Professional Documents

Culture Documents

PDF Created On 9 Aug 2014 Page 1 of 6

Uploaded by

Roget Alvis BatallanosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDF Created On 9 Aug 2014 Page 1 of 6

Uploaded by

Roget Alvis BatallanosCopyright:

Available Formats

snhy.

com/PBFBLAN-BCD

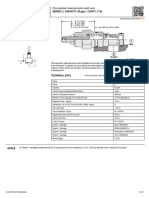

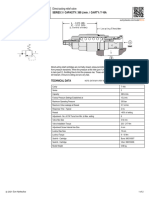

MODEL Pilot operated, pressure reducing valve

PBFBLAN-BCD CAPACITY: 20 gpm | CAVITY: T-2A

CARTRIDGE CONFIGURATION

L Control Standard Screw

Adjustment

A Adjustment 100 - 3000 psi (7 -

Range 210 bar), 200 psi

(14 bar) Standard

Setting

N Seal Material 60 - 800 psi (4 - 55

bar), 200 psi (14

bar) Standard

Setting

(none) Material/Coating Standard

Material/Coating

MANIFOLD CONFIGURATION Pilot-operated, pressure reducing valves reduce a high primary pressure at the inlet (port 2) to a

constant reduced pressure at port 1, allowing circuits with multiple pressure requirements to be

(none) Modifier 6061-T651 operated using a single pump.

Aluminum, Buna-N

CARTRIDGE TECHNICAL DATA

PORT HEADINGS AND SIZES Cavity T-2A

Model Port Heading Size Series 2

BCD Ports 1 & 2 3/4" NPTF Capacity 20 gpm

BCD Port 3 1/4" NPTF Factory Pressure Settings Established at blocked control port (dead headed)

Maximum Operating Pressure 5000 psi

NOTES Control Pilot Flow 10 - 15 in³/min.

Maximum pressure differentials for spring ranges: Adjustment - Number of Clockwise Turns to Increase Setting 5

A and B are 3000 psi (210 bar) N and Q are

2000 psi (140 bar) W is 5000 psi (350 bar)inlet Valve Hex Size 1 1/8 in.

pressure

Valve Installation Torque 45 - 50 lbf ft

For cartridges configured with an O control

(panel mount handknob), a .75 in. (19 mm) Adjustment Screw Internal Hex Size 5/32 in.

diameter hole is required in the panel.

Locknut Hex Size 9/16 in.

Important: Carefully consider the maximum

system pressure. The pressure rating of the Locknut Torque 80 - 90 lbf in.

manifold is dependent on the manifold material,

with the port type/size a secondary Seal kit - Cartridge Buna: 990-202-007

consideration. Manifolds constructed of

Seal kit - Cartridge Polyurethane: 990-002-002

aluminum are not rated for pressures higher

than 3000 psi (210 bar), regardless of the port

PDF created on 9 Aug 2014 Page 1 of 6

than 3000 psi (210 bar), regardless of the port Seal kit - Cartridge Viton: 990-202-006

type/size specified.

Model Weight 0.00 lb.

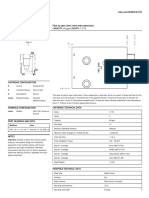

MANIFOLD TECHNICAL DATA

Body Type Line mount

Interface None

Body Features Ninety degree

Mounting Hole Diameter .42 in.

Mounting Hole Depth Through

Mounting Hole Quantity 2

Open Cavities 1

Cavity T-2A

Port Size 3/4" NPTF

Model Weight 1.12 lb.

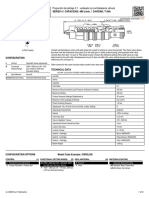

CARTRIDGE TECHNICAL FEATURES

All three-port pressure reducing and reducing/relieving cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

When considering mounting configurations, it is sometimes recommended that a full capacity return line (port 3) be used with reducing/relieving

cartridges.

Full reverse flow from reduced pressure (port 1) to inlet (port 2) may cause the main spool to close. If reverse free flow is required in the circuit, consider

adding a separate check valve to the circuit.

If pilot flow consumption is critical, consider using direct acting reducing/relieving valves.

Main stage orifice is protected by a 150 micron stainless steel screen.

