 - Textural Analysis of FatReduced Vanilla-AIMEMuhamad RizalNo ratings yet

- High viscous 316 stainless steel drum pump for low and high viscosity liquidsDocument1 pageHigh viscous 316 stainless steel drum pump for low and high viscosity liquidsTM HARRISNo ratings yet

- Exhaust Silencer Using Water InjectionDocument10 pagesExhaust Silencer Using Water InjectionLê Vy mạcNo ratings yet

- Kualifikasi AlatDocument6 pagesKualifikasi AlatatikswNo ratings yet

- Viscosity - WikipediaDocument7 pagesViscosity - WikipediazigaNo ratings yet

- Fluid Engineering - Flow in PipesDocument6 pagesFluid Engineering - Flow in PipesSherif Abdel Hamid FakhryNo ratings yet

- Unit 1.2 - Properties of FluidsDocument32 pagesUnit 1.2 - Properties of FluidsIshmael MvunyiswaNo ratings yet

- Units, Constants and Conversions: o o o o o o o o o o o o o o oDocument23 pagesUnits, Constants and Conversions: o o o o o o o o o o o o o o oecotechconsultants100% (1)

- Gear Pump EruditeDocument36 pagesGear Pump EruditeAdekoya IfeoluwaNo ratings yet

- Re-Evaluation of Recent Research On Metabolic Utilization of Energy in Poultry: Recommendations For A Net Energy System For BroilersDocument11 pagesRe-Evaluation of Recent Research On Metabolic Utilization of Energy in Poultry: Recommendations For A Net Energy System For BroilersniraalvesbeaNo ratings yet

- Tigist CFD Lab ReportDocument23 pagesTigist CFD Lab Reportdaniel hambissaNo ratings yet

- Data & Design Physical Property Estimation MethodsDocument16 pagesData & Design Physical Property Estimation MethodsAhmad BhattiNo ratings yet

- Mi - 154 - 04 - BC1-7229 DF - V1.1 - enDocument16 pagesMi - 154 - 04 - BC1-7229 DF - V1.1 - enmancor1969No ratings yet

- Manual ChangesDocument91 pagesManual ChangesPeng TerNo ratings yet

- Bernoulli EquationDocument40 pagesBernoulli EquationHassanKM100% (2)

- Heat Exchanger GuideDocument16 pagesHeat Exchanger GuideYoNo ratings yet

- Prosses Validation Protocol For Albendazole SuspensionDocument25 pagesProsses Validation Protocol For Albendazole Suspensionمحمد عطاNo ratings yet

- ICAR 108-1 (Proportioning)Document24 pagesICAR 108-1 (Proportioning)BartoFreitasNo ratings yet

- Fuel Oil FlowmeterDocument6 pagesFuel Oil Flowmeterpaulus sumaryotoNo ratings yet

- RoundupDocument8 pagesRoundupNina100% (1)