Recommended maximum inlet pressure is determined by the adjustment range. Ranges D, E, N, and Q are tested with a 2000 psi (140 bar) maximum

differential between inlet and reduced pressure. Ranges A, B, and H are tested with a 3000 psi (210 bar) maximum differential between inlet and reduced

pressure. Ranges C and W are tested with 5000 psi (350 bar) of inlet pressure.

Pilot operated valves exhibit exceptionally flat pressure/flow characteristics, are very stable and have low hysteresis.

Pressure at port 3 is directly additive to the valve setting at a 1:1 ratio and should not exceed 5000 psi (350 bar).

Pilot operated reducing, reducing/relieving valves by nature are not fast acting valves. For superior dynamic response, consider direct acting valves.

W and Y controls (where applicable) can be specified with or without a special setting. When no special setting is specified, the valve is adjustable

throughout its full range using the W or Y control. When a special setting is specified, this setting represents the maximum setting of the valve.

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or

cavity/cartridge machining variations.

MANIFOLD FACES

FACE GRID

1 2 3 4

5 6 7 8

9 10 11 12

Face 2

PDF created on 9 Aug 2014 Page 2 of 6

Face 5

Face 6

PDF created on 9 Aug 2014 Page 3 of 6

Face 7

PDF created on 9 Aug 2014 Page 4 of 6

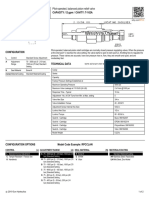

Face 8

PDF created on 9 Aug 2014 Page 5 of 6

Face 10

Copyright © 2002-2014 Sun Hydraulics Corporation. All rights reserved.

PDF created on 9 Aug 2014 Page 6 of 6

You might also like

- Man and Mystery Vol 13 - Monsters and Cryptids (Rev06)Document139 pagesMan and Mystery Vol 13 - Monsters and Cryptids (Rev06)Pablo Jr AgsaludNo ratings yet

- Future Visualized in The Movie BrazilDocument16 pagesFuture Visualized in The Movie BrazilsloutfyNo ratings yet

- Mathematics 2nd Quarter Test With TOSDocument8 pagesMathematics 2nd Quarter Test With TOSRona Mae Aira AvilesNo ratings yet

- HP DeskJet Report POM 20150413Document5 pagesHP DeskJet Report POM 20150413Carolina DelgadoNo ratings yet

- 17 The Tarrying TimeDocument22 pages17 The Tarrying Timeapi-303147801100% (1)

- RDFALWN-CAM S Full en Us LetterDocument5 pagesRDFALWN-CAM S Full en Us LetterJustinNo ratings yet

- Sun Hydraulics-Cbca Lan EccDocument5 pagesSun Hydraulics-Cbca Lan EcchendntdNo ratings yet

- DRBCLBN Full Es Us A4Document2 pagesDRBCLBN Full Es Us A4Erasmo LimaNo ratings yet

- CBCALHN-EAC Full en Us LetterDocument5 pagesCBCALHN-EAC Full en Us LetterVentas Control HidráulicoNo ratings yet

- PVDB Full en Us LetterDocument2 pagesPVDB Full en Us LetterIsrael RuizNo ratings yet

- SUN RPGC-JCN (Relief Valve)Document3 pagesSUN RPGC-JCN (Relief Valve)ful islamNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- X C N (None) : Important: Carefully Consider The Maximum SystemDocument4 pagesX C N (None) : Important: Carefully Consider The Maximum SystemenovanovaNo ratings yet

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument2 pagesModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMNo ratings yet

- Model 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Document2 pagesModel 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Erasmo LimaNo ratings yet

- DMDAMNN224-ECT en Us LetterDocument2 pagesDMDAMNN224-ECT en Us LetterLUIS SANCHEZ SANZCHEZNo ratings yet

- FREA Full en Us A4Document2 pagesFREA Full en Us A4Rodrigo LisboaNo ratings yet

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDocument2 pagesModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareNo ratings yet

- Modelo Proporción de Pilotaje 5:1, Venteado (A) Contrabalance VálvulaDocument2 pagesModelo Proporción de Pilotaje 5:1, Venteado (A) Contrabalance VálvulaManuel Patricio Gonzalez SanhuezaNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- RGFA Full en Metric LetterDocument4 pagesRGFA Full en Metric LetteressamNo ratings yet

- Model 20%, Accumulator Sense, Pump Unload Valve With Check - Pilot CapacityDocument2 pagesModel 20%, Accumulator Sense, Pump Unload Valve With Check - Pilot CapacityGamal El Deen KamalNo ratings yet

- Model Ventable, Pilot Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot Operated, Balanced Piston Relief ValveErasmo LimaNo ratings yet

- RVCALCN Full en Us A4Document2 pagesRVCALCN Full en Us A4Felipe DiazNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Model Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveJustinNo ratings yet

- Model Ventable, Pilot-Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Piston Relief ValveGamal El Deen KamalNo ratings yet

- SUN RPGC-LAN (Relief Valve)Document3 pagesSUN RPGC-LAN (Relief Valve)ful islamNo ratings yet

- Pilot-Operated Relief Valve Specs and PerformanceDocument2 pagesPilot-Operated Relief Valve Specs and PerformanceHassan KhattabNo ratings yet

- PBFB en Us A4Document1 pagePBFB en Us A4operacion hydratekNo ratings yet

- B C N (None) : C-Spool H-SpoolDocument2 pagesB C N (None) : C-Spool H-SpoolPasqualeNo ratings yet

- Sun Hydraulics FDBA-LANDocument2 pagesSun Hydraulics FDBA-LANJustinNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveLennyn Mamani VenturaNo ratings yet

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoDocument2 pagesModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaNo ratings yet

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNo ratings yet

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocument2 pagesModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument2 pagesModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- CBCY_full_en_us_letter (1)Document2 pagesCBCY_full_en_us_letter (1)Ventas Control HidráulicoNo ratings yet

- Normally closed balanced poppet valveDocument2 pagesNormally closed balanced poppet valvejuampacervantesNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- RDDALDN Full en Us A4Document3 pagesRDDALDN Full en Us A4clark jonesNo ratings yet

- RPEI Full en Metric LetterDocument4 pagesRPEI Full en Metric LetteressamNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24ADocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24AАндрей9No ratings yet

- 10:1 pilot ratio counterbalance valveDocument2 pages10:1 pilot ratio counterbalance valveVignesh PandiyanNo ratings yet

- Model Back-To-Back Check/shuttle Valve With Signal at Port 2Document2 pagesModel Back-To-Back Check/shuttle Valve With Signal at Port 2Erasmo LimaNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Sun Hydraulics NFCC-KCNDocument2 pagesSun Hydraulics NFCC-KCNJustinNo ratings yet

- CBEALBN Full en Us LetterDocument2 pagesCBEALBN Full en Us Letterangelo.araza0913No ratings yet

- PPDB en Us A4Document1 pagePPDB en Us A4Felipe DiazNo ratings yet

- Pump Unload Pilot Valve SUN QPABDocument2 pagesPump Unload Pilot Valve SUN QPABankesh_ghoghariNo ratings yet

- RPECOAN Full Es Metric LetterDocument2 pagesRPECOAN Full Es Metric Letteralfredo lopez regaladoNo ratings yet

- CBEWLJN Full en Metric A4Document2 pagesCBEWLJN Full en Metric A4Ηρακλης ΤσαπραζηςNo ratings yet

- Model Ventable, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Poppet Relief ValveGamal El Deen KamalNo ratings yet

- LPJCXHN Full en Us LetterDocument2 pagesLPJCXHN Full en Us LetterService - Anda Hydraulics Asia Pte LtdNo ratings yet

- Model Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10ADocument2 pagesModel Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10AHassan KhattabNo ratings yet

- RPCCLAN Full en Us LetterDocument2 pagesRPCCLAN Full en Us Lettera safaieNo ratings yet

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- Model Fully Adjustable Needle Valve: SERIES 4 / CAPACITY: 60 GPM (.56 Inch) / CAVITY: T-18ADocument2 pagesModel Fully Adjustable Needle Valve: SERIES 4 / CAPACITY: 60 GPM (.56 Inch) / CAVITY: T-18AErasmo LimaNo ratings yet

- CVCV Full en Metric A4Document2 pagesCVCV Full en Metric A4Ηρακλης ΤσαπραζηςNo ratings yet

- CBGH Full en Us LetterDocument2 pagesCBGH Full en Us LetterPrakash VasudevanNo ratings yet

- Pilot-to-close check valve technical detailsDocument2 pagesPilot-to-close check valve technical detailscesar5984No ratings yet

- Des Piece F Se 2003 MotorDocument26 pagesDes Piece F Se 2003 MotorPACHYYNNo ratings yet

- Algebra II PreAP SimplificationDocument4 pagesAlgebra II PreAP SimplificationSummer SharmaNo ratings yet

- Basic Integration Problems #1Document4 pagesBasic Integration Problems #1John Marlo GorobaoNo ratings yet

- Unit 1.Pptx Autosaved 5bf659481837fDocument39 pagesUnit 1.Pptx Autosaved 5bf659481837fBernadith Manaday BabaloNo ratings yet

- DSBV87ALP Two-Stage Differential Pressure Control Valve SpecsDocument2 pagesDSBV87ALP Two-Stage Differential Pressure Control Valve SpecsadrianioantomaNo ratings yet

- Rodriguez ViereaDocument51 pagesRodriguez ViereaAwawawawa UwuwuwuwuNo ratings yet

- Aisladores Polimericos vs. Aisladores Ceramicos Unmsm PDFDocument22 pagesAisladores Polimericos vs. Aisladores Ceramicos Unmsm PDFvgcasasNo ratings yet

- 60 Minutes-60 Questions: Mathematics TestDocument15 pages60 Minutes-60 Questions: Mathematics TestJihyun YeonNo ratings yet

- MR Skin Prick TestingDocument9 pagesMR Skin Prick TestingAyuAnatrieraNo ratings yet

- User Manual For Digital Logic Trainer KitDocument6 pagesUser Manual For Digital Logic Trainer KitHonnura HarijanaNo ratings yet

- ABR College Mechanical Mid Exam Questions on MetrologyDocument1 pageABR College Mechanical Mid Exam Questions on MetrologySrinu ArnuriNo ratings yet

- Ael Igniter CordsDocument1 pageAel Igniter CordsAlexander OpazoNo ratings yet

- Parts of the Globe: Prime Meridian, Equator and Climate ZonesDocument18 pagesParts of the Globe: Prime Meridian, Equator and Climate Zonesmelgazar tanjayNo ratings yet

- Unit 07Document9 pagesUnit 07ZackNo ratings yet

- Physical Education Week 1 ActivitiesDocument4 pagesPhysical Education Week 1 ActivitiesTummys TummieNo ratings yet

- Oukfxu DH Lwpuk Ladyu@Izs'K.K GSRQ Izns"K LRJ Ij MRRJNK H Ysoy 1) 2, Oa 3 LRJ Ds VF/KDKFJ Ksa Ds Leidz LWDocument12 pagesOukfxu DH Lwpuk Ladyu@Izs'K.K GSRQ Izns"K LRJ Ij MRRJNK H Ysoy 1) 2, Oa 3 LRJ Ds VF/KDKFJ Ksa Ds Leidz LWNishant KumarNo ratings yet

- DTP - Digital Transformer ProtectionDocument13 pagesDTP - Digital Transformer ProtectionHBNBILNo ratings yet

- Nireesh Kumar Paidi - Updated ResumeDocument5 pagesNireesh Kumar Paidi - Updated ResumeNikhil Reddy NamreddyNo ratings yet

- Viscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Document40 pagesViscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Majid KhanNo ratings yet

- Phases of Clinical Trials: OverlapDocument3 pagesPhases of Clinical Trials: OverlapMohammed El-GezeiryNo ratings yet

- Presidential Decree No. 1616 establishes Intramuros AdministrationDocument22 pagesPresidential Decree No. 1616 establishes Intramuros AdministrationRemiel Joseph Garniel BataoNo ratings yet

- Review of oxidative stress and antioxidants in dentistryDocument4 pagesReview of oxidative stress and antioxidants in dentistrySeeptianMaulanaNo ratings yet

- Build a Homebrew Pre-Amplified MicrophoneDocument3 pagesBuild a Homebrew Pre-Amplified MicrophoneMacario Imbudo BukatotNo ratings yet

- Nominal Pipe Size, Nominal Diameter & Outside Diameter For PipesDocument1 pageNominal Pipe Size, Nominal Diameter & Outside Diameter For PipesmdnorNo ratings yet

- Remote Sensing Mineral Exploration LithiumDocument16 pagesRemote Sensing Mineral Exploration LithiumGerald Darshan MogiNo ratings yet